JSA G17 Lift Container With Crane

Diunggah oleh

setiawanaji407Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

JSA G17 Lift Container With Crane

Diunggah oleh

setiawanaji407Hak Cipta:

Format Tersedia

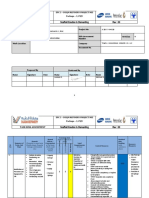

POWER

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA) / SAFE WORK METHOD STATEMENT

Location / Project:

ACTIVITY OR TASK: LIFTING CONTAINERS WITH CRANE

JSA Preparation & Job Number:

task work team: JSA Number: JSA G17 JSA Revision:

Competence = Relevant Training/Qualifications + Experience

Competence/ Qualificn

Codes of Practice &

reqd to complete work

Legislation that are

safely

applicable:

JSA approved by Name: Position / Competence/ License: Date:

person responsible i.e.

Team Leader / Tradesman

2. HAZARD IDENTIFICATION Identify hazards that may be present by ticking items on the list below. 3. PRECAUTIONS: hard hat, safety glasses, safety boots

compulsory

WORK LOCATION HAZARDOUS AREA HIGH RISK HIGH RISK ADDITIONAL PRECAUTIONS PERMITS

Difficult Entry/Exit Hazardous Substances Falling Objects Suspended loads Gloves: type . Hot Work

Oxygen Deficiency - attach MSDS to JSA Poor Lighting Poor Visibility Goggles Excavation

Oxygen Excess Working at Heights Slippery Surfaces Inhalable Dusts/Fibres Full Face Shield Confined Space

Engulfment (trench collapse) Remote Area Multiple Electrical Feeds High Noise Levels High Visibility Vest Hazardous Work Clearance

Poisonous Gas Present Motor Room Hazards Trip Hazards Use of Chemicals Harness Access to Area

Temperature Extremes Toxic Substances Electrical Hazards - LV Elevated Work Platform Fire Extinguishers High Voltage Access

Defined Confined Space Potential for Difficult Rescue Electrical Hazards - HV Difficulty to Communicate Barricades Scaffolding

Explosive Gas Present amongst workers Ventilation Other?

Manual Handling Moving Machinery Lighting

PERMIT NUMBER

HAZARDOUS SUBSTANCES in work area / to be used Sharp Materials Tools & Equipment Erect Scaffolding to access

-attach MSDS

Ladders used in the task Heat/ Sunlight/ Radiation Respirator or Dust mask

Working at Heights Traffic Movement Erect Warning signs

Working near Crane & Working near Operation Personal Locks or Tag system

Crane Runways Processing Lines Group isolation

Rail Movement Live Rails Welding screen

Pressurised Fluids Pneumatics Fall Arrest systems

Flamm. Materials Present Welding Face Shield

4. ENVIRONMENTAL HAZARDS (IMPACTS) tick those identified Consequences: how severe an

Likelihood:

Air Pollution (dust, fumes) Spills to ground Other: RISK RATING TABLE How likely is it to injury?

Noise (plant & equipment) Soil Erosion

This table is used to calculate whether be that bad? Death Serious Medical 1st Aid

the hazard you have identified is Injuries Treatment reqd

Spills to drains/waterways Hazard to Flora /Fauna Reqd

Extreme: 9-10 High: 7-8,

Medium: 5-6 or Low: 3-4 Almost Certain - 10 9 8 7

Expected to Occur

5. EQUIPMENT REQUIRED: Likely could 9 8 7 6

The objective of rating the risk is to lower the risk happen sometime

Static Plant & Equipment

by initiating risk control measures. The score is Moderate could

Mobile Plant & Equipment 8 7 6 5

happen but not likely

Unlikely could 7 6 5 4

happen but very rare

Revision Date: March 2005 . of .. Rare - could happen OHS-03-F01

6 5 4 3

but probably never will

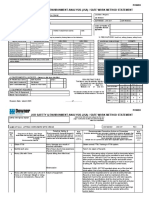

POWER

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA) / SAFE WORK METHOD STATEMENT

noted in the JSA risk score column on the next

Safety / Emergency Equipt

page both before & after risk control measures

have been nominated.

