Practice Questions For Api RP 577: 60 Términos

Diunggah oleh

vamsikrishnaDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Practice Questions For Api RP 577: 60 Términos

Diunggah oleh

vamsikrishnaHak Cipta:

Format Tersedia

PRACTICE QUESTIONS FOR API RP 577 60 trminos GoldFish2015

API 577_______ for the training is not a replacement

and experience required to

be an American Welding

Society Certified Welding

Inspector(CWI)

API 577______ all welds to be does not require

inspected.

Who determines the welds to Welding inspectors and/or engineers

be inspected??

Who should be consulted on A welding engineer

any critical , specialized or

complex welding issues?

Three of the items listed Tasks in selecting personnel

below are welding inspection

activities that can be

separated into three stages

corresponding to the welding

work process. Which one

does not belong??

Which of the basic arc SMAW

welding processes is the most

widely used?

How is shielding provided for Shielding is provided from the decomposition

the arc when using a of the electrode covering

consumable covered

electrode in shielded metal

What are some disadvantages Deposition rates are low and slag must be

or limitations of shielded removed at stops and starts.

metal arc welding?

What does the DCEN stand DCEN stands for direct current electrode-

for when used to describe the negative .

GTAW weld process?

What are some of the

advantages to gas tungsten It produces high purity welds and it allows for

arc welding ? excellent control of root pass weld

penetration.

What is a welding process GMAW-S

that produces fast a freezing

weld pool and is generally

suited for joining thin sections

or root passes.

What type of weld process FCAW

normally employs a

semiautomatic mode and

depends on a flux from a

tubular electrode that

contains a shielding gas from

an externally supplied gas?

What type of welding is used SAW

extensively in shop pressure

vessel fabrication and pipe

manufacturing?

What type of welding process SW

is predominantly limited to

welding insulation and

refractory support pins to

tanks, pressure vessels and

heater casings?

What is the definition of non- It is inspection methods,which allow materials

destructive examination? to be examined without changing or

destroying their usefulness.

What are the most commonly VT, MT, WFMT, PT, LT, ET, RT, UT, ACFM.

used NDE methods used

during weld inspection ?

NOTE: SELECT THE ANSWER

THAT HAS ALL THE CORRECT

METHODS!!!!

Where would you look for Weld metal zone and weld interface.

slag inclusion discontinuities?

Which NDE method is the PT

most acceptable for a lap

joint ?

What is the most capable UT

NDE method for finding a

discontinuity such as

incomplete fusion in a joint ?

When welding carbon steel, improper heat input and improper welding

what is the major cause of technique.

lack of fusion in all welding

processes?

When welding stainless steel Improper shielding, not using a low hydrogen

what would cause porosity in electrode, & welding in a high sulfur area.

the weld?

When welding stainless steel, fast travel speed.

what is the cause of

undercut?

When welding carbon steel, use proper heat input

how would you control burn

through?

The Alternating Current Field Nozzles, ring-grooves and grind-out areas or

Measurement (ACFM) radii.

technique is an

electromagnetic non-

contacting technique that is

able to detect and size

surface breaking defects in a

range of different materials

and through coatings of

varying thickness. This

technique is ideal for

inspecting:

What is the maximum 900 F

temperature that ACFM may

be used?

What are the 2 typical Iridium 192 or Cobalt 60

radioactive isotopes used for

radiography?

What is the normal 5 to 8 minutes

developing time for

radiographic film at 68 F?

The transmitted film density 2.0 to 4.0

through the radiographic

image through the

radiographic image through

the body of the hole type IQI

or adjacent to the wire IQI, in

the area of interest, should be

within the range of ______ for

Gamma

Radiographic _________ is the art interpretation

of extracting the maximum

information from a

radiographic image.

How many cycles per second greater than 20000 HZ

(now known as Hz or Hertz )

us classified as being in the

ultrasonic frequency range?

What type of UT technique is Straight beam

used for thickness evaluation

or to check for laminations,

and/or other conditions ?

What does a C-scan display It shows a plan view of the test object

show?

The temperature of the 25 F

calibration standard should

be within _______ of the part to

be examined .

What happens if during a All areas tested since the last calibration

system calibration check, it is should be reexamined

determined that the UT

equipment is not functioning

properly?

