Thermal Considerations For Hybrids AN007 1

Diunggah oleh

Ganesan SJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Thermal Considerations For Hybrids AN007 1

Diunggah oleh

Ganesan SHak Cipta:

Format Tersedia

APPLICATION NOTE

Thermal Considerations for Hybrid

DC-DC Power Converters

DC-DC CONVERTERS AND ACCESSORIES

AN007 1.0 Page 1 of 17

Sales Information: (phone) 425-353-3010 (fax) 425-353-4030 vptsales@vptpower.com www.vptpower.com

Contents:

Introduction .................................................................................................................................................................................... 3

Characteristics of Hybrid Packaging ................................................................................................................................ 3

Thermal Resistance Calculation ......................................................................................................................................... 4

DC-DC Converter Application .............................................................................................................................................. 5

Determining Internal Junction Operating Temperatures ...................................................................................... 6

Considerations for Proper Mounting ................................................................................................................................ 7

Determining the Case Temperature ................................................................................................................................. 8

Deadbug Style Mounting .................................................................................................................................................. 11

Deadbug Style Mounting with Heat Spreader ...................................................................................................... 13

PCB Mounting ........................................................................................................................................................................... 15

PCB Mounting with Heat Spreader ................................................................................................................................ 16

Conclusion .................................................................................................................................................................................. 17

Contact Information................................................................................................................................................................ 17

AN007 1.0 Page 2 of 17

Sales Information: (phone) 425-353-3010 (fax) 425-353-4030 vptsales@vptpower.com www.vptpower.com

Introduction

VPTs DV series Hybrid DC-DC converters are rated for the full military temperature range of

-55C to +125C and can be operated at full rated power within that range as long as the

power dissipation and temperature rise is properly addressed. This document discusses the

thermal management considerations for various assembly configurations of hybrid DC-DC

converters.

Solid state DC-DC power converters always have efficiency less than 100%, and therefore

always waste a percentage of their input power. This wasted power is dissipated as heat

and will cause the temperature of the DC-DC converter to rise above the ambient system

temperature. The temperature rise of the DC-DC converter must be considered during the

system mechanical and thermal design to ensure the converter does not exceed its maximum

rated operating temperature.

Characteristics of Hybrid Packaging

Thick film hybrid packaging technology uses bare semiconductor die and high thermal

conductivity materials to achieve high temperature operation. A diagram of the typical hybrid

package is shown in Figure 1. In its basic form, the bare silicon die is mounted to a ceramic

substrate, usually Al2O3 (alumina), which is mounted to the metal package, usually steel

or Kovar. Power is dissipated in the semiconductor die, which may be an IC, power transistor,

or power rectifier. The die has a maximum semiconductor junction operating temperature,

typically 150C or 175C, as specified by the manufacturer.

AN007 1.0 Page 3 of 17

Sales Information: (phone) 425-353-3010 (fax) 425-353-4030 vptsales@vptpower.com www.vptpower.com

The semiconductor junction temperature inside the hybrid, Tj, is determined by the following

formula:

Tj = Tcase + T (1)

T = Pd jc (2)

Figure 1. Internal Hybrid Construction.

Tcase is the case temperature of the hybrid; T is the temperature rise from junction to case; Pd

is the power dissipated in the die; and jc is the thermal resistance from the junction to the case.

jc is the sum of any intermediary thermal resistances, in this case the ceramic substrate, the

attachment materials, and the case itself.

Thermal Resistance Calculation

The thermal resistance for any material can be calculated according to the formula:

x

(3)

KA

Where A is the cross sectional area normal to the direction of the heat flow, x is the distance

that the heat travels, and K is the thermal conductivity of the material. For example a 0.75 tall

aluminum spacer block with dimensions 1 x 0.4 which could be mounted under the flange of

the DVTR package has a thermal resistance of:

0.75in C

0.47 (4)

W W

3.957 1.0in 0.4in

in C

The thermal conductivity of aluminum is 3.957W/in-C. From (2), each Watt of power dissipated

through this aluminum block causes a temperature rise across the block of 0.47C.

