One-Way Ribbed Slab Design As Per BS8110

Diunggah oleh

yusuf abdinasirJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

One-Way Ribbed Slab Design As Per BS8110

Diunggah oleh

yusuf abdinasirHak Cipta:

Format Tersedia

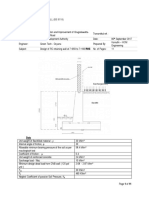

Project Details: Page # 1 of

Ribbed Slab Designs to BS 8110-97: Prepared: Y.A

Continuous 6m Long Spans & Imposed Loading 2.5kPa Checked:

REF CALCULATIONS OUTPUT

Slab Geometry:

6m 6m 6m

- Design a one-way ribbed slab with 3 equal continuous spans

BS8110- - It satisfies the criteria of BS8110 for using Table 3.12

3.5.2.3 &

3.5.2.4 For +ve moment, design the most critical section:

i.e. End Span, Span (upport c-r) L= 6 m

For -ve moment, design the most critical section:

i.e. First Interior Support

Material Properties:

fy = 460 N/mm (main & shear reinforcement)

fcu = 30 N/mm (C25/30 Concrete)

RCC Weight = 25 kN/m

Loading:

Floor Finishes & Services (SDL) = 1.20 kN/m2

Rapidwall Formwork (SDL) = 0.4 kN/m2

BS6399-1 Characteristic Imposed Load = 2.50 kN/m2

Slab Sizing:

Let topping thickness, hf = 100 mm

Rib width, bw = 230 mm

Flange Width b = 500 mm (Rib spacing)

bw/b = 0.46 > 0.3

BS8110- Interpolating Basic L/d = 26 -4.01 = 22.0

3.4.6.3

Table 3.9 Let modification factor = 1.6 (to be confirmed later)

Allowable L/d ratio = 35.2

Therefore, dmin= 170.5 mm

Bottom cover to links = 25 mm (includes 5mm for

deviation)

Rapidwall bottom skin = 15 mm

Dia of main bars = 14 mm

Dia of links = 8 mm

hreq = 225.5 mm

Try an overall depth of slab h = 224 mm

Project Details: Page # 2 of

Ribbed Slab Designs to BS 8110-97: Prepared: Y.A

Continuous 6m Long Spans & Imposed Loading 2.5kPa Checked:

REF CALCULATIONS OUTPUT

Ulitmate Load & Moment Calculation:

Width of slab carried by one rib = 500 mm

Self-weight of slab = 1.88 kN/m

Design Dead Load = 1.4xDL = 3.75 kN/m

Design Implosed Load = 1.6xLL = 2.00 kN/m

Total Design Load, w = 5.75 kN/m

Total Design Load on a span, F = wL = 34.48 kN

BS8110- Ultimate bending moment and shear force as per Table 3.12

3.5.2.3 & 0.086FL

3.5.2.4 0.063FL

BMD

0.086FL 0.063FL

0.5F 0.5F

0.4F

0.5F SFD

0.6F

Design of End Span (Bottom Reinforcement):

Ultimate Moment M = 0.086 FL = 17.8 kNm

T section, b = 500 mm, d = 169 mm

Assume 0.9x = hf = 100 mm

Mf = 0.45 fcu b hf (d - 0.5hf) = 80.325 kNm >M

Neutral axis lies in the flange; treat as a rectangular section,

having width b = 500 mm, h = 224 mm

BS8110- K = M/(fcu b d2) = 0.042 < 0.156

3.4.4.4

hence compression reinforcement is not required

z/d = 0.5+(0.25 - K/0.9) = 0.95 0.95

z = 0.95d = 160.55

Provide Bottom

As req = M/(0.87 fy z) = 277 mm2 Reinforcement

BS8110- Minimum reinforcement check: web in tension, bw/b0.4 2Y 14

Table 3.25

BS8110-

Table 3.25

Asmin = 0.13% bw h = 67 mm2 1Y 14

Asprov(mm )= 462

2

Project Details: Page # 3 of

Ribbed Slab Designs to BS 8110-97: Prepared: Y.A

Continuous 6m Long Spans & Imposed Loading 2.5kPa Checked:

REF CALCULATIONS OUTPUT

Design of First Interior Support (Top Reinforcement):

Ultimate Moment M = 0.086 FL = 17.8 kNm

Hogging moment over support; slab bottom face in compression.