NAME OF TASK: LIFTING CONTAINERS WITH CRANE JSA Number: JSA G17 Rev:

Potential Safety & Risk Recommended Corrective Action or Procedure Risk

Step Sequence of Basic Job Steps Environmental Hazards/Impacts Rating Determine what actions are necessary to eliminate or minimise all hazards that Rating

No. Break down Job into steps. Each step should Identify the hazards (health and safety or Use table on could lead to an accident, injury, illness or environmental

Of the risk

Logical accomplish a major task and environmental) associated with each step, the previous incident. The risk must be reduced or controlled to a level following

sequence

be logical. examine each to find all possible risk factors page to that is acceptable before work commences. corrective

score risk Indicate who is to perform the action where applicable against each action action

Environmental Aspects

1 Obtain PTW Injury / damage as a result of Obtain correct PTW. Training in PTW system.

incorrect information

2 Identify work area Risk of injury due to low awareness Take 5, be aware of hazards

of work environment

3 Heavy Lifts with Crane Objects falling from lifted load: The area of the swing radius of cranes shall be barricaded where

necessary. Employees shall not be permitted to work under the

load of cranes. Lifts MUST NOT be swung over the top of where

other people are working. Riggers to ensure and double check

for correct slinging method and everything on load is secure prior

to taking lift. Tag lines MUST BE USED to control loads.

Electrocution Equipment SHALL NOT BE operated where any of the load will

come within 6.4m of any electrical distribution or power line.

4 Heavy Lifts with Cranes (any Lift over 5 Failure of equipment: Cranes shall be inspected prior to use and at weekly intervals.

Tonne or of Unknown Weight or Using Records or test inspections shall be maintained at the site.

2 Cranes is Considered a Heavy Lift) Equipment must not be operated above its safe rated capacity.

Manufacturers specifications shall be observed by all crane

operators. Only certified riggers to be used to dog loads and give

signal to driver. All crane operators shall be appropriately

certified - records of certification shall be maintained at site.

Rated load capacity, operating speeds, special hazard warnings

and instructions shall be visible to the operator while at the

control station.

Revision Date: March 2005 . of .. OHS-03-F01

POWER

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA) / SAFE WORK METHOD STATEMENT

5 Lifting Containers Risk of injury due to crush points Take 5, be aware of crush points

Risk of load shifting due to incorrect Use qualified riggers to assess correct chain length. Crane

rigging, exceeding working radius operator to avoid exceeding working radius.

Risk of equipment failure due to

overloading Monitor container weight and do not exceed crane lifting limits

Risk of damage due to truck size

mismatch Check truck size matches container size prior to lift

Risk of injury / damage due to high Crane operator to check weather conditions

wind

Risk of damage / injury due to poor

Use spotter and correct signals to assist crane operator.

visibility related to large load

Revision Date: March 2005 . of .. OHS-03-F01

POWER

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA)

CONSULTATION & SIGN-OFF RECORD

I confirm by my signature below, that I have attended a briefing on the requirements of the attached Job Safety &

Environment Analysis and agree to perform the work in the manner detailed on it.

I confirm that copies of the relevant Permits, MSDS's, Isolation Plans etc. have been reviewed.