AN007 1.0 Page 4 of 17

Sales Information: (phone) 425-353-3010 (fax) 425-353-4030 vptsales@vptpower.com www.vptpower.com

DC-DC Converter Application

The maximum operating temperature range of VPTs hybrid DC-DC converters is -55C to

+125C. From Figure 1, it is apparent that the thermal path is entirely through the bottom of the

package. The operating temperature is specified and must be measured on the bottom surface

of the case. The lid offers very little path for heat transfer. Any temperatures measured on the lid

will give inaccurate results, and any heatsinking added to the lid will have only minimal effect.

The system thermal design must allow for the primary thermal path through the bottom of the

package.

The case temperature will always be slightly higher than the heatsink or ambient temperature

due to the power dissipated in the hybrid and the thermal resistance of the assembly. Case

temperature cannot be assumed to be equal to the heatsink or ambient temperature. This

wrong assumption is the cause of many system thermal problems. Proper system design

will allow high system temperatures, in excess of 100C, yet maintain hybrid component

temperatures well below 125C.

If the case of the hybrid is maintained below +125C, the internal semiconductor junction

temperatures will remain at safe levels, typically between 130 and 140C, well below their

maximum ratings. If the output power of the hybrid is reduced, the maximum allowable case

temperature can be increased further without increasing the internal junction temperatures.

The derating criteria for the DV series hybrid DC-DC converters is from full rated power at

+125C, linearly to half power at +130C, and to zero power at +135C, as shown in Figure 2.

Figure 2. Temperature Derating Curve

AN007 1.0 Page 5 of 17

Sales Information: (phone) 425-353-3010 (fax) 425-353-4030 vptsales@vptpower.com www.vptpower.com

Although hybrid DC-DC converters can be operated up to +125C, reliability can be increased

by operating them at a lower case temperature. Every electronic component has a failure rate

which is in theory related to its operating temperature. Lowering the operating temperature

of the hybrid by 5C can result in a 10-20% increase in MTBF according to MIL-HDBK-217

type calculations. In general, the system design should attempt to reduce thermal resistances

and minimize the temperature rise between the DC-DC converter and the system ambient.

For maximum reliability, the DC-DC converter should be operated as close as possible to

the ambient temperature rather than near its maximum operating temperature.

Determining Internal Junction Operating Temperatures

The maximum internal temperature rise for any individual semiconductor junction is given

in the absolute maximum ratings section of the DC-DC converter datasheet and is typically

between 5 and 15C. For example, the DVTR2800S datasheet gives and internal Junction

Temperature Rise to Case of 15C. The internal junction temperatures are all within 15C of

the case temperature. Since a typical hybrid package contains many semiconductor junctions,

the datasheet parameter refers to the internal junction with the largest temperature rise and is

given at rated load.

An internal thermal resistance from junction to case is often required for reliability calculations.

It is not practical to consider every distinct semiconductor junction, but an overall effective

thermal resistance can be calculated as follows:

jc = T / Pd, (5)

Where T is the junction temperature rise to case and Pd is the power dissipation at full load,

both from the absolute maximum ratings section of the datasheet. For example, the DVTR2800S

datasheet gives T = 15C and Pd = 13W. The effective internal thermal resistance from junction

to case would be:

jc = 15C / 13W = 1.15 C/W. (6)

AN007 1.0 Page 6 of 17

Sales Information: (phone) 425-353-3010 (fax) 425-353-4030 vptsales@vptpower.com www.vptpower.com

The maximum internal junction temperature can then be calculated at reduced output power.

