Aalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338

Diunggah oleh

minhyen88Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Aalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338

Diunggah oleh

minhyen88Hak Cipta:

Format Tersedia

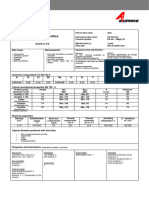

Aluminium Alloy

6082 - T6 Extrusions

SPECIFICATIONS ALLOY DESIGNATIONS

Aluminium alloy 6082 also corresponds to the following

Commercial 6082

standard designations and specifications but may not

EN 6082 be a direct equivalent:

AA6082

HE30

Aluminium alloy 6082 is a medium strength alloy with DIN 3.2315

excellent corrosion resistance. It has the highest EN AW-6082

strength of the 6000 series alloys. Alloy 6082 is known ISO: Al Si1MgMn

as a structural alloy. In plate form, 6082 is the alloy A96082

most commonly used for machining. As a relatively

new alloy, the higher strength of 6082 has seen it

replace 6061 in many applications. The addition of a

TEMPER TYPES

large amount of manganese controls the grain The most common tempers for 6082 aluminium are:

structure which in turn results in a stronger alloy. T6 - Solution heat treated and artificially aged

It is difficult to produce thin walled, complicated

extrusion shapes in alloy 6082. The extruded surface O - Soft

finish is not as smooth as other similar strength alloys T4 - Solution heat treated and naturaly aged to a

in the 6000 series.

substantially stable condition

In the T6 and T651 temper, alloy 6082 machines well

and produces tight coils of swarf when chip breakers T651 - Solution heat treated, stress relieved by

are used. stretching then artificially aged

Applications

6082 is typically used in: SUPPLIED FORMS

~ Highly stressed applications Alloy 6082 is typically supplied as Channel, Angle, Tee,

~ Trusses Square bar, Square box section, Rectangular box

~ Bridges section, Flat bar and Tube.

