Jsa Sample PDF

Diunggah oleh

Kaoru AmaneDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Jsa Sample PDF

Diunggah oleh

Kaoru AmaneHak Cipta:

Format Tersedia

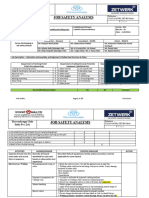

JOB SAFETY ANALYSIS

JSA No. JSABuilder Sample Library - 4 (short)

Job/Operation Title: Date:

Electric Arc Welding

Department/Division/Section: Analysis Developed By:

Facility Maintenance Name Person 2

Location(s): Analysis Reviewed By:

Welding Shop Name Person 3

Person(s) Performing This Job: Supervisor:

Name Person 1 Name Person 1

Name Person 2

Job Start Date: Duration:

2 hours

Task/Step Potential Hazards Recommended Safe Job Procedures

1. Sign in and inspect (Step 1) - Welding/Cutting/Burning - Before setting up the welding shop, visit the Admin desk

Equipment to sign in.

- Wires, cables, hoses - Inspect arc welding equipment cables and connections;

look for loose connections, frayed insulation on electrode

holders and cables (see photo), make sure electrical

cables are dry (complete safety checklist).

Step 1 Image:

2. Steps 2 - 6 - x--- NA ---x Steps 2 - 6 have been removed to keep this sample to a

reasonable length.

3. Perform the weld (Step 7) - Arc rays - User proper PPE (see photo).

- Combustible materials - Follow manufacturer recommended procedures, lessons

- Electrical equipment learned and experience.

(transformers, switching gear, - If possible, position shelf so that head is not in fumes

breakers, high voltage lines) while welding.

- Ignitable materials and liquids - If possible use sub arc process to minmimize light and

- Infrared (IR) fumes, and/or minimize the production of welding fumes

- Light (optical) radiation (i.e. by using the lowest acceptable amperage and holding the

JSA No: JSABuilder Sample Library - 4 (short) | Electric Arc Welding 1 of 4

welding operations, etc.). electrode perpendicular and as close to the

- Repetitive motion or other work surface and possible.

ergonomic concerns - Keep electrode moving. Tack as appropriate for project

- Rolling or pinching objects and metal type.

- Sharp objects - Finish the weld.

- Slag splatter

- Sparks

- Ultraviolet (UV)

- WELDING FUMES AND GASES

- Welding/Cutting/Burning

Equipment

- Wires, cables, hoses

Step 3 Image:

4. Steps 8 - 9 - x--- NA ---x Steps 8 - 9 have been removed to keep this sample to a

reasonable length.

5. Remove excess slag from - Electrical equipment When welded material has cooled, use chipping hammer

welded material (Step 10) (transformers, switching gear, or grinder to remove excess slag from weld (see photo).

breakers, high voltage lines) Secure material to workbench with clamps as necessary,

- Hand tools before chipping. FACE SHIELD IS REQUIRED FOR THIS

- metal chips ACTIVITY TO PROTECT FROM FLYING DEBRIS. Be

- Repetitive motion or other alert to fingers and pinch points and struck-by potential.

ergonomic concerns

- Sharp objects

- Sparks

- Wires, cables, hoses

Step 5 Image:

JSA No: JSABuilder Sample Library - 4 (short) | Electric Arc Welding 2 of 4

6. Steps 11 - 12 - x--- NA ---x Steps 11 - 12 have been removed to keep this sample to

a reasonable length.

POTENTIAL HAZARDS OF THIS JOB

Physical Hazards Consequences

Combustible materials

Awkward or static position

Electrical equipment (transformers, switching gear,

Cuts and abrasions

breakers, high voltage lines)

Electrocution or shock

Hand tools Excessive lifting, twisting, pushing, pulling, reaching, or bending

hot electrodes Exposure (inhaling, swallowing, or absorbing) to harmful levels of gases,

Ignitable materials and liquids vapors, aerosols, liquids, fumes, or dust)

Exposure to excessive light (welding)

Inadequate lighting Falling ( < 6 feet), tripping, or slipping

Light (optical) radiation (i.e. welding operations, Injury caused by slip, trip or fall

etc.). Pinches

metal chips Slag splatter

Sparks

Poor Housekeeping

Struck by falling or flying object

Repetitive motion or other ergonomic concerns Struck by uncontrolled pressure release

