CNC Petlje

Diunggah oleh

bhstudent_537083349Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

CNC Petlje

Diunggah oleh

bhstudent_537083349Hak Cipta:

Format Tersedia

CNC kontrola petlje

Kao stvarna brzina i pozicija detektora senzora je pohranjena na Upravljakoj ploici,

servo motor koji koristi CNC stroj neprestano se kontrolira kako bi se smanjie greke

brzine ili greke pozicije (sl. 1.10).

Povratne informacije kontrolnog sistema sastoji se od tri nezavisne kontrolne petlje za

svaku osu alatnog stroja;

najudaljenija kontrolna petlja je petlja za kontrolu pozicije,

srednji petlja je za regulaciju brzine petlje i

Unutarnja petlja je za regulacijsku struje

. Openito, poloaj kontrole petlja nalazi se u NC, a ostalo se nalaz u servo upravljakom

ureaju. Meutim, ne postoji apsolutni standard o lokaciji kontrolne petlje i lokacije se

mogu mijenjati zavisno o namjeri dizajnera.

1.4 CNC Control Loop

As the actual velocity and position detected from a sensor are fed back to a control

circuit, the servo motor used in the CNC machine is continuously controlled to minimize

the velocity error or the position error (Fig. 1.10). The feedback control system

consists of three independent control loops for each axis of the machine tool; the outermost

control loop is a position-control loop, the middle loop is a velocity-control

loop, and the innermost loop is a current-control loop. In general, the position-control

loop is located in the NC and the others are located in a servo driving device. However,

there is no absolute standard about the location of control loops and the locations

can be varied based on the intention of the designer.

In the spindle system of machine tools, feedback control of velocity is applied

to maintain a regular rotation speed. The feedback signal is generally generated in

two ways; a tacho-generator,which generates an induction voltage (analog signal) as

a feedback signal, and an optical encoder, which generates pulses (digital signals).

In recent times it is typical that feedback control is performed based on an optical

encoder signal instead of a tachometer signal.

The detector can be attached to the shaft of a servo motor or the moving part and

the control system can be categorized into four types according to the location at

which the detector is attached.

U vretenu maine, povratna kontrola brzine se koristi za odravanje regularne brzine rotacije. Povratni signal

obino nastaje na dva naina:

taho-generator koji stvara indukcioni napon (analogni signal), kao

povratni signal, i optiki enkoder( senzor), koji generie impulse (digitalni signal).

U novije vrijeme povratne informacije se kontroliu na osnovu optikog

enkodera umjesto tahometar signala.

Detektor se moe privrstiti na osovinu servo motora ili pokretni dio i

sistem kontrole mogu se svrstati u etiri vrste prema mjestu na

kojem detektor privren.

Tahometar ureaj za mjerenje brzine, odnosno brzinomjer. Tahometri zapravo mjere brzinu okretaja neke

osovine.

1.4.1 Semi-closed Loop

The semi-closed loop is the most popular control mechanism and has the structure

shown in Fig. 1.11a. In this type, a position detector is attached to the shaft of a servo

motor and detects the rotation angle. The position accuracy of the axis has a great

influence on the accuracy of the ball screw. For this reason, ball screws with high

accuracy were developed and are widely used. Due to the precision ball screw, the

problem with accuracy has practically been overcome.

If necessary, pitch-error compensation and backlash compensation can be used

in NC in order to increase the positional accuracy. The pitch-error compensation

method is that, at the specific pitch, the instructions to the servo driver system

are modified in order to remove the accumulation of positional error. The backlash

compensation method is that, whenever the moving direction is changed, additional

pulses corresponding to the amount of backlash are sent to the servo driver system.

Recently, the usage of the Hi-Lead-type ball screw with large pitch for high-speed

machining has increased.

1.4.1 Polu-zatvorene petlje

Petlja polu-zatvorena je najpopularniji kontrolni mehanizam i ima strukturu

prikazanu na slici. 1.11a. U ovoj vrsti, detektor pozicije je privrena na osovinu servo

motora i detektuje ugao rotacije. Na preciznost poloaja osa velik

utiecajima preciznost lopta vijak. Iz tog razloga, lopta vijaka se proizvodi sa visokim

preciznou i ima veliku primjenu. Upotrbom lopta vijak,

problem sa tanou je praktino nepoznat.

Lopta vijak je mehaniki Linearni pogoni koji prevodi rotaciono kretanja u linearno kretanje uz malo trenje.

