Department of Resources, Recycling, and Recovery: Lean 6-Sigma Green Belt Project

Diunggah oleh

YatinJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Department of Resources, Recycling, and Recovery: Lean 6-Sigma Green Belt Project

Diunggah oleh

YatinHak Cipta:

Format Tersedia

Lean 6-Sigma Green Belt Project

Department of Resources,

Recycling, and Recovery

Martin Perez Susan Markie

(Project Greenbelt) (Project Champion)

Permit Concurrence Process Project

Problem Statement: CalRecycle's regulatory timeline to complete the proposed SWFP process is

60 days upon receipt of the proposed SWFP package. In most cases the timeline is extended

to gather additional information necessary for the Department to take action. This creates high

levels of dissatisfaction for the applicants. The excessive processing time also leads to

duplicative work efforts.

Objective: To reduce the proposed SWFP process so that 95% of all permit packages are

completed within 35 days.

Project Team:

Susan Markie Champion

Martin Perez Green Belt

Jeff Hackett Team member

Mike Wochnick Team member

Andrew Parrish Team member

Cody Oquendo Team member

Laura Sullivan Team member

Elizabeth Felix Team member

Lean 6-Sigma Training Program

Baseline Capability

Process Capability Report for Before Total Days

USL

insert capability analysis graph

0 20 40 60 80

Sample Mean 48 total days; Sample Max - 92

Observed performance 26% within 35 total days.

Lean 6-Sigma Training Program

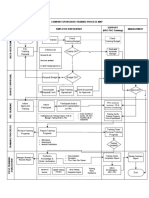

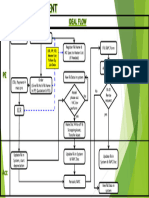

Process Map

Not in Compliance Permit Denial

X ESB Consistency Finding

X FA Finding

X CEQA Finding

X JPC Conformance Finding

X LEA's Proposed Permit Package

X E-mail X Final Staff Report

X Staff Request

Prepare Staff

Receive Permit Make Request to Pre-Permit Permit to Chief Send permit

Report, RFA Legal Review Permit Concurrence

Package WEEB Staff Inspection to LEA

memo, etc.

Y RFA Memo Signed

Y Staff Report prepared Y Prepare Inspection Report

In Compliance

Concur by

default

X Dot on the map

X Conformance Finding

Conformance

CF Approval

Finding Memo

Y Request for Action Memo prepared

Legal Review

(If RFA to Deputy Director Consistency Finding

expansion/new) Consistent Memo or E-mail to

PAB Staff

X Completeness Finding Comment Memo to

Complete Not Consistent

X Sharepoint Review Request X Checklist PAB/LEA/Operator

Consistency

If Disposal Finding Request to Plans Review

sites ---> ESB Staff

Incomplete Waiver of Time

FA

X Sharepoint Review Request Memo/Approval

Adequate

to PAB Staff

If Disposal Financial Assurance

Cost Estimate

Review Request to

sites ---> FA Staff

Information Review

Incomplete/Inadequate Waiver of

time/Follow up

with Operator

Legal Approval

Review (If

necessary)

The non-value added steps are highlighted in white while the value added

steps are highlighted in green.

Lean 6-Sigma Training Program

Analysis Tools

Analytical tools used to determine critical xs include:

Fishbone diagram FMEA

Capability analysis Multi-variable analysis

Histograms Hypothesis testing (One-

Boxplots Way ANOVA)

Scatterplots Multiple Regression Chart

Pareto chart I-MR Chart

Lean 6-Sigma Training Program

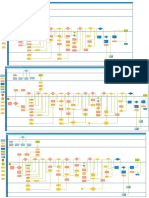

Processing Times for Key Tasks

Summary Report for FA Days Summary Report for PAB Review

0 10 20 30 40 0 20 40 60 80

95% Confidence Intervals 95% Confidence Intervals

Mean Mean

Median Median

0 2 4 6 8 10 12 15.0 17.5 20.0 22.5 25.0 27.5 30.0

The graphical summary is showing that each task went over the 35 day goal. There was

excessive variation and inconsistency in processing time which caused some tasks to

exceed 60 days.

Lean 6-Sigma Training Program

Processing Times for Key Tasks (cont.)

Summary Report for JPC Days Summary Report for WEEB Days

0 12 24 36 48 0 12 24 36 48

95% Confidence Intervals 95% Confidence Intervals

Mean Mean

Median Median

6 8 10 12 14 16 18 20 0 5 10 15 20

The graphical summary is showing that each task went over the 35 day goal. There was

excessive variation and inconsistency in processing time which caused some tasks to

exceed 60 days.