~ Cranes

Extrusions

~ Transport applications

~ Ore skips Bar

~ Beer barrels Tube

~ Milk churns

GENERIC PHYSICAL PROPERTIES

CHEMICAL COMPOSITION

Property Value

BS EN 573-3:2009

Alloy 6082 Density 2.70 g/cm

Element % Present Melting Point 555 C

Silicon (Si) 0.70 - 1.30 Thermal Expansion 24 x10-6 /K

Magnesium (Mg) 0.60 - 1.20 Modulus of Elasticity 70 GPa

Manganese (Mn) 0.40 - 1.00 Thermal Conductivity 180 W/m.K

Iron (Fe) 0.0 - 0.50 Electrical Resistivity 0.038 x10-6 .m

Chromium (Cr) 0.0 - 0.25

Zinc (Zn) 0.0 - 0.20

Others (Total) 0.0 - 0.15

Titanium (Ti) 0.0 - 0.10

Copper (Cu) 0.0 - 0.10

Other (Each) 0.0 - 0.05

Aluminium (Al) Balance

[1 OF 3] CONTINUED

Aalco is a registered trademark of Aalco Metals Ltd

Copyright: Aalco Metals Ltd, 25 High Street, Cobham, Surrey KT11 3DH

Aluminium Alloy

6082 - T6 Extrusions

MECHANICAL PROPERTIES BS EN 755-2:2008

Tube

Up to 5mm Wall Thickness

BS EN 755-2:2008

Rod & Bar

Property Value

Up to 20mm Dia. & A/F

Proof Stress 250 Min MPa

Property Value

Tensile Strength 290 Min MPa

Proof Stress 250 Min MPa

Elongation A50 mm 6 Min %

Tensile Strength 295 Min MPa

Hardness Brinell 95 HB

Elongation A50 mm 6 Min %

Elongation A 8 Min %

Hardness Brinell 95 HB

Elongation A 8 Min % Properties above are for material in the T6 condition

Properties above are for material in the T6 condition

BS EN 755-2:2008

Tube

5mm to 25mm Wall Thickness

BS EN 755-2:2008

Rod & Bar

Property Value

20mm to 150mm Dia. & A/F

Proof Stress 260 Min MPa

Property Value

Tensile Strength 310 Min MPa

Proof Stress 260 Min MPa

Elongation A50 mm 8 Min %

Tensile Strength 310 Min MPa

Hardness Brinell 95 HB

Hardness Brinell 95 HB

Elongation A 10 Min %

Elongation A 8 Min %

Properties above are for material in the T6 condition

Properties above are for material in the T6 condition

BS EN 755-2:2008

BS EN 755-2:2008

Open & Hollow Profile

Bar

Up To 5mm Wall Thickness

150mm to 200mm Dia. & A/F

Property Value

Property Value

Proof Stress 250 Min MPa

Proof Stress 240 Min MPa

Tensile Strength 290 Min MPa

Tensile Strength 280 Min MPa

Elongation A50 mm 6 Min %

Hardness Brinell 95 HB

Hardness Brinell 95 HB

Elongation A 6 Min %

Elongation A 8 Min %

Properties above are for material in the T6 condition

Properties above are for material in the T6 condition

BS EN 755-2:2008

Bar BS EN 755-2:2008

200mm to 250mm Dia. & A/F Open & Hollow Profile

5mm to 25mm Wall Thickness

Property Value

Property Value

Proof Stress 200 Min MPa

Proof Stress 260 Min MPa

Tensile Strength 270 Min MPa

Tensile Strength 310 Min MPa

Hardness Brinell 95 HB

Elongation A50 mm 8 Min %

Elongation A 6 Min %

Hardness Brinell 95 HB

Properties above are for material in the T6 condition

Elongation A 10 Min %

Properties above are for material in the T6 condition

[2 OF 3] CONTINUED

Aalco is a registered trademark of Aalco Metals Ltd

Copyright: Aalco Metals Ltd, 25 High Street, Cobham, Surrey KT11 3DH

Aluminium Alloy

6082 - T6 Extrusions

WELDABILITY

6082 has very good weldability but strength is lowered

in the weld zone. When welded to itself, alloy 4043

wire is recommended. If welding 6082 to 7005, then

the wire used should be alloy 5356.

Weldability Gas: Good

Weldability Arc: Good

Weldability Resistance: Good

Brazability: Good

Solderability: Good

FABRICATION

Workability - Cold: Good

Machinability: Good

CONTACT

Address: Please make contact directly with your local

service centre, which can be found via the

Locations page of our web site

Web: www.aalco.co.uk

REVISION HISTORY

Datasheet Updated 11 January 2016

DISCLAIMER

This Data is indicative only and as such is not to be relied upon in place of

the full specification. In particular, mechanical property requirements vary

widely with temper, product and product dimensions. All information is

based on our present knowledge and is given in good faith. No liability will

be accepted by the Company in respect of any action taken by any third

party in reliance thereon.

Please note that the 'Datasheet Update' date shown above is no guarantee

of accuracy or whether the datasheet is up to date.

The information provided in this datasheet has been drawn from various

recognised sources, including EN Standards, recognised industry references

(printed & online) and manufacturers data. No guarantee is given that the

information is from the latest issue of those sources or about the accuracy of

those sources.

Material supplied by the Company may vary significantly from this data, but

will conform to all relevant and applicable standards.

As the products detailed may be used for a wide variety of purposes and as

the Company has no control over their use; the Company specifically

excludes all conditions or warranties expressed or implied by statute or

otherwise as to dimensions, properties and/or fitness for any particular

purpose, whether expressed or implied.

Advice given by the Company to any third party is given for that partys

assistance only and without liability on the part of the Company. All

transactions are subject to the Companys current Conditions of Sale. The

extent of the Companys liabilities to any customer is clearly set out in those

Conditions; a copy of which is available on request.