If necessary, pitch-error compensation and backlash compensation can be used

in NC in order to increase the positional accuracy. The pitch-error compensation

method is that, at the specific pitch, the instructions to the servo driver system

are modified in order to remove the accumulation of positional error. The backlash

compensation method is that, whenever the moving direction is changed, additional

pulses corresponding to the amount of backlash are sent to the servo driver system.

Recently, the usage of the Hi-Lead-type ball screw with large pitch for high-speed

machining has increased

'''?????'''

Closed Loop

The performance of the semi-closed loop depends on the accuracy of the ball screw

and it is possible to increase the positional accuracy via pitch compensation and

backlash compensation.However, generally speaking, the amount of backlash can be

varied according to the weight of the workpiece and location and accumulation pitch

error of the ball screw is varied according to the temperature. In addition, because

the length of the ball screw is limited for practical reasons, a rack and pinion driving

system is used in large-scale machine tools. However, the accuracy of the rack is

limited. In this case, the closed loop shown in Fig. 1.11b is applied.

Zatvorene petlje

Performanse polu-zatvorene petlje zavise od tanosti lopta vijka, a tanost je mogue poveati sa pitch

compensation and backlash compensation. Generalno gledano, koliina backlash varira u zavisnosti od teine

radnog komada, a lokacija pitch error zavisi od temperature vijak lopte. pored toga, poto je duina vijak lopte

ograniena iz pratinih razloga, zupasta letva je u velikoj upotrbi. ali zupanicima je tanost ograniena..

Anda mungkin juga menyukai

- Differences Between Stepper Motors and Servo MotorsDokumen1 halamanDifferences Between Stepper Motors and Servo MotorsazharzebBelum ada peringkat

- ServomechanismDokumen4 halamanServomechanismamuthaneceBelum ada peringkat

- Servo Motor Control Using 8051Dokumen11 halamanServo Motor Control Using 8051Rajesh RavindranBelum ada peringkat

- Servo Motor Control Using 8051Dokumen11 halamanServo Motor Control Using 8051Rajesh RavindranBelum ada peringkat

- Ac ServoDokumen38 halamanAc ServoPhạm Hữu KỳBelum ada peringkat

- Servo MotorDokumen31 halamanServo Motoradiamiru25% (4)

- Final PresentationDokumen103 halamanFinal PresentationQasir NawazBelum ada peringkat

- Computer Numeric ControlDokumen48 halamanComputer Numeric Controlabdifatah.nadir.snu.eduBelum ada peringkat

- Lecture 12 - Servo Motor ControlDokumen16 halamanLecture 12 - Servo Motor ControlSaad Murad GorayaBelum ada peringkat

- Fundamentals of Numerical ControlDokumen67 halamanFundamentals of Numerical ControlSanjay MehrishiBelum ada peringkat

- Servo Motor - Types, Construction, Working, Controlling & ApplicationsDokumen7 halamanServo Motor - Types, Construction, Working, Controlling & ApplicationsAHMED YOUSEFBelum ada peringkat

- LAB 2-AngeladaDokumen20 halamanLAB 2-AngeladaAlehamarie AngeladaBelum ada peringkat

- Unit 5Dokumen30 halamanUnit 5kruthikaBelum ada peringkat

- ServomechanismDokumen4 halamanServomechanismJermaine StrachanBelum ada peringkat

- A ServomechanismDokumen3 halamanA ServomechanismChaitanya Kumar GBelum ada peringkat

- Servo Motors Types and ApplicationsDokumen22 halamanServo Motors Types and ApplicationsJavierBelum ada peringkat

- Basics of Servo System and SimulationDokumen45 halamanBasics of Servo System and Simulationgk_gbu100% (1)

- Computer Numeric Control: Prof. J. Ramkumar Department of Mechanical Engineering IIT KanpurDokumen48 halamanComputer Numeric Control: Prof. J. Ramkumar Department of Mechanical Engineering IIT KanpurHassnain MohdBelum ada peringkat

- Servo MotorsDokumen27 halamanServo Motorsc_archana100% (1)

- Servo TurorialDokumen38 halamanServo TurorialJamesBelum ada peringkat

- Computer Numeric Control: Prof. J. Ramkumar Department of Mechanical Engineering IIT KanpurDokumen48 halamanComputer Numeric Control: Prof. J. Ramkumar Department of Mechanical Engineering IIT KanpurAjay VermaBelum ada peringkat

- A Brief Guide To ServosDokumen7 halamanA Brief Guide To ServosRodrigo OrtizBelum ada peringkat

- 8150100273t2 PDFDokumen34 halaman8150100273t2 PDFAnonymous 6sZbadO2100% (2)

- Vibration Monitoring SystemDokumen28 halamanVibration Monitoring SystemAmit Kumar100% (1)

