Training Report

Diunggah oleh

fabilHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Training Report

Diunggah oleh

fabilHak Cipta:

Format Tersedia

Industrial Training Report 2014

INTRODUCTION

We have been assigned the construction site of a commercial building

owned by Mr Abid Ali for study by the company.The site is located near the

Mankav Bridge, off the Mini Bypass road in Kozhikode.

The building has been designed by NAZAR ASSOCIATES, CALICUT

and the structural consultants are STREAMLINE CONSORTIUM, Chalapuram,

Calicut.

SITE PLAN

CHAPTER 2

DETAILS OF STRUCTURE

The height of the structure is 13.75m.

The total area of the building is 2583 m2.

The structure consists of four floors.

The structures has a lift well and two staircases.

The basement floor is designed as parking space.

Dept. Of Civil Engineering 1 GEC

Kozhikode

Industrial Training Report 2014

CHAPTER 3

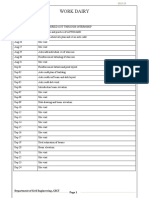

REPORT OF INDUSTRIAL TRAINIG DAY 1 13/12/2013

We reached the site by 10 am. We collected all the drawings (structural

and architectural) from the supervisor. Then we studied the plan with the

existing site conditions.

1. PILE AND PILE CAP

We compared the location and orientation of the pile caps in the

basement floor with the key plan. There were both 2 headed and 3 headed pile

caps. As there was a well in the site, the orientation of one of the pile cap was

made different from other caps. Architect Mr. Basil explained about the piling

process. Following were the observations, new information and findings.

Direct Mud Circulation (DMC) piles were used.

From the drawings we compared the size of the piles, detailing of

reinforcement etc.

Piling procedure.

Pile chipping.

2. STAIRCASE DETAILING

Detailing of reinforcement of one of the front staircases was studied. We

found the reinforcement main rings are of 10 mm diameter and distributor of 8

mm diameter. Then we observed the position of beams. One of the two beams of

each flight was under the first step and the second one at the end of the landing.

We observed a difference in the drawing and the provision I the site. As per

drawing the beam was to be provided just below the first step of the flight. But

in the site it was at a distance from the first step. The site supervisor Mr. Jithu

explained the detailing of that beam.

Dept. Of Civil Engineering 2 GEC

Kozhikode

Industrial Training Report 2014

3. CONCEALED BEAM

The structural plan introduced us a new type of beam called concealed

beam. It is the beam provided with the same thickness of the slab. In the

building it was provided for the sunshade. Sunshade was 160 cm wide and not

supported by cantilever beams. Therefore the concealed beam was provided to

support the sunshade as the normal detailing could not work effectively.

4. BAR BENDING SCHEDULE

The first task that was given to us was to prepare the bar bending

schedule of the entire building for the next week. As we were unaware about the

bar bending schedule the supervisors explained what it is. We understood it is

actually the estimation of the quantity of steel to be bought for providing the

reinforcement to the structural elements in the structures. It is calculated by

finding the total length of bar for each beam and slab from the detailing and

d2

then converting it into weight in kg by multiplying by a factor (x 7850 ).

4

We were provided with a sample bar bending schedule. We also estimated the

steel for a single beam.

We also enquired about the duties of a site engineer, the challenges that

would to be faced, the general details of the ongoing construction etc and left

the site by 4 pm. The day 1 of the training in short was really informative.

DAY 2 14/12/2013

The days training started at 10.30 am. The first task assigned was to

calculate the quantity of concrete for the columns of ground floor. We were

provided with the key plan. From the dimensions of different columns we

calculated the volume of columns and thereby the quantity of concrete

required.The volume obtained was 13.636 m3.

Then we were asked to calculate the quantity of concrete for the rear stair for

one floor. We found the width of thread and rise using a tape. Calculated the

volume of concrete for thread, rise and landing seperately.The 0.522m 3,

obtained values are thread = 0.54 m 3, rise =0.27m3,and landing 1-landing 2-

0.256m3.

One batch of students joined us. For them we explained the procedure for

preparing bar bending schedule.

Dept. Of Civil Engineering 3 GEC

Kozhikode

Industrial Training Report 2014

In the afternoon session we divided ourselves into different groups to prepare

the bar bending schedule for the beams of ground floor. We calculated the

quantity of steel till evening.