Ribs are not terminated before the support, hence:

Solid section: b = 230 mm, h = 224 mm

BS8110- Table coefficient include 20% redistribution of moment at support

3.5.2.3 &

3.5.2.4 b = 0.8

K' = 0.402(bb 0.4) 0.18(bb 0.4)2 = 0.132

BS8110- K = M/(fcu b d2) = 0.051 < K'

3.4.4.4

hence compression reinforcement is not required

z/d = 0.5+(0.25 - K/0.9) = 0.94 0.95

z = 0.95d = 160.55

Provide Top

As req = M/(0.87 fy z) = 277 mm2 Reinforcement

BS8110- Minimum reinforcement check: for rectangular sections 2Y 10

Table 3.25

3.12.11.2 Asmin = 0.13% b h = 67 mm2 +1Y 12

Asprov(mm2)= 270

Shear Check:

Max. shear force at first interior support = 0.6F = 20.7 kN

Ribs are not terminated before the support, hence critical section is at

the face of the load-bearing Rapidwall:

x= 62 mm from support centerline

Shear Force V = (0.6F) - (wx) = 20.3 kN

BS8110- Calculate design applied shear stress:

Eq. 22

v = V/bvd = 0.52 N/mm < vcmax= 4.38

BS8110- Calculate design concrete shear stress:

Table 3.8

100 As/bvd = 0.70 3

(400/d)1/4 = 1.24 0.67

BS8110- vc = (0.79/gm)*{100As/(bwd)} 1/3

(400/d) 1/4

(fcu/25) = 0.74 N/mm v < vc , no shear

3.6.4.7 links required

BS8110- v < vc , no shear

3.6.4.7 links required

BS8110- 'Where two or more bars are used in a rib, the use of link reinforcement

3.6.6.3 is recommended to ensure correct cover to reinforcement. The spacing of Provide Double

the links can generally be of the order of 1 m to 1.5 m depending on the Legged Links

size of the main bars'

Y8@500mm c/c

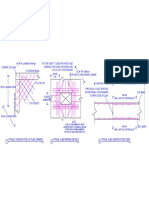

Project Details: Page # 4 of

Ribbed Slab Designs to BS 8110-97: Prepared: Y.A

Continuous 6m Long Spans & Imposed Loading 2.5kPa Checked:

REF CALCULATIONS OUTPUT

Deflection Check (Middle of End Span):

BS8110- Code says that Table 3.9 ratios "are based on limiting the total deflection to

3.4.6.3 span/250 and this should normally ensure that the part of the deflection

Table 3.9 occurring after construction of finishes and partitions will be limited to

span/500 or 20 mm, whichever is the lesser, for spans up to 10 m"

bw/b = 0.46 > 0.3,

Interpolated Basic L/d = 22.0

M/bd2 = 1.25 N/mm

b 0.95

BS8110- fs = 194 N/mm

Eq. 8

BS8110-

Eq. 7

tension m.f = 1.65 2 = 1.65

As'prov = 157 mm As'prov/bd = 0.19

compression m.f = 1.06 1.5 = 1.06

Allowable L/d = Basic L/d*m.f = 38.4

Actual L/d = 35.5 < Allowable L/d Deflection Check

No further checks are required. Satisfactory

Reinforcement in Topping:

Single layer of welded steel fabric is needed for the topping:

Use Mesh A252

BS8110- Taking 1m width of the topping, b = 1000 mm Y8 bars

3.6.6.2

As = 0.12% b hf = 120 mm2/m S = 200 mm

Maximum spacing Smax = rib spacing/2 = 250 mm As = 252 mm2/m

Detailing Diagram:

Anda mungkin juga menyukai

- Ribbed Slab Design TemplateDokumen4 halamanRibbed Slab Design Templateyusuf abdinasir75% (4)

- Ribbed Slab DesignDokumen4 halamanRibbed Slab Designyusuf abdinasir100% (1)

- Design For Torsion (Beams BS 8110)Dokumen3 halamanDesign For Torsion (Beams BS 8110)dhanya1995100% (1)