Rolling or pinching objects Thermal burns

Sharp objects

Slag splatter

Sparks

Welding/Cutting/Burning Equipment

Wires, cables, hoses

x--- NA ---x

Chemical Hazards Description/Health Hazards

WELDING FUMES AND GASES Welding smoke is a mixture of very fine particles (fumes) and gases. Many of

() the substances in welding smoke, such as chromium, nickel, arsenic,

asbestos, manganese, silica, beryllium, cadmium, nitrogen oxides,phosgene,

acrolein, fluorine compounds, carbon monoxide, cobalt, copper, lead, ozone,

selenium, and zinc can be extremely toxic.

Generally, welding fumes and gases come from:

- base material being welded or the fi ller material that is used;

JSA No: JSABuilder Sample Library - 4 (short) | Electric Arc Welding 3 of 4

- coatings and paints on the metal being welded, or coatings covering the

electrode;

- shielding gases supplied from cylinders;

The health effects of welding exposures are difficult to list, because the

fumes may contain so many different substances that are known to be

harmful (depending on the factors listed above). The individual components

of welding smoke can affect just about any part

of the body, including the lungs, heart, kidneys, and central nervous system.

(Welding Hazard Safety Program, TX Dept of Insurance)

Radiological Hazards Description/Health Hazards

Arc rays Effect on the Eyes - Welder's flash (feeling of sand or grit in eyes, blurred

vision, intense pain, burning, and headache)

Infrared (IR)

Effects on the Eyes - Cataracts

Ultraviolet (UV) Effects on the Skin - Burns

Visible light momentary blinding

HAZARD CONTROL MEASURES USED FOR THIS JOB

Administrative Controls: Required Training:

Certified operators Ergonomics

Competent person Fire protection (extinguishers)

Drug and alcohol policy General Safety

Emergency procedures Hazard Communication (HAZCOM)

Equipment maintenance and servicing manual Orientation (site or job)

Ergonomic procedure Personal protective equipment (PPE)

Hot work procedure Respiratory protection

Housekeeping practices Welding, cutting, and brazing

Inspections (ongoing) work areas, equipment, tools,

etc.

Inspections (pre-job) - work areas, equipment, tools,

etc.

Material Safety Data Sheets (MSDS)

Monitoring (hazardous atmospheres)

Operating instructions (equipment)

Operating procedures (process)

Radiological safety program

Safety checklists (use to document inspections)

Engineering Controls: Required PPE:

Ventilation and exhausting. Boots - compatible for OSHA electrical protection requirements

Clothing - fire resistant

Clothing - long pants

Clothing - long sleeve shirt

Fire resistant gauntlet glove

Safety glasses: see manual for lens shade requirements for welder & spotter

Side shield

Welding hood

Welding jacket & apron

Required Permit(s): Other Information:

No permit required - verify no LOTO is in progress A 2A20B:C fire extinguisher must be readily available and within arm's reach

on chosen equipment at all times. Fire alarm operability must be confirmed prior to start of work.

Welding shop - space reservation (see Admin desk Follow manufacturer instructions to test fire alarm. Also, follow all

for list of welding operations & times) manufacturer instructions for operation of the electic arc welder. STOP

WORK immediately if an unsafe or potentially unsafe condition exists.

JSABuilder chemical Description/Health Hazards is from the CAMEO database maintained by the U.S. EPA, NOAA, and the U.S. Coast Guard

(www.cameochemicals.noaa.gov). The creator of this JSA is responsible for any edits to this information.

This sample created at www.JSABuilder.com.

