Tech Clarity Perspective CAD Switch

Diunggah oleh

mksamy2021Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Tech Clarity Perspective CAD Switch

Diunggah oleh

mksamy2021Hak Cipta:

Format Tersedia

Are You Changing CAD

Tools?

What You Should Know

Tech-Clarity, Inc. 2015

Table of Contents

Executive Overview ....................................................................... 3

Understand Business Needs for Design ....................................... 4

What Drives a Change in CAD? .................................................... 6

Set Expectations for the Change ................................................. 10

Identifying Top Performers .......................................................... 12

Identify the Right CAD Solution ................................................... 14

Extend CAD ................................................................................. 16

Conclusion ................................................................................... 17

Recommendations ...................................................................... 18

About the Author ......................................................................... 19

About the Research ..................................................................... 19

2 Tech-Clarity, Inc. 2015

Executive Overview

If you are competing in todays global economy, it is not easy. Significant global

competition plus pressure from new entrants and innovative start-ups make it difficult to

stand out. To improve competitiveness, Tech-Claritys study, Product Lifecycle

Management Beyond Managing CAD, finds companies have shifted focus from market

factors like time-to-market or cost to product-centric strategies. Design tools, especially

CAD, are key to executing these product strategies. With the right design tools,

companies are better positioned to quickly bring high-performing, high-quality,

innovative products to market. Companies looking to upgrade these tools to keep up with

competitors may want to consider switching CAD tools.

So what should you do if you find your CAD tool is holding you back? What if your

company needs to update CAD tools? Why would you consider a change? What should

you expect? Is it worth the time to convert archived data into a new format? Most

importantly, do the benefits outweigh potential risks?

Business reasons rather than problems with CAD tools

have become more influential when choosing a CAD tool.

Tech-Clarity surveyed 192 companies to answer these questions. While there are many

interesting findings, the most striking is that business reasons rather than problems with

CAD tools have become more influential when choosing a CAD tool and are motivating

factors behind the need to switch tools. Growing influencers include supply chains,

relationships, the vendors vision for design, and the CAD vendors full breadth of

offerings. This big picture view of CAD indicates higher levels of management make

buying decisions and they view CAD as a strategic piece of a larger product development

solution.

Management views CAD as a strategic piece of a larger

product development solution.

The biggest challenges of switching CAD tools are overcoming the learning curve and

reusing legacy data. However, not all legacy data needs to be converted and in fact,

companies only convert about half of it, 52%. Despite the efforts involved, companies

who have made a CAD change tend to be very happy. Eighty-three percent (83%) rate

their satisfaction a 4 or 5 on a scale of 1 to 5.

Since implementing their current CAD tools, Top Performers have reduced

development time by 19%, development costs by15%, and the time to implement

an ECO by 16%, putting them at a significant competitive advantage.

3 Tech-Clarity, Inc. 2015

The study also identified what successful companies look for. When selecting a new

CAD tool, Top Performers are more likely to consider ease of use, Technical Support,

software quality, and market share, which includes the size of the user community. Since

implementing their current CAD tools, Top Performers have reduced development time

by 19%, development costs by15%, and the time to implement ECOs (engineering

change orders) by 16%, putting them at a significant competitive advantage. They have

also been able to increase the number of design iterations by 17%, which leads to greater

innovation.

Understand Business Needs for Design

It is very difficult to compete in todays global economy. The world has become smaller

and the Internet has enabled even small companies to have a global presence. Not only do

companies find they must defend market share against global competitors, but options

like Kickstarter have reduced the barrier to entry for new startups with innovative

offerings. Now companies must work even harder to differentiate themselves.

The leading strategies today are very product-centric.

Tech-Claritys study, Product Lifecycle Management Beyond Managing CAD asked

survey respondents how they differentiate themselves (Figure 1).

Product Performance 58%

Innovation 56%

Quality / Reliability 55%

Customization 45%

Brand / Reputation 39%

Service 37%

Cost 37%

Agility / Speed 27%

Figure 1 Top Differentiation Strategies

The study finds, The leading strategies today are very product-centricRespondents

appear to be focused on getting the product right for the customer with less focus on

market factors such as speed to market or cost, which have been higher drivers in past

4 Tech-Clarity, Inc. 2015

surveys. Although they are not listed as ways to differentiate, we expect they are both still

important factors for competitiveness in crowded, global markets.