Rev:

JSA NAME JSA No:

NAME (Please print) SIGNATURE DATE

THIS SAFE WORK BRIEFING / TRAINING WAS CARRIED OUT BY (responsible person at that location) :

Name: Signature: Date:

Client sign off (where applicable)

Site / Project Manager sign off (document reviewed)

Revision Date: March 2005 OHS-03-F01

Anda mungkin juga menyukai

- Secret Service Bomb BookDokumen27 halamanSecret Service Bomb BookGasMaskBob88% (8)

- MDLZ-RBIPL-MS-01-SITE MOBILIZATION WORK - UptdDokumen21 halamanMDLZ-RBIPL-MS-01-SITE MOBILIZATION WORK - Uptdshamshad ahamedBelum ada peringkat

- 2014 Energized Electrical Work Permit - ByU-IdahoDokumen2 halaman2014 Energized Electrical Work Permit - ByU-Idahocarrot123456Belum ada peringkat

- JSA G20 Scaffolding Erection DismantlingDokumen4 halamanJSA G20 Scaffolding Erection DismantlingemmyBelum ada peringkat

- Hazard Identification FormDokumen1 halamanHazard Identification Formabdulrazzaq hatem100% (1)

- RoutineJobHazardAnalysis 000Dokumen2 halamanRoutineJobHazardAnalysis 000sugiyanto100% (1)

- Using Hand Drill (WS)Dokumen2 halamanUsing Hand Drill (WS)John KalvinBelum ada peringkat

- Permanent Facilities Storage ProtectionDokumen2 halamanPermanent Facilities Storage ProtectionMOHAMMED RIYAN TBelum ada peringkat

- 013100.1 - CSI Form 1.5A Subcontractors and Major Material Suppliers ListDokumen1 halaman013100.1 - CSI Form 1.5A Subcontractors and Major Material Suppliers ListWestmere Fire DistrictBelum ada peringkat

- JSA For Scaffoding Erection and DismentlingDokumen17 halamanJSA For Scaffoding Erection and DismentlingShekh BabulBelum ada peringkat

- Appendix 3 01 Health Safety and Fire Regulations 3rd EditionDokumen168 halamanAppendix 3 01 Health Safety and Fire Regulations 3rd EditionB.Peer Muhammad NishathBelum ada peringkat

- Permit To WorkDokumen1 halamanPermit To WorkIshtiaq AhmadBelum ada peringkat

- Machine excavation hazard analysisDokumen7 halamanMachine excavation hazard analysisVenkadesh Periathambi100% (1)

- Does This Location Have Particulate Solids?: ONLY Non-CombustibleDokumen39 halamanDoes This Location Have Particulate Solids?: ONLY Non-CombustibleSuad BushiBelum ada peringkat

- Analysis Criteria:: Karbala Refinery ProjectDokumen10 halamanAnalysis Criteria:: Karbala Refinery Projectmustafa falehBelum ada peringkat

- Incident Accident RegisterDokumen2 halamanIncident Accident RegisterMuruganBelum ada peringkat

- Scaffold Erection & Dismantling Rev: 00: Task Risk AssessmentDokumen9 halamanScaffold Erection & Dismantling Rev: 00: Task Risk Assessmentibrahim100% (1)

- NICE3000new Elevator Controller ManualDokumen233 halamanNICE3000new Elevator Controller ManualIrwaenk Sevenfold81% (31)

- JSA Safety AnalysisDokumen3 halamanJSA Safety AnalysisLusy Gusti EfendiBelum ada peringkat

- Chemical Manifest and Hazardous Chemical Substance List KathuDokumen13 halamanChemical Manifest and Hazardous Chemical Substance List KathuVictorBelum ada peringkat

- JSA for Chainsaw Tree ClearingDokumen2 halamanJSA for Chainsaw Tree ClearingRetselisitsoeBelum ada peringkat

- Risk Ass. - AD 417 - Installation of SocketDokumen6 halamanRisk Ass. - AD 417 - Installation of SocketnsadnanBelum ada peringkat

- Job Hazard Analysis: Format For JHA WorksheetDokumen3 halamanJob Hazard Analysis: Format For JHA WorksheetWaseem AhmadBelum ada peringkat

- Crane Safety TipsDokumen4 halamanCrane Safety Tipssetiawanaji407100% (1)

- Hse Team Organization Chart - 2018: Qhse ManagerDokumen1 halamanHse Team Organization Chart - 2018: Qhse ManagerMohammad Mokhtarul HaqueBelum ada peringkat

