Xylowatt Presentation January 2017 1 PDF

Diunggah oleh

choppinJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Xylowatt Presentation January 2017 1 PDF

Diunggah oleh

choppinHak Cipta:

Format Tersedia

Biomass to Energy

The NOTAR Gasification Solution

Validity Date : January 2017 Xylowatt Biomass to Energy 0

Section 1

BUSINESS SCOPE &

TECHNOLOGY

Validity Date : January 2017 Xylowatt Biomass to Energy 1

XYLOWATT

Turnkey projects worldwide

Our Industrial partner:

Engineering

EPC

Validity Date : January 2017 Xylowatt Biomass to Energy 2

NOTAR story -

15 years from spin-off to industrialisation

2015 2017

2013

2011

2010

2009

2007

2004

2001

Validity Date : January 2017 Xylowatt Biomass to Energy 3

XYLOWATT

THE partner of your biomass to energy project

Validity Date : January 2017 Xylowatt Biomass to Energy 4

NOTAR - production of clean gas

Biomass

A multi-stage downdraft gasifier

Advantages:

Clean gas (99,95% tars destroyed)

Elimination of heavy metals and organic

pollutants

Ability to use high mineral content waste

Compact gasification unit

Validity Date : January 2017 Xylowatt Biomass to Energy 5

NOTAR - a unique technology

Validity Date : January 2017 Xylowatt Biomass to Energy 6

NOTAR technology

Summary of Tar management

Zone Tar management

Pyrolysis Thanks to perfect control of the pyrolysis parameters (max 700C and residence time )

and pyrolysis completeness in pyrolysis zone (=NOTAR patent), production mainly of

primary and secondary tar (99%) instead of heavy tertiary tar (1%)

Combustion Destruction (1.200C) of the main part of tar during combustion in gaseous phase

Measurement campaign CIRAD on our TGP (2012):

Low level of tar out of NOTAR technology <100 mg/Nm

Mainly light tertiary tar in residual tar

Gas Conditioning Unit Residual tar eliminated in a simple Gas Conditioning unit

Measurement campaign on our Tournai Plant (2013) < 5 mg/Nm

Tar content measured with a gravimetric tar probe

Validity Date : January 2017 Xylowatt Biomass to Energy 7

NOTAR technology

Syngas characteristics

Stability

LHV : ~ 5.5 MJ/Nm CO H2

Composition

H2 22%

CO 18%

CO2 13%

CH4 2% CO2

N2 45%

Compatible with engine

(CHP) manufacturers

CH4

specifications

Validity Date : January 2017 Xylowatt Biomass to Energy 8

Power plant integrating NOTAR technology

Performance

Biomass

(Moisture content 35%wb)

Preparation

Biomass (10%wb) 3 MW

Biomass

3.15 MW 960 kg/h

685 kg/h Electricity

35 kWe

Heat to dryer Net

330 kW OUTPUTS

Overall Project

Syngas Total Heat

2.2 MW (1) + (2)

Net Heat

1250 kW

920 kW

Power Plant

Electricity Net

Syngas 815 kWe

2.2 MW Electricity

685 kWe

Self consumption

130 kWe

BioChar

(1) Heat GCU (2) Heat Engine

330 kW 920 kW 490 kW

Validity Date : January 2017 Xylowatt Biomass to Energy 9

Section 2

OVERVIEW OF GASIFICATION POWER

PLANT

Validity Date : January 2017 Xylowatt Biomass to Energy 10

NOTAR Gasification Plant

Typical layout: 2 Notar units 2 CHP engines

Dryer Gasifier Gas conditioning unit Cogeneration Engine

By-products storage Control room Starting syngas burner Utilities storage

Validity Date : January 2017 Xylowatt Biomass to Energy 11

Gasification Plant

Typical layout: 2 Notar units 2 CHP engines

Dryer

Gasifier

Gas conditioning unit

Cogeneration Engine

By-products storage

Control room

Starting syngas burner

Utilities storage

Validity Date : January 2017 Xylowatt Biomass to Energy 12

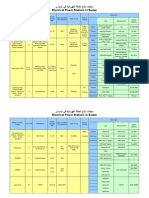

CAPEX structure

Initial Investment (CAPEX)