For an application requiring 12V at 30W, the efficiency of the DVTR2812S is 83% read from the

graph in the datasheet. The power dissipated under this condition is:

1 1

PD POUT 1 30W 1 6.1W (7)

Eff 83%

The effective temperature rise from junction to case under this condition would be:

T = 6.1W * 1.15 C/W = 7C (8)

If the case of the hybrid were held at 90C by the system, the effective internal maximum

junction temperature would be 97C.

Considerations for Proper Mounting

DV series DC-DC converters are typically used in applications where the dominant mode of

heat transfer is conduction. Any radiation or convection cooling is usually neglected in the

thermal analysis. Low power models such as DVCH and DVSA, and high efficiency models

such as the DVHE and DVPL, can often be mounted without a heatsink or rely on the PCB for

heatsinking, depending on the ambient temperature. On the other hand, the higher power

DVFL will usually require a low thermal resistance connection to a substantial heatsink, such

as a system chassis.

Aluminum is typically used for a heatsink or heatspreader material, since it has high thermal

conductivity, low weight, and is easily machined. A thermally conductive gap filler material

should be used between the mounting surface of the hybrid and the heatsink. This gap filler

is typically a thermal pad, thermal grease, or adhesive. It will fill any surface irregularities and

decrease the thermal resistance of the interface. Materials are available from various

manufacturers with various properties: thickness, hardness, dielectric breakdown, adhesive,

outgassing, etc.

VPT offers pre-cut thermal pads sized to fit various hybrid packages. The thermal resistances

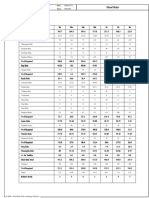

of these thermal pads are given in Table 1.

AN007 1.0 Page 7 of 17

Sales Information: (phone) 425-353-3010 (fax) 425-353-4030 vptsales@vptpower.com www.vptpower.com

Thermal Resistance

VPT P/N Use With

tp [C/W]

TP-001 DVFL2800S, DVFL2800D, DVME28 0.06

DVHF2800S, DVHF2800D, DVHF+2800T,

TP-002 0.14

DVSB2800D, DVGF+2800T

DVTR2800S, DVTR2800D, DVHV2800S,

TP-003 0.10

DVHV2800D, DVEHF2800T, DVHE2800S

TP-004 DVTR2800T, DVETR2800S, DVETR2800D 0.09

TP-005 DVSA2800S, DVSA2800D 0.24

Table 1. Thermal resistance of TP-xxx thermal pads.

The DC-DC converter should be mounted securely to the heatsink for good thermal conductivity.

The flange package, adhesive, or a mounting strap is recommended for best performance.

Some gap filler materials require adequate mounting pressure to maintain good thermal

performance. Solder connections to the pins are usually not sufficient if a good thermal interface

is required.

Determining the Case Temperature

The operating temperature of the hybrid should be verified by both analysis and measurement.

For design purposes the operating temperature can be calculated using computerized finite

element analysis methods or a simple thermal resistance model. A thermocouple mounted

on the baseplate of the hybrid in the actual system is a good method of verification, but usually

must wait until late in the development cycle. Basic thermal resistance calculations will be

presented in this paper for several mounting configurations. These calculations, usually

approximate, are a good design tool early in the development cycle before full system thermal

models are developed.

AN007 1.0 Page 8 of 17

Sales Information: (phone) 425-353-3010 (fax) 425-353-4030 vptsales@vptpower.com www.vptpower.com

Figure 3. DVFL mounted directly to metal heat spreader.

Figure 4. Mechanical stackup and thermal resistance model for DVFL.

Figure 3 shows a side-leaded DVFL hybrid mounted directly to a heatspreader. Figure 4 shows

the mechanical stackup and equivalent thermal resistance model, assuming the heatspreader

is mounted to a chassis with a known ambient temperature.