Lean 6-Sigma Training Program

Comparison of Key Tasks

The plot shows that the PAB review task has a much greater

influence on the total days.

Lean 6-Sigma Training Program

Critical xs

Critical xs determined by the analysis tools:

Review time for Permitting & Assistance Branch

staff due to 1) incomplete staff work and 2) lengthy

management review process.

Scheduling of pre-permit inspections between

WEEB staff, PAB staff & LEA staff.

Review time of JPC conformance finding due to

missing or incomplete information.

Lean 6-Sigma Training Program

Improvement Techniques

Training to internal staff and stakeholders (LEAs) on the FA

and permit application requirements.

Assistance to LEAs relative to permit processing

requirements and concurrent review earlier in the process.

Elimination of JPCs conformance finding process step.

WEEB inspection scheduled prior to receipt of proposed

permit would eliminate delays in waiting for the

compliance finding.

Lean 6-Sigma Training Program

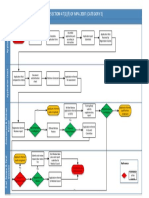

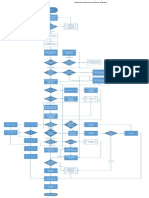

New Process Map

Not in Compliance Permit Denial

Prepare Staff

Make Request to Pre-Permit Receive Permit

Report, RFA

WEEB Staff Inspection Package

memo, etc.

Send permit

In Compliance Legal Review Permit to Chief Permit Concurrence

to LEA

Concur by

default

Consistency Finding

Proceed to Staff

Consistent Memo or E-mail to

Report Preparation

PAB Staff

Comment Memo to

Complete Not Consistent

PAB/LEA/Operator

Consistency Finding

Request to ESB Plans Review

Staff

Incomplete Waiver of Time

If a disposal site,

begin here...

FA Memo/Approval to Proceed to Staff

Adequate

PAB Staff Report Preparation

Financial Assurance

Cost Estimate Legal Approval Review

Review Request to

Information Review (If necessary)

FA Staff

Waiver of

Incomplete/Inadequate time/Follow up with

Operator

Most of the value added steps are completed prior to the receipt of the

proposed permit package.

Lean 6-Sigma Training Program

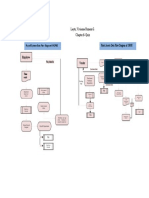

New Capability Analysis

Total Days (Before) Total Days (after)

USL USL

insert capability analysis graph

0 20 40 60 80 0 20 40 60 80

Projected mean 15 total days.

Projected performance 95% within 35 total days.

Lean 6-Sigma Training Program

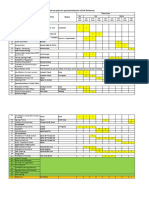

Control Plan

Control elements to be utilized:

Standard Operating Procedures (SOPs) Revisions to procedures for

preparing and reviewing a permit package and staff report.

Mistake-proofing Assistance to stakeholders and concurrent review of

the permit package to ensure it is complete and correct.

Process elimination Eliminate the process step for JPC conformance

findings.

Training to internal staff and stakeholders on complete and correct

application requirements.

Total days (Y output) to be monitored using an

I-MR chart

Lean 6-Sigma Training Program

Additional Benefits from the Project

We improved the staff communication between the different

units and are better aware of the each others roles and needs

in the proposed permit process.

While PAB staff manages the permit, each unit has an

important role in the process. Working together allowed us to

achieve a greater perspective on what was necessary as a part

of our duties.

The project made us aware that we should consider each unit

as parts of a whole team rather than independent from

another.

Lean 6-Sigma Training Program

Contact Information

Name: Martin Perez, Sr. Environmental Scientist

Phone: 916.323.0834

Email: Martin.Perez@calrecycle.ca.gov

Lean 6-Sigma Training Program

Anda mungkin juga menyukai

- IrccDokumen1 halamanIrcc1000 Subscribe without any videoBelum ada peringkat

- Company Sponsored Training Process Map - DrawioDokumen1 halamanCompany Sponsored Training Process Map - DrawioAudrey AyosoBelum ada peringkat

- Section 47 1 F Website GuidanceDokumen1 halamanSection 47 1 F Website Guidancehammad123456789Belum ada peringkat