4% Gasification Equipment

7%

CHP package

16%

Biomass Drying -

55% Screening - Conveying

18% Civil Works

Contingencies

Validity Date : January 2017 Xylowatt Biomass to Energy 13

OPEX structure

Operational Expenses (OPEX)

Woodchips (Untreated wood)

3%

4%

Maintenance Gasification unit +

Spare parts

16%

Technical staff for operations

42%

11%

Maintenance CHP

24% By-Product Management

Utilities

Validity Date : January 2017 Xylowatt Biomass to Energy 14

Section 3

REFERENCES

Validity Date : January 2017 Xylowatt Biomass to Energy 15

BELGIUM Louvain-la-Neuve

TGP (Test gasifier Pilot)- Laboratory tool - R&D Center

Project Key Data

TGP Optimising

Location Institute of Mechanics, Materials

parameters

and Civil Engineering (IMMC),

Louvain-la-Neuve, Belgium

Evaluation/R&D Optimizing operational

scope parameters to various types of

woodchips and biomasses

Industrial benchmark for On site

commercial purposes analysis

Gas conditioning unit

adjustment

Biomass preparation

By-product measurement

Capacity 150 kWth syngas power LHV Several

feedstocks

Technology NOTAR

Feedstock Various

Commissioning Start operation in 2010

Validity Date : January 2017 Xylowatt Biomass to Energy 16

BELGIUM -Mont-Godinne

First Belgian Hospital with 50% renewable energy

Project Key Data

Location Mont-Godinne Hospital, Belgium

Owner Special Purpose Vehicule (MGGE)

Application Combined Heat & Power

(Jenbacher J320S) for hospital

energy consumption

Capacity 700kWe + 1200kWth

Technology NOTAR v.3

Feedstock Woodchips

Commissioning First semester2017 (Under

construction from 2016)

Validity Date : January 2017 Xylowatt Biomass to Energy 17

BELGIUM -Tournai

Swimming-pool heated by wood energy

Gasifier

Project Key Data

Outisde

Location Tournai, Belgium

Owner Tournai City

Application Combined Heat & Power (MTU G12).

Heat consumed by local swimming- Dried

pool biomass

Capacity from Nov. 2015 :200kWe + 400kWth

Until Nov. 2015 :260kWe + 475kWth.

Technology NOTAR v.2

Feedstock Woodchips

Commissioning 17th December 2009 Conveyor

Validity Date : January 2017 Xylowatt Biomass to Energy 18

FRANCE- Glass bottle plant

Clean syngas out of vineyards residues, feeding an industrial kiln

Project Key Data

Location Champagne Area (France)

Owner Glass bottles manufacturer

Application Direct use of syngas for fossil fuel

substitution in industrial process Aerial photo

Capacity 950 kW syngas power

Technology NOTAR v.2

Feedstock Woodchips from vineyards pruning

branches and obsolete vine stocks

Commissioning 02th March 2015 (Plant)

3D Design

Validity Date : January 2017 Xylowatt Biomass to Energy 19

Xylowatt s.a.

Avenue Jean Monnet, 1

1348 Louvain-la-Neuve

Belgium

info@xylowatt.com

www.xylowatt.com

Validity Date : January 2017 Xylowatt Biomass to Energy 20

Anda mungkin juga menyukai

- Solutions For Generating Energy in Industry and Commerce PDFDokumen24 halamanSolutions For Generating Energy in Industry and Commerce PDFanon_411130333Belum ada peringkat

- Vector8 Te2: Enset NgineDokumen2 halamanVector8 Te2: Enset NgineBayu Aji Dwi NurlaksonoBelum ada peringkat

- Take Our Plugs to Save on Maintenance CostsDokumen5 halamanTake Our Plugs to Save on Maintenance Costsgeorge_scalaBelum ada peringkat

- CHP 530 To 660 KW PDFDokumen16 halamanCHP 530 To 660 KW PDFJunifero1Belum ada peringkat

- SM012807093970 - en - PDF Piston HoningDokumen24 halamanSM012807093970 - en - PDF Piston Honingibrahim salemBelum ada peringkat

- GE Jenbacher High Efficiency ConceptDokumen9 halamanGE Jenbacher High Efficiency Conceptjulihardo parulian simarmataBelum ada peringkat

- Off RoadDokumen74 halamanOff Roadtom souzaBelum ada peringkat

- CHP Units For Heat and PowerDokumen20 halamanCHP Units For Heat and Poweranon_411130333Belum ada peringkat