- Servo Motor - Servo Mechanism - Theory and Working PrincipleDokumen6 halamanServo Motor - Servo Mechanism - Theory and Working PrincipleBrahmanand SinghBelum ada peringkat

- Experiment No. 02: DR D Y Patil School of Engineering & TechnologyDokumen3 halamanExperiment No. 02: DR D Y Patil School of Engineering & Technologypradnya sadigaleBelum ada peringkat

- Experiment No. 02: DR D Y Patil School of Engineering & TechnologyDokumen3 halamanExperiment No. 02: DR D Y Patil School of Engineering & Technologypradnya sadigaleBelum ada peringkat

- CNC MachinesDokumen52 halamanCNC Machinespranav sharmaBelum ada peringkat

- Torque SensorDokumen6 halamanTorque SensorBayu Ari MurtiBelum ada peringkat

- Servo Tuning TutorialDokumen38 halamanServo Tuning TutorialpranavBelum ada peringkat

- Mechatronics Lab Assignment: Servo MotorsDokumen3 halamanMechatronics Lab Assignment: Servo MotorsNavendu GuptaBelum ada peringkat

- Instituto Tecnologico de Tlalnepantla: Manufactura AvanzadaDokumen55 halamanInstituto Tecnologico de Tlalnepantla: Manufactura AvanzadaElizabeth HernandezBelum ada peringkat

- Stepper Motor ReportDokumen19 halamanStepper Motor ReportIan Bagunas100% (2)

- Objective: Theory:: Indian Institute of Information Technology, Design & Manufacturing, Jabalpur (M.P.)Dokumen3 halamanObjective: Theory:: Indian Institute of Information Technology, Design & Manufacturing, Jabalpur (M.P.)Ansh NarulaBelum ada peringkat

- Operational Torque Measurement in Picking StorageDokumen6 halamanOperational Torque Measurement in Picking StorageKHADIJABelum ada peringkat

- Servo MotorDokumen4 halamanServo MotorWasil BabarBelum ada peringkat

- Penggerak Servo Untuk CCTVDokumen5 halamanPenggerak Servo Untuk CCTVDoniBelum ada peringkat

- The Mcu and Other Components of The NCDokumen7 halamanThe Mcu and Other Components of The NCKavuri PhaniBelum ada peringkat

- Lab 1Dokumen19 halamanLab 1dasdasdBelum ada peringkat

- Introduction Robot Drive SystemsDokumen17 halamanIntroduction Robot Drive SystemsTemesgen100% (2)

- Stepper MotorDokumen25 halamanStepper Motorhemamanikumar100% (1)

- 05 - Electro - Hydraulic ControllerDokumen7 halaman05 - Electro - Hydraulic Controllerwildhoney1979Belum ada peringkat

- Servo Motors Types and ApplicationsDokumen22 halamanServo Motors Types and ApplicationsLakshman ReddyBelum ada peringkat

- Servo MotorDokumen21 halamanServo MotorsafvanshaikhBelum ada peringkat

- A Simple Algorithm For Microstepping A Bipolar Stepper MotorDokumen10 halamanA Simple Algorithm For Microstepping A Bipolar Stepper Motorcrescent moon knightBelum ada peringkat

- Control of DC Motor Using Different Control StrategiesDari EverandControl of DC Motor Using Different Control StrategiesBelum ada peringkat

- Session02 - MET437-Introduction To Servo Systems (Motion Control)Dokumen13 halamanSession02 - MET437-Introduction To Servo Systems (Motion Control)Ahmad A. Al-AteeqiBelum ada peringkat

- Servo Motor ControlDokumen13 halamanServo Motor ControlChirkov Kire100% (1)

- Brushless Servomotor: Presented byDokumen16 halamanBrushless Servomotor: Presented byDev KumarBelum ada peringkat

- ServoDokumen7 halamanServohaaenBelum ada peringkat

- Lec 4Dokumen16 halamanLec 4Shubham SharmaBelum ada peringkat

- Whats A Servo?: (Click On Picture For Larger View)Dokumen8 halamanWhats A Servo?: (Click On Picture For Larger View)Dhana SingarajaBelum ada peringkat

- SAI Hydraulic Motors - Displacement Variation PDFDokumen16 halamanSAI Hydraulic Motors - Displacement Variation PDFbrunosamaeianBelum ada peringkat

- Unit-II: Robot Drive Systems and End EffectorsDokumen81 halamanUnit-II: Robot Drive Systems and End EffectorsSatheesh KumarBelum ada peringkat