[3 OF 3]

Aalco is a registered trademark of Aalco Metals Ltd

Copyright: Aalco Metals Ltd, 25 High Street, Cobham, Surrey KT11 3DH

Anda mungkin juga menyukai

- Aalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Dokumen3 halamanAalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Karan NanwaniBelum ada peringkat

- Aluminium Alloy - 6082 - T6 T651 Plate: Specifications Chemical CompositionDokumen3 halamanAluminium Alloy - 6082 - T6 T651 Plate: Specifications Chemical Compositionhardik033Belum ada peringkat

- Aluminium-Alloy-6082-T6 or T651Dokumen2 halamanAluminium-Alloy-6082-T6 or T651Marcelo Noé CorsiBelum ada peringkat

- Aluminium Alloy 6082 - T6 T651 PlateDokumen2 halamanAluminium Alloy 6082 - T6 T651 Plateyokartik100% (1)

- Callister - Fundamentals of Materials Science and Engineering 5e HQDokumen2 halamanCallister - Fundamentals of Materials Science and Engineering 5e HQsathwikBelum ada peringkat

- 6005a t6 Extrusion TCDokumen4 halaman6005a t6 Extrusion TCKhamda Aja DuluBelum ada peringkat

- Aluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesDokumen3 halamanAluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesBeni hidayatullahBelum ada peringkat

- Aluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesDokumen3 halamanAluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesMellierBelum ada peringkat

- Aluminium 6082 Spec SheetDokumen3 halamanAluminium 6082 Spec SheetDeepak KumarBelum ada peringkat

- AISI 1012 Steel, Cold Drawn Bar, 19-32 MM (0.75-1.25 In) Round or ThicknessDokumen2 halamanAISI 1012 Steel, Cold Drawn Bar, 19-32 MM (0.75-1.25 In) Round or ThicknessdavmedclBelum ada peringkat

- Aluminium Alloy 6082 - T4 ExtrusionsDokumen2 halamanAluminium Alloy 6082 - T4 ExtrusionsRaj DomadiyaBelum ada peringkat

- Sae 5160 VBDokumen2 halamanSae 5160 VBBarron ValentinBelum ada peringkat

- Alloy 6082 - Rev2012Dokumen2 halamanAlloy 6082 - Rev2012Ysraels Santisteban DurandBelum ada peringkat

- AISI 4620 Steel, Direct Quench From Pot, Carburized, Oil Quenched, 150°C (300°F) TemperDokumen1 halamanAISI 4620 Steel, Direct Quench From Pot, Carburized, Oil Quenched, 150°C (300°F) Temperapurv bhartiBelum ada peringkat

- Aalco Metals LTD - Aluminium Alloy 5083 0 H111 Sheet and Plate - 149 PDFDokumen2 halamanAalco Metals LTD - Aluminium Alloy 5083 0 H111 Sheet and Plate - 149 PDFOvidiu ChertesBelum ada peringkat

- Din 1Dokumen1 halamanDin 1ttpatelBelum ada peringkat

- Mil-Spec Mil-S-6049, Sae J404, Sae J412, Sae J770, Uns G87400, Ams 6322, Ams 6323, Ams 6325, Ams 6327, Ams 6358, Astm A322Dokumen2 halamanMil-Spec Mil-S-6049, Sae J404, Sae J412, Sae J770, Uns G87400, Ams 6322, Ams 6323, Ams 6325, Ams 6327, Ams 6358, Astm A322FlavioBelum ada peringkat

- Aalco Metals LTD Aluminium Alloy 2011 T3 Rod and Bar 3Dokumen2 halamanAalco Metals LTD Aluminium Alloy 2011 T3 Rod and Bar 3Agung SulisBelum ada peringkat

- Thyssenkrupp Materials (UK) LTD Aluminium Alloy 6082: Material Data SheetDokumen2 halamanThyssenkrupp Materials (UK) LTD Aluminium Alloy 6082: Material Data SheetSatendra ThakurBelum ada peringkat