- "You Haven't Been Paid Yet? Who Are You? OR Feeling The PAIN of Re-Engineering The Requisition Process at Coppin State CollegeDokumen21 halaman"You Haven't Been Paid Yet? Who Are You? OR Feeling The PAIN of Re-Engineering The Requisition Process at Coppin State CollegeHimanshu SinghBelum ada peringkat

- Sourcing Process - Flow - E2E - Aug2020Dokumen12 halamanSourcing Process - Flow - E2E - Aug2020ardiannikko0Belum ada peringkat

- Amnesty RenewalDokumen1 halamanAmnesty Renewalnja3531Belum ada peringkat

- Walkin Customer Process FlowDokumen1 halamanWalkin Customer Process FlowsubodhBelum ada peringkat

- Edited Tesda Op Ias 01 f05 A CookerynciiDokumen6 halamanEdited Tesda Op Ias 01 f05 A CookerynciiKim Sarah Jane RembulatBelum ada peringkat

- Document flow chart for contractor task approvalDokumen1 halamanDocument flow chart for contractor task approvalRaj VeenBelum ada peringkat

- PPAPDokumen16 halamanPPAPOsvaldo Da Silva Neto100% (1)

- University of Information Technology and Communications College of Business Informatics Ism Department Enterprise Resource PlanningDokumen28 halamanUniversity of Information Technology and Communications College of Business Informatics Ism Department Enterprise Resource PlanningAbdalla BassamBelum ada peringkat

- Airtel Form P ErformanceDokumen3 halamanAirtel Form P ErformanceGuruprasad ShejwalkarBelum ada peringkat

- Procurement Monitoring Report As of December 31, 2017 (2nd Sem 2017)Dokumen3 halamanProcurement Monitoring Report As of December 31, 2017 (2nd Sem 2017)jayson àrandiaBelum ada peringkat

- Attachment 6-9 WorkflowNDokumen4 halamanAttachment 6-9 WorkflowNwidiarinBelum ada peringkat

- BDEA ProcessDokumen8 halamanBDEA ProcessJoji VargheseBelum ada peringkat

- HAS Infographic July2018 v2Dokumen5 halamanHAS Infographic July2018 v2Dickyard Mini PuckyBelum ada peringkat

- TH EAM Screenv1Dokumen36 halamanTH EAM Screenv1muhdnasoha07Belum ada peringkat

- NPIDokumen1 halamanNPIsuree_leo0% (1)

- Six Sigma RFI Project Reduces RejectionsDokumen20 halamanSix Sigma RFI Project Reduces RejectionsBoppudBelum ada peringkat

- As Is - Inspection and GRN - Wooden Ply, Pallet and Top CoverDokumen1 halamanAs Is - Inspection and GRN - Wooden Ply, Pallet and Top CoverYousuf KhanBelum ada peringkat

- HRDO 4 Process Flow: Faculty AppointmentsDokumen2 halamanHRDO 4 Process Flow: Faculty AppointmentsEA MendozaBelum ada peringkat

- Advisian Business Process - MAINDokumen10 halamanAdvisian Business Process - MAINDavid PrastyanBelum ada peringkat

- Chap 6Dokumen1 halamanChap 6Zion IlaganBelum ada peringkat

- BRUNSFIELD CONSTRUCTION SB PROJECT UPDATEDokumen7 halamanBRUNSFIELD CONSTRUCTION SB PROJECT UPDATEMuhamad HaykalBelum ada peringkat

- RGX offshore projects cost forecast activities for 2007Dokumen1 halamanRGX offshore projects cost forecast activities for 2007MarkyBelum ada peringkat

- Flowchart RFI VgiDokumen1 halamanFlowchart RFI VgiCameronBelum ada peringkat

- 1 - Appro - Achats ImportationDokumen1 halaman1 - Appro - Achats Importationmerouane usmisteBelum ada peringkat

- 000.100.8100 Baseline Centric Execution - Deliver To The Baseline WorkflowDokumen1 halaman000.100.8100 Baseline Centric Execution - Deliver To The Baseline WorkflowmiltonBelum ada peringkat

- FA ID Flow -1Dokumen1 halamanFA ID Flow -1widhi.ti07Belum ada peringkat

- RFQ & Sample Approval ProcessDokumen1 halamanRFQ & Sample Approval ProcessKarthik MadhavanBelum ada peringkat

- Web Rs Inv OverviewDokumen12 halamanWeb Rs Inv OverviewJohn Rey RayalaBelum ada peringkat