JSA No: JSABuilder Sample Library - 4 (short) | Electric Arc Welding 4 of 4

Anda mungkin juga menyukai

- Risk AssessmentDokumen13 halamanRisk AssessmentNauman Qureshi60% (5)

- John Deere 322, 330, 332, 430 Manual PDFDokumen566 halamanJohn Deere 322, 330, 332, 430 Manual PDFPaul Bronco50% (2)

- Aha Welding PDFDokumen4 halamanAha Welding PDFcrnkarlos100% (1)

- Hard Hat, Safety Glasses, Safety Boots Compulsory: PowerDokumen9 halamanHard Hat, Safety Glasses, Safety Boots Compulsory: PowerEbeneshwar Anthony71% (7)

- Samsung MM-C430D EDCDokumen60 halamanSamsung MM-C430D EDCbaris999100% (2)

- JSA. Electrical PullingDokumen2 halamanJSA. Electrical PullingSajid Hussain100% (1)

- Jsa - Sample Hot Tapping PDFDokumen4 halamanJsa - Sample Hot Tapping PDFrongohcoleman100% (1)

- JHA Arc WeldingDokumen2 halamanJHA Arc WeldingechaBelum ada peringkat

- Atlas Copco - QAS 80 (Brugervejledning ENG) PDFDokumen64 halamanAtlas Copco - QAS 80 (Brugervejledning ENG) PDFsustrasBelum ada peringkat

- Activity Hazard AnalysisDokumen4 halamanActivity Hazard AnalysisGerrard Singh100% (1)

- Jsabuilder: Job Safety AnalysisDokumen5 halamanJsabuilder: Job Safety Analysisandika eka putraBelum ada peringkat

- Civil (Barbending Work)Dokumen3 halamanCivil (Barbending Work)pavanBelum ada peringkat

- JSA-Fabrication, AssemblyDokumen19 halamanJSA-Fabrication, AssemblyAshfaq Husain AnsariBelum ada peringkat

- Rov Electronics - Laboratory WorkbookDokumen20 halamanRov Electronics - Laboratory WorkbookXyriz Paz EstrelladoBelum ada peringkat

- Sho AssignmentDokumen10 halamanSho AssignmentnourBelum ada peringkat

- Exter Lighting SystemsDokumen1 halamanExter Lighting SystemsomarqasimBelum ada peringkat

- Method of Statement 230KV TerminationsDokumen7 halamanMethod of Statement 230KV Terminationsjmohamed.ukkasBelum ada peringkat

- Ssds ESD Control Training: Jamil Fares (Jef283), 09/03/2017Dokumen24 halamanSsds ESD Control Training: Jamil Fares (Jef283), 09/03/2017huynh thi y viBelum ada peringkat

- Electronics (1St Quarter) : Grade 10 - TLE-ELXDokumen8 halamanElectronics (1St Quarter) : Grade 10 - TLE-ELXSawit YshieharaBelum ada peringkat

- Job Safety and Environmental Analysis WorksheetDokumen2 halamanJob Safety and Environmental Analysis WorksheetCherry Betonio100% (1)

- Electrical Safety PresentDokumen193 halamanElectrical Safety PresentSHIJAD SRAJUBelum ada peringkat

- LK 3 - Pemeliharaan InstrumenDokumen5 halamanLK 3 - Pemeliharaan Instrumenchoiriyatul munawarohBelum ada peringkat

- JSA New Line Installation 2012Dokumen2 halamanJSA New Line Installation 2012Deshbandhu Aman PandeyBelum ada peringkat

- Samsung MM-D430 PDFDokumen43 halamanSamsung MM-D430 PDFboroda2410100% (1)

- L&T PresentationDokumen124 halamanL&T Presentationrajib ranjan panda100% (1)

- Handy Plasma 125: Plasma Arc Cutting Package - P/N 37884 115V 60HzDokumen24 halamanHandy Plasma 125: Plasma Arc Cutting Package - P/N 37884 115V 60Hzbouriahi hassaneBelum ada peringkat

- Science & Technology For New Dod Capabilities:: Interdisciplinary Research Examples in Optical Science at NRLDokumen41 halamanScience & Technology For New Dod Capabilities:: Interdisciplinary Research Examples in Optical Science at NRLjcsquirlyBelum ada peringkat

- Robotic Interfase Digipulse ESABDokumen28 halamanRobotic Interfase Digipulse ESABJohan ZraghozBelum ada peringkat

- Electrical Safety PPT (Tokesh Kumar)Dokumen27 halamanElectrical Safety PPT (Tokesh Kumar)vineet juglanBelum ada peringkat