- Astm A700Dokumen40 halamanAstm A700hegiro2011Belum ada peringkat

- 11 as-F-HSE 011 - First Aid RegisterDokumen1 halaman11 as-F-HSE 011 - First Aid RegisterJHUPEL ABARIALBelum ada peringkat

- 13.2.11 RA SWP For Installation of Instruments and Instrument Tubing at DCLDokumen17 halaman13.2.11 RA SWP For Installation of Instruments and Instrument Tubing at DCLkeertiraj09100% (1)

- JSA For WIndow Opening and Finishing WorkDokumen17 halamanJSA For WIndow Opening and Finishing WorkShekh BabulBelum ada peringkat

- Ra Lightning Protection SystemDokumen16 halamanRa Lightning Protection SystemamalBelum ada peringkat

- Emergency Response and Contingency PlanDokumen21 halamanEmergency Response and Contingency PlanKarimo KilaniBelum ada peringkat

- JHA Maintenance Tech HVACDokumen2 halamanJHA Maintenance Tech HVACMdavaBelum ada peringkat

- Boom Lift - Working From - 2Dokumen4 halamanBoom Lift - Working From - 2Alejandro CampomarBelum ada peringkat

- PPE Risk Assessment DocumentDokumen5 halamanPPE Risk Assessment DocumentFarzanaBelum ada peringkat

- MSDS Cement PDFDokumen5 halamanMSDS Cement PDFHendrik SimatupangBelum ada peringkat

- Contractor Ehs Risk Assessment For NDT TestingDokumen6 halamanContractor Ehs Risk Assessment For NDT TestingBernard PenuliarBelum ada peringkat

- Hot Work Safety MeasuresDokumen6 halamanHot Work Safety Measurestamoor sarwarBelum ada peringkat

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Dokumen3 halamanRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (1)

- Fame Steel HSE Matrix Daily HazardsDokumen3 halamanFame Steel HSE Matrix Daily HazardsSaboor KabierBelum ada peringkat

- Contractor Work Permit: 1 ObjectiveDokumen11 halamanContractor Work Permit: 1 ObjectiveZeremia SamosirBelum ada peringkat

- Dassault Falcon 000dx Ex StructureDokumen30 halamanDassault Falcon 000dx Ex StructureAB1984Belum ada peringkat

- Weekly ReportDokumen2 halamanWeekly ReportNovia Zulfa HanumBelum ada peringkat

- Master Rigger - ITI Course Ebook 012218Dokumen14 halamanMaster Rigger - ITI Course Ebook 012218Asad AwanBelum ada peringkat

- JHA ANALYSIS SCALE REMOVAL VESSELDokumen2 halamanJHA ANALYSIS SCALE REMOVAL VESSELRiyadh SalehBelum ada peringkat

- JSA For Erection & Dismantling of ScaffoldingDokumen4 halamanJSA For Erection & Dismantling of ScaffoldingNoe AranelBelum ada peringkat

- 130718Dokumen176 halaman130718Th NattapongBelum ada peringkat

- Operating Manual GBTK 6023: Overspeed Governor 02/2017Dokumen64 halamanOperating Manual GBTK 6023: Overspeed Governor 02/2017Rodrigo Antonio100% (1)

- Bulk Cargo - Safe Loading and Unloading of Bulk Carriers 2003 - Uk Govt RegulationsDokumen36 halamanBulk Cargo - Safe Loading and Unloading of Bulk Carriers 2003 - Uk Govt Regulationsearthanskyfriends100% (2)

- Bulk Cargo - Safe Loading and Unloading of Bulk Carriers 2003 - Uk Govt RegulationsDokumen36 halamanBulk Cargo - Safe Loading and Unloading of Bulk Carriers 2003 - Uk Govt Regulationsearthanskyfriends100% (2)