Companies also find they can no longer focus on a single area. To be competitive, they

must consider a variety of factors such as performance, innovation, quality, and

personalization. This drives many companies to invest in the design process. Figure 2

shows the top reasons for design investment.

Lower cost 63%

Shorter product development schedules 61%

Better quality/reliability 59%

Better product performance 45%

Innovation 41%

Compliance 26%

Lower lifecycle costs (warranty, recalls, 24%

etc.)

Other 8%

Figure 2 Business Needs Driving Investments in Design

Companies make investments to lower their costs as well as to improve efficiency. Both

impact top and bottom lines. Quick product cycles shrink the window of opportunity for

maximum revenue potential. Before long, products are superseded by even newer

products, diminishing the opportunity for additional revenue. In addition, the faster a

company releases its product, the smaller the development investment, making it easier to

recoup those costs. Also, first to market has a competitive advantage for capturing market

share, leading to higher revenues.

To be competitive, manufacturers must consider a variety of factors such as

performance, innovation, quality, and personalization to differentiate products.

5 Tech-Clarity, Inc. 2015

Additional cost savings can also come from IT. Tech-Claritys Consolidating CAD finds

that not only does consolidating CAD tools save licensing and hardware costs, but there

are other benefits as well. The report states, From the IT perspective, consolidation

provides the ability to focus resources on a smaller number of solutions. This reduces

workload and cost and allows IT to provide a higher level of business support with

todays lean organizations Beyond cost savings, though, are even greater strategic

benefits For example, a single CAD environment can enable a design anywhere

build anywhere strategy. This approach allows companies to rapidly adjust to market

changes and resource shortages by offering the ability to transfer design or production to

new facilities without concern for incompatible design data, tools, or processes.

What Drives a Change in CAD?

A potential design investment may involve a change in CAD tools. There are many

reasons why a company may switch CAD tools. For example, Arihant, a water park and

playground equipment manufacturer, sought a design solution that was easier and faster

to use so the company could boost productivity. We needed to become more efficient to

increase throughput, says Assistant ManagerDesign Mithun S. Mandal, Other goals

related to switching platforms included better graphical representation of product

designs, shorter design cycles, and enhanced recruitment. The change has certainly paid

off. Since implementing their new CAD software, Arihant has realized meteoric growth,

boosting annual revenues by 250 percent in just two years.

Since implementing their new CAD software, Arihant has realized meteoric

growth, boosting annual revenues by 250 percent in just two years.

In other cases, the current CAD tool may be working well, but it may no longer fit

corporate goals for growth, as was the case at Hutchinson Hayes Separation. Hutchinson

Hayes Separation manufacturers separation equipment to separate solids from liquids in a

wide range of applications from meat rendering to oilfield, petrochemical to marine fuels

and vegetable oils to biodiesel. Although we were successful using our old tools to

support our standard product line, our business plan required us to develop new products

for additional applications. To support the increased activity, we needed a 3D platform

that would enable us to tighten up development and manufacturing, says Sales Manager

Hans van der Voort at Hutchinson Hayes Separation. By doing so, we could shorten

delivery lead times and free up resources to go after new opportunities.

To support the increased activity, we needed a 3D development platform that

would enable us to tighten up development and manufacturing.

Hans van der Voort, Sales Manager, Hutchinson Hayes Separation

6 Tech-Clarity, Inc. 2015

Companies may also have other reasons for switching. To understand the primary factors,

Tech-Clarity looked at both business reasons and CAD challenges. Business reasons are

external to CAD and are impacted by management decisions, corporate initiatives, or the

vendor relationship. Over the last seven years, with economic factors such as the recent

recession, business needs have evolved, impacting the motivators for a CAD change.

Figure 3 compares some of the top business reasons for changing CAD.

50%

Reduction in engineering 27%

budget 26%

10%

38%

Pressure from supply 20%

chain/OEM 30%

10%

25%

Politics - management 13%

change 17%

3%

25%

Vendor's eco-system - 13%

PLM etc. 13%

10%

25%

Vendor's vision not 7%

aligned to us 17%

7%

21%

23%

IT policy to standardize 35%

17%

8%

40%

Going from 2D to 3D 26%

52%

<1 year 1-3 years 4-6 years > 7 years

Figure 3 Business Reasons Driving a CAD Change

7 Tech-Clarity, Inc. 2015

Companies who made a CAD change seven or more years ago, were often going from 2D

CAD to 3D. Now, companies are driven by budget reductions. This could be because

they are looking to achieve cost savings by consolidating CAD tools and the number of

licenses. Interestingly, this was also a top driver four to six years ago, at the height of the

recession, but the pressure was coming from IT rather than the engineering budget.