- Finance Roadmap (Jul-22) v1.2Dokumen5 halamanFinance Roadmap (Jul-22) v1.2avisek_dharBelum ada peringkat

- 4M Change Control Management Matrix For Supplier: MonthDokumen1 halaman4M Change Control Management Matrix For Supplier: Monthsuresh kumar100% (3)

- Carton Process Flow Chart: Make SampleDokumen1 halamanCarton Process Flow Chart: Make SampleMunem ShahriarBelum ada peringkat

- CAPA Process FlowchartDokumen3 halamanCAPA Process FlowchartAbdur Rashid KhanBelum ada peringkat

- Roll Out Plan For Operationalization of Coe Peshawar Time LineDokumen2 halamanRoll Out Plan For Operationalization of Coe Peshawar Time LinehamayunBelum ada peringkat

- Mobilization & Familiarization ProceduresDokumen6 halamanMobilization & Familiarization ProceduresparamgaganBelum ada peringkat

- PM OrientationDokumen135 halamanPM OrientationNikhil GeorgeBelum ada peringkat

- Specs Issue 1 2011Dokumen32 halamanSpecs Issue 1 2011JEGL Industrial Engineering ServicesBelum ada peringkat

- Poster Sindh 2-01-2024Dokumen11 halamanPoster Sindh 2-01-2024FM Printers111Belum ada peringkat

- Process: Area Office Operated AFE Process Process Owner: Area/Regional OfficeDokumen1 halamanProcess: Area Office Operated AFE Process Process Owner: Area/Regional OfficeAbang GaffiBelum ada peringkat

- Related Parties ISA 550 Audit ProceduresDokumen11 halamanRelated Parties ISA 550 Audit ProceduresAbdul WahabBelum ada peringkat

- Fy20 Fy24 It Strategic PlanDokumen52 halamanFy20 Fy24 It Strategic PlanIzoorViinaBelum ada peringkat

- Flow Chart For Shop Inspection: Prepared Checked ApprovedDokumen2 halamanFlow Chart For Shop Inspection: Prepared Checked ApprovedRanu JanuarBelum ada peringkat

- Year Clientcode A6 Time BudgetDokumen1 halamanYear Clientcode A6 Time BudgetReinnalyn UlandayBelum ada peringkat

- Career Feb2019 PDFDokumen6 halamanCareer Feb2019 PDFleo mateoBelum ada peringkat

- Description: Tags: AppendixEFiscalReviewWorksheetDokumen1 halamanDescription: Tags: AppendixEFiscalReviewWorksheetanon-253249Belum ada peringkat

- Procurement Process FlowDokumen11 halamanProcurement Process Flowlairah.mananBelum ada peringkat

- Flowchart - RecruitmentDokumen1 halamanFlowchart - RecruitmentemmalyneBelum ada peringkat

- Action Catalog OAP NC II UTPRAS 2021Dokumen3 halamanAction Catalog OAP NC II UTPRAS 2021mario layanBelum ada peringkat

- US Tax Reform - Timeline (May 8)Dokumen2 halamanUS Tax Reform - Timeline (May 8)Araman JabilBelum ada peringkat

- Compliance Audit ProceduresDokumen1 halamanCompliance Audit ProceduresCabanatuan School of Beauty and wellnessBelum ada peringkat

- APMT 2016 - FinalDokumen17 halamanAPMT 2016 - FinalmarivicBelum ada peringkat

- Working Plan (Contract & Cost Control) - 26.12.20Dokumen7 halamanWorking Plan (Contract & Cost Control) - 26.12.20kyi zin ayeBelum ada peringkat

- Wi 87 04Dokumen1 halamanWi 87 04Erick DomínguezBelum ada peringkat

- GDPEP / AIAG APQP / VDA Maturity Level Assurance: A1 A2 A3 A4 A5 A6 A7 A8Dokumen1 halamanGDPEP / AIAG APQP / VDA Maturity Level Assurance: A1 A2 A3 A4 A5 A6 A7 A8Kumaravel SivaBelum ada peringkat

- ? أهم أسئلة الإنترفيو لمهندس إدارة المشروعات ❤Dokumen22 halaman? أهم أسئلة الإنترفيو لمهندس إدارة المشروعات ❤EHABBelum ada peringkat

- Action CatalogueDokumen1 halamanAction CatalogueMarkBelum ada peringkat

- Microsoft Dynamics GP 2013 - System Admin Guide PDFDokumen110 halamanMicrosoft Dynamics GP 2013 - System Admin Guide PDFsivextienBelum ada peringkat