- Aalco Metals LTD Aluminium Alloy 6060 T5 Extrusions 144Dokumen2 halamanAalco Metals LTD Aluminium Alloy 6060 T5 Extrusions 144anilbabu4Belum ada peringkat

- Carbon Steel fact sheetDokumen2 halamanCarbon Steel fact sheettshepo hlakudiBelum ada peringkat

- Aisi 1010 Carbon Steel (Uns g10100)Dokumen5 halamanAisi 1010 Carbon Steel (Uns g10100)prasadjoshi781429Belum ada peringkat

- AISI 1018 Mild Low Carbon Steel PDFDokumen3 halamanAISI 1018 Mild Low Carbon Steel PDFYogesh ChaudhariBelum ada peringkat

- Mild Steel PDFDokumen3 halamanMild Steel PDFHardikBelum ada peringkat

- AISI 1018 Mild Low Carbon Steel PDFDokumen3 halamanAISI 1018 Mild Low Carbon Steel PDFFebrian JhaBelum ada peringkat

- AISI 1018 Mild Low Carbon Steel PDFDokumen3 halamanAISI 1018 Mild Low Carbon Steel PDFMayand DuaBelum ada peringkat

- AISI 1018 Mild Low Carbon Steel PDFDokumen3 halamanAISI 1018 Mild Low Carbon Steel PDFbbbBelum ada peringkat

- AISI 1018 Mild Low Carbon Steel PDFDokumen3 halamanAISI 1018 Mild Low Carbon Steel PDFHardikBelum ada peringkat

- TDS Material Astm-A193-Grade-B8Dokumen1 halamanTDS Material Astm-A193-Grade-B8ASTRID AMBelum ada peringkat

- Cw008a Cu-Of Version1Dokumen1 halamanCw008a Cu-Of Version1Gaka RtaBelum ada peringkat

- Astm A216 WCBDokumen1 halamanAstm A216 WCBAkshay ValaBelum ada peringkat

- Wilsons LTD Aluminium Alloy QQ A 25011 T6 Sheet 200Dokumen2 halamanWilsons LTD Aluminium Alloy QQ A 25011 T6 Sheet 200williamBelum ada peringkat

- AISI 4130 alloy steel guideDokumen2 halamanAISI 4130 alloy steel guideALEX MURPHYBelum ada peringkat

- Aero Metal Alliance Aluminium Alloy QQ A 2504 0 Sheet 196Dokumen2 halamanAero Metal Alliance Aluminium Alloy QQ A 2504 0 Sheet 196jayalakshmivinothBelum ada peringkat

- AISI 1050 Steel, As RolledDokumen2 halamanAISI 1050 Steel, As RolledCristobal Gutierrez CarrascoBelum ada peringkat

- Aero Metal Alliance - Aluminium Alloy QQ A 25011 T6 Sheet - 200Dokumen2 halamanAero Metal Alliance - Aluminium Alloy QQ A 25011 T6 Sheet - 200erikaBelum ada peringkat

- Astm hk40 Chemical Composition Astm hk40 Mechanica 2 PDFDokumen2 halamanAstm hk40 Chemical Composition Astm hk40 Mechanica 2 PDFprashant mishraBelum ada peringkat

- Aluminium Alloy 1050 H14 TDSDokumen1 halamanAluminium Alloy 1050 H14 TDSfaria1969Belum ada peringkat

- BronzeLG2LeadedGunmetalBronze PDFDokumen2 halamanBronzeLG2LeadedGunmetalBronze PDFAnthonyBelum ada peringkat

- Aluminum Brass Specifications for Condenser TubesDokumen1 halamanAluminum Brass Specifications for Condenser Tubesm_f_deathBelum ada peringkat

- AISI 1141 Steel, Hot Rolled, 19-32 MM (0.75-1Dokumen2 halamanAISI 1141 Steel, Hot Rolled, 19-32 MM (0.75-1PrasadBelum ada peringkat

