Equations of Fluid Flow (Page 2 of 4

Diunggah oleh

Engr Ghulam MustafaHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Equations of Fluid Flow (Page 2 of 4

Diunggah oleh

Engr Ghulam MustafaHak Cipta:

Format Tersedia

How to calculate head loss hL: page 2/4

L V2 Q

1) for flow in pipes: hL = f V = A d2

d 2g A 4

L = pipe length; d = pipe diameter; f = Darcy friction factor

64 V d

(a) for laminar flow (all pipes): f = R

R

(b) for turbulent flow,

( f ) is obtained from Moody chart, which is a logarithmic plot with

Reynolds Number, (R) along the x-axis and ( f ) along the the y-

axis. Value of ( f ) depends on the e/d-ratio, where e is the pipe

material roughness.

pipe material e (ft) e (mm)

riveted steel 0..003 0.03 0.9 9.0

concrete 0.001 0.01 0.3 3.0

cast iron 0.00085 0.25

galvanized iron 0.0005 0.15

commercial steel 0.00015 0.046

wrought iron 0.00015 0.046

drawn tubing 0.000005 0.0015

------------------------------------------------------------------------------------

for turbulent flow in smooth pipes, f = 0.316 / R1/4 (valid for R < 105)

n2L 1 Q

2) for flow in channels: hL = 2 4/3

V2 = So L V =

k Rh A

hL

L = channel length; So = channel bed slope =

L

n = Mannings coefficient

k = unit system constant [ k = 1.49 ( for U.S.); k = 1.0 ( for SI )]

Rh = A / P

where A is the flow area; P is the wetted perimeter of the flow area

Channel wall surface Mannings n

glass 0.011

cement / concrete 0.012

riveted steel 0.015

cast iron 0.013

asphalt 0.016

planed wood 0.012

brickwork 0.015

corrugated metal 0.022

rubble masonry 0.025

---------------------------------------------------------------------------------------------

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Proth Psgs Manual PDFDokumen106 halamanProth Psgs Manual PDFBala SingamBelum ada peringkat

- BOQ Fountain Water Body (1) .XLSXBDokumen6 halamanBOQ Fountain Water Body (1) .XLSXBPrashant Singh Chauhan60% (5)

- Excel Workbook No. 05 Atterberg LimitsDokumen4 halamanExcel Workbook No. 05 Atterberg LimitsEngr Ghulam MustafaBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Gas Cylider Technical Regulation PDFDokumen37 halamanGas Cylider Technical Regulation PDFVinod Varadan SBelum ada peringkat

- Sentence FormationDokumen5 halamanSentence FormationEngr Ghulam MustafaBelum ada peringkat

- A. B. C. D.: P Is The Force Acting On A Body Whose Mass Is M and Acceleration Is F. The Equation P - MFDokumen3 halamanA. B. C. D.: P Is The Force Acting On A Body Whose Mass Is M and Acceleration Is F. The Equation P - MFEngr Ghulam MustafaBelum ada peringkat

- Assistant Engineer 136 G 2018Dokumen3 halamanAssistant Engineer 136 G 2018Engr Ghulam MustafaBelum ada peringkat

- Input DataDokumen2 halamanInput DataEngr Ghulam MustafaBelum ada peringkat

- Rub-Nawaz S/o Pathana: Supervisor (Civil)Dokumen2 halamanRub-Nawaz S/o Pathana: Supervisor (Civil)Engr Ghulam MustafaBelum ada peringkat

- Payment CertificateDokumen1 halamanPayment CertificateEngr Ghulam MustafaBelum ada peringkat

- Syllabus Summer I I 2017Dokumen5 halamanSyllabus Summer I I 2017Engr Ghulam MustafaBelum ada peringkat

- Input Data: Material PropertiesDokumen2 halamanInput Data: Material PropertiesEngr Ghulam MustafaBelum ada peringkat

- Input DataDokumen2 halamanInput DataEngr Ghulam MustafaBelum ada peringkat

- Homework 1Dokumen2 halamanHomework 1Engr Ghulam Mustafa100% (1)

- 4 2017 02 20!11 27 46 PMDokumen36 halaman4 2017 02 20!11 27 46 PMEngr Ghulam MustafaBelum ada peringkat

- RailwaysDokumen14 halamanRailwaysEngr Ghulam MustafaBelum ada peringkat

- Fruendlich Isotherm Carbon "A": MG MG MG MG M XDokumen9 halamanFruendlich Isotherm Carbon "A": MG MG MG MG M XEngr Ghulam MustafaBelum ada peringkat

- Instructions: Referencing at Least Two Chapters of The Main Text in This Class in Your Response To Each QuestionDokumen1 halamanInstructions: Referencing at Least Two Chapters of The Main Text in This Class in Your Response To Each QuestionEngr Ghulam MustafaBelum ada peringkat