Companies making a change now may also feel they will lower cost through efficiency

improvements that better utilize resources and help release products more quickly.

Compared to the past, companies are also much more influenced by supply chains or

OEMs, internal politics, the CAD vendors vision for design, and the CAD vendors

portfolio of products.

Compared to the past, companies are also much more influenced by supply

chains or OEMs, internal politics, and the vision and portfolio of products

offered by the vendor.

Tech-Clarity also looked at challenges using CAD tools, which led to a change.

Lack of functionality 39%

Inefficient workflow 34%

Poor ease of use 24%

Too expensive 22%

Poor software quality 22%

Design changes took too long 22%

Users preferred a different tool 21%

Figure 4 CAD Challenges Driving a Change

While CAD tools have evolved significantly over the last seven years, interestingly, there

is little difference between those who made a recent CAD change and those who did it

seven years ago. The most common reason for making a change is the existing tool lacks

needed functionality. An inefficient workflow, such as too many mouse clicks or a user

interface that is not intuitive, is another top reason. In these cases, companies likely turn

to a different CAD tool with an expectation that additional functionality and a more

efficient workflow will improve their productivity.

8 Tech-Clarity, Inc. 2015

An inefficient workflow, such as too many mouse clicks or a user interface that

is not intuitive is another top reason for changing CAD.

This was the case at Induce Design, a design services company. The company

transitioned to new 3D design software in 2010 because the solution was easier to use,

provided a more complete set of modeling capabilities, and helped the design firm

leverage design for manufacturability tools. I chose our design software as our primary

tool because its easier and more efficient for both modeling and engineering new

product designs, says Owner and Principal Designer Hrishikesh Borude. Our new CAD

software simply is a better fit for the design and engineering needs of our studio.

Since implementing the new design software, Induce Design has cut its design cycles by

30 percent and shortened the time to make design decisions by 30 percent. Borude

attributes these productivity gains to the intuitive user interface of the new CAD software

and the ability to communicate more effectively with clients.

Since implementing the new design software, Induce Design

has cut its design cycles by 30 percent and shortened the time

to make design decisions by 30 percent.

Survey respondents were then asked to select the primary driver for making a CAD

change. Interestingly, that the primary driver has changed over time. Trends show that

business decisions rather than problems with the CAD tool have become more influential

when deciding to switch CAD tools (Figure 5).

Trends show that business decisions rather than problems with a CAD tool have

become more influential when deciding to switch CAD tools

Four or more years ago, challenges with the CAD tool were more important. Now it is

business reasons driving the change. Supply chains, vendor relationships, vendor vision,

and the full portfolio of offerings are more influential in the choice of CAD tools,

indicating that CAD tools have become a strategic piece of the overall product

development solution.

9 Tech-Clarity, Inc. 2015

61%

50%

Business reasons 26%

31%

22%

20%

Challenges with former CAD tool 65%

48%

17% <1 year

30% 1-3 years

They are equal drivers 9%

4-6 years

21% > 7 years

Figure 5 Primary Driver of Change over Time

Set Expectations for the Change

What should companies expect when making a CAD change? Figure 6 shows the top

challenges.

Learning curve 52%

Reusing / accessing legacy data 46%

Loss of productivity 28%

Configuring for your workflow 27%

Cultural changes required 25%

(resistance to change)

Figure 6 Top Challenges of Switching CAD Tools

10 Tech-Clarity, Inc. 2015

Employee education is the most common challenge, followed by reusing legacy data.

Tech-Clarity explored the legacy data challenge further. Despite the advancements to

support multi-CAD data, by far, the most common approach to legacy data is recreating

it. Converting to a neutral format such as IGES or STEP comes next (Figure 7).

Recreate it in new CAD tool 53%

Convert to neutral file (IGES or 32%

STEP)

Use multi-CAD tools inside new 28%

CAD tool

Use 3rd party translation tools 27%

Convert to visualization data 20%

Figure 7 Approach to Legacy Data

Overall, companies convert 52% of their legacy CAD data, but product complexity has

an impact. Legacy data is more likely to be converted if it is complex (Figure 8).