- Sae 4320 FPDokumen2 halamanSae 4320 FPBarron ValentinBelum ada peringkat

- BS1400 HTB1Dokumen2 halamanBS1400 HTB1Atul KulkarniBelum ada peringkat

- Data Sheet Aluminium 6061 t6 Group (H)Dokumen7 halamanData Sheet Aluminium 6061 t6 Group (H)احمد نعيمBelum ada peringkat

- GRADE 302: Element Content (%)Dokumen3 halamanGRADE 302: Element Content (%)Shashank Saxena100% (1)

- 6063 ProfilesDokumen1 halaman6063 ProfilesBPP-Tech PythonBelum ada peringkat

- Aalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Dokumen3 halamanAalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Jessicalba LouBelum ada peringkat

- 954 - Bronze Aluminio PDFDokumen2 halaman954 - Bronze Aluminio PDFivanoliveira3261Belum ada peringkat

- Aalco Metals LTD Aluminium Alloy 2011 T6 Extruded Rod and Bar 56 SS4355Dokumen2 halamanAalco Metals LTD Aluminium Alloy 2011 T6 Extruded Rod and Bar 56 SS4355novkovic1984Belum ada peringkat

- Aalco Metals LTD - Aluminium Alloy 6063 T6 Extrusions - 158 PDFDokumen3 halamanAalco Metals LTD - Aluminium Alloy 6063 T6 Extrusions - 158 PDFganmosesBelum ada peringkat

- Stainless Steel 1.4462 Sheet & PlateDokumen3 halamanStainless Steel 1.4462 Sheet & PlatePaulBelum ada peringkat

- Austnitic Stainless Steel 316 316LDokumen2 halamanAustnitic Stainless Steel 316 316LbladdeeBelum ada peringkat

- Raffmetal: UNI EN 1676 and 1706Dokumen2 halamanRaffmetal: UNI EN 1676 and 1706Raj RajeshBelum ada peringkat

- LM4 Aluminium Casting Alloy (Al - Si5Cu3) : Chemical CompositionDokumen3 halamanLM4 Aluminium Casting Alloy (Al - Si5Cu3) : Chemical Compositiona.suleimanBelum ada peringkat

- Bronze c54400 SpecificationsDokumen3 halamanBronze c54400 SpecificationsRam Parimalam100% (1)

- Filler Wire For Gtaw PDFDokumen27 halamanFiller Wire For Gtaw PDFrezaBelum ada peringkat

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363Dari EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363Belum ada peringkat

- Thai Metal Import Co.,LtdDokumen3 halamanThai Metal Import Co.,Ltdminhyen88Belum ada peringkat

- CV Vothiminhyen PDFDokumen4 halamanCV Vothiminhyen PDFminhyen88Belum ada peringkat

- SN200-7 2016-05 eDokumen9 halamanSN200-7 2016-05 eminhyen88Belum ada peringkat

- Standardi (BBM Italija)Dokumen129 halamanStandardi (BBM Italija)anon_684421324100% (1)

- Equivalent ASTM MaterialDokumen34 halamanEquivalent ASTM Materialgolf0910251891% (45)

- Pre-Qualification of DKHG - 2017Dokumen25 halamanPre-Qualification of DKHG - 2017minhyen88Belum ada peringkat

- Overall Cost LeadershipDokumen8 halamanOverall Cost Leadershipminhyen88Belum ada peringkat

- Offshore Mag Poster - FPSODokumen1 halamanOffshore Mag Poster - FPSODing LiuBelum ada peringkat

- Ace Institute of Management: Assignment # 2: Competitive AnalysisDokumen6 halamanAce Institute of Management: Assignment # 2: Competitive AnalysisRupesh ShahBelum ada peringkat

- ISO 27001 Certification OverviewDokumen22 halamanISO 27001 Certification OverviewDiana SimonBelum ada peringkat