- 100-460e-4.0 Engine Pressure SENSOR PDFDokumen66 halaman100-460e-4.0 Engine Pressure SENSOR PDFDoDuyBacBelum ada peringkat

- Honing HelperDokumen1 halamanHoning HelperDamianos 980Belum ada peringkat

- MTU CI Ag Mining SalesProgramDokumen37 halamanMTU CI Ag Mining SalesProgramMarcial MilitanteBelum ada peringkat

- BSc-Mechanical Engineering Module Handbook SPO 2015 Valid From 20181001Dokumen435 halamanBSc-Mechanical Engineering Module Handbook SPO 2015 Valid From 20181001أيوب حسنBelum ada peringkat

- WFMDokumen44 halamanWFMedima79Belum ada peringkat

- Protecting ResourcesDokumen19 halamanProtecting ResourcesDaniel DaiaBelum ada peringkat

- Institutional EN PDFDokumen40 halamanInstitutional EN PDFKadirOzturkBelum ada peringkat

- 2011 Engine Tech Review MWMDokumen2 halaman2011 Engine Tech Review MWMGrietekeBelum ada peringkat

- 2206C-E13TAG3 ElectropaK PN1885 PDFDokumen2 halaman2206C-E13TAG3 ElectropaK PN1885 PDFvictoros27Belum ada peringkat

- Schedle Maintenance JenbacherDokumen3 halamanSchedle Maintenance JenbacherEnrique Garcia0% (1)

- Engine Sheet Type 3 e 2015Dokumen2 halamanEngine Sheet Type 3 e 2015Esteban Vasquez GiraldoBelum ada peringkat

- 0606 - TD - E2842 LE312 - Nat - EngDokumen8 halaman0606 - TD - E2842 LE312 - Nat - EngfaridBelum ada peringkat

- VIESSMANN - Biomass - BrochureDokumen16 halamanVIESSMANN - Biomass - BrochureAnonymous QY7Iu8fBBelum ada peringkat

- Industrial and Genset Engines Issue 9Dokumen47 halamanIndustrial and Genset Engines Issue 9ramon hidalgoBelum ada peringkat

- Laser structuring optimizes tribological systems through functional surface structuresDokumen16 halamanLaser structuring optimizes tribological systems through functional surface structuresCarlos CarabelliBelum ada peringkat

- MAN Biogas EngineDokumen16 halamanMAN Biogas EngineMuhammad rizkiBelum ada peringkat

- Lister Peter Running Manual ENITELDokumen16 halamanLister Peter Running Manual ENITELRommel SaavedraBelum ada peringkat

- DG 01 010 e 12 17 PANDAROS III 8155Dokumen55 halamanDG 01 010 e 12 17 PANDAROS III 8155علوي الهاشميBelum ada peringkat

- MotoHawk Software PSDokumen6 halamanMotoHawk Software PSCABean1Belum ada peringkat

- Siemens industrial diesel and gas engines & generator setsDokumen2 halamanSiemens industrial diesel and gas engines & generator setsAlejandro SanchezBelum ada peringkat

- MBH Conversion References - Deutz-MWM TBD 6M 628Dokumen1 halamanMBH Conversion References - Deutz-MWM TBD 6M 628Marbun Benny100% (1)

- Bosch Parts in Marine & Power Generation EnginesDokumen4 halamanBosch Parts in Marine & Power Generation EnginesNeoteric IndustrialBelum ada peringkat

- Series 8000 Diesel Engines For Marine ApplicationsDokumen3 halamanSeries 8000 Diesel Engines For Marine ApplicationsMaurizioBelum ada peringkat

- CZ Product CatalogDokumen82 halamanCZ Product CatalogEurocorp DistributionBelum ada peringkat

- Ignition Coils TypesDokumen27 halamanIgnition Coils TypesMohamed EssamBelum ada peringkat

- Cogeneration: The Benefits of CogenerationDokumen23 halamanCogeneration: The Benefits of CogenerationJAY PARIKH100% (1)

- 3210Q011 04gb PDFDokumen2 halaman3210Q011 04gb PDFDenim102100% (1)

- Champion Industrial Spark Plugs - DigipubZDokumen8 halamanChampion Industrial Spark Plugs - DigipubZiyan22suryana_827197Belum ada peringkat