- Column Design As Per BS 8110-1:1997: PHK/JSNDokumen16 halamanColumn Design As Per BS 8110-1:1997: PHK/JSNJennifer Tang100% (2)

- Deflection Check (Beams BS 8110)Dokumen2 halamanDeflection Check (Beams BS 8110)dhanya1995Belum ada peringkat

- Unbraced Slender Column To BS 8110Dokumen7 halamanUnbraced Slender Column To BS 8110Gihan Chathuranga67% (3)

- Strip Footing DesignDokumen4 halamanStrip Footing Designkm_ananth100% (1)

- Structural Engineering - Slab Design To BS 8110Dokumen4 halamanStructural Engineering - Slab Design To BS 8110Gladson Js100% (2)

- Stepped Footing - 1 PDFDokumen11 halamanStepped Footing - 1 PDFSushil Dhungana93% (15)

- Strip Footing 3 Columns Bsi 8110 - 2Dokumen11 halamanStrip Footing 3 Columns Bsi 8110 - 2Magdy Bakry100% (2)

- Vertical Reinforcement (Walls BS 8110)Dokumen4 halamanVertical Reinforcement (Walls BS 8110)dhanya1995100% (1)

- Hollow Pot Slabs DesignDokumen4 halamanHollow Pot Slabs Designchris100% (4)

- Design Shear Resistance (Beams - BS 8110)Dokumen2 halamanDesign Shear Resistance (Beams - BS 8110)Lavanyan SatchithananthanBelum ada peringkat

- Flat Slab Design ExampleDokumen5 halamanFlat Slab Design ExampleKong SooYit58% (12)

- Eurocode Side BarsDokumen6 halamanEurocode Side BarsraymondBelum ada peringkat

- Slab Design To BS 8110Dokumen11 halamanSlab Design To BS 8110Samuel Antobam100% (2)

- Helicoidal Stair Design Spreadsheet by Olusegun - VerifiedDokumen2 halamanHelicoidal Stair Design Spreadsheet by Olusegun - Verifiedsegun ajibola100% (2)

- Beam Design To BS 8110Dokumen14 halamanBeam Design To BS 8110Gihan Chathuranga60% (5)

- RCC92 Ribbed Slabs (Tables)Dokumen8 halamanRCC92 Ribbed Slabs (Tables)lucianduBelum ada peringkat

- One Ways Slab Design To BS 8110-1997Dokumen6 halamanOne Ways Slab Design To BS 8110-1997Gihan Chathuranga100% (9)

- RC Column Design BS8110Dokumen5 halamanRC Column Design BS8110dantevariasBelum ada peringkat

- Design Strip FootingDokumen12 halamanDesign Strip FootingHenra HalimBelum ada peringkat

- Column Design To Bs8110 TemplateDokumen6 halamanColumn Design To Bs8110 TemplateMitra Rampersad100% (9)

- Flat Slab ExcelDokumen50 halamanFlat Slab ExcelJEFFY JACOB100% (1)

- Design of Purlins and Sag RodDokumen2 halamanDesign of Purlins and Sag Rodliezel100% (1)

- Design of Raft Foundation of Water TankDokumen1 halamanDesign of Raft Foundation of Water TankNIHARIKA KARETHABelum ada peringkat

- RC Raft Foundation (BS8110) - Part1Dokumen1 halamanRC Raft Foundation (BS8110) - Part1Himura_100% (1)

- Unbraced Short Column Design To BS 8110Dokumen8 halamanUnbraced Short Column Design To BS 8110Gihan Chathuranga100% (3)

- Design of Beams To BS 8110Dokumen14 halamanDesign of Beams To BS 8110Kasun Karunaratne99% (76)

- Resistance Moment Calculations (Columns BS 8110)Dokumen3 halamanResistance Moment Calculations (Columns BS 8110)dhanya1995100% (2)

- Top Circular Slab DesignDokumen3 halamanTop Circular Slab Designanshutomar791580% (5)

- Column Design Bs 8110 PDFDokumen2 halamanColumn Design Bs 8110 PDFAlexis60% (5)

- Unit 6 (DESIGN OF REINFORCED CONCRETE CONTINUOUS BEAMS)Dokumen26 halamanUnit 6 (DESIGN OF REINFORCED CONCRETE CONTINUOUS BEAMS)Zara Nabilah90% (30)