- Unit-II Drive SystemDokumen84 halamanUnit-II Drive SystemSatheesh KumarBelum ada peringkat

- 080544R - Stepper Motor and DriversDokumen8 halaman080544R - Stepper Motor and DriversAnuruddha WijerathneBelum ada peringkat

- Lecture 8 Stepper MotorsDokumen7 halamanLecture 8 Stepper MotorsRafi Andanawari Drajat100% (1)

- Servo MotorDokumen41 halamanServo MotorVaibhav Patil100% (1)

- ExcelforEveryoneTheSimplestWaytoEntertheRichWorldoftheCalcSpreadsheetbyFrancescoIannello 1 PDFDokumen42 halamanExcelforEveryoneTheSimplestWaytoEntertheRichWorldoftheCalcSpreadsheetbyFrancescoIannello 1 PDFNajim Ahmed BulbulBelum ada peringkat

- Relaxing PhotoDokumen1 halamanRelaxing Photobhstudent_537083349Belum ada peringkat

- The New FileDokumen1 halamanThe New Filebhstudent_537083349Belum ada peringkat

- Milling End MillDokumen1 halamanMilling End Millbhstudent_537083349Belum ada peringkat

- The New Relaxing PhotoDokumen1 halamanThe New Relaxing Photobhstudent_537083349Belum ada peringkat

- 2015 Widin CatalogueDokumen413 halaman2015 Widin Catalogue*mile*Belum ada peringkat

- Relaxing PlacesDokumen2 halamanRelaxing Placesbhstudent_537083349Belum ada peringkat

- New Image of LifeDokumen1 halamanNew Image of Lifebhstudent_537083349Belum ada peringkat

- New Document AboutDokumen1 halamanNew Document Aboutbhstudent_537083349Belum ada peringkat

- LabVIEW Introduction ThreeHourDokumen50 halamanLabVIEW Introduction ThreeHourbhstudent_537083349Belum ada peringkat

- New E-BooksDokumen2 halamanNew E-Booksbhstudent_537083349Belum ada peringkat

- Sheet Metal K-Factors For Various Combinations of Material Thickness and Bend RadiusDokumen1 halamanSheet Metal K-Factors For Various Combinations of Material Thickness and Bend Radiusbhstudent_537083349Belum ada peringkat

- New ForcesDokumen1 halamanNew Forcesbhstudent_537083349Belum ada peringkat

- Akimulator Sa Mjehurom PDFDokumen8 halamanAkimulator Sa Mjehurom PDFbhstudent_537083349Belum ada peringkat

- Akimulator Sa Mjehurom PDFDokumen8 halamanAkimulator Sa Mjehurom PDFbhstudent_537083349Belum ada peringkat

- Cut List - Bill of Materials: Finish Size Rough Size FeetDokumen1 halamanCut List - Bill of Materials: Finish Size Rough Size Feetbhstudent_537083349Belum ada peringkat

- Syswin3.4 SupplementDokumen1 halamanSyswin3.4 Supplementbhstudent_537083349Belum ada peringkat

- Syswin3.4 SupplementDokumen1 halamanSyswin3.4 Supplementbhstudent_537083349Belum ada peringkat

- 03 Stober Spindelmotoren EZS-EZM Brochure enDokumen4 halaman03 Stober Spindelmotoren EZS-EZM Brochure enbhstudent_537083349Belum ada peringkat

- Akumulator Sa HidrogenomDokumen6 halamanAkumulator Sa Hidrogenombhstudent_537083349Belum ada peringkat

- CNC NotesDokumen21 halamanCNC NotesradhiostrokesBelum ada peringkat

- Akumulatori Sa DiafragmomDokumen6 halamanAkumulatori Sa Diafragmombhstudent_537083349Belum ada peringkat

- Tobul Interim II Catalog 111113v1Dokumen44 halamanTobul Interim II Catalog 111113v1bhstudent_537083349Belum ada peringkat

- CNC NotesDokumen21 halamanCNC NotesradhiostrokesBelum ada peringkat

- Safety Manual 2012Dokumen57 halamanSafety Manual 2012bhstudent_537083349Belum ada peringkat

- Corel Draw - UputstvoDokumen19 halamanCorel Draw - UputstvovladishaBelum ada peringkat

- Campus Map Construction 2015Dokumen1 halamanCampus Map Construction 2015bhstudent_537083349Belum ada peringkat

- CNC NotesDokumen21 halamanCNC NotesradhiostrokesBelum ada peringkat

- Tablica LaplaceDokumen1 halamanTablica Laplacebhstudent_537083349Belum ada peringkat