- Samsung mm-d530dDokumen43 halamanSamsung mm-d530dPedroBelum ada peringkat

- K To 12 Basic Education Curriculum: Technology and Livelihood EducationDokumen13 halamanK To 12 Basic Education Curriculum: Technology and Livelihood EducationMARFE IMPASTABelum ada peringkat

- Systems of Safety Applied To Focus Four Hazards: Usdol-Osha Susan Harwood Grant SHT21005SH0Dokumen72 halamanSystems of Safety Applied To Focus Four Hazards: Usdol-Osha Susan Harwood Grant SHT21005SH0Mohamad TaufiqBelum ada peringkat

- Non - Destructive TestDokumen22 halamanNon - Destructive TestAlsonChinBelum ada peringkat

- Circuit BreakersDokumen79 halamanCircuit BreakersSun TzuBelum ada peringkat

- Peb New Jha - Hot WorkDokumen2 halamanPeb New Jha - Hot WorkChe Wan ErliyasBelum ada peringkat

- Estudio 200lDokumen354 halamanEstudio 200lChamilka NuwandiBelum ada peringkat

- Test 2 UitmDokumen4 halamanTest 2 UitmMohd Khairul FahmiBelum ada peringkat

- Esd EmcDokumen44 halamanEsd EmccoaxinBelum ada peringkat

- Arc Flash Awarenedss Training Perunding Shanu 2021Dokumen127 halamanArc Flash Awarenedss Training Perunding Shanu 2021Rajasegaran ThevarajBelum ada peringkat

- WeldingDokumen2 halamanWeldingPrakash PalaiBelum ada peringkat

- Elec. PresnDokumen50 halamanElec. Presnprovidence bizBelum ada peringkat

- NP540U3CDokumen87 halamanNP540U3CandibdgBelum ada peringkat

- Arc FlashDokumen57 halamanArc FlashFrancisco AndradeBelum ada peringkat

- Hazard Identification and Risk Assessment FormDokumen8 halamanHazard Identification and Risk Assessment FormMOHAMEDBelum ada peringkat

- Job Safety Analysis: Step 1: Job Safety Hazard & PPE Checklist: (General Hazards Associated With The Job)Dokumen7 halamanJob Safety Analysis: Step 1: Job Safety Hazard & PPE Checklist: (General Hazards Associated With The Job)Ranadheer Reddy KanthalaBelum ada peringkat

- Electrical SafetyDokumen21 halamanElectrical SafetyMicron Mega100% (1)

- JVC MX-S6MD PDFDokumen103 halamanJVC MX-S6MD PDFboroda2410Belum ada peringkat

- Panasonic TC P42S1Dokumen115 halamanPanasonic TC P42S1Vicente EsquerreBelum ada peringkat

- Glow Wire Test BS EN 60695 - 2 - 10Dokumen21 halamanGlow Wire Test BS EN 60695 - 2 - 10Aritra DasguptaBelum ada peringkat

- NDT Schedule Time TableDokumen4 halamanNDT Schedule Time Tableabdullaziz.albazBelum ada peringkat

- Risk AssessmentDokumen8 halamanRisk AssessmentEkoms GamingBelum ada peringkat

- TC-42X1 Part 1Dokumen50 halamanTC-42X1 Part 1Pedro SandovalBelum ada peringkat

- GRADE-10 TLE Electronic Products Assembly and Servicing Week OneDokumen15 halamanGRADE-10 TLE Electronic Products Assembly and Servicing Week OneSer Takeshi100% (1)

- LG LH t552sbDokumen59 halamanLG LH t552sbJose RosemarBelum ada peringkat

- Dismantling WorksDokumen1 halamanDismantling WorksKoneti JanardhanaraoBelum ada peringkat

- JSA Pipe Installation 2012Dokumen2 halamanJSA Pipe Installation 2012Deshbandhu Aman Pandey100% (2)

- Safety Concerns With New PV Polymeric Materials: Tim Zgonena Underwriters Laboratories Inc (UL) February 19, 2010Dokumen21 halamanSafety Concerns With New PV Polymeric Materials: Tim Zgonena Underwriters Laboratories Inc (UL) February 19, 2010azielnikBelum ada peringkat

- Panasonic Sa Ak28Dokumen78 halamanPanasonic Sa Ak28sanava9100% (1)