- HIPhazard Id PlanDokumen27 halamanHIPhazard Id PlanAhmed Raza KhanBelum ada peringkat

- HSE Equipment Inspection RegisterDokumen1 halamanHSE Equipment Inspection RegistersubhanmusadiqBelum ada peringkat

- Jsa For TIE INS in Accommodation BlockDokumen4 halamanJsa For TIE INS in Accommodation BlockAliBelum ada peringkat

- FR - HSE - 061 - en Permit To Work Audit ChecklistDokumen2 halamanFR - HSE - 061 - en Permit To Work Audit ChecklistNibu P ShajiBelum ada peringkat

- Bajaj Electricals EHS Meeting MinutesDokumen3 halamanBajaj Electricals EHS Meeting Minutesanil kumarBelum ada peringkat

- JSA G17 Lift Container With CraneDokumen4 halamanJSA G17 Lift Container With Cranesetiawanaji407Belum ada peringkat

- Excavation Working in Trenches Swms 10281-6Dokumen17 halamanExcavation Working in Trenches Swms 10281-6JamesBelum ada peringkat

- Project HSE Plan KOC - Ge.048Dokumen4 halamanProject HSE Plan KOC - Ge.048Wellfro0% (1)

- Incident Report SummaryDokumen7 halamanIncident Report SummaryDoan Ngoc DucBelum ada peringkat

- Hse Orientation Training & TopicsDokumen2 halamanHse Orientation Training & TopicsGanga Daran100% (1)

- Complex Building Design Laws and CodesDokumen18 halamanComplex Building Design Laws and CodesRency Ramos100% (1)

- CSMS CHANDRA ASI SHE Regulation 2019 (Approved) (Attachment Included)Dokumen207 halamanCSMS CHANDRA ASI SHE Regulation 2019 (Approved) (Attachment Included)OKKY100% (1)

- Kone LCE Fault CodesDokumen28 halamanKone LCE Fault Codesalberto peña100% (1)

- Hazardous Substances RegisterDokumen1 halamanHazardous Substances RegisterArmandoBelum ada peringkat

- Project No. 074-10 JHA No. 1Dokumen20 halamanProject No. 074-10 JHA No. 1Adel SukerBelum ada peringkat

- 10-F20 Fuel Driven Equipment InspectionDokumen3 halaman10-F20 Fuel Driven Equipment InspectionSn AhsanBelum ada peringkat

- 13.JHA-Site Visit For Checking The Location of Drilling Hole For Cable Entry at 33KV SubstationDokumen5 halaman13.JHA-Site Visit For Checking The Location of Drilling Hole For Cable Entry at 33KV SubstationFrancis Enriquez TanBelum ada peringkat

- Sample JHADokumen5 halamanSample JHAKen100% (1)

- Larsen & Toubro Limited Buildings and Factories Independent CompanyDokumen5 halamanLarsen & Toubro Limited Buildings and Factories Independent CompanyabbasBelum ada peringkat

- BOND-NG18000096-GBRG2-HX5880-00001 - HSSE Plan - C01a-Sign2Dokumen21 halamanBOND-NG18000096-GBRG2-HX5880-00001 - HSSE Plan - C01a-Sign2Jude EdohorBelum ada peringkat

- Confined Space Rescue Plan: Description of The WorkDokumen2 halamanConfined Space Rescue Plan: Description of The Workidigiti100% (1)

- Method Statement Form: Method Statement For Excavation / Dewatering of FGD (Chimney)Dokumen4 halamanMethod Statement Form: Method Statement For Excavation / Dewatering of FGD (Chimney)poovazhaganBelum ada peringkat

- Safety BoardDokumen1 halamanSafety BoardsunilBelum ada peringkat

- JSA - Scissor - Lift 2023Dokumen4 halamanJSA - Scissor - Lift 2023syed khaja misbhuddinBelum ada peringkat

- Manual Handling Risks Control MeasuresDokumen3 halamanManual Handling Risks Control Measuressetiawanaji407Belum ada peringkat

