Virgin and Filled PTFE (Teflon) PDF

Diunggah oleh

Anjani PrabhakarJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Virgin and Filled PTFE (Teflon) PDF

Diunggah oleh

Anjani PrabhakarHak Cipta:

Format Tersedia

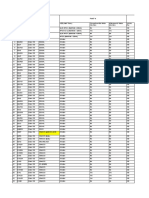

Technical Data Sheet TDS Physical Properties of PTFE and Filled PTFE Products

Physical properties of Virgin PTFE & Filled Grade of PTFE are dependent upon many factors such as Grades of PTFE Conventional, Modified PTFE or Fill ed PTFE, Particle size of r esin Fine Cut or Coarse, Particle Shape of Resin Spherical,

Flake, Irregular, Type & content of filler, Manufacturi ng Process Compression Molding, Ram Extrusion, I sostatic, Paste Extrusion. Due to this Physical Properties of PTFE & Filled PTFE Products have the wide range of Values:-

25% Carbon / 35% Carbon /

Chemically 5% Glass 15% Glass 40% Bronze/ 40% Bronze 55% Bronze +

15% Glass 25% Glass 23% Carbon + 2% 33% Carbon + 15% Graphite 60% Bronze

Sr. Virgin PTFE Modified +5% MoS2 +5% MoS2 TSQ Filled + 5% MoS2 5% MoS2 Filled

Filled PTFE Filled PTFE Graphite Filled 2% Graphite Filled PTFE Filled PTFE

Property Unit Test Method PTFE Filled PTFE Filled PTFE PTFE Filled PTFE PTFE

PTFE Filled PTFE

No.

1 2 3 4 5 6 7 8 9 10 11 12 13

1 Density gm / cc ASTM D-792 2.1 2.2 2.15 2.2 2.15 2.22 2.22 2.25 2.20 2.24 2.20 2.24 2.0 2.2 2.0 2.14 2.10 2.16 3.0 3.2 3 3.2 3.8 4.0 3.8 4

2

2 Tensile Strength kgf/cm ASTM D-638 210 375 300 325 180 260 125 200 175 250 150 220 125200 100 175 150 200 125 225 125-225 100 200 100-200

3 Elongation of Break % ASTM D-638 250 400 400 450 225-325 200-300 200-300 220-320 80150 100-150 150-250 200-350 200-350 150-300 150-300

2

4 Compressive Strength kgf/cm ASTM D-695 40-50 45-55 65-75 75-85 60-70 65-75 7585 80-90 65-75 85-100 80-95 115-125 115-125

5 Deformation under load (Max.)

0

a 2 Hrs. 23 C 113 kgf % 12 3.5 10 9 11 10 5 4 6 5 5 4 4

0

b 24 Hrs. 23 C 113 kgf ASTM D-621 15 5 12 11 13 12 7 6 8 6 6 5 5

c Permanent 8 2.5 7.5 7 8.5 7.5 3.5 3 4.5 3 3 2.5 2.5

0

d 2 Hrs. 150 C 113 kgf 55 40 52 50 52 50 35 30 43 42 42 40 40

6 Impact strength J/cm ASTM D-256 1.4 1.5 1.6 1.75 1.2 1.3 1.0 1.1 1.25 1.35 1.2 1.3 0.7 0.8 0.6 0.7 0.8 0.9 0.9 1.0 0.9 1.0 0.8 0.9 0.85 0.95

7 Hardness Shore D ASTM D-2240 58 62 56 62 58 62 58 63 60 65 60 65 60 65 60 65 60 65 62 66 62 66 64 68 64 68

8 Coefficient of Friction ASTM-D-1894 -

2

a DynamicP-7 kg/cm V-0.5 0.04-0.06 0.02-0.03 0.31-0.37 0.5-0.54 0.15-0.20 0.15-0.20 0.12-0.17 0.13-0.18 0.11-0.16 0.11-0.15 0.1-0.14 0.12-0.16 0.11-0.14

2

b Static P-35 kg/cm 0.05-0.08 0.04-0.06 0.01-0.12 0.11-0.13 0.08-0.01 0.08-0.01 0.09-0.11 0.01-0.12 0.08-0.10 0.08-0.10 0.075-0.09 0.08-0.10 0.07-0.09