Dept. Of Civil Engineering 4 GEC

Kozhikode

Industrial Training Report 2014

A sample of the work done in bar bending schedule

DAY 3 - 17/12/2013

1. EARTHFILL CALCULATION

We started the day's work with the calculation of the quantity of earth fill

required for the basement floor. For this measured the length and width of the

area to be filled. Measured the dimensions of pile cap and subtracted that area

from the area calculated from the first measured dimensions. Levels at various

locations were found out and took their average to obtain the height. The height

multiplied by the area gives the quantity of earth to be filled in cubic meters.

Dept. Of Civil Engineering 5 GEC

Kozhikode

Industrial Training Report 2014

2. CONCRETE ESTIMATION

After the calculation of quantity of earthfill we calculated the quantity of

concrete required for beams of half of the span of the ground floor. For this we

calculated the volume of the beam from the dimensions of the area and

multiplied it by the density of concrete.

Sample calculation (Slab concrete)

1 . 6.1 3.25 0.12=2.379 m3

2 . 5.8 3.2 0.12=2.227 m 3

3. 5.7 3.3 0.12=2.257 m3

4. 3.9 3.7 0.12=1.731m 3

5. 3.75 2.85 0.12=1.282m 3

6. 5.75 3 0.12=2.07 m3

7. 5.75 3 0.12=2.07 m3

8 . 5.75 3 0.12=2.07 m 3

9 . 2.75 3.65 0.12=1.2045 m3

Dept. Of Civil Engineering 6 GEC

Kozhikode

Industrial Training Report 2014

10. 3.5 2.8 0.12=1.176 m3

11 . 5.7 2.7 0.12=1.932m 3

12. 2.8 5.75 0.12=1.932m 3

13. 2.8 5.75 0.12=1.932m 3

14. 2.75 3.45 0.12=1.138m 3

15. 5.7 3.2 0.12=2.188 m3

16. 2.5 5.7 0.12=1.71m 3

17. 5.65 2.55 0.12=1.728 m 3

18. 5.65 2.55 0.12=1.728 m 3

19 . 1.6038m 3

Total=34.2723 m3

Concrete for beam

A0.3 0.6 13.8=2.484 m3

Z 83.9 0.2 0.4=0.312 m3

C0.3 0.6 11.85=2.1330.3 0.2

Z 73.65 0.2 0.4=0.292

D0.3 0.6 11.8=2.124 3.5 0.3 0.2

DAY 4 18/12/2013

Today we visited the construction site at Pattambi. It is a five story building for

a shopping complex. Presently the reinforcement work for the basement roof

slab is going on. Hence we were able to see the provision of reinforcement for

columns, beams, staircase etc. We cleared our doubts from the site supervisor.

The capsule lift was a new knowledge for us from the site. We watched the

Dept. Of Civil Engineering 7 GEC

Kozhikode

Industrial Training Report 2014

laying of reinforcement for slabs from the site. We compared all the detailing

with drawings. Also checked the detailing of the reinforcement of the retaining

wall.

DAY - 5 19/12/2013

For the first time we were able to see the reinforcement of the mezzanine roof of

the Mankav site. The site engineer Mr.C.Umesh was doing the reinforcement

check. We joined him. We collected the detailing and measured the provided

reinforcement and checked with the drawings. Cleared our doubts with the

engineer and supervisors.

Dept. Of Civil Engineering 8 GEC

Kozhikode

Industrial Training Report 2014

CONCLUSION

It was a wonderful learning experience at the various worksites of

streamline consortium for 5 days. We gained a lot of insight regarding every

aspect of sites. The friendly welcome from the employees is appreciating,

sharing their experience and their peace of wisdom, which they have gained in

long journey of work. We hope this experience will surely help us in our future

and also in shaping our career.

Dept. Of Civil Engineering 9 GEC

Kozhikode

Industrial Training Report 2014

SITE VISIT

DEVADHAR RAILWAY OVER BRIDGE, TANUR

Dept. Of Civil Engineering 10 GEC

Kozhikode

Industrial Training Report 2014

INTRODUCTION

Cherian Varkey construction company is an IS / ISO 9001:2008

certified company established in 1975, engaged in the field of construction of

Bridges, Roads, Residential Commercial and Industrial buildings and

infrastrucutral works. Ever since it's inception the company has been able to

address the issue of quality in the works it has undertaken with consistency till

date. This has been possible mainly due to the efficient and able Board of

Directors and key Personals involved.