AN007 1.0 Page 9 of 17

Sales Information: (phone) 425-353-3010 (fax) 425-353-4030 vptsales@vptpower.com www.vptpower.com

The case temperature of the DVFL is calculated similarly to (1) and (2):

Tcase = Tamb + Pd (9)

Tamb is the known ambient temperature of the system chassis. Pd is the total power dissipation

of the hybrid and can be calculated from (7) where the efficiency has been measured or read

from the datasheet graph at the correct operating condition. The total thermal resistance is

the sum of all intermediate thermal resistances from the hybrid to the ambient, in this case the

thermal pad and the heat spreader.

= thermalpad + heatsink (10)

The thermal resistance of the thermal pad can be read from Table 1. The thermal resistance of

the heatsink can be obtained from its manufacturer or calculated according to equation (3).

The power dissipated internal to the hybrid can be assumed to be spread evenly across its

baseplate, so the area in (3) would be the area of the DVFL baseplate, not the entire area of the

heat spreader. If the heatsink is unusual or nonrectangular in shape, its thermal resistance can

be approximated by breaking it up into rectangular blocks which are in series with respect to

the heat flow. The thermal resistance of each block can be calculated individually and summed

to obtain the total thermal resistance.

For this example: the ambient temperature is 70C; the power dissipated for the DVFL2815S at

28V input; full load is 30W; the thermal resistance of the thermal pad TP-001 is 0.06C/W from

table 1. The aluminum heat spreader is 0.5 thick. From (3) the thermal resistance of the heat

spreader is:

0.5in C

0.028

W W

3.957 3.0in 1.5in

in C (11)

And the case temperature of the DVFL is:

Tcase = 70C + 30W (0.06C/W + 0.028C/W) = 72.64C (12)

This configuration with the hybrid mounted directly to a heatsink will usually result in the lowest

possible operating case temperature. It can be applied to down-leaded type packages such as

the DVHF and DVTR by adding clearance holes in the heatsink for electrical connections to the

pins.

AN007 1.0 Page 10 of 17

Sales Information: (phone) 425-353-3010 (fax) 425-353-4030 vptsales@vptpower.com www.vptpower.com

Deadbug Style Mounting

Figure 5 shows an example of deadbug style mounting for the DVTR hybrid in the flanged

package. This is a common mounting configuration for severe vibration environments. Electrical

connections to the pins can be made with discrete wires or a flexible or rigid printed circuit

board.

Figure 5. Deadbug Style Mounting for Downleaded Flanged Units.

Figure 6. Deadbug thermal model.

AN007 1.0 Page 11 of 17

Sales Information: (phone) 425-353-3010 (fax) 425-353-4030 vptsales@vptpower.com www.vptpower.com

In this case, heat is transferred only through the mounting flanges. The maximum temperature

is assumed to be in the center of the hybrid, and there is an additional thermal resistance and

temperature rise from the center to the mounting flange. For this configuration since power is

dissipated across the surface of the baseplate, finite element methods were used to obtain an

effective thermal resistance, R-deadbug, from the center of the package to the flange, as shown

in Figure 6. This effective thermal resistance will give a valid hot spot case temperature when

used in conjunction with the total power dissipation of the hybrid. This effective thermal

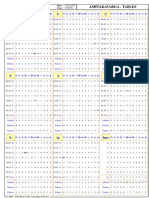

resistance is given in Table 2 for various flanged packages.

Thermal Resistance

Converter Model

[C/W]

DVHF, flanged package 4.06

DVTR, flanged package 6.22

DVTR, triple output, flanged package 4.80

Table 2. Thermal resistance of the hybrid case for dead-bug mounting (from center of package to mounting locations).

The hot spot temperature in the center of the hybrid is given by (13) where each flange is held at

the same temperature, Tflange. The power dissipated, Pd is divided by 2 since there are two

parallel thermal paths, one to each flange.

P

d

Tcase T (13)

flange 2 deadbug

The deadbug mounting method will usually result in higher case temperatures than the direct

heatsink configuration of Figure 3.