Solid metals are _______ in crystalline

nature and all have a structure

in which the atoms of each

crystal are arranged in a

specific geometric pattern.

metals in molten or liquid casting

state solidify , Interlocking

grains into a solid metallic

structure called a :

the vast majority of metallic wrought

materials used for the

fabrication of refinery and

chemical plant equipment are

used in the___ form rather than

cast

Mechanical working of a cast wrought

ingot produces ____ materials

by processes such as

rolling,forging, or

extrusion,which are normally

at an elevated temperature

The addition of ___ to carbon

austenitic stainless leads to

the formation of a very small

iron and chromium carbide

precipitates in the grains and

at grain boundaries

Carbon steel is a two-phase pearlite

alloy.One phase is a relatively

pure form of iron called

ferrite.With the addition of

more than 0.06% percent of

carbon, a second phase is

formed called_____.This adds

strength to steel

lamellar means : a plate-like

The parts of a weld comprises the weld metal ,the heat affected metal (zone),

three zones.What are these and the base metal

zones ?

The portion of the base metal heat affected zone

has not been melted,but

whose mechanical properties

or microstructure have been

altered by the heat of welding

is called the:

What happens to the gas it breaks down into carbon and oxygen

,carbon dioxide, when it is

exposed to weld arc

temperatures ?

The primary purpose for to reduce the tendency for hydrogen induced

preheating carbon and low- delayed cracking

alloy steels is :

How far on each side of the 2 inches

weld should be preheat be

maintained ?

The primary reason for post- relieve the residual stresses in a welded

weld heat treatment (PWHT) fabrication

is to:

What is the Brinnell hardness 200

limit value for carbon steel in

reining service ?

what are the two types of a heat analysis and a product analysis

material test reports ?

typically ,steels with a carbon 0.35

equivalent of less that___

require no preheat

Steels with a carbon 0.55

equivalent of higher than ___

require both preheat PWHT.

What are the two main burn through and cracking

concerns when welding on in

service piping and equipment

?

hot tap and in service welding E7018

operations should be carried

out only with low-hydrogen

consumables and electrodes

such as :

carbon steels with a carbon 0.43%

equivalent (CE) greater than

___ should be welded with an

extra low hydrogen electrode

such as EXXXX-H4 .

liquid flow rates in piping to 1.3,4.0

be hot tapped shall be

between __ feet per second

and ___ feet per second

how much liquid should be 3 feet

above the area that is to be

hot tapped on a storage tank

or vessel?

What size electrodes should 3/32 inch or smaller

be used on the first weld pass

on a hot tap or an in-service

weld on piping or equipment

less than 1/4 inch thick?

when using SMAW, what do 70000 psi ultimate strength

the first two numbers of E7018

electrode identify ?

with a SMAW electrode AWS position

designation , the 4th

character represents what?

(EXXXX)

If a welder makes identify reason the welder failed and re train

unacceptable production the welder

welds, the inspector must

identify and quarantine all the

improper weldments made by

the welder . The welder is

than retested and fails his test.

What is the nest step ?

Anda mungkin juga menyukai

- Is 3177 Eot CraneDokumen62 halamanIs 3177 Eot CraneDnyanesh Bhalerao75% (4)

- 577 ExerciseDokumen40 halaman577 Exerciseariyamanjula2914100% (1)

- A Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersDari EverandA Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersPenilaian: 3.5 dari 5 bintang3.5/5 (19)

- API 510 QUIZ No.1Dokumen3 halamanAPI 510 QUIZ No.1Hatem RagabBelum ada peringkat

- How to Calculate PayrollDokumen87 halamanHow to Calculate PayrollMichael John D. Natabla100% (1)

- Asme Sec 5 QuestionsDokumen13 halamanAsme Sec 5 Questionsanasseeksscribd100% (1)

- Welding Metallurgy and Weldability of Nickel-Base AlloysDari EverandWelding Metallurgy and Weldability of Nickel-Base AlloysPenilaian: 5 dari 5 bintang5/5 (1)

- API-580 Exam Q&As from ITExamsDokumen8 halamanAPI-580 Exam Q&As from ITExamsegs egsBelum ada peringkat

- Chemicals Zetag DATA Powder Magnafloc 351 - 0410Dokumen2 halamanChemicals Zetag DATA Powder Magnafloc 351 - 0410PromagEnviro.comBelum ada peringkat

- Open Book For API 653Dokumen10 halamanOpen Book For API 653gopiBelum ada peringkat

- Api 577 Reponse01Dokumen3 halamanApi 577 Reponse01korichiBelum ada peringkat

- 12) Api 510 Day 4Dokumen67 halaman12) Api 510 Day 4hamedBelum ada peringkat

- API 580 Exam QuestionsDokumen24 halamanAPI 580 Exam QuestionsMourad AdelBelum ada peringkat

- API 577 FlashCardsDokumen7 halamanAPI 577 FlashCardsqaisarabbas9002100% (5)