They have over the years shown their capability in construction of

bridges on pile foundations/well foundations and open foundations. The bridges

included both roads & railway bridges and for most of these bridges the

superstructure comprised of prestressed concrete box girders and of spans

ranging more than 15 metres. Besides bridges, they have also carried out

general civil engineering works including industrial buildings such as

workshop, dry dock complexes, Shopping Malls.

They have all the required infrastructure and man power to carry out

civil work on any scale. For the past 3 decades they have been executing various

types of prestigious projects for private as well as government sector. To

execute these projects in schedule, they utilize our vast infra structural resources

that is at hand. They have a highly efficient team at all levels to operate,

maintain, repair and overhaul these resources.

Roads and Bridges Development corporation (RBDC) has got the

construction empowerment of DROB. After detailed examination of tenders by

Kitko, the consulting agency of RBDC, CheriyanVarkey Construction Company

(CVCC) Pvt Ltd has got the responsibility of construction.

Dept. Of Civil Engineering 11 GEC

Kozhikode

Industrial Training Report 2014

SITE DESCRIPTION

The site is near Devadhar Government Higher Secondary school, Tanur. The

structure consists of 21 spans of each having 20m with a total length of 689 m.

There are 20 piers and 2 abutments out of which the construction of four piers

and three spans are undertaken by railway. 11 piers constructed by CVCC, 2

railway piers and an abutment are at Calicut side. On the tirur side there are 5

piers constructed by CVCC, 2 railway piers and an abutment. There are

retaining walls beyond the abutments towards the approach road. Retaining wall

in Calicut side rests on paddy field and there is a culvert also, while the

retaining wall in tirur side rests on good soil. Red sand is filled against the

retaining wall and compacted well. Against the retaining wall and compacted

well.

Dept. Of Civil Engineering 12 GEC

Kozhikode

Industrial Training Report 2014

The railway piers are circular in cross section and there is a group of 3 piers

resting on each pile cap. The reinforcement of railway section was epoxy

coated to prevent corrosion. All the 16 piers constructed by CVCC are of

rectangular cross section and are rests on pile foundation. The foundation

consists of pile group of 4 circular piles. Over that square pile cap is constructed

above which a single rectangular pier rests. Pier cap is constructed above the

rectangular piers. Above the pier cap, 3 pedestals are provided above which the

prestressed I girders rests. There is a neoprene bearing in between the pedestal

and the girder. The girder rests on the pedestal by its own weight through

bearing. Neoprene bearing is a steel bar reinforced rubber pad which provides a

perfect joint between the pedestal and the girder and also acts as a shock

absorber. There is a transverse girder at the centre of the span. The girders are

prestressed concrete I girders.

Prestessed concrete is basically concrete in which internal stresses of a suitable

magnitude and distribution are introduced so that the stresses resulting from

external loads are counteracted to a desired degree. Prestressing is a method for

overcoming concrete's natural weakness in tension. It can be used to produce

Dept. Of Civil Engineering 13 GEC

Kozhikode

Industrial Training Report 2014

beams, floors or bridges with a longer span than is practical with ordinary

reinforced concrete. Prestressing tendons (generally of high tensilesteelcable or

rods) are used to provide a clamping load which produces a compressive stress

that balances the tensile stress that the concrete compression member would

otherwise experience due to a bending load. The prestressing of concrete has

several advantages as compared to traditional reinforced concrete (RC) without

prestressing. A fully prestressed concrete member is usually subjected to

compression during service life. This rectifies several deficiencies of concrete.

Prestessed concrete is hence generally used for the construction of bridges. It

also allows high span to depth ratios for bridges. The depth of a prestressed

concrete (PSC) beam will be very less compared to the depth of an ordinary

reinforced concrete beam of the same span. Hence the self weight of the beam

will be less and it provides a more aesthetic appeal due to slender sections.

Overall, the presressed concrete will provide economic sections.

Based on the sequence of casting the concrete and applying tension to the

tendons, the prestressing may be either pretensioning or post tensioning. Pre-

tensioning is a method of prestressing concrete in which the tendons are

tensioned before concreting. Post-tensioning is a method of prestressing

concrete in which prestessing steel is tensioned against the hardened concrete.