Complex 64%

Medium 48%

Simple 35%

Figure 8 Amount of Legacy Data Converted

11 Tech-Clarity, Inc. 2015

Overall, companies convert 52% of their legacy CAD data,

but product complexity has an impact.

Very complex models take a long time to recreate so it is worth the effort to convert

them. On the other hand, since very simple models are easily recreated, it is harder to

justify investing time for conversion. As a mechanical engineering manager at a

communications company commented, The odds are you do not need to move all your

legacy data into the new CAD tool. Keep one seat of the old CAD tool and move legacy

data as needed. Odds are that most of the legacy data will not be needed in the future.

Identifying Top Performers

To understand how the most successful companies approach a change in CAD tools,

Tech-Clarity researchers identified Top Performing companies. Survey respondents were

asked to rank their performance in relation to their competitors on four key design

metrics. Respondents used a scale of one to five, with five being extremely effective. The

top 20% were defined as Top Performers. Figure 9 shows the metrics used to define

success and each groups respective performance.

Regardless of performance category, companies report significant

improvements since implementing their new CAD tool.

4.5

Develop products efficiently 3.3

4.7

Design high quality products 3.7

4.6

Develop Innovative Products 3.3

4.2

Meet product cost targets 3.1

Top Performer Average Performer

Figure 9 Top Performers Defined

Table 1 quantifies the benefits enjoyed by Top Performers since implementing their

current CAD tool.

12 Tech-Clarity, Inc. 2015

Since Implementing Current CAD Top Performers Average Performer

Change in Development Time 19% Reduction 14% Reduction

Change in Development Costs 15% Reduction 10% Reduction

Change in Time to Implement ECOs 16% Reduction 8% Reduction

Change in Number of Design 17% Increase 9% Increase

Iterations Evaluated

Table 1 Benefits Since Implementing New CAD Tool

Regardless of performance category, companies report significant improvements since

implementing their new CAD tool, but Top Performers see even bigger improvements.

Companies find that with their new CAD tool, they are more efficient, which allows them

to develop products in less time, for less cost. They also implement engineering changes

more quickly. The ability to quickly make changes combined with efficiency

improvements enable companies to evaluate more design iterations. Top Performers

evaluate 76% more design alternatives than competitor. Evaluating more options and

building off existing ideas leads to greater innovation.

In fact, the need to evaluate more design concepts was an important consideration when

ElliptiGO, an elliptical bike manufacturer, selected their CAD tool. I knew that we

would need to do a ton of iterations and analysis studies to get the design ready for

commercialization and then support machining and production, stresses Brent Teal, Co-

president at ElliptiGO.

Top Performers evaluate 76% more design alternatives than competitors,

which is important for innovation.

While the efficiency gains companies enjoy after switching CAD tools seem appealing,

how much effort is required to make that change? Table 2 shows the average training

time, time to resume productivity, and the time to recoup the investment.

Since Implementing Current CAD Top Performers Average Performer

Training Time 6 Weeks 9 Weeks

Time to Resume Productivity 13 Weeks 21 Weeks

Time to Recoup Investment 46 Weeks 50 Weeks

Satisfaction with ROI of CAD 4.7 4.0

Switch (scale of 1 to 5, with 5 being

extremely satisfied)

Table 2 What to Expect During a Change

13 Tech-Clarity, Inc. 2015

Top Performers report they spend less time on training, yet they resume productivity

eight weeks sooner than their lesser performing competitors. The criteria Top Performers

look for in a CAD tool likely contributes to this.

Despite the time investments to make the switch, companies tend to be very

happy with the return on their investment.

Despite the time investments to make the switch, companies tend to be very happy with

the return on their investment. Overall, companies rate it a 4.2 on a scale of one to five,

with five being extremely satisfied. Considering they invest less to make the switch and

see even better performance improvements, unsurprisingly, Top Performers are

especially satisfied with their return, ranking their satisfaction a 4.7 out of five.

Identify the Right CAD Solution

What do Top Performers look for in a CAD solution? Compared to lesser performing

competitors, Top Performers are more likely to look for ease of use, software quality, and

the ability to work with multi-CAD data (Figure 10).

77%

Ease of use 65%

65%

Software quality 59%

58%

Ability to work with multi-CAD data 50%

54%

Ability to support my workflows 50%

50%

Cost of solution 45%

Level of integration with other 42%

applications 39%

Top Performer Average Performer

Figure 10 Top Qualities Sought in a New CAD Solution

14 Tech-Clarity, Inc. 2015

Top Performing companies are 19% more likely than competitors to rate ease of use as a

top quality of a CAD solution. This likely helps them resume full productivity eight

weeks before their competitors, even with less training.