9 Wear Rate (Max.) gm/s ASTM-G-137 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01

10 Water Absorption (Max.) % ASTM D-570 0 0 0.015 0.013 0.015 0.015 0 0 0 0 0 0 0

0

11 Continuous Service Temperature C ASTM-D-648 +260 +260 +260 +260 +260 +260 +260 +260 +260 +260 +260 +260 +260

12 Heat Resistance (Max.) % ASTM-D-648 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01

-6

13 Coefficient of Linear Thermal Expansion 10 X % ASTM D-696 250 275 250 275 240 265 235 255 245 270 240 265 225 250 215 240 240 265 200 225 200 225 175 200 175 200

14 Linear Thermal Expansion (Max.) A R A R A R A R A R A R A R A R A R A R A R A R A R

0

a 30 150 C 1.5 1.5 1.5 1.5 1.5 1 1.5 0.7 1.5 1 1.5 1 1.2 1 1.1 0.9 1.3 1 1.15 0.95 1.15 0.95 1.1 0.9 1.1 0.9

% ASTM D-696

0

b 30 200 C 2.4 2.3 2.4 2.3 2.3 1.8 2.2 1 2.3 1.8 2.3 1.8 1.9 1.5 1.8 1.4 2 1.7 1.85 1.55 1.85 1.55 1.8 1.5 1.8 1.5

0

c 30 250 C 3.4 3.6 3.4 3.6 3.3 2.2 3.2 1.4 3.3 2.2 3.3 2.2 2.7 2.4 2.5 2.3 3 2.5 2.55 2.25 2.55 2.25 2.5 2.2 2.5 2.2

15 Dielectric Strength Kv/mm ASTM D-149 22 24 30 35 15 16 11 12 15 16 15 16 12 12 12 Conductive Conductive Conductive Conductive

16 Dimensional stability

a Length % ASTM-D-1710 1.5 3 1.5 3 1.5 3 1.5 3 1.5 3 1.5 3 1.5 3 1.5 3 1.5 3 1.5 3 1.5 3 1.5 3 1.5 3

b Diameter % 0.5 1 0.5 1 0.5 1 0.5 1 0.5 1 0.5 1 0.5 1 0.5 1 0.5 1 0.5 1 0.5 1 0.5 1 0.5 1

17 Chemical Resistance (Max.)

a Permeability % ASTM-D-543 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01

b Dissolution % 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01

PTFE is chemically inert & unaffected by all known chemicals except molten or dissolved alkali metalsSodium; Potassium; Rubidium; Cesiurn; Francium & Fluorine gas, certain fluorine compounds & complexes at elevated temperatures. Filled PTFE has inferior chemical

c

resistance depending upon the particular filler.

The physical properties of Standard & Non-standard filled grade composition not mentioned in above table are to be referred on the basis of Material Test Certificate issued by Raw Material Supplier / Manufacturer. Data quoted are average values only & should not be used for designed

purpose.

Company has in-house test facility / Laboratory to test above properties. The testing equipments are calibrated as per procedures laid down in QMS-ISO-9001:2008, having traceability with NPL. The test procedures are self designed, similar to above referred ASTMs.

Anda mungkin juga menyukai

- Butterfly Valves GuideDokumen28 halamanButterfly Valves GuideLAWRENCEBelum ada peringkat

- CVC Steel FullDokumen28 halamanCVC Steel FullSergio Bacca SantiagoBelum ada peringkat

- Trim Number Chart API ValveDokumen2 halamanTrim Number Chart API ValveVelu .cBelum ada peringkat

- Baking ProcedureDokumen2 halamanBaking Proceduregopuvinu4uBelum ada peringkat

- Sulphate Resisting Cement ManufactureDokumen3 halamanSulphate Resisting Cement ManufactureshaayashanmugaBelum ada peringkat

- The Development of The Surface Finish StandardDokumen7 halamanThe Development of The Surface Finish StandardSunilBelum ada peringkat

- What TitleDokumen17 halamanWhat TitleBernathTurnipBelum ada peringkat

- Socket Head Cap ScrewsDokumen1 halamanSocket Head Cap Screwsapi-3848892100% (5)

- Weld Restoration of Disk - Example of Elliott Repair TechnologyDokumen49 halamanWeld Restoration of Disk - Example of Elliott Repair TechnologyMachineryengBelum ada peringkat

- Datasheet Wear PadDokumen3 halamanDatasheet Wear PadGILBERTO YOSHIDABelum ada peringkat

- Slewing Bearing Installation and Maintenance Manual: Yantai Haoyang Machinery Co.,LtdDokumen22 halamanSlewing Bearing Installation and Maintenance Manual: Yantai Haoyang Machinery Co.,Ltddony ramdhaniBelum ada peringkat

- Catalog Swivel Joints PDFDokumen24 halamanCatalog Swivel Joints PDFluiggi19970530Belum ada peringkat