Dept. Of Civil Engineering 14 GEC

Kozhikode

Industrial Training Report 2014

Here the girders constructed by CVCC are cast in situ post tensioned girders and

the girders constructed by railway are precast post tensioned girders. The use of

precast girders will results into rapid construction, better quality control and

reduced maintenance of the structure.

WORK PROGRESS AT SITE

The construction of all 16 piers and 2 abutments of CVCC and 2 railway piers

has been completed. All spans of CVCC except 2 spans were casted. The

stressing of all spans except 4 spans was completed. There is a gap left between

each span to allow the expansion due to temperature changes.

Dept. Of Civil Engineering 15 GEC

Kozhikode

Industrial Training Report 2014

The post tensioning of the span-P2-P3 was observed. The profiling of the span-

P10-P11 was completed and formworks are placed at suitable cover distance.

The parabolic profiling of the tendons was achieved by providing Galvanized

Iron (GI) sheathing pipe whose ends were fixed at both ends of the girder at

each duct. There are 6 ducts out of which the topmost one is dummy. A set of

tendons are fished through the duct and the concrete is poured. The side shutters

were removed after 24 hours. Once the concrete has hardened, the stressing can

be done. A circular bearing plate of some specification is fixed at the end of the

girder. The bearing plate consists of 7 holes through which the tendons were

taken out. The holes in the bearing plate are tapered towards the inside portion

of the bearing plate so as to provide the provision for holding the tapered wedge

with tendon in position. After fixing the wedges in position, tendons are

tensioned by hydraulic jack that react against the concrete member itself. The

pressure was applied as per the design specification and the corresponding

elongation of the tendon was measured. When the tendons have stretched

sufficiently according to the design specifications, the tendons were wedged in

position and maintain tension after the jack is removed. This tension in the

tendons will be transferred to the concrete as compression. The extended ends

Dept. Of Civil Engineering 16 GEC

Kozhikode

Industrial Training Report 2014

of the tendon were then cut and removed.The duct is then grouted to protect the

tendons from corrosion.

Dept. Of Civil Engineering 17 GEC

Kozhikode

Industrial Training Report 2014

Dept. Of Civil Engineering 18 GEC

Kozhikode

Anda mungkin juga menyukai

- Steel Structures Design Based on Eurocode 3Dari EverandSteel Structures Design Based on Eurocode 3Penilaian: 3 dari 5 bintang3/5 (1)

- IMPT - Report FormatDokumen19 halamanIMPT - Report FormatKarthepan visionsBelum ada peringkat

- IV Report 2014 Kochi by GeotechDokumen13 halamanIV Report 2014 Kochi by GeotechMahandra PrakashBelum ada peringkat

- Submitted By: "Singapore Life City" Flat Scheme ProjectDokumen10 halamanSubmitted By: "Singapore Life City" Flat Scheme Projectayushi tiwariBelum ada peringkat

- Final IntershipDokumen18 halamanFinal IntershipRiya SantoshwarBelum ada peringkat

- TrainingDokumen21 halamanTrainingumang panchalBelum ada peringkat

- Civil Tranning ReportDokumen35 halamanCivil Tranning ReportalsahariBelum ada peringkat

- An Mol Final ReportDokumen35 halamanAn Mol Final ReportShweta JaiswalBelum ada peringkat

- Internship 105Dokumen68 halamanInternship 105praveenputluruBelum ada peringkat

- Project Report On Bridge ConstructionDokumen19 halamanProject Report On Bridge ConstructionVibha kakkar100% (3)

- Final Project ReportDokumen65 halamanFinal Project ReportVikas Dalal75% (4)

- Abdul Basith P (16103112) Org.Dokumen24 halamanAbdul Basith P (16103112) Org.Samil MusthafaBelum ada peringkat

- Divyansh Totla Mid Term 189102062Dokumen15 halamanDivyansh Totla Mid Term 189102062Divyansh TotlaBelum ada peringkat

- ReportDokumen15 halamanReportA 33 TECE Shivam NikamBelum ada peringkat

- Time Estimation of A BuildingDokumen35 halamanTime Estimation of A BuildingAvalanche SainiBelum ada peringkat