- CBT Questions-A Story of Real Experience PDFDokumen5 halamanCBT Questions-A Story of Real Experience PDFramBelum ada peringkat

- Practice Questions For API RP 577Dokumen17 halamanPractice Questions For API RP 577vamsikrishna100% (4)

- 9.API 574 Practive QnsDokumen6 halaman9.API 574 Practive QnsvamsikrishnaBelum ada peringkat

- Cswip Question and Answers: ResponsibilitiesDokumen11 halamanCswip Question and Answers: Responsibilitiesfery0% (1)

- C Closed B Losed B Ook Ook P Practice Que Ractice Questio Stio Ns NsDokumen10 halamanC Closed B Losed B Ook Ook P Practice Que Ractice Questio Stio Ns NsElankumaran Periakaruppan100% (1)

- API 510 Closed Book QuestionsDokumen16 halamanAPI 510 Closed Book QuestionsRavindra S. Jivani100% (1)

- API 570 Closed Book Question PaperDokumen41 halamanAPI 570 Closed Book Question Papervamsikrishna71% (7)

- 17 Multiple Choice Questions: No Answer GivenDokumen5 halaman17 Multiple Choice Questions: No Answer GivenAnonymous Q4YUvRBelum ada peringkat

- 11.API 574 Practive QnsDokumen6 halaman11.API 574 Practive QnsvamsikrishnaBelum ada peringkat

- 60 Multiple Choice Questions: No Answer GivenDokumen21 halaman60 Multiple Choice Questions: No Answer GivenAnonymous Q4YUvRBelum ada peringkat

- Healthcare Financing in IndiADokumen86 halamanHealthcare Financing in IndiAGeet Sheil67% (3)

- 17 Multiple Choice Questions: No Answer GivenDokumen5 halaman17 Multiple Choice Questions: No Answer GivenAkram AlhaddadBelum ada peringkat

- Consider Recycled Water PDFDokumen0 halamanConsider Recycled Water PDFAnonymous 1XHScfCIBelum ada peringkat

- API 577 Questions Scope and DefinitionsDokumen10 halamanAPI 577 Questions Scope and DefinitionsmaorealesBelum ada peringkat

- General 2Dokumen4 halamanGeneral 2Sobia KalsoomBelum ada peringkat

- API 570 - Mockup CB - Paper 2Dokumen16 halamanAPI 570 - Mockup CB - Paper 2Shanawas Abdul Razak100% (1)

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsDari EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsBelum ada peringkat

- 8.API Practice QuestionsDokumen27 halaman8.API Practice QuestionsvamsikrishnaBelum ada peringkat

- 9 Multiple Choice Questions: No Answer GivenDokumen3 halaman9 Multiple Choice Questions: No Answer GivenAnonymous Q4YUvRBelum ada peringkat

- Isolation and Characterization of Galactomannan From Sugar PalmDokumen4 halamanIsolation and Characterization of Galactomannan From Sugar PalmRafaél Berroya Navárro100% (1)

- API 578 Mock Guide Quality AssuranceDokumen27 halamanAPI 578 Mock Guide Quality Assurancesheikmoin100% (1)

- API 577 Key Points - Chapter 5Dokumen4 halamanAPI 577 Key Points - Chapter 5muhammadazharBelum ada peringkat

- Api 510 Study Guide Practice Questions PDFDokumen2 halamanApi 510 Study Guide Practice Questions PDFPrashant KumarBelum ada peringkat

- Ultrasonic Methods API 941 Annex E Draft 3 CleanDokumen5 halamanUltrasonic Methods API 941 Annex E Draft 3 CleanRupam BaruahBelum ada peringkat

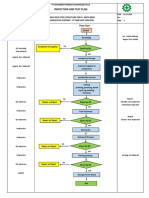

- Inspection and Test Plan: Flow Chart Start IncomingDokumen1 halamanInspection and Test Plan: Flow Chart Start IncomingSinden AyuBelum ada peringkat

- Closed Book Questions For Api 575Dokumen25 halamanClosed Book Questions For Api 575vamsikrishna100% (1)

- Closed Book Questions For Api 575Dokumen25 halamanClosed Book Questions For Api 575vamsikrishna100% (1)

- Closed Book Questions For Api 575Dokumen25 halamanClosed Book Questions For Api 575vamsikrishna100% (1)

- Test - API 577 - Quizlet 145qDokumen38 halamanTest - API 577 - Quizlet 145qAnonymous Q4YUvRBelum ada peringkat

- AWS Qualification Program: Dr. Eng. Hamed A. NagyDokumen65 halamanAWS Qualification Program: Dr. Eng. Hamed A. Nagyislamaktham100% (3)