- Tedom Handbook For Designers 2008Dokumen57 halamanTedom Handbook For Designers 2008ManretyBelum ada peringkat

- (PDF) Maintenance Schedule For Gas Genset - GE JENBACHER - CompressDokumen5 halaman(PDF) Maintenance Schedule For Gas Genset - GE JENBACHER - CompressArie AozBelum ada peringkat

- G3306Dokumen4 halamanG3306carlucido247970100% (1)

- MWM Factsheet 2011 enDokumen2 halamanMWM Factsheet 2011 enAbhijit MannaBelum ada peringkat

- M-Combustion Chamber and Cold StartingDokumen45 halamanM-Combustion Chamber and Cold StartingAnonymous LFgO4WbIDBelum ada peringkat

- محطات إنتاج الطاقة الكهربائية في السودانDokumen6 halamanمحطات إنتاج الطاقة الكهربائية في السودانTruuth SeekerBelum ada peringkat

- Mic520 525 530 eDokumen86 halamanMic520 525 530 eMaia Naiara BarrientosBelum ada peringkat

- Maintenance ScheduleDokumen8 halamanMaintenance ScheduleArun KumarBelum ada peringkat

- COG July August 2012Dokumen110 halamanCOG July August 2012confyBelum ada peringkat

- Power-To-Gas - Key Technology For Linking Different Sectors: Heating Systems Refrigeration SystemsDokumen6 halamanPower-To-Gas - Key Technology For Linking Different Sectors: Heating Systems Refrigeration Systemsanon_411130333Belum ada peringkat

- J920 Jenbacher Factsheet EnglishDokumen8 halamanJ920 Jenbacher Factsheet Englishoverlord5555Belum ada peringkat

- SSP+227+++3 3L+V8+TDI+common+rail+injection+systemDokumen36 halamanSSP+227+++3 3L+V8+TDI+common+rail+injection+systemĐức HòangBelum ada peringkat

- Training Program Singapore, Asia: ValuecareDokumen13 halamanTraining Program Singapore, Asia: Valuecareguichen wangBelum ada peringkat

- Green Power International (P) LTD.: Selection Chart For Natural Gas Based GensetsDokumen1 halamanGreen Power International (P) LTD.: Selection Chart For Natural Gas Based GensetssanitermBelum ada peringkat

- Compact CHP Units 40-400 kW for Efficient EnergyDokumen6 halamanCompact CHP Units 40-400 kW for Efficient EnergysilvercristiBelum ada peringkat

- 16V4000G83 3D en ConsumptionDokumen9 halaman16V4000G83 3D en ConsumptionmsahbkBelum ada peringkat

- SUNNEN BilgiDokumen29 halamanSUNNEN BilgiSerkan TopcuBelum ada peringkat

- For C & I and Mining Applications EPA Tier 4 Certification: Diesel Engine 12V 1600Dokumen2 halamanFor C & I and Mining Applications EPA Tier 4 Certification: Diesel Engine 12V 1600Megat Rambai SrBelum ada peringkat

- Operating InstructionsDokumen402 halamanOperating InstructionsTưởng VũBelum ada peringkat

- MAN marine medium duty enginesDokumen4 halamanMAN marine medium duty enginesKost KurniaBelum ada peringkat

- Vector 8 Technical and Repair Manual - Industrial ApplicationDokumen206 halamanVector 8 Technical and Repair Manual - Industrial ApplicationAlejandro Di Gregorio100% (1)

- October 1999: Office of Industrial TechnologiesDokumen32 halamanOctober 1999: Office of Industrial TechnologiesSagar_pdfBelum ada peringkat

- Net Zero Energy Design PDFDokumen72 halamanNet Zero Energy Design PDFshaimaa08100% (1)

- Renewable Energy Conversion, Transmission, and StorageDari EverandRenewable Energy Conversion, Transmission, and StoragePenilaian: 3 dari 5 bintang3/5 (2)

- Chemistry TextbookDokumen148 halamanChemistry TextbookOtuku DavidBelum ada peringkat

- International Journal of Heat and Mass Transfer: Peter Lloyd Woodfield, Aloke Kumar Mozumder, Masanori MondeDokumen6 halamanInternational Journal of Heat and Mass Transfer: Peter Lloyd Woodfield, Aloke Kumar Mozumder, Masanori MondeRanjith RNBelum ada peringkat