- Rite Sized Check Valves: ASME Class 125 - 2500 1" (25mm) - 60" (1500mm)Dokumen8 halamanRite Sized Check Valves: ASME Class 125 - 2500 1" (25mm) - 60" (1500mm)Cristian PisitelloBelum ada peringkat

- Slewing Bearing Slewing Ring Slewing Gear Swing CircleDokumen15 halamanSlewing Bearing Slewing Ring Slewing Gear Swing Circlezczc32z5Belum ada peringkat

- Technical Specification: GID-PIP-TS-630 - (E)Dokumen41 halamanTechnical Specification: GID-PIP-TS-630 - (E)santiagoBelum ada peringkat

- Butterfly ValvesDokumen6 halamanButterfly ValvestezgidenBelum ada peringkat

- Thread Types and UsesDokumen1 halamanThread Types and UsesJDPNetoBelum ada peringkat

- Rollix Slewing Ring Installation Maintenance English PDFDokumen7 halamanRollix Slewing Ring Installation Maintenance English PDFBülent KabadayiBelum ada peringkat

- Comparison List Copper Bronze 2011 1Dokumen7 halamanComparison List Copper Bronze 2011 1NaldoVicenteBelum ada peringkat

- Kitz Butterfly Valve Catalog PDFDokumen28 halamanKitz Butterfly Valve Catalog PDFlyguyenquocduyBelum ada peringkat

- Triple-offset Butterfly Valves for Diverse IndustriesDokumen20 halamanTriple-offset Butterfly Valves for Diverse IndustriesamoldholeBelum ada peringkat

- Swagelok Needle ValvesDokumen12 halamanSwagelok Needle Valvesnegg 348Belum ada peringkat

- App10 Fundamentals of ConnectionsDokumen23 halamanApp10 Fundamentals of ConnectionsjdmacbookBelum ada peringkat

- Valve Material TypesDokumen3 halamanValve Material TypesimanadbBelum ada peringkat

- Ansi B 16.11Dokumen34 halamanAnsi B 16.11Elangovan ArumugamBelum ada peringkat

- Shell Corena S3 R 68: Performance, Features & BenefitsDokumen3 halamanShell Corena S3 R 68: Performance, Features & BenefitsjkamraBelum ada peringkat

- Colakoglu Metalurji BrosurDokumen5 halamanColakoglu Metalurji BrosurEnrique Ruiz HonoratoBelum ada peringkat

- CS Steel Pipe Selection GuideDokumen40 halamanCS Steel Pipe Selection GuideImran HussainBelum ada peringkat

- Chapter 2-RRL BindersDokumen4 halamanChapter 2-RRL BindersAlfred Louie RimorinBelum ada peringkat

- Marine Painting FundamentalsDokumen57 halamanMarine Painting FundamentalsMin SoeBelum ada peringkat

- Dyneon PTFE All Grades PDFDokumen11 halamanDyneon PTFE All Grades PDFRajanSharmaBelum ada peringkat

- 5D Bends Combine RFQDokumen376 halaman5D Bends Combine RFQMuhammad Ghufran KhanBelum ada peringkat

- Cement - API Oilwell Cement, Class 'G', Moderate Sulphate Resistant - Lehigh Cement Limited 2014 PDFDokumen6 halamanCement - API Oilwell Cement, Class 'G', Moderate Sulphate Resistant - Lehigh Cement Limited 2014 PDFAMSBelum ada peringkat

- Apl Apollo PDFDokumen16 halamanApl Apollo PDFAditya ShilkarBelum ada peringkat

- Surface Preparation EssentialsDokumen4 halamanSurface Preparation EssentialsPJOE81Belum ada peringkat

- Airtech - Pc51-Z - OrderingDokumen4 halamanAirtech - Pc51-Z - OrderingSnaider SilveraBelum ada peringkat

- Carpenterguidetomachining PDFDokumen170 halamanCarpenterguidetomachining PDFNitin AggarwalBelum ada peringkat

- Asme Sa 106 Grade B PipesDokumen1 halamanAsme Sa 106 Grade B PipesFerroPipEBelum ada peringkat

- Comprehensive guide to EUROSTOP Butterfly Valves DN150-2000mm PN10, 16 and 25 barDokumen36 halamanComprehensive guide to EUROSTOP Butterfly Valves DN150-2000mm PN10, 16 and 25 barGloriaBelum ada peringkat

- Astm 1.05Dokumen3 halamanAstm 1.05asprclms durgapurBelum ada peringkat

- VAMDokumen2 halamanVAMtongsabaiBelum ada peringkat

- PTFE Design HandbookDokumen16 halamanPTFE Design HandbookOscar CruzBelum ada peringkat