- Oracle Enterprise Data Quality: Match and Parse: DurationDokumen4 halamanOracle Enterprise Data Quality: Match and Parse: DurationJinendraabhiBelum ada peringkat

- Brisko Structural Steel BrochureDokumen5 halamanBrisko Structural Steel Brochureyousef alfrkhBelum ada peringkat

- Chap. 3 - Project Control and MonitoringDokumen46 halamanChap. 3 - Project Control and MonitoringRuzengulalebih ZEta's-Listik40% (5)

- Blog - Oscarliang - Net - Build A Quadcopter Beginners Tutorial 1Dokumen23 halamanBlog - Oscarliang - Net - Build A Quadcopter Beginners Tutorial 1Number ButBelum ada peringkat

- Enterprise Technology ReportDokumen3 halamanEnterprise Technology ReportResource 4 BusinessBelum ada peringkat

- Cable Chains Catalogue 2019.01 enDokumen123 halamanCable Chains Catalogue 2019.01 enJose Ramon Florez OrdizBelum ada peringkat

- English lesson plan on terminal functionsDokumen2 halamanEnglish lesson plan on terminal functionsKarina Barrios100% (1)

- Telescopic/knuckleboom Cranes: Shipboard Handling ExcellenceDokumen4 halamanTelescopic/knuckleboom Cranes: Shipboard Handling ExcellenceIrda OnesBelum ada peringkat

- List of Gear StandardDokumen7 halamanList of Gear StandardManoj SinghBelum ada peringkat

- Citation Chap1Dokumen9 halamanCitation Chap1Aj RosalBelum ada peringkat

- Sappress Change Request ManagementDokumen53 halamanSappress Change Request Managementzahid948650% (2)

- CEAT Annual Report 2014 15Dokumen196 halamanCEAT Annual Report 2014 15Raven FormourneBelum ada peringkat

- Moccu Agency PresentationDokumen44 halamanMoccu Agency PresentationCameron BellingBelum ada peringkat

- CV en Angel Niculae 2014Dokumen6 halamanCV en Angel Niculae 2014bobeluBelum ada peringkat

- Finance Manager or Lead AccountantDokumen3 halamanFinance Manager or Lead Accountantapi-78280760Belum ada peringkat

- Digital India ProgrammeDokumen7 halamanDigital India ProgrammeAmbarish GadgilBelum ada peringkat

- Axial AngularDokumen9 halamanAxial AngularAlejandroInostrozaBelum ada peringkat

- CIV003 Technical Approval of DesignDokumen62 halamanCIV003 Technical Approval of DesignAlex ChanBelum ada peringkat

- RIT Case Brief ALGO2 Algorithmic Market MakingDokumen3 halamanRIT Case Brief ALGO2 Algorithmic Market MakingmarioBelum ada peringkat

- Pure2 Brochure ENDokumen12 halamanPure2 Brochure ENSalvador Petanas EstebanBelum ada peringkat

- Cemil KocDokumen12 halamanCemil KocCemil KoçBelum ada peringkat

- Έπιπλα 2016714105722Dokumen1.199 halamanΈπιπλα 2016714105722Marcel LazarBelum ada peringkat

- Company NameDokumen6 halamanCompany NameMuhammad ZulkarnainBelum ada peringkat

- Astra Construction: Quality Control DepartmentDokumen2 halamanAstra Construction: Quality Control Departmentmd_rehan_2Belum ada peringkat

- Risk Management Strategies for Global ExpansionDokumen18 halamanRisk Management Strategies for Global ExpansionAlolika DattaBelum ada peringkat

- NASENI Announces Vacancies for Managing Directors of R&D InstitutesDokumen14 halamanNASENI Announces Vacancies for Managing Directors of R&D InstitutesJoe EkanemBelum ada peringkat

- DSWD SMAW NC Training Budget: Total Amount P147,050.00Dokumen1 halamanDSWD SMAW NC Training Budget: Total Amount P147,050.00Ramil Raquit0% (1)