Ganache Formulation PDF

Diunggah oleh

tavibastiJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Ganache Formulation PDF

Diunggah oleh

tavibastiHak Cipta:

Format Tersedia

The Crystallization of

Ganache

The temper of the chocolate and the temperature of the

cream are the key variables in making ganache for slabbed

confectionery use.

Peter P. Greweling, CMB

The Culinary Institute of America

The objective of this paper is to observe dard formulation for a confectionery

the textural and visual differences in ganache: two parts dark chocolate to one

ganache made by varying techniques in part liquefier, which includes 50 g of Grand

order to determine the effect of chocolate Marnier as a flavor. Glucose syrup has been

precrystallization on the finished ganache, added as a stabilizer for the emulsion, as

and arrive at the optimum method for mak- well as for preservation. The heavy cream

ing ganache for slabbed confectionery use. used was 40 percent butterfat; the chocolate

This informal investigation was performed was 64 percent total cacao, 38 percent total

by a chocolatier, confectioner and pastry fat (cocoa butter) (Figure 1). Peter Greweling is a

chef with over 25 years experience in the Each batch of ganache was made using professor in baking

field, and essential knowledge of confec- the identical formula, with the variables of and pastry arts at The

tionery technology. The work performed different forms of chocolate and different Culinary Institute of

and observations made were under profes- America (CIA). Chef

temperatures of cream. The specific vari-

Greweling teaches

sional kitchen conditions, not in a labora- ables were chosen because they represent chocolates and con-

tory. The results were evaluated in a quali- some of the more common variables in mak- fections to students

tative way, based on the senses and ing ganache, and because they help to illus- pursuing their bache-

experience of the author, and the conclu- lors and associate

trate the effects of the temper of the choco-

degrees from the CIA.

sions reached are intended for practical late and the temperature of the cream. He has earned the

application.The ultimate goal is to help con- After mixing, each ganache was imme- designation of Certi-

fectioners gain a clearer understanding of diately poured into a frame one-half inch fied Master Baker

how the method used to make ganache thick on a sheet of plastic, and allowed to and is the author of

affects the outcome of the product. Further Chocolates & Confec-

Standard Confectionery Ganache tios: Formula, Theory

investigation of the topic under laboratory

and Technique for the

conditions using instruments to obtain quan- Heavy Cream 250 g

Glucose Syrup 75 g Artisan Confectioner.

titative results would provide another per- Dark Chocolate, 64% Cacao 600 g

Grand Marnier 50 g

spective on the subject.

The experiment utilizes a relatively stan- Figure 1

The Manufacturing Confectioner March 2007 53

The Crystallization of Ganache

crystallize overnight (approximately 18 hours) at a room Mouthfeel Short textured and grainy. Although most

temperature of 20C. of the ganache melts readily in the mouth, very pal-

The next day, each ganache was evaluated for its sur- pable hard grains linger and melt much more slowly.

face appearance, its firmness and cutting quality, its

internal appearance and its mouthfeel. From these Variation C

observations, hypotheses are presented as to the causes See Figure 5

of the various qualities, and a conclusion is reached Surface Appearance A lot of fat is visible in streaks on

regarding the best method for making ganache for slab- top of the crystallized ganache. A few spots are also

visible, although they are not as noticeable as the

bing. Variation A is the control in the experiment, as it

spots on variation B.

is the method that is published by this author in Choco-

Firmness and Cutting Quality Firm, short texture that

lates & Confections: Formula, Theory and Technique for cracks when depressed to indent. Creates very notice-

the Artisan Confectioner. (John Wiley & Sons 2007). able ridges of ganache when cut. Slightly less prone to

The variations used in this investigation are listed in breakage after cutting than B, more so than A.

Figure 2. Internal Appearance Obvious and large grains in the

Upon mixing, each ganache was smooth, showing nei- interior of the ganache. Fewer grains than B, but

ther signs of a separated emulsion nor of any unmelted noticeably larger.

chocolate. The ganache was immediately poured into Mouthfeel Short textured and grainy. Although most

of the ganache melts readily in the mouth, very pal-

the frame without undue agitation, and was not tabled

pable large grains linger and melt much more slowly.

to temper it prior to depositing, as for a piped ganache.