AN007 1.0 Page 12 of 17

Sales Information: (phone) 425-353-3010 (fax) 425-353-4030 vptsales@vptpower.com www.vptpower.com

Deadbug Style Mounting with Heat Spreader

For applications with high power dissipation or high ambient temperature, the case temperature

of the hybrid can be lowered by adding a heat spreader to the basic deadbug mounting

configuration, as shown in Figure 7. The heat spreader should have a thermal conductivity

greater than that of the hybrid package (cold rolled steel, K = 1.318W/in-C). For example, for

the DVTR package an aluminum bar 0.6 x 2.9 x 0.1 thick could be used. To be effective, the

spreader must clear the electrical pins and maintain thermal contact along its entire length; a

thermally conductive adhesive is recommended.

Figure 7. Heat Spreader Attached to DVTR to Reduce Thermal Resistance.

Figure 8. Thermal model for deadbug mounting with heat spreader.

AN007 1.0 Page 13 of 17

Sales Information: (phone) 425-353-3010 (fax) 425-353-4030 vptsales@vptpower.com www.vptpower.com

Again using finite element methods, an approximate thermal resistance model can be derived

for this configuration. The thermal resistance of the heat spreader can be assumed to be in

parallel with the effective thermal resistance of the package with an additional factor of 2. This

additional factor was derived through finite element modeling to account for the fact that heat

is actually transferred to the heat spreader along its entire length, instead of simply at the center

of the hybrid. The thermal resistance of the spreader is calculated for heat flow along its length,

and for this case, would be:

1.275in C

spreader 5.37 (14)

W W

3.957 0.6in 0.1in

in C

Where x is the distance from the center of the package to the center of the flange. Using the

formula for parallel resistors, the case temperature of the hybrid would be:

P 1

Tcase T flange d (15)

2 1 1

deadbug spreader / 2

Note that -spreader is divided by 2 as mentioned above. It is apparent that this configuration

with the heat spreader (15) will always result in a lower case temperature than the previous

configuration without the heat spreader (13). The thermal resistance of the heat spreader must

be low enough to have a significant impact; it must be made of a high thermal conductivity

material and have adequate size.

AN007 1.0 Page 14 of 17

Sales Information: (phone) 425-353-3010 (fax) 425-353-4030 vptsales@vptpower.com www.vptpower.com

PCB Mounting

Lower power hybrids can often be mounted directly to the circuit board or PCB as shown in

Figure 9. Good thermal contact should be maintained between the hybrid and the board. An

adhesive is often used. Mounting flanges or a mounting strap across the top of the hybrid can

also help maintain good thermal contact. The thermal resistance of the PCB should be

calculated lengthwise through the PCB material from the center of the hybrid to the mounting

locations of the PCB using (3). The case temperature can be calculated from (9). Typical PCB

materials are not good thermal conductors. Copper planes are often employed to improve

thermal conductivity along the length of the PCB. Likewise, thermal vias are used to improve

thermal conductivity through the PCB, usually under the hybrid or at the board mounting

locations.

Figure 9. DVSA Mounted to a Circuit Board.

AN007 1.0 Page 15 of 17

Sales Information: (phone) 425-353-3010 (fax) 425-353-4030 vptsales@vptpower.com www.vptpower.com

PCB Mounting with Heat Spreader

When the PCB alone is not sufficient to carry heat away from the hybrid, a heat spreader can

be added to the assembly as shown in Figure 10. In this case, the thermal path through the

PCB can usually be ignored and the case temperature of the hybrid can be calculated directly

from (9). Additionally, intentionally isolating the thermal spreader and hybrid from the PCB

can serve to lower the temperature of the PCB and surrounding components.

Figure 10. Converter/Heat Spreader/PCB Assembly.

Another option is to cut a hole in the PCB, and allow a heat spreader to protrude up and make

contact with the heat spreader. The mechanical mounting should again be sufficient to ensure

good thermal contact between the baseplate and the heat spreader.