- 4VP17CV027 Internship Presentation-1Dokumen22 halaman4VP17CV027 Internship Presentation-1Manu P SBelum ada peringkat

- In PlantTraining Final Report3Dokumen54 halamanIn PlantTraining Final Report3Krishna KanhaiyaBelum ada peringkat

- Supervised Industrial Training Report Mes (Military Engineering Services)Dokumen78 halamanSupervised Industrial Training Report Mes (Military Engineering Services)Adeel Aslam RajpootBelum ada peringkat

- Cven 9809-Reinforced Concrete Design Assignment-2: Strut & Tie ModelDokumen18 halamanCven 9809-Reinforced Concrete Design Assignment-2: Strut & Tie ModelSibani MishraBelum ada peringkat

- Priyadarshini Indira Gandhi Colleege of Engineering, Digdoh, NagpurDokumen45 halamanPriyadarshini Indira Gandhi Colleege of Engineering, Digdoh, NagpurSumit Natu100% (1)

- 19 30GB056Dokumen14 halaman19 30GB056Mashood Olamilekan MuhammedBelum ada peringkat

- Module-1 ECE403-CECS IntroductionDokumen21 halamanModule-1 ECE403-CECS Introduction121810201004 KURELLA SIDHARTHBelum ada peringkat

- Anil 2Dokumen29 halamanAnil 2balaji xeroxBelum ada peringkat

- Time Estimation of A BuildingDokumen48 halamanTime Estimation of A BuildingAvalanche SainiBelum ada peringkat

- Site Visit ReportDokumen17 halamanSite Visit ReportAlphaBelum ada peringkat

- Summer Internship ReportDokumen39 halamanSummer Internship ReportmustafaBelum ada peringkat

- Site Visit ReportDokumen15 halamanSite Visit ReportKaushal PatelBelum ada peringkat

- Work DairyDokumen19 halamanWork DairyYo YoBelum ada peringkat

- Abhishek InternshipDokumen29 halamanAbhishek InternshipshriBelum ada peringkat

- DSR MicroprojectDokumen22 halamanDSR Microproject725 Radhika RajdharBelum ada peringkat

- J Component Report: Dr. Senthil KumarDokumen18 halamanJ Component Report: Dr. Senthil KumarshashwatBelum ada peringkat

- Department of Civil Engineering, Narowal University of Engineering & Technology, LahoreDokumen9 halamanDepartment of Civil Engineering, Narowal University of Engineering & Technology, LahoreAbid HussainBelum ada peringkat

- IPT Theni REPORT 17.6-18.7Dokumen17 halamanIPT Theni REPORT 17.6-18.7mohammadmazid996Belum ada peringkat

- Site VisitDokumen17 halamanSite VisitShantanuShahBelum ada peringkat

- ArvindDokumen22 halamanArvindPRABHUDEV G EBelum ada peringkat

- Internship On Delhi-Mumbai Expressway ConstructionDokumen25 halamanInternship On Delhi-Mumbai Expressway ConstructionMark JetBelum ada peringkat

- Final Training ReportDokumen19 halamanFinal Training ReportAkshay JadhavBelum ada peringkat

- Internship ReportDokumen30 halamanInternship ReportAbhishek SengarBelum ada peringkat

- Total IptDokumen36 halamanTotal Iptamritha amritha100% (1)

- 1by17cv020 - Internship PresentationDokumen30 halaman1by17cv020 - Internship PresentationMani K CBelum ada peringkat

- Internship Report On 120 Mens Hostel ConstructionDokumen47 halamanInternship Report On 120 Mens Hostel ConstructionApollyon A100% (3)

- Internship ReportDokumen32 halamanInternship ReportSiddh Nayak100% (2)

- Practicum: (On-the-Job Training)Dokumen41 halamanPracticum: (On-the-Job Training)Francis Philippe Cruzana CariñoBelum ada peringkat

- Ok Report On Botnical Garden ReportDokumen24 halamanOk Report On Botnical Garden ReportDãmìñì Gãjpùrē100% (1)

- Presentation 8th SemDokumen60 halamanPresentation 8th SemZayan Khan100% (1)

- SP - Constructions: Industrial Training Report ON Analysis and Design of G+3 Building Using Staad ProDokumen55 halamanSP - Constructions: Industrial Training Report ON Analysis and Design of G+3 Building Using Staad ProSagarKasarla100% (1)