- Most Repeated Mcqs in PPSC Past PapersDokumen4 halamanMost Repeated Mcqs in PPSC Past PapersEngr Ghulam Mustafa0% (1)

- Change Parking 594 X 420Dokumen1 halamanChange Parking 594 X 420Engr Ghulam MustafaBelum ada peringkat

- Final Layout ISO A2 594 X 420Dokumen1 halamanFinal Layout ISO A2 594 X 420Engr Ghulam MustafaBelum ada peringkat

- Omnova Coatings PresentationDokumen12 halamanOmnova Coatings PresentationNatalia Rodriguez100% (1)

- Solid State - Study Material - Yak9Dokumen33 halamanSolid State - Study Material - Yak9Amrit Kumar BiswasBelum ada peringkat

- Types of Dosage Forms Lecture2,2Dokumen34 halamanTypes of Dosage Forms Lecture2,2Bhuvana TejaBelum ada peringkat

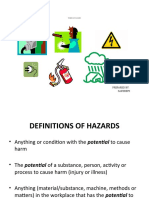

- Workplace HazardsDokumen26 halamanWorkplace HazardsPageduesca RouelBelum ada peringkat

- Minimess Katalog PDFDokumen39 halamanMinimess Katalog PDFaneesh awasthiBelum ada peringkat

- WPS Format For ASME IX - WPS - SAWDokumen1 halamanWPS Format For ASME IX - WPS - SAWThe Welding Inspections CommunityBelum ada peringkat

- Design of Unistrut Farming SystemDokumen256 halamanDesign of Unistrut Farming Systemjudaspriest21100% (1)

- Kinetics of The Iodination of Acetone PDFDokumen6 halamanKinetics of The Iodination of Acetone PDFsamBelum ada peringkat

- Tanks and Equipment: For Liquefied Petroleum Gases - Storage and ServiceDokumen48 halamanTanks and Equipment: For Liquefied Petroleum Gases - Storage and ServiceAlroukn MechanicalBelum ada peringkat

- Certify Sulfur and Monitor Critical Elements at Sub-Ppm LevelsDokumen6 halamanCertify Sulfur and Monitor Critical Elements at Sub-Ppm LevelsMiguelBelum ada peringkat

- Recruitment and Selection Bharathi CementsDokumen73 halamanRecruitment and Selection Bharathi Cementskum124267% (3)

- Growing and Feeding Lucerne: Key MessagesDokumen20 halamanGrowing and Feeding Lucerne: Key MessagesMike MurefuBelum ada peringkat

- Single Effect EvaporatorDokumen5 halamanSingle Effect Evaporatorprakashom01880% (5)

- Design of An AqueductDokumen7 halamanDesign of An Aqueduct4gen_5Belum ada peringkat

- Merck Index Front MatterDokumen14 halamanMerck Index Front MatterCristian Meneguzzi100% (1)

- Advantages of Deep Bed Filters - OriginalDokumen75 halamanAdvantages of Deep Bed Filters - OriginalYadav ShwetaBelum ada peringkat

- MITOCHONDRIADokumen3 halamanMITOCHONDRIAAbid RazaBelum ada peringkat

- Abn Abwa 8s eDokumen8 halamanAbn Abwa 8s efrancis eugenioBelum ada peringkat

- Egyptian Blue Cuprorivaite A Window To Ancient Egyptian TechnologyDokumen13 halamanEgyptian Blue Cuprorivaite A Window To Ancient Egyptian TechnologyDοмenıκ CaesarBelum ada peringkat

- Claus Process: Claus, The Claus Process Has Become The Industry StandardDokumen23 halamanClaus Process: Claus, The Claus Process Has Become The Industry StandardNhan Nguyen VanBelum ada peringkat

- Gas Processing Fundamentals Manual1Dokumen12 halamanGas Processing Fundamentals Manual1Ahmed Khamees ShatlaBelum ada peringkat

- Inventory Price Listing: Sky Pharmaceuticals (PVT) LTDDokumen9 halamanInventory Price Listing: Sky Pharmaceuticals (PVT) LTDOwen F MarimiraBelum ada peringkat

- Transformer Oil: Bangladesh Power Management Institute (BPMI) 2019Dokumen34 halamanTransformer Oil: Bangladesh Power Management Institute (BPMI) 2019Farhan AhmedBelum ada peringkat

- TI-Polymer-Shrinkage in PlasticsDokumen6 halamanTI-Polymer-Shrinkage in PlasticsRadu Sorin MarinescuBelum ada peringkat

- Module 3 Heat EffectsDokumen41 halamanModule 3 Heat EffectsJatskinesisBelum ada peringkat

- Objectives of Food PreservationDokumen4 halamanObjectives of Food Preservationavadhut.malji19Belum ada peringkat

- HTB17PaDGFXXXXcIXXXX PRXFXXXs PDFDokumen17 halamanHTB17PaDGFXXXXcIXXXX PRXFXXXs PDFDark DungeonBelum ada peringkat