AN007 1.0 Page 16 of 17

Sales Information: (phone) 425-353-3010 (fax) 425-353-4030 vptsales@vptpower.com www.vptpower.com

Conclusion

Proper system thermal design is necessary to allow hybrid DC-DC converters to operate reliably

over the full military temperature range. To ensure maximum ratings are not exceeded, it

must be recognized that the hybrid operating temperature will be greater than the ambient

or heatsink temperature. The hybrid operating temperature is specified at the bottom center

of the baseplate. It can be determined either by analysis or measurement. Knowing the actual

temperature will allow accurate reliability calculations and proper tradeoffs between design

complexity and reliability.

Contact Information

For further information about any of VPTs products, policies, or programs contained herein, or

to request a quotation or place orders please contact your sales representative or the VPT Inc.

Sales Department at:

Phone: (425) 353-3010

Fax: (425) 353-4030

E-mail: vptsales@vptpower.com

Website: www.vptpower.com

Sales & Marketing Headquarters:

19909 120th Avenue NE

Suite 102

Bothell, WA 98011

Company Headquarters:

1971 Kraft Drive

Blacksburg, VA 24060

AN007 1.0 Page 17 of 17

Sales Information: (phone) 425-353-3010 (fax) 425-353-4030 vptsales@vptpower.com www.vptpower.com

Anda mungkin juga menyukai

- PCB Trace Width Calculator Guide & Current TableDokumen5 halamanPCB Trace Width Calculator Guide & Current TableGanesan SBelum ada peringkat

- PCB Trace Spacing Calculation For Voltage LevelsDokumen5 halamanPCB Trace Spacing Calculation For Voltage LevelsGanesan SBelum ada peringkat

- Printed Circuit Design & Fab Online Magazine - The Dynamics of PCB Trace Heating and Cooling, and A Call To ActionDokumen13 halamanPrinted Circuit Design & Fab Online Magazine - The Dynamics of PCB Trace Heating and Cooling, and A Call To ActionGanesan SBelum ada peringkat

- Final - Radio Technology WuDokumen15 halamanFinal - Radio Technology WuGanesan SBelum ada peringkat

- English VyDokumen30 halamanEnglish VyGanesan SBelum ada peringkat

- Final - Radio Technology WuDokumen15 halamanFinal - Radio Technology WuGanesan SBelum ada peringkat

- Huber: House Chart Interpretation For PrakasDokumen7 halamanHuber: House Chart Interpretation For PrakasGanesan S100% (1)

- Predicting Fusing Time of Overloaded PCB Traces Can We Predict It at All - With Douglas Brooks, PHD and Dr. Johannes Adam - ARTECH HOUSE INSIDERDokumen12 halamanPredicting Fusing Time of Overloaded PCB Traces Can We Predict It at All - With Douglas Brooks, PHD and Dr. Johannes Adam - ARTECH HOUSE INSIDERGanesan SBelum ada peringkat

- Gap Analysis of GNSS Receivers and Technology: GSA-227890 GRAMMAR D1.4 Version 1.17Dokumen72 halamanGap Analysis of GNSS Receivers and Technology: GSA-227890 GRAMMAR D1.4 Version 1.17Ganesan SBelum ada peringkat

- MMIC/RFIC For Receivers Front-End: To Cite This VersionDokumen7 halamanMMIC/RFIC For Receivers Front-End: To Cite This VersionGanesan SBelum ada peringkat

- English VyDokumen30 halamanEnglish VyGanesan SBelum ada peringkat

- Angelina Jolie Shad BalaDokumen1 halamanAngelina Jolie Shad BalaGanesan S100% (1)

- Gap Analysis of GNSS Receivers and Technology: GSA-227890 GRAMMAR D1.4 Version 1.17Dokumen72 halamanGap Analysis of GNSS Receivers and Technology: GSA-227890 GRAMMAR D1.4 Version 1.17Ganesan SBelum ada peringkat