Top Performing companies are 19% more likely than competitors

to rate ease of use as a top quality of a CAD solution.

In addition to the CAD tool, the vendor relationship is also an important consideration.

With CAD playing a more strategic role in development, manufacturers need a vendor

who is a true partner. Figure 11 shows the top qualities companies value in a CAD

vendor.

Quality and availability of 69%

Technical Support 59%

Quality and availability of 46%

Professional Services 42%

Company's vision and long-term 46%

commitment 42%

35%

Market leadership / Market share 24%

35%

Length of time in business 26%

Top Performer Average Performer

Figure 11 Top Qualities in a CAD Vendor

Top Performers are 18% more likely than their competitors to rate quality Technical

Support as their top criteria for a vendor. Good phone support provides Top Performers

with yet another resource to supplement training and enable engineers to quickly resume

full productivity. Technical Support can come both from the vendor and VAR (Value

Added Reseller) channels. Whats important is that engineers have easy access to help.

USSC, a manufacturer of seating for a variety of vehicles, credits the support of their

VAR with helping facilitate the deployment of their new CAD tool. "Our VAR did an

excellent job supporting the process, explains Jeff Krueger Director of Product

15 Tech-Clarity, Inc. 2015

Development. They held weekly conference calls with us, supported us at every step,

and made us aware of what we could do with our new CAD software."

Top Performers are also 47% more likely to consider market share.

Top Performers are also 47% more likely to consider market share. Market share makes it

easier to find partners and suppliers who are working with the same design tools. It also

makes it easier to find a resource pool from which to hire. Hiring trained users means the

company doesnt need to invest in additional training. This was part of the selection

criteria at USSC. They evaluated different CAD tools against a range of criteria including

ability to hire trained designers and engineers, partners and customers using the solution,

and pervasiveness within the supply chain. USSC chose the CAD solution that gave the

company more freedom to work with partners, customers, and other integrated

technologies.

A larger pool of trained users to hire from was also important to water park and

playground equipment manufacturer, Arihant. Assistant ManagerDesign Mithun S.

Mandal notes, In addition to providing greater accuracy and a much better graphical

representation of our products, its much easier to recruit talented designers and

engineers who already know how to use it.

Its much easier to recruit talented designers and

engineers who already know how to use it.

Mithun S. Mandal. Assistant ManagerDesign, Arihant

The many factors to consider when selecting a CAD tool can be overwhelming.

Considering this advice from a configuration manager can help maintain perspective,

The non-financial aspects of CAD: culture, ease of use, vendor support, customer

support, etc. are the real cost drivers and will affect your bottom line, not annual

subscription price.

Extend CAD

Extended applications are another important consideration. Survey respondents rated

their importance using the following scale:

5: Essential part of the CAD solution

4: Should be part of CAD solution

3: Nice to have as part of CAD solution

2: Can be separate functionality not part of CAD solution

1: Do not care about this functionality

16 Tech-Clarity, Inc. 2015

Overall, companies prefer extended applications as part of their CAD solution, ranking

them between nice to have and should be part of the solution (Figure 11). As

products increase in complexity, respondents assign a higher importance rating on

extended applications.

Companies prefer extended applications as part of their CAD solution, ranking

them between nice to have and should be part of the solution.

Embedded Simulation 3.6

PDM 3.6

Technical Communications 3.4

Importance Rating

Support for Electrical 3.2

Components

1.0 1- Dont 2.0

care about 3.0 4.0

5- Essential Part 5.0

of

functionality Solution

Figure 12 Importance of Embedding Extended Applications in CAD

Integrated extended applications are important to Harvard Apparatus, a manufacturer of

laboratory equipment for bioscience research products. "We moved all our design work to

a CAD tool that is easier to use, has integrated analysis capabilities, and is better for

sheet-metal and plastic part design. We realized that with its additional functionality and

file transfer capabilities, it was better for our company," says Engineering Manager Mark

Davis.

Conclusion

An increased focus on products can help companies as they struggle to compete in

todays global economy. Quickly developing high-quality, innovative products more

economically helps companies differentiate and stand out from competitors. Investments

17 Tech-Clarity, Inc. 2015

in the design process can help companies achieve this. CAD tools in particular, have a

significant impact on the design process. CAD has evolved significantly over the last

decade and those who find their existing tool no longer meets their needs or will not

support plans for growth, may want to consider switching CAD tools. In many cases,

companies have found a switch in CAD tools has had a very positive impact on their

business.