- Purchasing Audit ProgrammeDokumen12 halamanPurchasing Audit ProgrammemercymabBelum ada peringkat

- Lecture Five Strategic Information Systems Planning (Sisp)Dokumen3 halamanLecture Five Strategic Information Systems Planning (Sisp)R Ant SimbaBelum ada peringkat

- MAX17077AETM 1tDokumen1 halamanMAX17077AETM 1tAlejandro clericoBelum ada peringkat

- WT - P U ' G: ERF SER S UideDokumen4 halamanWT - P U ' G: ERF SER S UideLuong AnhBelum ada peringkat

- MTM and Motion Economy in Industrial EngineeringDokumen12 halamanMTM and Motion Economy in Industrial Engineeringmdravi89Belum ada peringkat

- Seven Pragmatic Practices To Improve Software QualityDokumen10 halamanSeven Pragmatic Practices To Improve Software QualityZeeshan Ahmed KhanBelum ada peringkat

- Overmold Design GuideDokumen18 halamanOvermold Design GuideCuco MartinezBelum ada peringkat

- CEB 1043 Principles of Chemical Engineering Tutorial 3 (CLO1, C1:PO1Dokumen1 halamanCEB 1043 Principles of Chemical Engineering Tutorial 3 (CLO1, C1:PO1Nur KamiliaBelum ada peringkat

- Manual Uganda CatfishDokumen65 halamanManual Uganda CatfishDare Kehinde100% (2)

- Vertex Payroll Tax Q Series Integration With Oracle Fusion HCMDokumen2 halamanVertex Payroll Tax Q Series Integration With Oracle Fusion HCMsam22nowBelum ada peringkat

- Lean and Agile Supply ChainDokumen30 halamanLean and Agile Supply ChainboschabdelBelum ada peringkat

- Final Weld Strength CalnsDokumen3 halamanFinal Weld Strength CalnsSajal KulshresthaBelum ada peringkat

- Technical Information ASSET DOC LOC 8869243Dokumen1 halamanTechnical Information ASSET DOC LOC 8869243Francis Jan DiscayaBelum ada peringkat

- Hazard RegisterDokumen18 halamanHazard RegisterImenuel AlexBelum ada peringkat

- RIBA Plan of WorkDokumen2 halamanRIBA Plan of WorkSyed Moinullah Hussaini100% (2)

- Adobe Case Study - DTI Intelligent DocumentsDokumen3 halamanAdobe Case Study - DTI Intelligent DocumentsrpcooperBelum ada peringkat

- PEI Trucking Sector - 2010: DefinitionDokumen3 halamanPEI Trucking Sector - 2010: Definitionn3xtnetworkBelum ada peringkat

- PLM SyllabusDokumen1 halamanPLM SyllabusGobivel KathirvelBelum ada peringkat

- Jonathan Baeza's Resume - Java Consultant & IT Co-FounderDokumen5 halamanJonathan Baeza's Resume - Java Consultant & IT Co-FounderJonathan BaezaBelum ada peringkat

- SAS Institute A00-250Dokumen21 halamanSAS Institute A00-250rajeshmsitBelum ada peringkat

- Operation ManualDokumen9 halamanOperation Manualapi-202718495Belum ada peringkat

- SS 671Dokumen9 halamanSS 671OwBelum ada peringkat

- Master Planning Process Diagram - Google SearchDokumen3 halamanMaster Planning Process Diagram - Google SearchKevin RotichBelum ada peringkat

- Catalog General Kaysun - 2016 Eng SPDokumen376 halamanCatalog General Kaysun - 2016 Eng SPAnca JianuBelum ada peringkat

- Competitor PlantDokumen18 halamanCompetitor Plantபிரதீப் கதிரேசன்Belum ada peringkat

- HUDA Policy Allowing Four BasementsDokumen3 halamanHUDA Policy Allowing Four BasementsRahul JindalBelum ada peringkat

- Abdul Rauf - Mechanical Engineer-Production ManagerDokumen3 halamanAbdul Rauf - Mechanical Engineer-Production ManagercdeekyBelum ada peringkat

- VI Semester Airport and Railway EngineeringDokumen2 halamanVI Semester Airport and Railway EngineeringdineshBelum ada peringkat

- Bek MDPDokumen43 halamanBek MDPluisgalo91143Belum ada peringkat