- Crack Width Calc BS 8110Dokumen1 halamanCrack Width Calc BS 8110mvap2856Belum ada peringkat

- 10m R.C BEAM DESIGNDokumen3 halaman10m R.C BEAM DESIGNchris100% (1)

- One Way Slab DesignDokumen4 halamanOne Way Slab DesignMario FeghaliBelum ada peringkat

- Design Shear Resistance (Beams EC2)Dokumen2 halamanDesign Shear Resistance (Beams EC2)dhanya1995Belum ada peringkat

- Inverted T FootingDokumen7 halamanInverted T FootingMohamed100% (2)

- Purlin DesignDokumen20 halamanPurlin Designarif_rubin100% (1)

- British Standard Bs 8110Dokumen10 halamanBritish Standard Bs 8110م.عمرو عبداللهBelum ada peringkat

- Excel Template For Strap Footing Using ES en CodeDokumen9 halamanExcel Template For Strap Footing Using ES en CodeJim JamBelum ada peringkat

- Culvert Design Notes 2016Dokumen10 halamanCulvert Design Notes 2016Mwengei Muteti100% (1)

- Two Way Design Slab To BS 8110Dokumen6 halamanTwo Way Design Slab To BS 8110Gihan Chathuranga100% (18)

- Footing Design According To BS8110 CodeDokumen4 halamanFooting Design According To BS8110 CodePre SheetBelum ada peringkat

- 5 Examples Shear WallDokumen15 halaman5 Examples Shear WallRacharla Narasimha Raju Varma100% (2)

- Ribbed Slab DesignDokumen11 halamanRibbed Slab DesignJavier_GL100% (2)

- Structural Design of Staircase According To Eurocode2Dokumen11 halamanStructural Design of Staircase According To Eurocode2prakash100% (1)

- Calculation of Loads For Column and Foundation DesignDokumen2 halamanCalculation of Loads For Column and Foundation DesignMandar Nadgaundi100% (1)

- Design of RC Retaining Wall (BS 8110) )Dokumen11 halamanDesign of RC Retaining Wall (BS 8110) )Chiran Semasinghe100% (3)

- Analysis of Ribbed SlabDokumen12 halamanAnalysis of Ribbed Slabmickymat100% (1)

- Steel Staircase DesignDokumen6 halamanSteel Staircase Designserafini75% (4)

- Structural Design Detailing and Construc PDFDokumen40 halamanStructural Design Detailing and Construc PDFIbnuyusoff77Belum ada peringkat

- RC Beam Torsion Design (BS8110)Dokumen2 halamanRC Beam Torsion Design (BS8110)Osarieme Osakue100% (3)

- Chapter 2 Beams Curved in Plan FinalDokumen12 halamanChapter 2 Beams Curved in Plan Finalyosef gemessa100% (1)

- Calculation NoteDokumen10 halamanCalculation NoteJay EvansBelum ada peringkat

- Crack Width Calculation: MaterialsDokumen2 halamanCrack Width Calculation: MaterialsIrfan AliBelum ada peringkat

- Triangle Beam B1Dokumen6 halamanTriangle Beam B1sallysel90Belum ada peringkat

- AnchorboltsDokumen2 halamanAnchorboltsrammohanBelum ada peringkat

- Doubly Reinforced BeamDokumen19 halamanDoubly Reinforced BeamLavender HoneyBelum ada peringkat

- Base Plate DesignDokumen21 halamanBase Plate Designtitir bagchi100% (1)

- Project Management Crash Course FlyerDokumen1 halamanProject Management Crash Course Flyeryusuf abdinasirBelum ada peringkat

- Minutes of Meeting TemplateDokumen1 halamanMinutes of Meeting Templateyusuf abdinasirBelum ada peringkat

- RectangularBeam Design in Mathcad To BS8110Dokumen1 halamanRectangularBeam Design in Mathcad To BS8110yusuf abdinasirBelum ada peringkat

- Project Management Crash Course FlyerDokumen1 halamanProject Management Crash Course Flyeryusuf abdinasirBelum ada peringkat

- Sample BOQ TemplateDokumen4 halamanSample BOQ Templateyusuf abdinasirBelum ada peringkat