- Husni 2016 IOP Conf. Ser. - Mater. Sci. Eng. 128 012026 PDFDokumen11 halamanHusni 2016 IOP Conf. Ser. - Mater. Sci. Eng. 128 012026 PDFsetiawanaji407Belum ada peringkat

- Guidance Manual Handling PDFDokumen42 halamanGuidance Manual Handling PDFRohan RoyBelum ada peringkat

- Nav PLM Brochure 2018Dokumen4 halamanNav PLM Brochure 2018setiawanaji407Belum ada peringkat

- AssetMain OV CorpDokumen5 halamanAssetMain OV Corpsetiawanaji407Belum ada peringkat

- Guidance Manual Handling PDFDokumen42 halamanGuidance Manual Handling PDFRohan RoyBelum ada peringkat

- Husni 2016 IOP Conf. Ser. - Mater. Sci. Eng. 128 012026Dokumen11 halamanHusni 2016 IOP Conf. Ser. - Mater. Sci. Eng. 128 012026setiawanaji407Belum ada peringkat

- Sistem Monitoring Volume Tangki Solar MenggunakanDokumen9 halamanSistem Monitoring Volume Tangki Solar Menggunakanrifki wahyudiBelum ada peringkat

- Access ERP on the Go with iUIMobileDokumen16 halamanAccess ERP on the Go with iUIMobileWilson GayoBelum ada peringkat

- Nav PLM Brochure 2018Dokumen4 halamanNav PLM Brochure 2018setiawanaji407Belum ada peringkat

- ESOP 14 Bulk Fuel StorageDokumen26 halamanESOP 14 Bulk Fuel Storagesetiawanaji407Belum ada peringkat

- K3Dokumen10 halamanK3Anonymous OEiGK0OZBelum ada peringkat

- Starter Foundation Android ERPDokumen62 halamanStarter Foundation Android ERPWilson GayoBelum ada peringkat

- Microsoft Dynamics AX 2012 System Requirements PDFDokumen37 halamanMicrosoft Dynamics AX 2012 System Requirements PDFcbgunBelum ada peringkat

- JSP 886 Defence Logistics Support Chain Manual: WWW - Defencegateway.mod - UkDokumen27 halamanJSP 886 Defence Logistics Support Chain Manual: WWW - Defencegateway.mod - Uksetiawanaji407Belum ada peringkat

- Sop Sampling Lab& ReciptDokumen6 halamanSop Sampling Lab& Reciptsetiawanaji407Belum ada peringkat

- Berat Material - Besi DLLDokumen50 halamanBerat Material - Besi DLLsetiawanaji407Belum ada peringkat

- 4.01 Petrochemical and Offshore - ASTM D 1500 ColorDokumen2 halaman4.01 Petrochemical and Offshore - ASTM D 1500 Colorsetiawanaji407Belum ada peringkat

- 4.01 Petrochemical and Offshore - ASTM D 1500 ColorDokumen2 halaman4.01 Petrochemical and Offshore - ASTM D 1500 Colorsetiawanaji407Belum ada peringkat

- Colour StandardsDokumen5 halamanColour Standardssetiawanaji407Belum ada peringkat

- 5 Transportation 2013 PDFDokumen14 halaman5 Transportation 2013 PDFsetiawanaji407Belum ada peringkat

- Transportasi Distribusi Dalam Sistem Logistik Rantai Pasok 2015 PDFDokumen18 halamanTransportasi Distribusi Dalam Sistem Logistik Rantai Pasok 2015 PDFPiedro Phieta ApriliyantoBelum ada peringkat

- 4.01 Petrochemical and Offshore - ASTM D 1500 ColorDokumen2 halaman4.01 Petrochemical and Offshore - ASTM D 1500 Colorsetiawanaji407Belum ada peringkat

- Refined Fuel Truck WMLT2120ENPRDokumen14 halamanRefined Fuel Truck WMLT2120ENPRsetiawanaji407Belum ada peringkat