- Dizziness - Vertigo and HomoeopathyDokumen38 halamanDizziness - Vertigo and HomoeopathyDr. Rajneesh Kumar Sharma MD HomBelum ada peringkat

- Marketing Management 4th Edition Winer Test BankDokumen35 halamanMarketing Management 4th Edition Winer Test Bankapneaocheryzxs3ua100% (24)

- Hot Topic 02 Good Light Magazine 56smDokumen24 halamanHot Topic 02 Good Light Magazine 56smForos IscBelum ada peringkat

- Resumen C37 010 Aplicacion de Breaker Disenados IC Simetrica PDFDokumen9 halamanResumen C37 010 Aplicacion de Breaker Disenados IC Simetrica PDFglendathais100% (1)

- Bhagwati School Strap Report AnalysisDokumen60 halamanBhagwati School Strap Report AnalysisReverse Minded100% (1)

- Hurricanes Grade5Dokumen3 halamanHurricanes Grade5Anonymous m3yrUPBelum ada peringkat

- Prawn ProcessingDokumen21 halamanPrawn ProcessingKrishnaBelum ada peringkat

- 40 RT-flex Control-System Rev01Dokumen68 halaman40 RT-flex Control-System Rev01Mayvon Botelho100% (2)

- Cell Wall Synthesis InhibitorsDokumen6 halamanCell Wall Synthesis InhibitorsRPh Krishna Chandra JagritBelum ada peringkat

- Government of West Bengal:: Tata Motors LTD: Abc 1 1 1 1 NA 0 NA 0Dokumen1 halamanGovernment of West Bengal:: Tata Motors LTD: Abc 1 1 1 1 NA 0 NA 0md taj khanBelum ada peringkat

- Astm 2017-F2059Dokumen5 halamanAstm 2017-F2059laythBelum ada peringkat

- Time Value of Money LectureDokumen54 halamanTime Value of Money LectureRanin, Manilac Melissa SBelum ada peringkat

- Fama Fraternitatis Rosae Crucis PDFDokumen2 halamanFama Fraternitatis Rosae Crucis PDFJudy50% (2)

- Pythagorean Theorem WorksheetDokumen11 halamanPythagorean Theorem WorksheetJames ChanBelum ada peringkat

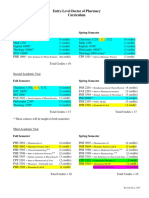

- Pharmd CurriculumDokumen18 halamanPharmd Curriculum5377773Belum ada peringkat

- Banachek UnlimitedDokumen34 halamanBanachek UnlimitedserenaBelum ada peringkat

- Antoine Constants PDFDokumen3 halamanAntoine Constants PDFsofiaBelum ada peringkat

- Armor MagazineDokumen32 halamanArmor Magazine"Rufus"100% (1)

- Yadea User Manual For e Scooter 1546004910Dokumen44 halamanYadea User Manual For e Scooter 1546004910Danthe ThenadBelum ada peringkat

- Sw34 Religion, Secularism and The Environment by NasrDokumen19 halamanSw34 Religion, Secularism and The Environment by Nasrbawah61455Belum ada peringkat

- Book BindingDokumen14 halamanBook Bindingpesticu100% (2)

- (Eng) Zx890lch 5a Ks En316Dokumen13 halaman(Eng) Zx890lch 5a Ks En316MC TAK LEEBelum ada peringkat

- Physics 101Dokumen21 halamanPhysics 101Kuna KunavathiBelum ada peringkat

- Astm A194 2020Dokumen12 halamanAstm A194 2020rolando cuadro blancoBelum ada peringkat

- Stanley B. Alpern - Amazons of Black Sparta - The Women Warriors of Dahomey-New York University Press (2011)Dokumen308 halamanStanley B. Alpern - Amazons of Black Sparta - The Women Warriors of Dahomey-New York University Press (2011)georgemultiplusBelum ada peringkat

- Full Download Short Term Financial Management 3rd Edition Maness Test BankDokumen35 halamanFull Download Short Term Financial Management 3rd Edition Maness Test Bankcimanfavoriw100% (31)

- Inform LetterDokumen2 halamanInform LetterMc Suan75% (4)

- Sample Dilapidation ReportDokumen8 halamanSample Dilapidation ReportczarusBelum ada peringkat

- Final Thesis - Aris PotliopoulosDokumen94 halamanFinal Thesis - Aris PotliopoulosCristinaBelum ada peringkat

- Poems Prescribed For 2012-2014 English B CSEC ExamsDokumen24 halamanPoems Prescribed For 2012-2014 English B CSEC ExamsJorge Martinez Sr.100% (2)