OBSERVATIONS FROM THE CRYSTALLIZED Variation D

GANACHE X X X X X X X X X X X X X X X X See Figure 6

Surface Appearance No fat is visible on the surface of

Variation A, Control

the ganache. Many small spots appear prominently

See Figure 3

on the top.

Surface Appearance Smooth exterior, no signs of fat

Firmness and Cutting Quality Relatively soft texture

bloom, uniform color and appearance.

that gives way easily without cracking when depressed

Firmness and Cutting Quality Firm, yet malleable. Does to indent. The ganache does not cut cleanly, but

not crack when pressed to indent. Cuts cleanly, and is becomes distorted and forms slight ridges when cut.

cohesive enough to release from the plastic in one The cut ganache is not cohesive enough to release

piece when cut. easily from the plastic; it stretches and tears when

Internal Appearance The interior appears smooth and released.

homogeneous. No visible irregularities. Internal Appearance The interior has an abundance of

Mouthfeel Smooth and creamy. The ganache melts uni- smaller grains apparent in it.

formly in the mouth at a moderate pace, leaving no Mouthfeel Elastic texture, with a small amount of slower

graininess behind. melting grains left after the ganache melts in the

mouth.

Variation B The hypotheses from these results are all related to the

See Figure 4 crystallization of the fat in the ganache.There was no evi-

Surface Appearance Some fat is visible in streaks on dence of separation of the emulsion in any of the vari-

top of the crystallized ganache; spots also can be seen ables, therefore it is not a factor in the results. While

on the surface. the combination of butterfat and cocoa butter in ganache

Firmness and Cutting Quality Firm texture, slightly brit- is polymorphic due to the cocoa butter content, it is

tle. Cracks when depressed to indent. When cut, cre-

unlikely that different forms of fat crystals caused the

ates small ridges of ganache on each side of the cut.

Lacks cohesiveness. Breaks apart easily when pulled differences between the variations, because they all crys-

from the plastic on which it had crystallized. tallized under identical temperature conditions; they

Internal Appearance The interior texture exhibits visi- therefore crystallized with the same form of fat crystal.

ble graininess. The more probable explanation is the presence or lack

54 March 2007 The Manufacturing Confectioner

The Crystallization of Ganache

Standard Confectionery Ganache

Condition of Temperature of

Variation Chocolate Used Liquids Added Mixing Technique

A Melted, tempered 40C Boil cream and glucose syrup

Control chocolate @ 32C Remove from heat

Add Grand Marnier

Cool liquids to 40C

Mix liquids into melted tempered chocolate

B Melted, untempered 40C Boil cream and glucose syrup

chocolate @ 32C Remove from heat

Add Grand Marnier

Cool liquids to 40C

Mix liquids into melted untempered chocolate

C Tempered, unmelted Just off of boil Boil cream and glucose syrup

chopped chocolate Remove from heat

@ 20C Add Grand Marnier

Pour hot liquids over chopped tempered chocolate

Allow to sit 60 seconds

Stir until homogeneous

D Untempered, Just off of boil Boil cream and glucose syrup

unmelted chopped Remove from heat

chocolate @ 20C Add Grand Marnier

Pour hot liquids over chopped untempered chocolate

Allow to sit 60 seconds

Stir until homogeneous

Figure 2

Variation A (Control) Variation C

Figure 3 Figure 5

Variation B Variation D

Figure 4 Figure 6

The Manufacturing Confectioner March 2007 55

The Crystallization of Ganache

of seed crystals to initiate rapid and even crystalliza- ficient seed crystals, causing the growth of fewer and

tion of the ganache. larger fat crystals than desired, leading to the grainy

Variation A was precrystallized by the presence of mouthfeel and the spots on the surface, similar to Vari-

seed crystals in the melted tempered chocolate.Although ation B. This ganache will not cut cleanly with a guitar,

the liquids were at 40C, when heat loss of the system is leaving ridges on the corners, and will be prone to break-

taken into account, at no time did the mixture reach a age during handling. Ongoing crystallization of the fats

sufficient temperature for enough time to melt the seed will result in a deterioration of the mouthfeel during

crystals in the chocolate. As a result, this ganache crys- the shelf life of the centers.