- JSP 886 Defence Logistics Support Chain Manual: WWW - Defencegateway.mod - UkDokumen27 halamanJSP 886 Defence Logistics Support Chain Manual: WWW - Defencegateway.mod - Uksetiawanaji407Belum ada peringkat

- CPT 0018 Commissioning Procedure of Fuel Oil System PDFDokumen5 halamanCPT 0018 Commissioning Procedure of Fuel Oil System PDFsetiawanaji407Belum ada peringkat

- Armanni Lift Truck CatalogDokumen44 halamanArmanni Lift Truck CatalogRenzo De PisisBelum ada peringkat

- Examples of Mechatronic Systems Dr. Lutfi Al-Sharif (2012)Dokumen2 halamanExamples of Mechatronic Systems Dr. Lutfi Al-Sharif (2012)Saravanan MathiBelum ada peringkat

- Compact Power Pack Program: The Drive & Control CompanyDokumen16 halamanCompact Power Pack Program: The Drive & Control CompanyAnonymous N0VcjC1ZoBelum ada peringkat

- Warning: PETOL™ Suckerod Elevator For FRP Sucker Rods REAS025H-F Data BookDokumen16 halamanWarning: PETOL™ Suckerod Elevator For FRP Sucker Rods REAS025H-F Data BookIkki Ventrue-Belum ada peringkat

- Scissor - Platform - Hidral - Tech SpecificationsDokumen10 halamanScissor - Platform - Hidral - Tech SpecificationsSajidBelum ada peringkat

- Otis Elevator WorldDokumen8 halamanOtis Elevator WorldFERNS100% (1)

- Dependable Reliable: Rental SolutionsDokumen8 halamanDependable Reliable: Rental SolutionsSudhir Power LimitedBelum ada peringkat

- Everything You Need to Know About Tricable Gondola LiftsDokumen16 halamanEverything You Need to Know About Tricable Gondola Liftspanji hastawirataBelum ada peringkat

- Service Manual 200/250 Ton Elevator/SpiderDokumen46 halamanService Manual 200/250 Ton Elevator/SpiderImed HammoudaBelum ada peringkat

- Deep Drilling UnitDokumen8 halamanDeep Drilling Unitbinoyraj2010Belum ada peringkat

- TNR Lifts-G+5, MR, 6P, MS-Swing Small Vision Glass Doors - SamiuddinDokumen7 halamanTNR Lifts-G+5, MR, 6P, MS-Swing Small Vision Glass Doors - SamiuddintnrgenuineBelum ada peringkat

- 1250mm Aluminum and Steel Coil Coating LineDokumen33 halaman1250mm Aluminum and Steel Coil Coating LineValmik SoniBelum ada peringkat

- CollateralDokumen126 halamanCollateralBOFTA IndiaBelum ada peringkat

- Effective Fall Prevention Measures For Working at HeightDokumen59 halamanEffective Fall Prevention Measures For Working at HeightakubestlahBelum ada peringkat

- 2014 Chapter 33 - Safeguards During Construction or Demolition PDFDokumen52 halaman2014 Chapter 33 - Safeguards During Construction or Demolition PDFJohn Doe0% (1)

- Module Machines Sheet DigitalDokumen2 halamanModule Machines Sheet DigitalkrisBelum ada peringkat

- Gates and ValvesDokumen9 halamanGates and ValveshailishBelum ada peringkat

- 17 05 02 CCA SG Rev03Dokumen57 halaman17 05 02 CCA SG Rev03Александър ПухлевBelum ada peringkat

- Addison Residential HandbookDokumen153 halamanAddison Residential Handbooktahreem aliBelum ada peringkat

- Xinspect 3500ic Operating Instructions - Version 1.0 May 2010Dokumen84 halamanXinspect 3500ic Operating Instructions - Version 1.0 May 2010Vince TzortzisBelum ada peringkat