- Plazma Service PDFDokumen157 halamanPlazma Service PDFMark ShanksBelum ada peringkat

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsDari EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsBelum ada peringkat

- Week-1-PBM5143 Formation Evaluation Jan2021-IntroductionDokumen8 halamanWeek-1-PBM5143 Formation Evaluation Jan2021-IntroductionKaoru AmaneBelum ada peringkat

- Soft Drink Product Development The Search For Function Flavour and HealthDokumen6 halamanSoft Drink Product Development The Search For Function Flavour and HealthKaoru AmaneBelum ada peringkat

- Week-01-Tutorials-PBM5144 and PAM5143 Formation Evaluation - Jan2021-SemesterDokumen43 halamanWeek-01-Tutorials-PBM5144 and PAM5143 Formation Evaluation - Jan2021-SemesterKaoru AmaneBelum ada peringkat

- Energies: Method of Real-Time Wellbore Surface Reconstruction Based On Spiral ContourDokumen19 halamanEnergies: Method of Real-Time Wellbore Surface Reconstruction Based On Spiral ContourKaoru AmaneBelum ada peringkat

- The BBC's Management of Its Digital Media Initiative: House of Commons Committee of Public AccountsDokumen44 halamanThe BBC's Management of Its Digital Media Initiative: House of Commons Committee of Public AccountsKaoru AmaneBelum ada peringkat

- Project Management Methodologies and Bodies of Knowledge in Contemporary Global ProjectsDokumen16 halamanProject Management Methodologies and Bodies of Knowledge in Contemporary Global ProjectsKaoru AmaneBelum ada peringkat

- Image, Information and Changing Work Practices: The London School of Economics and Political ScienceDokumen303 halamanImage, Information and Changing Work Practices: The London School of Economics and Political ScienceKaoru AmaneBelum ada peringkat

- 450d Officer Agreement and Release FormDokumen1 halaman450d Officer Agreement and Release FormKaoru AmaneBelum ada peringkat

- Week-02-Tuesday-02March2021-PBM5144 and PAM5143 - Formation Evaluation-Acoustic and NMR Logging ToolsDokumen50 halamanWeek-02-Tuesday-02March2021-PBM5144 and PAM5143 - Formation Evaluation-Acoustic and NMR Logging ToolsKaoru AmaneBelum ada peringkat

- Steady State FlowDokumen111 halamanSteady State FlowKaoru AmaneBelum ada peringkat

- Tutorial Mbe 2010 JulDokumen3 halamanTutorial Mbe 2010 JulKaoru AmaneBelum ada peringkat

- We Are Intechopen, The First Native Scientific Publisher of Open Access BooksDokumen21 halamanWe Are Intechopen, The First Native Scientific Publisher of Open Access BooksKaoru AmaneBelum ada peringkat

- Test 2-20202021-1-SPACE KLDokumen4 halamanTest 2-20202021-1-SPACE KLKaoru AmaneBelum ada peringkat

- SSCE2393 FinalNumerical Space1Dokumen9 halamanSSCE2393 FinalNumerical Space1Kaoru AmaneBelum ada peringkat

- 450c District Leader Nominating FormDokumen1 halaman450c District Leader Nominating FormKaoru AmaneBelum ada peringkat

- 1189 Speech Contestant Profile-FfDokumen1 halaman1189 Speech Contestant Profile-FfKaoru AmaneBelum ada peringkat

- Water SupplyDokumen5 halamanWater SupplyKaoru AmaneBelum ada peringkat

- Integrated Operations in Oil and Gas DrillingDokumen25 halamanIntegrated Operations in Oil and Gas DrillingKaoru AmaneBelum ada peringkat

- Average 0.18: BC 1 / KXDokumen6 halamanAverage 0.18: BC 1 / KXKaoru AmaneBelum ada peringkat

- MSDS - Acrylic HomopolymerDokumen3 halamanMSDS - Acrylic HomopolymerBeh Jyh JiunnBelum ada peringkat

- Navigating 2021 NFPA 70E and How To Stay CompliantDokumen38 halamanNavigating 2021 NFPA 70E and How To Stay CompliantahmaddanilrizalBelum ada peringkat

- Lesson VIII Occupational Health and Safety PracticesDokumen42 halamanLesson VIII Occupational Health and Safety PracticesRoss Armyr GeliBelum ada peringkat