Top Performing companies are more likely to consider ease of use and support resources

when selecting a CAD tool. This contributes to their ability to realize even more value, in

less time, from their new solution.

Recommendations

Based on industry experience and research for this report, Tech-Clarity offers the

following recommendations:

Understand the business goals of your design process and ensure your CAD tool

will support them. If not, consider a change.

Consider other factors beyond the features and functions of the CAD tool, but also

the ability to collaborate with your supply chain, market share including available

community, the vendors vision, the relationship with the vendor, and the needs

for other supporting design tools

Consider extended applications as part of the CAD solution such as embedded

simulation, PDM, technical communications, and support for electrical

components.

Avoid overestimating requirements for training and loss of productivity by

considering ease of use as well as available resources such as Technical Support,

market share, and potential hiring pools.

Convert only the legacy data you need. It is likely you will only need half of it.

18 Tech-Clarity, Inc. 2015

About the Author

Michelle Boucher is the Vice President of Research for Engineering Software for

research firm Tech-Clarity. Michelle has spent over 20 years in various roles in

engineering, marketing, management, and as an analyst. She has broad experience

with topics such as product design, simulation, systems engineering, mechatronics,

embedded systems, PCB design, improving product performance, process improvement,

and mass customization. She graduated magna cum laude with an MBA from Babson

College and earned a BS in Mechanical Engineering, with distinction, from Worcester

Polytechnic Institute.

Michelle began her career holding various roles as a mechanical engineer at Pratt &

Whitney and KONA (now Synventive Molding Solutions). She then spent over 10 years

at PTC, a leading MCAD and PLM solution provider. While at PTC, she developed a

deep understanding of end user needs through roles in technical support, management,

and product marketing. She worked in technical marketing at Moldflow Corporation

(acquired by Autodesk), the market leader in injection molding simulation. Here she was

instrumental in developing product positioning and go-to-market messages. Michelle then

joined Aberdeen Group and covered product innovation, product development, and

engineering processes, eventually running the Product Innovation and Engineering

practice.

Michelle is an experienced researcher and author. She has benchmarked over 7000

product development professionals and published over 90 reports on product

development best practices. She focuses on helping companies manage the complexity of

todays products, markets, design environments, and value chains to achieve higher

profitability.

About the Research

Tech-Clarity gathered and analyzed 192 responses to a web-based survey on designing

software-intensive products. Survey responses were gathered by direct e-mail, social

media, and online postings by Tech-Clarity.

The respondents were comprised of 42% who were individual contributors and 39% were

manager or director level, and the remaining 19% were from VP and executive levels.

The respondents represented a mix of company sizes, including 49% from smaller

companies (less than $250 million), 7% between $250 million and $1 billion, 13%

between $1 billion and $5 billion, and 11% greater than $5billion. 20% chose not to

disclose their company size or did not know. All company sizes were reported in US

dollar equivalent.

19 Tech-Clarity, Inc. 2015

The responding companies were a good representation of the manufacturing industries,

including Industrial Equipment and Machinery (35%), Automotive (23%), Architecture,

Engineering, and Construction (20%), Aerospace and Defense (14%), Consumer

Products (14%), High-tech and Electronics (12%), and others. Note that these numbers

add up to greater than 100% because some companies indicated that they are active in

more than one industry.

The respondents reported doing business globally, with most companies doing business

in the North America (67%), about one-third doing business in Western Europe (34%),

about another one-third doing business in the Asia-Pacific regions (32%), Eastern Europe

(13%), and Latin America (10%).

Respondents included manufacturers as well as service providers and software

companies, but responses from those determined not to be end users of CAD software

(including software vendors and consultants) were not included in the analysis. The

majority of companies were considered to have direct involvement in designing and

developing products and the report reflects their experience.