- 10) Api 510 Day 2Dokumen206 halaman10) Api 510 Day 2hamedBelum ada peringkat

- ch4 - API 574 PDFDokumen6 halamanch4 - API 574 PDFRAMADOSSBelum ada peringkat

- API 570 Exam Prep TrainingDokumen3 halamanAPI 570 Exam Prep Trainingalouis100% (1)

- Practice Questions For API RP 577Dokumen10 halamanPractice Questions For API RP 577vamsikrishnaBelum ada peringkat

- API 575 Practice QuestionsDokumen32 halamanAPI 575 Practice QuestionsvamsikrishnaBelum ada peringkat

- Test - API 577 - 9 Quizlet PDFDokumen2 halamanTest - API 577 - 9 Quizlet PDFAnonymous Q4YUvR100% (1)

- Final Exam (Closed Book) : Answer SheetDokumen13 halamanFinal Exam (Closed Book) : Answer SheetDAMIAN ALEJANDRO100% (1)

- Demo API 571Dokumen5 halamanDemo API 571wajdi100% (1)

- 2-Questions API 650 Question N°02 2022Dokumen3 halaman2-Questions API 650 Question N°02 2022korichiBelum ada peringkat

- 1.510 Sample QuestionSDokumen7 halaman1.510 Sample QuestionSvamsikrishnaBelum ada peringkat

- June 2018 API RP 577 Practice QuestionsDokumen4 halamanJune 2018 API RP 577 Practice QuestionsMahmoud Alwasif100% (2)

- Boost Your API-570 Piping Inspectors Exam ScoreDokumen6 halamanBoost Your API-570 Piping Inspectors Exam Scorejaire esparzaBelum ada peringkat

- Test - API 577 - Quizlet 72qDokumen23 halamanTest - API 577 - Quizlet 72qAnonymous Q4YUvRBelum ada peringkat

- 63 Multiple Choice Questions: No Answer GivenDokumen16 halaman63 Multiple Choice Questions: No Answer GivenAnonymous Q4YUvR100% (1)

- Api 577 3 PDFDokumen10 halamanApi 577 3 PDFElankumaran Periakaruppan100% (1)

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingDari EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghBelum ada peringkat

- CBT QuestionsDokumen17 halamanCBT QuestionsNaseer Ahmed SokhalBelum ada peringkat

- API-510 Exam Prep Course Practice Exam #3 SolutionsDokumen14 halamanAPI-510 Exam Prep Course Practice Exam #3 SolutionsKarim MamdouhBelum ada peringkat

- 17 Multiple Choice QuestionsDokumen3 halaman17 Multiple Choice QuestionsAnonymous Q4YUvR100% (1)

- 3.4 Arc Length: The Distance From The Tip of The WeldingDokumen7 halaman3.4 Arc Length: The Distance From The Tip of The WeldingMohammed IlliasuddinBelum ada peringkat

- (PDF) PRACTICE QUESTIONS FOR API RP 577 Quizlet - Gustavo HC - Academia - EduDokumen4 halaman(PDF) PRACTICE QUESTIONS FOR API RP 577 Quizlet - Gustavo HC - Academia - EduKumar R100% (1)

- API RP 577 - Question Table 6 PDFDokumen9 halamanAPI RP 577 - Question Table 6 PDFQuyền Trương QuốcBelum ada peringkat

- Paper 4Dokumen10 halamanPaper 4UmaibalanBelum ada peringkat

- Technology Multiple Choice 3Dokumen10 halamanTechnology Multiple Choice 3Alex KullehBelum ada peringkat

- Api 577 Quastion01Dokumen2 halamanApi 577 Quastion01korichiBelum ada peringkat

- API 571+à+ç+å+Dokumen7 halamanAPI 571+à+ç+å+Bilal Ghazanfar100% (1)

- Undercut (Per API 577, Table 6) Can Be Corrected by (Practical Solution Column)Dokumen2 halamanUndercut (Per API 577, Table 6) Can Be Corrected by (Practical Solution Column)korichiBelum ada peringkat

- Hydrogen Cracking Causes and PreventionDokumen6 halamanHydrogen Cracking Causes and Preventionshahid khanBelum ada peringkat

- Twi Cswip 3.1 Set-4b - 1Dokumen5 halamanTwi Cswip 3.1 Set-4b - 1miteshBelum ada peringkat

- Closed Book Api 572-A (55-65) - 2Dokumen11 halamanClosed Book Api 572-A (55-65) - 2slxanto100% (1)

- Api 577 Question-02Dokumen2 halamanApi 577 Question-02korichiBelum ada peringkat