- Manuales de Servicio Serie FB-VIIIDokumen540 halamanManuales de Servicio Serie FB-VIIIJose Roca100% (1)

- PC290 M Ueam004000 PC290LC NLC 7 0412Dokumen321 halamanPC290 M Ueam004000 PC290LC NLC 7 0412ado_22100% (1)

- Revised - Roads Works Daily Permit FormatDokumen1 halamanRevised - Roads Works Daily Permit Formatsalauddin0mohammedBelum ada peringkat

- 15 18 047 1M - Notice - 12M26.2 - ENDokumen128 halaman15 18 047 1M - Notice - 12M26.2 - ENsxturboBelum ada peringkat

- 301 Dr. Fixit Pidicrete URPDokumen4 halaman301 Dr. Fixit Pidicrete URPAlpesh ShahBelum ada peringkat

- 004-Civil - MS Construction of Temporary Roads PDFDokumen17 halaman004-Civil - MS Construction of Temporary Roads PDFKöksal Patan100% (2)

- Method Statement For Panel InstallationDokumen8 halamanMethod Statement For Panel InstallationveksBelum ada peringkat

- Rigging Equipment Maintenance PDFDokumen566 halamanRigging Equipment Maintenance PDFAfzaalUmair100% (1)

- Mega Check Developer Msds English VerDokumen9 halamanMega Check Developer Msds English Vermaxpan max100% (1)

- Block Work and PlasteringDokumen7 halamanBlock Work and Plasteringmohammed sohailBelum ada peringkat

- Elmhurst Teacher's Council's Filing With The Illinois Educational Labor Relations BoardDokumen27 halamanElmhurst Teacher's Council's Filing With The Illinois Educational Labor Relations BoardDavid GiulianiBelum ada peringkat

- MVML/TPM/3S Audit Sheet-Shop Floor/f/03: Rev. No.: 01 Rev. Date: 12th Nov'2014Dokumen5 halamanMVML/TPM/3S Audit Sheet-Shop Floor/f/03: Rev. No.: 01 Rev. Date: 12th Nov'2014BALACHANDAR SBelum ada peringkat

- MM 1 - Grammar Test Unit 10Dokumen12 halamanMM 1 - Grammar Test Unit 10Jose Antonio Mattaz AsturizagaBelum ada peringkat

- TR HEO (On Highway Dump Truck Rigid)Dokumen74 halamanTR HEO (On Highway Dump Truck Rigid)Angee PotBelum ada peringkat

- MSDS Phenol RedDokumen4 halamanMSDS Phenol RedAulia ArlynBelum ada peringkat

- AFTEK - Penapatch Fairing Coat Mortar SDS 2009Dokumen4 halamanAFTEK - Penapatch Fairing Coat Mortar SDS 2009Aria NickbakhtBelum ada peringkat

- Tarea 1 - Turco 4181L (1546533)Dokumen3 halamanTarea 1 - Turco 4181L (1546533)Abraham GamerosBelum ada peringkat

- JHA-011 (Power Brush & Touch-Up Painting Activities 1)Dokumen1 halamanJHA-011 (Power Brush & Touch-Up Painting Activities 1)shaiful annuar50% (2)

- INSPEXX - 200 - SDS IngDokumen13 halamanINSPEXX - 200 - SDS IngcalidadplantaBelum ada peringkat

- SDS Sullair Sullube US enDokumen10 halamanSDS Sullair Sullube US enAnonymous BsJNyP5ivBelum ada peringkat

- Sample-Risk Assessment & Safe Work Method StatementDokumen4 halamanSample-Risk Assessment & Safe Work Method StatementioanchiBelum ada peringkat

- Risk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityDokumen2 halamanRisk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityJhundel FactorBelum ada peringkat

- Netsure™ 7100 Series - 48 VDC Power System: Installation ManualDokumen220 halamanNetsure™ 7100 Series - 48 VDC Power System: Installation ManualDebabrata Saha100% (1)

- Safety Officer's Monthly Inspection Report (Ocean)Dokumen1 halamanSafety Officer's Monthly Inspection Report (Ocean)HirBelum ada peringkat