tallized rapidly and uniformly throughout, just as prop- Variation D likewise contained insufficient fat crystals

erly precrystallized chocolate will set rapidly, and with to adequately seed the ganache. Because the chocolate

a smooth, uniform texture. Variation A solidified after that was used to make the ganache was untempered, it

only two hours, long before any of the other variations contained large and uneven fat crystals. The heat of the

showed any signs of hardening. This ganache will cut liquids melted most of these crystals, just as they did in

cleanly on a guitar, and will have positive handling attrib- variation C, resulting in an underseeded ganache with

utes, not crumbling or becoming distorted during han- all of the same flaws as variations B and C. This varia-

dling. Because this ganache is well tempered, it will be tion will be difficult to release from the plastic on which

stable throughout its shelf life, not losing quality under it has set, and will distort when cut on a guitar and dur-

proper storage conditions. ing handling. The graininess of variation D will also

Variation B contained no cocoa butter seed crystals, increase during the life of the centers as the fats continue

as the chocolate was not itself tempered. As a result, to crystallize.

the ganache was underseeded, and crystallized slowly,

without uniformity. The slow crystallization allowed CONCLUSION

some of the fat to migrate to the surface before the The conclusion of the investigation is that the preferred

ganache set, accounting for the fat streaks that are vis- method for making a ganache that is to be slabbed and

ible on the surface. Like untempered chocolate, due to cut without any tabling is to use Variation A to provide

the lack of seed crystals, fewer, larger fat crystals formed, the most consistent results of a smooth product that

causing the grainy texture of the ganache and the spots cuts cleanly and maintains its fine texture throughout the

on the surface. This variation will not cut cleanly with a shelf life of the ganache.

Begin with tempered melted chocolate at 30C for

guitar, leaving ridges on the corners, and will tend to

dark chocolate.

break during handling. Given time, these crystals will

Add liquifiers at 40C; stir to emulsify.

become more prominent, resulting in visible bloom and

Pour into frame, and allow to crystallize overnight at

a more uneven texture, just as they do in underseeded room temperature.

chocolate.As a result, the textural quality of the ganache Ganache is a surprisingly complex system involving a fat-

will continue to deteriorate during the expected shelf life in-water emulsion as well as the crystallization of a poly-

of the centers. morphic fat. It is affected by myriad factors such as dis-

Variation C is the most commonly used technique for solved solids content, cacao particles and pH, among

making ganache, utilizing tempered unmelted choco- others, all of which contribute to its complexity, yet it

late. Because this chocolate is tempered, it contains is ubiquitous throughout artisan confectionery. In spite

cocoa butter crystals that are not only in a stable form, of its importance in the confectionery world, there is a

but are small and well distributed. This variation, how- dearth of studies on how ganache functions as a sys-

ever, did not set evenly as tempered ganache should. tem. I invite and welcome the scientific community to

The heat from the liquifiers was too high and melted perform more complete quantitative investigations into

most or all of the seed crystals that the tempered choco- the intricacies of ganache that would greatly benefit the

late contained.As a result, this variation contained insuf- body of knowledge about this beloved center.

56 March 2007 The Manufacturing Confectioner

Anda mungkin juga menyukai

- chocolate book review ramon moratóDokumen9 halamanchocolate book review ramon moratóEmmanuel Torres0% (4)

- Four ONE: On The Boundaries of ChocolateDokumen12 halamanFour ONE: On The Boundaries of ChocolateJordi Caseros25% (4)

- Chocolate PresentationDokumen12 halamanChocolate PresentationMoaaz Ahmed100% (3)

- reading-comprehension-tHE HISTORY ABOUT CHOCOLATE WEEK 2Dokumen2 halamanreading-comprehension-tHE HISTORY ABOUT CHOCOLATE WEEK 2Janeth Callejas86% (14)

- Ganache FormulationDokumen4 halamanGanache FormulationmimigiudiBelum ada peringkat

- Absolu Cristal: Service ProductsDokumen2 halamanAbsolu Cristal: Service ProductsAttila NagyBelum ada peringkat

- Pastry Seminar & Workshop 2006 in The United States of AmericaDokumen35 halamanPastry Seminar & Workshop 2006 in The United States of AmericaHicham MerouaneBelum ada peringkat

- Master Viennoiserie Class with Johan MartinDokumen1 halamanMaster Viennoiserie Class with Johan MartinManuel FerraroBelum ada peringkat