- The Role of Innovation in Building On The Past To Create A Sustainable FutureDokumen1 halamanThe Role of Innovation in Building On The Past To Create A Sustainable Futureyusuf abdinasirBelum ada peringkat

- Sample Construction ScheduleDokumen10 halamanSample Construction Scheduleyusuf abdinasirBelum ada peringkat

- Loading Criteria For Office BuildingDokumen1 halamanLoading Criteria For Office Buildingyusuf abdinasirBelum ada peringkat

- Typical Loading Criteria For Office BuildingDokumen2 halamanTypical Loading Criteria For Office Buildingyusuf abdinasirBelum ada peringkat

- Sample Ribbed Slab Design by TCC SpreadsheetsDokumen3 halamanSample Ribbed Slab Design by TCC Spreadsheetsyusuf abdinasirBelum ada peringkat

- Sample Construction ScheduleDokumen8 halamanSample Construction Scheduleyusuf abdinasirBelum ada peringkat

- Sample Construction ScheduleDokumen10 halamanSample Construction Scheduleyusuf abdinasirBelum ada peringkat

- C1 Stiffener Column C1 15: Made by DateDokumen1 halamanC1 Stiffener Column C1 15: Made by Dateyusuf abdinasirBelum ada peringkat

- 1) Displacements: Direction Cosines: Locate Local Origin For Each Member at A. Member X y Z L (M) L M NDokumen2 halaman1) Displacements: Direction Cosines: Locate Local Origin For Each Member at A. Member X y Z L (M) L M Nyusuf abdinasirBelum ada peringkat

- Standard Slab DetailsDokumen1 halamanStandard Slab Detailsyusuf abdinasirBelum ada peringkat

- Undamped Free VibrationDokumen18 halamanUndamped Free Vibrationyusuf abdinasir100% (1)

- Standard Opening and Corner DetailsDokumen1 halamanStandard Opening and Corner Detailsyusuf abdinasirBelum ada peringkat

- Standard Slab DetailsDokumen1 halamanStandard Slab Detailsyusuf abdinasirBelum ada peringkat

- Member Ab:: Ya 3 2 3 2 A Xa Xa Za 2 2 Za Yb 3 2 3 2 B XB XB ZB 2 2 ZBDokumen2 halamanMember Ab:: Ya 3 2 3 2 A Xa Xa Za 2 2 Za Yb 3 2 3 2 B XB XB ZB 2 2 ZByusuf abdinasirBelum ada peringkat

- Member Ab:: Ya 3 2 3 2 A Xa Xa Za 2 2 Za Yb 3 2 3 2 B XB XB ZB 2 2 ZBDokumen2 halamanMember Ab:: Ya 3 2 3 2 A Xa Xa Za 2 2 Za Yb 3 2 3 2 B XB XB ZB 2 2 ZByusuf abdinasirBelum ada peringkat

- Member Ab:: Ya 3 2 3 2 A Xa Xa Za 2 2 Za Yb 3 2 3 2 B XB XB ZB 2 2 ZBDokumen2 halamanMember Ab:: Ya 3 2 3 2 A Xa Xa Za 2 2 Za Yb 3 2 3 2 B XB XB ZB 2 2 ZByusuf abdinasirBelum ada peringkat

- Machine Design Question PaperDokumen2 halamanMachine Design Question Papersushil.vgi100% (1)

- Kolhan University SEM4 GE PHYSICSDokumen26 halamanKolhan University SEM4 GE PHYSICSGaurav KumarBelum ada peringkat

- Cable and ArchesDokumen15 halamanCable and Archess k sharmaBelum ada peringkat

- Ex-10 - Laboratory Vane Shear Test in Cohesive SoilDokumen10 halamanEx-10 - Laboratory Vane Shear Test in Cohesive Soilmathirenga88Belum ada peringkat

- Lecture 03Dokumen27 halamanLecture 03nghaBelum ada peringkat

- A Vortex Model of The Darrieus Turbine: An Analytical and Experimental StudyDokumen6 halamanA Vortex Model of The Darrieus Turbine: An Analytical and Experimental Studyjohn arbuckleBelum ada peringkat

- Similarity and Modelling - 2Dokumen7 halamanSimilarity and Modelling - 2Alexander MugabeBelum ada peringkat