- CPWD REPORT - RemovedDokumen15 halamanCPWD REPORT - RemovedMANISH KHARWARBelum ada peringkat

- A Project ProposalDokumen6 halamanA Project ProposalKham Wee PabayosBelum ada peringkat

- Mid Report of My Major ProjectDokumen52 halamanMid Report of My Major ProjectIshfaq AbassBelum ada peringkat

- Chapter - 1: Industrial Training ReportDokumen27 halamanChapter - 1: Industrial Training Reportreloaded63Belum ada peringkat

- Black and WhiteDokumen16 halamanBlack and WhiteRaju PurohitBelum ada peringkat

- Stage Wise Construction DetailsDokumen20 halamanStage Wise Construction Detailskrishna kumar100% (1)

- G+4 Building Internship ReportDokumen41 halamanG+4 Building Internship ReportSOMSUBHRA SINGHA82% (11)

- Construction of Residential Building: A Practical Traning Report ONDokumen34 halamanConstruction of Residential Building: A Practical Traning Report ONlokesh nagarBelum ada peringkat

- Civil EngineeringDokumen19 halamanCivil EngineeringKimuchu NjugunaBelum ada peringkat

- 14cl113 Sadbhav ReportDokumen21 halaman14cl113 Sadbhav ReportYash VajaBelum ada peringkat

- 4-Week Internship ReportDokumen24 halaman4-Week Internship Reporttapankusethi1996Belum ada peringkat

- DCM Construction MethodDokumen12 halamanDCM Construction MethodHaryadi WirawanBelum ada peringkat

- Seminar On Internship SumanthDokumen39 halamanSeminar On Internship Sumanthsumanthkrishnas25Belum ada peringkat

- Planning It ParkDokumen79 halamanPlanning It ParkMdshZubair100% (1)

- Untitled SpreadsheetDokumen1 halamanUntitled SpreadsheetfabilBelum ada peringkat

- Booking Successful: Onward JourneyDokumen1 halamanBooking Successful: Onward JourneyfabilBelum ada peringkat

- Bore Loge Mankave 1Dokumen1 halamanBore Loge Mankave 1fabilBelum ada peringkat

- Factors Behind The Selection of Construction EquipmentsDokumen6 halamanFactors Behind The Selection of Construction EquipmentsfabilBelum ada peringkat

- Marine and Offshore Construction EquipmentDokumen42 halamanMarine and Offshore Construction Equipmentfabil100% (1)

- Carbon FootprintDokumen12 halamanCarbon FootprintfabilBelum ada peringkat

- Roce EvaDokumen20 halamanRoce EvafabilBelum ada peringkat

- ACI and PTI Requirements For Encapsulated Systems, PTI Journal, July 2007Dokumen6 halamanACI and PTI Requirements For Encapsulated Systems, PTI Journal, July 2007neve08Belum ada peringkat

- Fundamental of Bridge InspectionDokumen31 halamanFundamental of Bridge InspectionSeptinurriandianiBelum ada peringkat

- Design For Prestressed BeamDokumen12 halamanDesign For Prestressed BeamHaymanAHMEDBelum ada peringkat

- Design of UHPC Structural Members: Lessons Learned and ASTM Test RequirementsDokumen21 halamanDesign of UHPC Structural Members: Lessons Learned and ASTM Test RequirementsFabianBelum ada peringkat

- Post Tensioning in Building StructuresDokumen84 halamanPost Tensioning in Building StructuresSree NivasBelum ada peringkat

- Economic Long Span Concrete Floors, Bca, Uk, 1995. 50p.Dokumen50 halamanEconomic Long Span Concrete Floors, Bca, Uk, 1995. 50p.MANUEL ARTURO FIGUEROA LEONBelum ada peringkat

- EN 1995-2 Timber Structures Bridges Eurocodes Background & Applications 18 - 20 of February 2008, BrusselsDokumen79 halamanEN 1995-2 Timber Structures Bridges Eurocodes Background & Applications 18 - 20 of February 2008, BrusselsJames AugustinoBelum ada peringkat

- Performance Study On Prestressed Concrete Girder Bridge: KeywordsDokumen5 halamanPerformance Study On Prestressed Concrete Girder Bridge: KeywordsVikramBelum ada peringkat