- Baker, BachourDokumen178 halamanBaker, BachourHoward BrandonBelum ada peringkat

- Savage Gear 2019 PDFDokumen140 halamanSavage Gear 2019 PDFtavibastiBelum ada peringkat

- Savage Gear 2019 PDFDokumen140 halamanSavage Gear 2019 PDFtavibastiBelum ada peringkat

- Case Study of CadburyDokumen19 halamanCase Study of CadburyMusawwirBelum ada peringkat

- Pastries BulletinDokumen13 halamanPastries BulletinFrederico BarrosBelum ada peringkat

- Information Sheet: GanacheDokumen14 halamanInformation Sheet: GanacheIrish50% (2)

- Sweet Chocolate: Homemade Chocolate Praline and Cookies RecipesDari EverandSweet Chocolate: Homemade Chocolate Praline and Cookies RecipesBelum ada peringkat

- Most Recent Bake 256 Intro To Pastries Making Recipe Cards 2021Dokumen73 halamanMost Recent Bake 256 Intro To Pastries Making Recipe Cards 2021Jorja LoewenBelum ada peringkat

- Glazes and Spray Glazes RecipesDokumen16 halamanGlazes and Spray Glazes RecipesDayana AriasBelum ada peringkat

- Tuile Recipe - Pastry Chef & Author Eddy Van DammeDokumen8 halamanTuile Recipe - Pastry Chef & Author Eddy Van DammeaBelum ada peringkat

- 2021 06 01 Proteines Vegetals Muntants ENGDokumen20 halaman2021 06 01 Proteines Vegetals Muntants ENGDaniel NikolovBelum ada peringkat

- n4gb PDFDokumen4 halamann4gb PDFOlga Ge MABelum ada peringkat

- Al Wolff DrageeDokumen3 halamanAl Wolff Drageecklcat1437Belum ada peringkat

- Russian Honey CakeDokumen3 halamanRussian Honey CakeEimBelum ada peringkat

- CW EquipmentDokumen62 halamanCW EquipmentAlonso Ordinola100% (1)

- Caramelised Almond and Spice Dragée - Cacao BarryDokumen4 halamanCaramelised Almond and Spice Dragée - Cacao Barryeditte666Belum ada peringkat

- Eng Dark DropDokumen2 halamanEng Dark DropDorjana LaskuBelum ada peringkat

- Files (Ramon Morato)Dokumen502 halamanFiles (Ramon Morato)pizbol pizbola100% (1)

- Butter and dairy spreads guideDokumen41 halamanButter and dairy spreads guidehtc587uy100% (1)

- Ferrero Fantasia - Bruno AlbouzeDokumen1 halamanFerrero Fantasia - Bruno AlbouzeAhmedsabri SabriBelum ada peringkat

- Sosa-By Jordi PuigvertDokumen8 halamanSosa-By Jordi PuigvertOlivier Douliac100% (1)

- The Rubylicious TrilogyDokumen15 halamanThe Rubylicious TrilogyMahrez Taalbi100% (1)

- Ruby Encyclopedia - Volume II - en-USDokumen37 halamanRuby Encyclopedia - Volume II - en-USAlejandro MendozaBelum ada peringkat

- Callebaut Annual Report 2009Dokumen140 halamanCallebaut Annual Report 2009Cristian VasilescuBelum ada peringkat

- Callebaut NXT - Education Guide - LRDokumen29 halamanCallebaut NXT - Education Guide - LRPavel TanevBelum ada peringkat

- Exotic Perfume: Gelified Mango CoulisDokumen2 halamanExotic Perfume: Gelified Mango CoulisDairoMRivero100% (1)

- RecipesDokumen31 halamanRecipesAbdo AhmedBelum ada peringkat

- Saful HudaDokumen34 halamanSaful HudaInamulBelum ada peringkat

- N 23 Caprecette Londres A4 EN BD1Dokumen28 halamanN 23 Caprecette Londres A4 EN BD1Dương Tuấn PhụngBelum ada peringkat

- Decorative Dead Dough SyrupDokumen9 halamanDecorative Dead Dough SyrupTemet NoscheBelum ada peringkat

- All About ChocolateDokumen17 halamanAll About ChocolateinfernandoxBelum ada peringkat