- SOM Lab ManualDokumen32 halamanSOM Lab ManualMuhammad Junaid100% (1)

- Compresor CentrifugoDokumen16 halamanCompresor CentrifugoIgnacio SotoBelum ada peringkat

- Thrust BlockDokumen39 halamanThrust BlockShankarappa NBelum ada peringkat

- Aristotle and Galileo On MotionDokumen46 halamanAristotle and Galileo On MotionMaria TheresaBelum ada peringkat

- Pile Group Analysis: A Study of Two Methods: by Harry G. Poulos, M. ASCE and Mark F. RandolphDokumen18 halamanPile Group Analysis: A Study of Two Methods: by Harry G. Poulos, M. ASCE and Mark F. Randolphkalyan rangadhamBelum ada peringkat

- 2.3 Temperature Conversions: Chapter 2 Energy and MatterDokumen18 halaman2.3 Temperature Conversions: Chapter 2 Energy and MatterBeverly PamanBelum ada peringkat

- Fall 2016 Lab Manual - CHEG455 (Sec 51 & 52) PDFDokumen68 halamanFall 2016 Lab Manual - CHEG455 (Sec 51 & 52) PDFMashaelBelum ada peringkat

- AvcDokumen18 halamanAvcgulshanBelum ada peringkat

- To Investigate Relationship Between Specific Energy and Depth of FlowDokumen9 halamanTo Investigate Relationship Between Specific Energy and Depth of FlowFaisal Sardar100% (12)

- Deflection and Cracking ControlDokumen8 halamanDeflection and Cracking ControlChanthy RathedBelum ada peringkat

- Annel Saavedra - S.PHY1.Q1.W7.AAS35-36 PDFDokumen4 halamanAnnel Saavedra - S.PHY1.Q1.W7.AAS35-36 PDFTerius KimBelum ada peringkat

- Recent Advances in Spline Couplings Reliability Recent Advances in Spline Couplings ReliabilityDokumen8 halamanRecent Advances in Spline Couplings Reliability Recent Advances in Spline Couplings ReliabilityRehan AhmedBelum ada peringkat

- CCB 2092 Experiment 3 - Fluid StaticsDokumen6 halamanCCB 2092 Experiment 3 - Fluid StaticsFahmi EsaBelum ada peringkat

- Mathematics of Motion Control Profiles: Chuck Lewin, Founder and CEO Performance Motion Devices, IncDokumen12 halamanMathematics of Motion Control Profiles: Chuck Lewin, Founder and CEO Performance Motion Devices, IncElias80Belum ada peringkat

- Liquefaction of Gases Lecture NotesDokumen10 halamanLiquefaction of Gases Lecture NotesmelvindavidBelum ada peringkat

- A New Deformable Catenary Element For The Analysis of Cable Net Structures - 2006Dokumen9 halamanA New Deformable Catenary Element For The Analysis of Cable Net Structures - 2006Truong Viet HungBelum ada peringkat

- Start Download: Orifice Equations Formulas Design CalculatorDokumen4 halamanStart Download: Orifice Equations Formulas Design CalculatorPriesilia PresleyBelum ada peringkat

- Double Helical - Herring BoneDokumen6 halamanDouble Helical - Herring BoneMohamed Abd El RahmanBelum ada peringkat

- Multiple Choice Questions (MODULE 4 & 5) Mechanics of SolidsDokumen67 halamanMultiple Choice Questions (MODULE 4 & 5) Mechanics of SolidsA22 Tekale AdityaBelum ada peringkat

- B Tech Mechanical Engineering Syllabus For Batch 2013-14Dokumen30 halamanB Tech Mechanical Engineering Syllabus For Batch 2013-14ra44993541Belum ada peringkat

- Power Transmission: Belt Drives, Rope Drives, Chain Drives, Gear DrivesDokumen27 halamanPower Transmission: Belt Drives, Rope Drives, Chain Drives, Gear DrivesAshwin AdithyaBelum ada peringkat

- Ae401 SyllabusDokumen2 halamanAe401 SyllabusMehmet AliBelum ada peringkat

- Circular MotionDokumen51 halamanCircular MotionPankaj KumarBelum ada peringkat