- Newtons Laws of MotionDokumen50 halamanNewtons Laws of MotionJoshua MeraBelum ada peringkat

- Essentials of The Living World 4th Edition by Johnson ISBN Solution ManualDokumen5 halamanEssentials of The Living World 4th Edition by Johnson ISBN Solution Manualalison100% (22)

- Effects of Weather Systems in The PhilippinesDokumen19 halamanEffects of Weather Systems in The PhilippinesCaloykOoy Danday Dueñas100% (1)

- CO2 Conversion and Utilization-American Chemical Society (2002)Dokumen427 halamanCO2 Conversion and Utilization-American Chemical Society (2002)Nguyen TrangBelum ada peringkat

- Chapter - 17 Static ElectricityDokumen54 halamanChapter - 17 Static ElectricityNayeem HakimBelum ada peringkat

- Photosynthesis Lesson at Fisher Valley CollegeDokumen5 halamanPhotosynthesis Lesson at Fisher Valley CollegeRomielyn MenguezBelum ada peringkat

- NPCIL's Role in Meeting India's Growing Energy NeedsDokumen8 halamanNPCIL's Role in Meeting India's Growing Energy NeedsNikunjBelum ada peringkat

- Hydrogen ApplicationDokumen66 halamanHydrogen ApplicationHisham Zainal AbidinBelum ada peringkat

- Mc3 Chapter 1Dokumen7 halamanMc3 Chapter 1Lorraine RiegoBelum ada peringkat

- SoilThermalResistivity PDFDokumen29 halamanSoilThermalResistivity PDFgnklol3Belum ada peringkat

- Computational Pollutant of So2/no2 in The Environment Using Aermod in Semi-Urban Area, Studi Case in Tuban, East JavaDokumen6 halamanComputational Pollutant of So2/no2 in The Environment Using Aermod in Semi-Urban Area, Studi Case in Tuban, East JavaIJAR JOURNALBelum ada peringkat

- Solar Powered Cathodic ProtectionDokumen2 halamanSolar Powered Cathodic ProtectionncharalaBelum ada peringkat

- Green Building ReportDokumen18 halamanGreen Building Reportchechumenendez100% (1)

- Hitachi Energy Transformer Line CardDokumen1 halamanHitachi Energy Transformer Line Cardlinksofgowvideous1Belum ada peringkat

- Thermo ChemistryDokumen27 halamanThermo ChemistryhannahBelum ada peringkat

- Group 1 ELS FIDPDokumen16 halamanGroup 1 ELS FIDPjayson babaran100% (1)

- Sizing According To ASME Code Sect VIII and API RP 520 and API 521Dokumen31 halamanSizing According To ASME Code Sect VIII and API RP 520 and API 521matrix69Belum ada peringkat

- Born-Oppenheimer ApproximationDokumen5 halamanBorn-Oppenheimer ApproximationIjaz TalibBelum ada peringkat

- Project SynopsisDokumen6 halamanProject Synopsislive userBelum ada peringkat

- ThermodynamicsDokumen6 halamanThermodynamicsabdulhafizmy87100% (1)

- r050210801 Fluid Mechanics For Chemical EngineeringDokumen7 halamanr050210801 Fluid Mechanics For Chemical EngineeringSrinivasa Rao GBelum ada peringkat

- Lecture One Power PlantDokumen38 halamanLecture One Power PlantEmmanuel Anosisye MwangomoBelum ada peringkat

- Class 4 Worksheet on Tenses, Conversion, Rights and Duties, MatterDokumen7 halamanClass 4 Worksheet on Tenses, Conversion, Rights and Duties, MatterTech trixBelum ada peringkat

- Petroleum Systems of MEDokumen10 halamanPetroleum Systems of MEDiya Disha100% (1)

- General Physics 1 - Course OutlineDokumen2 halamanGeneral Physics 1 - Course OutlineFeliph Angelo Sinfuego CalunodBelum ada peringkat

- Grid Connect PV Design Guidelines CEC Issue 5 - 1Dokumen22 halamanGrid Connect PV Design Guidelines CEC Issue 5 - 1Lakshmi NarayananBelum ada peringkat

- Mansilungan - Experiment 5Dokumen8 halamanMansilungan - Experiment 5theressaBelum ada peringkat

- Pv-Wind Hybrid PowerDokumen49 halamanPv-Wind Hybrid PowerHAIMANOT100% (1)