- The Most Amazing Chocolate CakeDokumen2 halamanThe Most Amazing Chocolate CakeGustavo HernándezBelum ada peringkat

- 3 Glazing BulletinDokumen8 halaman3 Glazing BulletinFrederico BarrosBelum ada peringkat

- Introduction To Molecular Gastronomy: Molecule-R Flavors 5425 de Bordeaux #402, Montreal (Quebec) Canada H2H 2P9Dokumen7 halamanIntroduction To Molecular Gastronomy: Molecule-R Flavors 5425 de Bordeaux #402, Montreal (Quebec) Canada H2H 2P9poivioBelum ada peringkat

- Homemade Vegan Cakes, Brownies & Baking RecipesDokumen7 halamanHomemade Vegan Cakes, Brownies & Baking Recipesanhte0% (1)

- ANG Coupe ForestDokumen1 halamanANG Coupe ForestRicardo Rovira ChalerBelum ada peringkat

- Novelties2016 PDFDokumen36 halamanNovelties2016 PDFIsbravaBelum ada peringkat

- Vladimir Mukhin's Russian Recipes and DishesDokumen5 halamanVladimir Mukhin's Russian Recipes and DishesPaullo VitorBelum ada peringkat

- 2016 CW Pastry Catalog Web Test SizeDokumen49 halaman2016 CW Pastry Catalog Web Test SizeTrân HuỳnhBelum ada peringkat

- Catálogo de ProductosDokumen7 halamanCatálogo de ProductosYerson RomeroBelum ada peringkat

- Catalogue Laboratoire EN PDFDokumen32 halamanCatalogue Laboratoire EN PDFNuno Emanuel Araújo100% (1)

- Viennoiserie de SamiraDokumen31 halamanViennoiserie de Samirapepora100% (2)

- Catalogue Laboratoire EN PDFDokumen32 halamanCatalogue Laboratoire EN PDFolgutza123Belum ada peringkat

- Bbga Baguette Formula PDFDokumen1 halamanBbga Baguette Formula PDFmighterBelum ada peringkat

- Apple Pie Bonbons Recipe with Cacao Barry ChocolateDokumen5 halamanApple Pie Bonbons Recipe with Cacao Barry ChocolatePavelBelum ada peringkat

- Taste of Maya - Cacao Barry® World Chocolate MastersDokumen3 halamanTaste of Maya - Cacao Barry® World Chocolate MastersCwt ChanBelum ada peringkat

- Kriss Harvey RecipesDokumen2 halamanKriss Harvey RecipesAl AhmedBelum ada peringkat

- Gelato ReceipeDokumen5 halamanGelato ReceipenadgoudBelum ada peringkat

- Brownies Dominique AnselDokumen1 halamanBrownies Dominique AnselGiuseppina75Belum ada peringkat

- 2021 08 01 Escumes ENGDokumen23 halaman2021 08 01 Escumes ENGDaniel NikolovBelum ada peringkat

- CP First Bread Supereasy English CZXBGXDokumen4 halamanCP First Bread Supereasy English CZXBGXdani danBelum ada peringkat

- En Puff Pastry Recipe BookDokumen30 halamanEn Puff Pastry Recipe BookIsmael KchoukBelum ada peringkat

- 12 Must-Have Equipment for Starting a Pastry BusinessDokumen27 halaman12 Must-Have Equipment for Starting a Pastry BusinessCookie LiciousBelum ada peringkat

- Guillaume Lopvet Strawberry Dessert Savour Online ClassesDokumen7 halamanGuillaume Lopvet Strawberry Dessert Savour Online ClassesJoe ChoiBelum ada peringkat

- 03-hjbc 44 4 395 399 Fatma Hepsag ManuscriptDokumen6 halaman03-hjbc 44 4 395 399 Fatma Hepsag Manuscripttayyaba mehmoodBelum ada peringkat

- Patents. GoogleDokumen5 halamanPatents. GoogletavibastiBelum ada peringkat

- Talanta: Qiu-Hua Wang, Li-Ju Yu, Yang Liu, Lan Lin, Ri-Gang Lu, Jian-Ping Zhu, Lan He, Zhong-Lin LuDokumen12 halamanTalanta: Qiu-Hua Wang, Li-Ju Yu, Yang Liu, Lan Lin, Ri-Gang Lu, Jian-Ping Zhu, Lan He, Zhong-Lin LutavibastiBelum ada peringkat