20 Tech-Clarity, Inc. 2015

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Pub - Essentials of Nuclear Medicine Imaging 5th Edition PDFDokumen584 halamanPub - Essentials of Nuclear Medicine Imaging 5th Edition PDFNick Lariccia100% (1)

- 6th Central Pay Commission Salary CalculatorDokumen15 halaman6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Hindustan Motors Case StudyDokumen50 halamanHindustan Motors Case Studyashitshekhar100% (4)

- ASMOPS 2016 - International Invitation PHILIPPINEDokumen4 halamanASMOPS 2016 - International Invitation PHILIPPINEMl Phil0% (3)

- 2revit ArchitectureDokumen14 halaman2revit Architecturemksamy2021Belum ada peringkat

- Stakeholder Comments on CERC Approach Paper for Tariff Regulations 2014-19Dokumen3 halamanStakeholder Comments on CERC Approach Paper for Tariff Regulations 2014-19mksamy2021Belum ada peringkat

- Revit ArchitectureDokumen15 halamanRevit Architecturemksamy2021Belum ada peringkat

- 2revit ArchitectureDokumen14 halaman2revit Architecturemksamy2021Belum ada peringkat

- Todays RealityDokumen9 halamanTodays Realitymksamy2021Belum ada peringkat

- Full Plan14-ModelDokumen1 halamanFull Plan14-Modelmksamy2021Belum ada peringkat

- 5revit ArchitectureDokumen13 halaman5revit Architecturemksamy2021Belum ada peringkat

- 2revit ArchitectureDokumen14 halaman2revit Architecturemksamy2021Belum ada peringkat

- NBC - Fire SafetyDokumen200 halamanNBC - Fire Safetyvenkin84507486% (7)

- Civil Plan13 ModelDokumen1 halamanCivil Plan13 Modelmksamy2021Belum ada peringkat

- CLR Frmtig Ex PT 07Dokumen1 halamanCLR Frmtig Ex PT 07mksamy2021Belum ada peringkat

- Full Plan13-ModelDokumen1 halamanFull Plan13-Modelmksamy2021Belum ada peringkat

- Employment Personal DetailDokumen8 halamanEmployment Personal Detailmksamy2021Belum ada peringkat

- Form 1: Employee Personal Information Name of DepartmentDokumen12 halamanForm 1: Employee Personal Information Name of DepartmentRajashree PatilBelum ada peringkat

- Kerala Municipal Building RuleDokumen105 halamanKerala Municipal Building RuleSharath Kumar KBelum ada peringkat

- Process AutomationDokumen16 halamanProcess Automationmksamy2021Belum ada peringkat

- Wind Energy Conversion Systems Using DFIG With Integrated Active Filter CapabilitiesDokumen8 halamanWind Energy Conversion Systems Using DFIG With Integrated Active Filter Capabilitiesmksamy2021Belum ada peringkat

- Solco Training Solar Collectors enDokumen22 halamanSolco Training Solar Collectors enmksamy2021Belum ada peringkat

- Lec1sand Casting PDFDokumen16 halamanLec1sand Casting PDFSujit MishraBelum ada peringkat

- Micro Grid PDFDokumen33 halamanMicro Grid PDFmksamy2021Belum ada peringkat

- Introduction To Programmable Logic Controllers (PLC'S) : Industrial Control Systems Fall 2006Dokumen47 halamanIntroduction To Programmable Logic Controllers (PLC'S) : Industrial Control Systems Fall 2006Hamidreza MoaddeliBelum ada peringkat

- 3DS 2015 SWK Industrial Designer Data Sheet FINALDokumen2 halaman3DS 2015 SWK Industrial Designer Data Sheet FINALJeferson GevinskiBelum ada peringkat

- Nanotronics Project List 2016Dokumen20 halamanNanotronics Project List 2016mksamy2021Belum ada peringkat

- FlexiPanels LineDokumen4 halamanFlexiPanels Linemksamy2021Belum ada peringkat

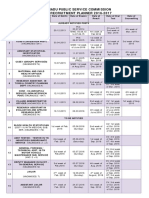

- Tamil Nadu Public Service Commission Annual Recruitment Planner 2016-2017Dokumen3 halamanTamil Nadu Public Service Commission Annual Recruitment Planner 2016-2017Ananda PreethiBelum ada peringkat

- PEL Lab ManualDokumen127 halamanPEL Lab Manualmksamy2021Belum ada peringkat

- Scada (Supervisory Control & Data Acquisition) For Remote Industrial PlantDokumen2 halamanScada (Supervisory Control & Data Acquisition) For Remote Industrial Plantmksamy2021Belum ada peringkat

- 8 Page Brochure - 2015 Product OfferingDokumen8 halaman8 Page Brochure - 2015 Product Offeringmksamy2021Belum ada peringkat