- Experience & Achievement:: Prof. Rajesh BhagatDokumen52 halamanExperience & Achievement:: Prof. Rajesh BhagatGelana KeneaBelum ada peringkat

- Hollow CoreDokumen6 halamanHollow CorershyamsBelum ada peringkat

- Rapt 11Dokumen16 halamanRapt 11tailieuxaydung2019Belum ada peringkat

- Iwozizcfyr Oaqøhv Ikbi (Fo'Ks"K LGK Dkax LFGR) Fof'Kf"V: HKKJRH EkudDokumen38 halamanIwozizcfyr Oaqøhv Ikbi (Fo'Ks"K LGK Dkax LFGR) Fof'Kf"V: HKKJRH EkudPratik KharmateBelum ada peringkat

- Bd-Ps1E: Pcefv-V39 Pcefv-V47 Pcefv-V55 Pcefv-V63 Pcefv-V71 Pcefv-V79Dokumen14 halamanBd-Ps1E: Pcefv-V39 Pcefv-V47 Pcefv-V55 Pcefv-V63 Pcefv-V71 Pcefv-V79Marlon MartinezBelum ada peringkat

- Shear Tests On Continuous Prestressed Concrete Beams With External PrestressingDokumen10 halamanShear Tests On Continuous Prestressed Concrete Beams With External PrestressingJan GnatBelum ada peringkat

- Conbox TutorialsDokumen292 halamanConbox TutorialsRam Nepali50% (2)

- 2.6 Losses: Eas458 Prestressed Concrete Design 2017/2018Dokumen11 halaman2.6 Losses: Eas458 Prestressed Concrete Design 2017/2018Chee Fong MakeBelum ada peringkat

- Prestressed ConcreteDokumen154 halamanPrestressed ConcretejohnnBelum ada peringkat

- BDM 2021Dokumen547 halamanBDM 2021Messy CoolBelum ada peringkat

- FRP Reinforced Spun Concrete Poles Flexure Jan 15 3Dokumen11 halamanFRP Reinforced Spun Concrete Poles Flexure Jan 15 3luchyl100% (1)

- SECTION 03 45 00 Precast Architectural ConcreteDokumen30 halamanSECTION 03 45 00 Precast Architectural ConcreteJuanPaoloYbañezBelum ada peringkat

- Fritz Leonhardt 1 2007Dokumen3 halamanFritz Leonhardt 1 2007David AndrésBelum ada peringkat

- University of Jordan Department of Civil Engineering: " Prestressed Concrete Design "Dokumen41 halamanUniversity of Jordan Department of Civil Engineering: " Prestressed Concrete Design "Waseem Al OmariBelum ada peringkat

- SAES-Q-012: PCI-MNL-120 PCI-MNL-122 Minimum 35 Mpa (5,000 Psi) Minimum 35 Mpa (5,000 Psi)Dokumen5 halamanSAES-Q-012: PCI-MNL-120 PCI-MNL-122 Minimum 35 Mpa (5,000 Psi) Minimum 35 Mpa (5,000 Psi)Nino Celso Astillero100% (2)

- Rock Anchor DesignDokumen2 halamanRock Anchor Designraj.karanBelum ada peringkat

- M23-50 15complete PDFDokumen1.306 halamanM23-50 15complete PDFIbnuyusoff77Belum ada peringkat

- Analysis and Design of Railway Over Bridge at Kumaranellur-1231 PDFDokumen4 halamanAnalysis and Design of Railway Over Bridge at Kumaranellur-1231 PDFRojan MathewBelum ada peringkat

- Cap 3. Columnas A Flexo Compresión BiaxialDokumen9 halamanCap 3. Columnas A Flexo Compresión BiaxialManuel Mendoza JaraBelum ada peringkat

- Handbook Foundation Form Work Rebar ConcreteDokumen216 halamanHandbook Foundation Form Work Rebar ConcretebittuchintuBelum ada peringkat

- Post - Tensioned Concrete SlabsDokumen18 halamanPost - Tensioned Concrete SlabsAakash MohanBelum ada peringkat

- Issued For Construction: ZAIT Engineering Solutions Pty LTDDokumen1 halamanIssued For Construction: ZAIT Engineering Solutions Pty LTDAhmedBoutlyBelum ada peringkat