- 1 s2.0 S0308814619304133 MainDokumen9 halaman1 s2.0 S0308814619304133 MaintavibastiBelum ada peringkat

- How To Write A Scientific Article PDFDokumen6 halamanHow To Write A Scientific Article PDFcretinusmaximusBelum ada peringkat

- How It Works: What Is A FODMAP?Dokumen10 halamanHow It Works: What Is A FODMAP?tavibastiBelum ada peringkat

- Akin MHort Organic Acids SugarsDokumen6 halamanAkin MHort Organic Acids SugarstavibastiBelum ada peringkat

- Ebook-Uri, Achiziþionate Ín Cadrul Proiectului ExpertDokumen3 halamanEbook-Uri, Achiziþionate Ín Cadrul Proiectului ExperttavibastiBelum ada peringkat

- How To Write A Scientific Article PDFDokumen6 halamanHow To Write A Scientific Article PDFcretinusmaximusBelum ada peringkat

- Effect of Ultra-High Pressure Homogenisation Processing On Phenolic PDFDokumen7 halamanEffect of Ultra-High Pressure Homogenisation Processing On Phenolic PDFtavibastiBelum ada peringkat

- Hibiscus Sabdariffal. - A Phytochemical and Pharmacological ReviewDokumen20 halamanHibiscus Sabdariffal. - A Phytochemical and Pharmacological ReviewtavibastiBelum ada peringkat

- How To Write A Scientific Article PDFDokumen6 halamanHow To Write A Scientific Article PDFcretinusmaximusBelum ada peringkat

- Quantifying Postharvest Loss and The ImplicationDokumen15 halamanQuantifying Postharvest Loss and The ImplicationtavibastiBelum ada peringkat

- Chinese Vinegar and Its Solid-StateDokumen20 halamanChinese Vinegar and Its Solid-StatetavibastiBelum ada peringkat

- Prod de La de LB Palntarum in Molases-Medium Composition Optimisation PB PDFDokumen10 halamanProd de La de LB Palntarum in Molases-Medium Composition Optimisation PB PDFtavibastiBelum ada peringkat

- Chemical Composition of White Morus Alba PDFDokumen5 halamanChemical Composition of White Morus Alba PDFtavibastiBelum ada peringkat

- Nutritional and Sensory Quality of Edible InsectsDokumen5 halamanNutritional and Sensory Quality of Edible InsectstavibastiBelum ada peringkat

- Precisi - Lista If 2017Dokumen437 halamanPrecisi - Lista If 2017nihilx27374Belum ada peringkat

- 3D Printing Printing Precision and Application in Food SectorDokumen12 halaman3D Printing Printing Precision and Application in Food SectorAhmad Al-HusainBelum ada peringkat

- A Comparative Study of Black Mulberry Juice Concentrates by ThermalDokumen8 halamanA Comparative Study of Black Mulberry Juice Concentrates by ThermaltavibastiBelum ada peringkat

- 0362-028x-68 12 2686Dokumen7 halaman0362-028x-68 12 2686tavibastiBelum ada peringkat

- NV Carob PowderDokumen3 halamanNV Carob PowdertavibastiBelum ada peringkat

- Histamine ProfileDokumen106 halamanHistamine ProfiletavibastiBelum ada peringkat

- Liquor (A.k.a. Cocoa Paste), Cocoa Powder, and 60-65% Cocoa Content Chocolate BarsDokumen7 halamanLiquor (A.k.a. Cocoa Paste), Cocoa Powder, and 60-65% Cocoa Content Chocolate BarstavibastiBelum ada peringkat

- DeZaan Cocoa ManualDokumen171 halamanDeZaan Cocoa Manualannerootje100% (5)

- Canning fruits safelyDokumen6 halamanCanning fruits safelytavibastiBelum ada peringkat

- A Resource Guide To: Chocolate and HealthDokumen10 halamanA Resource Guide To: Chocolate and HealthtavibastiBelum ada peringkat

- Know Your Chocolates LatestDokumen1 halamanKnow Your Chocolates Latestkzn_guyBelum ada peringkat