- Huber: Natal Chart Interpretation For PrakasDokumen7 halamanHuber: Natal Chart Interpretation For PrakasGanesan S100% (1)

- MMIC/RFIC For Receivers Front-End: To Cite This VersionDokumen7 halamanMMIC/RFIC For Receivers Front-End: To Cite This VersionGanesan SBelum ada peringkat

- Angelina Jolie - Yoga Judgment - ShastiamsaDokumen1 halamanAngelina Jolie - Yoga Judgment - ShastiamsaGanesan S100% (1)

- Angelina Jolie Birth ControlDokumen1 halamanAngelina Jolie Birth ControlGanesan SBelum ada peringkat

- Angelina Jolie Birth ControlDokumen1 halamanAngelina Jolie Birth ControlGanesan SBelum ada peringkat

- Angelina Jolie Ashtakavarga - TablesDokumen1 halamanAngelina Jolie Ashtakavarga - TablesDakshinamoorthi RamasamyBelum ada peringkat

- Installation Guide of AstrotransitDokumen3 halamanInstallation Guide of AstrotransitGanesan SBelum ada peringkat

- Angelina Jolie VARSHAPHALADokumen1 halamanAngelina Jolie VARSHAPHALAGanesan SBelum ada peringkat

- Angelina Jolie Ashtakavarga - TablesDokumen1 halamanAngelina Jolie Ashtakavarga - TablesDakshinamoorthi RamasamyBelum ada peringkat

- Prepared and Compiled by Govindon Gopalan (Harish)Dokumen1 halamanPrepared and Compiled by Govindon Gopalan (Harish)Ganesan SBelum ada peringkat

- Angelina Jolie - Yoga Judgment - ShastiamsaDokumen1 halamanAngelina Jolie - Yoga Judgment - ShastiamsaGanesan S100% (1)

- Using PATENTS To Reduce R&D Efforts: First Edition 2016Dokumen31 halamanUsing PATENTS To Reduce R&D Efforts: First Edition 2016Ganesan SBelum ada peringkat

- 25 Myths About PATENTS Demystified EbookDokumen52 halaman25 Myths About PATENTS Demystified EbookGanesan SBelum ada peringkat

- Caste and CastelessnessDokumen8 halamanCaste and CastelessnessJayanth TadinadaBelum ada peringkat

- Ebook Minimising Patent Infringement RiskDokumen70 halamanEbook Minimising Patent Infringement RiskAnandBelum ada peringkat

- PVR Lessons Book 2Dokumen149 halamanPVR Lessons Book 2api-1993729390% (10)

- Ebook Minimising Patent Infringement RiskDokumen70 halamanEbook Minimising Patent Infringement RiskAnandBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5783)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- (WWW - Manuallib.com) - IDEAL 61-760 Series Commercial-Industrial TightSight&Reg Clamp Meters InstructionsDokumen19 halaman(WWW - Manuallib.com) - IDEAL 61-760 Series Commercial-Industrial TightSight&Reg Clamp Meters InstructionsEspartaco ToorrentsBelum ada peringkat

- THS4131CD: Analog Devices Process Technology: 2.5um 2 Bipolar (AD8672, AD829, AD620)Dokumen15 halamanTHS4131CD: Analog Devices Process Technology: 2.5um 2 Bipolar (AD8672, AD829, AD620)ikperha jomafuvweBelum ada peringkat

- Temperature FundamentalsDokumen39 halamanTemperature Fundamentalsartup3l0nBelum ada peringkat

- TCXD 46-1984 / Lightning Protection For Buildings - Standard For Design and ConstructionDokumen30 halamanTCXD 46-1984 / Lightning Protection For Buildings - Standard For Design and ConstructiontrungjindoBelum ada peringkat

- Data Acquisition PrincipleDokumen20 halamanData Acquisition PrincipleTg TarroBelum ada peringkat