- Industrial radiography A Complete Guide - 2019 EditionDari EverandIndustrial radiography A Complete Guide - 2019 EditionBelum ada peringkat

- API 577 FlashCardsDokumen6 halamanAPI 577 FlashCardsfaiz_oeBelum ada peringkat

- Quiz 4Dokumen3 halamanQuiz 4vamsikrishnaBelum ada peringkat

- Understanding Empathy and SympathyDokumen2 halamanUnderstanding Empathy and SympathyFrinces MarvidaBelum ada peringkat

- Olpers MilkDokumen4 halamanOlpers MilkARAAJ YOUSUFBelum ada peringkat

- PTA Resolution for Donation to School WashroomDokumen2 halamanPTA Resolution for Donation to School WashroomMara Ciela CajalneBelum ada peringkat

- Understanding Anxiety Disorders and Abnormal PsychologyDokumen7 halamanUnderstanding Anxiety Disorders and Abnormal PsychologyLeonardo YsaiahBelum ada peringkat

- Flashover Influence of Fog Rate On The Characteristics of Polluted Silicone Rubber InsulatorsDokumen5 halamanFlashover Influence of Fog Rate On The Characteristics of Polluted Silicone Rubber InsulatorsdaaanuBelum ada peringkat

- Group 17-Solid State NMR - Questions-AnswersDokumen5 halamanGroup 17-Solid State NMR - Questions-AnswersOmkar AkulwarBelum ada peringkat

- 21 - Effective Pages: Beechcraft CorporationDokumen166 halaman21 - Effective Pages: Beechcraft CorporationCristian PugaBelum ada peringkat

- Class9. CVD and PVDDokumen30 halamanClass9. CVD and PVDiraBelum ada peringkat

- NMC Confirmation FormDokumen3 halamanNMC Confirmation FormGianina AvasiloaieBelum ada peringkat

- PhilLife claims process ECQDokumen18 halamanPhilLife claims process ECQNoel EboniaBelum ada peringkat

- Pakistan List of Approved Panel PhysicianssDokumen5 halamanPakistan List of Approved Panel PhysicianssGulzar Ahmad RawnBelum ada peringkat

- Darnell's Father Goes StrictDokumen2 halamanDarnell's Father Goes StrictDavid Theodore Richardson IIIBelum ada peringkat

- Impact of Dairy Subsidies in NepalDokumen123 halamanImpact of Dairy Subsidies in NepalGaurav PradhanBelum ada peringkat

- Atomic and Molecular PhysicsDokumen28 halamanAtomic and Molecular PhysicsAvinash GuptaBelum ada peringkat

- The Congressional Committee and Philippine Policymaking: The Case of The Anti-Rape Law - Myrna LavidesDokumen29 halamanThe Congressional Committee and Philippine Policymaking: The Case of The Anti-Rape Law - Myrna LavidesmarielkuaBelum ada peringkat

- Afforestation in Arid and Semi Arid RegionsDokumen68 halamanAfforestation in Arid and Semi Arid RegionsMilian Marian SanduBelum ada peringkat

- To 1 BUMN 2023 Bahasa Inggris StructureDokumen5 halamanTo 1 BUMN 2023 Bahasa Inggris StructureKukuh Perkasa WirayudaBelum ada peringkat

- Jamec Air FittingsDokumen18 halamanJamec Air Fittingsgoeez1Belum ada peringkat

- Human Resources Management Article Review On "The 3 Essential Jobs That Most Retention Programs Ignore"Dokumen14 halamanHuman Resources Management Article Review On "The 3 Essential Jobs That Most Retention Programs Ignore"Pang Kok ShengBelum ada peringkat

- PGAU - BOHC2018-05 - 20pg - Lowres - Leader Cable AAC Conductor Data PDFDokumen20 halamanPGAU - BOHC2018-05 - 20pg - Lowres - Leader Cable AAC Conductor Data PDFKelly chatBelum ada peringkat

- RJ Bensingh Pub Composites CoatingsDokumen5 halamanRJ Bensingh Pub Composites CoatingsFakkir MohamedBelum ada peringkat

- Bibie Evana OsmanDokumen6 halamanBibie Evana OsmanStabat Jaya TrademarkBelum ada peringkat

- Final Profile Draft - Zach HelfantDokumen5 halamanFinal Profile Draft - Zach Helfantapi-547420544Belum ada peringkat

- Plant Cell Culture: Genetic Information and Cellular MachineryDokumen18 halamanPlant Cell Culture: Genetic Information and Cellular MachineryYudikaBelum ada peringkat