- Equipment and Technology in Hard Candy IndustryDokumen1 halamanEquipment and Technology in Hard Candy IndustryMtra. Violeta Cecilia Morales VértizBelum ada peringkat

- When It Comes To Chocolate, What Does Cocoa Percentage Actually Mean?Dokumen1 halamanWhen It Comes To Chocolate, What Does Cocoa Percentage Actually Mean?hardik shethBelum ada peringkat

- Reading A Bar Graph: 8 Banana Watermelon Orange 4 8 Banana Watermelon 4 6Dokumen2 halamanReading A Bar Graph: 8 Banana Watermelon Orange 4 8 Banana Watermelon 4 6Ravineel Kumar0% (1)

- Overview of Chocolate Confectioneries in PakistanDokumen15 halamanOverview of Chocolate Confectioneries in PakistanM Javaid BokhariBelum ada peringkat

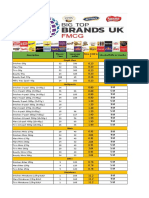

- Chocolate BrandsDokumen14 halamanChocolate BrandsSaloni SarvaiyaBelum ada peringkat

- Reading - ChocolateDokumen4 halamanReading - ChocolateImanolBelum ada peringkat

- LLIGoldHistoryofChewingGumSample PDFDokumen17 halamanLLIGoldHistoryofChewingGumSample PDFSofía LecterBelum ada peringkat

- Tempering Chocolate - by Pastry Chef - Author Eddy Van DammeDokumen6 halamanTempering Chocolate - by Pastry Chef - Author Eddy Van DammeMaría del Carmen Alvarez100% (1)

- Valrhona Food Service Brochure LRDokumen26 halamanValrhona Food Service Brochure LRNeverthless123100% (1)

- Toffee Food TechnologyDokumen19 halamanToffee Food TechnologyNgọc DungBelum ada peringkat

- Caramelised Almond and Spice Dragée - Cacao BarryDokumen4 halamanCaramelised Almond and Spice Dragée - Cacao Barryeditte666Belum ada peringkat

- Lollipop PoemDokumen1 halamanLollipop Poempetitelady345Belum ada peringkat

- History of CadburyDokumen19 halamanHistory of CadburygutiufiBelum ada peringkat

- Besa Trading Price List 15 June - 2023Dokumen1 halamanBesa Trading Price List 15 June - 2023creativegirl328Belum ada peringkat

- Brownies CookiesDokumen1 halamanBrownies CookieskasnoryBelum ada peringkat

- White DolphinDokumen1 halamanWhite Dolphinaiza tauseefBelum ada peringkat

- How to Make Crystalline and Noncrystalline CandyDokumen16 halamanHow to Make Crystalline and Noncrystalline Candynabila OktavianiBelum ada peringkat

- Candy and Snack Price List with Descriptions and Shelf LifeDokumen148 halamanCandy and Snack Price List with Descriptions and Shelf LifeTazwid LibyaBelum ada peringkat

- Benjamin Fowler - A Tale of Two Chocolate CompaniesDokumen2 halamanBenjamin Fowler - A Tale of Two Chocolate Companiesbenjamin fowlerBelum ada peringkat

- 175 Profitable Candy Shop Name Ideas You Can StealDokumen7 halaman175 Profitable Candy Shop Name Ideas You Can StealMartin SandersonBelum ada peringkat

- ChocolateDokumen2 halamanChocolateJose Francisco Meneses SoteloBelum ada peringkat

- Charlie and The Choclate FactoryDokumen1 halamanCharlie and The Choclate FactoryDaniel Ruiz0% (1)

- Chocolate From Cocoa - PPT 5.15Dokumen21 halamanChocolate From Cocoa - PPT 5.15Sandhya ArulBelum ada peringkat

- Explanation Text How To Make Chocolate: Grestia Angraini Panggabean XA9 Sman 1 Matauli PandanDokumen15 halamanExplanation Text How To Make Chocolate: Grestia Angraini Panggabean XA9 Sman 1 Matauli PandanGrestiaangraini PanggabeanBelum ada peringkat

- Clairmont 1Dokumen3 halamanClairmont 1RnD KuekuBelum ada peringkat

- CCF Script For OnlineDokumen20 halamanCCF Script For OnlineSurbhi MadanBelum ada peringkat