- Phys101 CS Mid Sem 16 - 17Dokumen1 halamanPhys101 CS Mid Sem 16 - 17Nicole EchezonaBelum ada peringkat

- Site Visit Risk Assessment FormDokumen3 halamanSite Visit Risk Assessment FormAmanuelGirmaBelum ada peringkat

- The Ultimate Advanced Family PDFDokumen39 halamanThe Ultimate Advanced Family PDFWandersonBelum ada peringkat

- John Titor TIME MACHINEDokumen21 halamanJohn Titor TIME MACHINEKevin Carey100% (1)

- PROF ED 10-ACTIVITY #1 (Chapter 1)Dokumen4 halamanPROF ED 10-ACTIVITY #1 (Chapter 1)Nizelle Arevalo100% (1)

- PandPofCC (8th Edition)Dokumen629 halamanPandPofCC (8th Edition)Carlos Alberto CaicedoBelum ada peringkat

- Orc & Goblins VII - 2000pts - New ABDokumen1 halamanOrc & Goblins VII - 2000pts - New ABDave KnattBelum ada peringkat

- TheEconomist 2023 04 01Dokumen297 halamanTheEconomist 2023 04 01Sh FBelum ada peringkat

- ERP Complete Cycle of ERP From Order To DispatchDokumen316 halamanERP Complete Cycle of ERP From Order To DispatchgynxBelum ada peringkat

- UAPPDokumen91 halamanUAPPMassimiliano de StellaBelum ada peringkat

- Impact of IT On LIS & Changing Role of LibrarianDokumen15 halamanImpact of IT On LIS & Changing Role of LibrarianshantashriBelum ada peringkat

- Do You Agree With Aguinaldo That The Assassination of Antonio Luna Is Beneficial For The Philippines' Struggle For Independence?Dokumen1 halamanDo You Agree With Aguinaldo That The Assassination of Antonio Luna Is Beneficial For The Philippines' Struggle For Independence?Mary Rose BaluranBelum ada peringkat

- Federal Complaint of Molotov Cocktail Construction at Austin ProtestDokumen8 halamanFederal Complaint of Molotov Cocktail Construction at Austin ProtestAnonymous Pb39klJBelum ada peringkat

- Resume of Deliagonzalez34 - 1Dokumen2 halamanResume of Deliagonzalez34 - 1api-24443855Belum ada peringkat

- Report Emerging TechnologiesDokumen97 halamanReport Emerging Technologiesa10b11Belum ada peringkat

- DLL - The Firm and Its EnvironmentDokumen5 halamanDLL - The Firm and Its Environmentfrances_peña_7100% (2)

- RUJUKANDokumen3 halamanRUJUKANMaryTibanBelum ada peringkat

- Data Sheet: Experiment 5: Factors Affecting Reaction RateDokumen4 halamanData Sheet: Experiment 5: Factors Affecting Reaction Ratesmuyet lêBelum ada peringkat

- John Hay People's Alternative Coalition Vs Lim - 119775 - October 24, 2003 - JDokumen12 halamanJohn Hay People's Alternative Coalition Vs Lim - 119775 - October 24, 2003 - JFrances Ann TevesBelum ada peringkat

- Instrumentation Positioner PresentationDokumen43 halamanInstrumentation Positioner PresentationSangram Patnaik100% (1)

- TWP10Dokumen100 halamanTWP10ed9481Belum ada peringkat

- Last Clean ExceptionDokumen24 halamanLast Clean Exceptionbeom choiBelum ada peringkat

- Resume Template & Cover Letter Bu YoDokumen4 halamanResume Template & Cover Letter Bu YoRifqi MuttaqinBelum ada peringkat

- Artist Biography: Igor Stravinsky Was One of Music's Truly Epochal Innovators No Other Composer of TheDokumen2 halamanArtist Biography: Igor Stravinsky Was One of Music's Truly Epochal Innovators No Other Composer of TheUy YuiBelum ada peringkat

- Pom Final On Rice MillDokumen21 halamanPom Final On Rice MillKashif AliBelum ada peringkat

- Exercises2 SolutionsDokumen7 halamanExercises2 Solutionspedroagv08Belum ada peringkat

- Marketing Plan for Monuro Clothing Store Expansion into CroatiaDokumen35 halamanMarketing Plan for Monuro Clothing Store Expansion into CroatiaMuamer ĆimićBelum ada peringkat