- Storage Batteries - Measuring Battery-To-Ground VoltagesDokumen2 halamanStorage Batteries - Measuring Battery-To-Ground VoltagescadtilBelum ada peringkat

- Electrostatic Accelerated Electrons Within Symmetric Capacitors During Field Emission Condition Events Exert Bidirectional Propellant-Less ThrustDokumen24 halamanElectrostatic Accelerated Electrons Within Symmetric Capacitors During Field Emission Condition Events Exert Bidirectional Propellant-Less ThrustGary McKinnonBelum ada peringkat

- Electronics Today 1976 09Dokumen82 halamanElectronics Today 1976 09cornel_24Belum ada peringkat

- Castillo - E109Dokumen1 halamanCastillo - E109Ian CastilleBelum ada peringkat

- G Timers Gt3Dokumen41 halamanG Timers Gt3bansalrBelum ada peringkat

- Product Discontinuation: EOL Material Material Description Nearest ReplacementDokumen31 halamanProduct Discontinuation: EOL Material Material Description Nearest ReplacementYosephanderBelum ada peringkat

- Solar Mobile Battery Charger PDFDokumen32 halamanSolar Mobile Battery Charger PDFKumar KommaBelum ada peringkat

- Designing custom test equipment for insulation materialDokumen6 halamanDesigning custom test equipment for insulation materialanuBelum ada peringkat

- Bureau of Indian Standards Is 15652 - 2006 Electrical MatDokumen16 halamanBureau of Indian Standards Is 15652 - 2006 Electrical MatSreekanth PCBelum ada peringkat

- System Sensor PR-1 Data SheetDokumen2 halamanSystem Sensor PR-1 Data SheetJMAC SupplyBelum ada peringkat

- Specs 1 PDokumen34 halamanSpecs 1 Pnp1101992Belum ada peringkat

- PCV CableDokumen12 halamanPCV CableMahamud MusaBelum ada peringkat

- Solar Night Light AssemblyDokumen14 halamanSolar Night Light AssemblyYamut Si akoBelum ada peringkat

- Module 2 Series-Parallel and ConductanceDokumen25 halamanModule 2 Series-Parallel and Conductancesuga linBelum ada peringkat

- Diode EquationsDokumen38 halamanDiode EquationsToptens700Belum ada peringkat

- Generac QTS ManualDokumen166 halamanGenerac QTS ManualChris MaytumBelum ada peringkat

- D 5778 - 95 Método de Prueba Estándar para El Ensayo de Penetración de Cono de Fricción Electrónico y Piezocono de Suelos.Dokumen19 halamanD 5778 - 95 Método de Prueba Estándar para El Ensayo de Penetración de Cono de Fricción Electrónico y Piezocono de Suelos.Dagoberto VergaraBelum ada peringkat

- 0 A 78279Dokumen9 halaman0 A 78279Igmar Franco NegreteBelum ada peringkat

- Fix IAT Sensor or PCM for High Voltage CodeDokumen7 halamanFix IAT Sensor or PCM for High Voltage Codeflash_24014910Belum ada peringkat

- Dimas Manual Eng.Dokumen20 halamanDimas Manual Eng.bsisuBelum ada peringkat

- Mmi Final Copy DN PDFDokumen127 halamanMmi Final Copy DN PDFAkhilprasad SadigeBelum ada peringkat

- Subminiature FuseDokumen14 halamanSubminiature FuseGautham VenkatBelum ada peringkat

- Marantz SR 6005 Service ManualDokumen189 halamanMarantz SR 6005 Service ManualsrinivasanBelum ada peringkat

- 1000 Electric Circuits MCQsDokumen100 halaman1000 Electric Circuits MCQskibrom atsbhaBelum ada peringkat

- DEE APPLIED PHYSICS - Remedial TestDokumen2 halamanDEE APPLIED PHYSICS - Remedial TestMilan SasmolBelum ada peringkat