- SIS-S 501 50 AG Hot Rolled Steel Rounds (Up To Dia 180mm)Dokumen5 halamanSIS-S 501 50 AG Hot Rolled Steel Rounds (Up To Dia 180mm)Rajoo PrajapatiBelum ada peringkat

- DSI Valves: Forged Steel Carbon, Stainless and Alloy Gate, Globe and Check ValvesDokumen32 halamanDSI Valves: Forged Steel Carbon, Stainless and Alloy Gate, Globe and Check ValvesJordan Magaña MoralesBelum ada peringkat

- Is 3063-Spring WashersDokumen11 halamanIs 3063-Spring Washerspbp2956Belum ada peringkat

- Prince Product Catalogue 26-08-2021Dokumen44 halamanPrince Product Catalogue 26-08-2021ADITYA KUMARI100% (1)

- Piping Classes for Various MaterialsDokumen24 halamanPiping Classes for Various MaterialsThân KhaBelum ada peringkat

- Pressure Test Flushing Pickling PassivationDokumen12 halamanPressure Test Flushing Pickling PassivationVidal Choque N.100% (1)

- Technical Standards For Insulation-Mineral Wool-RockwoolDokumen2 halamanTechnical Standards For Insulation-Mineral Wool-RockwooljaganBelum ada peringkat

- Forged Gate, Globe and Check Valves CatalogDokumen80 halamanForged Gate, Globe and Check Valves CatalogSulist N WahyudieBelum ada peringkat

- Alloy Valves PDFDokumen4 halamanAlloy Valves PDFYamil Diaz SantosBelum ada peringkat

- Details of AbrasivesDokumen6 halamanDetails of AbrasivesskBelum ada peringkat

- Compression Packing Selection Guide: Sealing Products For IndustryDokumen13 halamanCompression Packing Selection Guide: Sealing Products For IndustryAdverBelum ada peringkat

- SS 430, Type 430, WNR 1.4016, UNS S43000, AISI 430, ASTM 430, Grade 430, AFNOR Z8C-17Dokumen3 halamanSS 430, Type 430, WNR 1.4016, UNS S43000, AISI 430, ASTM 430, Grade 430, AFNOR Z8C-17Harish AmpoluBelum ada peringkat

- Pipe Specification Standards GuideDokumen14 halamanPipe Specification Standards GuideAdam NumalBelum ada peringkat

- PTFE Material Property SheetDokumen1 halamanPTFE Material Property Sheetkdalavadi3905Belum ada peringkat

- Virgin and Filled PTFE TeflonDokumen1 halamanVirgin and Filled PTFE TeflonRedzaBelum ada peringkat

- Virgin and Filled PTFE (Teflon) New PDFDokumen1 halamanVirgin and Filled PTFE (Teflon) New PDFmohan115Belum ada peringkat

- PTFE SammenligningstabellDokumen2 halamanPTFE SammenligningstabellHardRockDiskBelum ada peringkat

- Armacell ArmaPET StructDokumen4 halamanArmacell ArmaPET StructPeter Pumpkin EaterBelum ada peringkat

- Podar International School CBSE Progress Report Term IIDokumen1 halamanPodar International School CBSE Progress Report Term IIAnjani PrabhakarBelum ada peringkat

- PR 1013Dokumen38 halamanPR 1013Anjani PrabhakarBelum ada peringkat

- PR 1754Dokumen42 halamanPR 1754Anjani PrabhakarBelum ada peringkat

- GU-629 Application and Selection of Standard Pipe Supports (Formerly SP1187)Dokumen48 halamanGU-629 Application and Selection of Standard Pipe Supports (Formerly SP1187)Ibrahim Naguib100% (1)

- Vulnerability Assessment of Buried Pipelines: A Case Study: Frontiers in Geotechnical Engineering (FGE)Dokumen11 halamanVulnerability Assessment of Buried Pipelines: A Case Study: Frontiers in Geotechnical Engineering (FGE)Anjani Prabhakar100% (1)

- SP 1127 PDFDokumen26 halamanSP 1127 PDFAnjani PrabhakarBelum ada peringkat

- (Pdo Oman) Electrical Safety Specs.Dokumen56 halaman(Pdo Oman) Electrical Safety Specs.KT MENON100% (7)

- Petroleum Development Oman L.L.C.: Instrumented Protective Functions Test Procedure Revision1Dokumen15 halamanPetroleum Development Oman L.L.C.: Instrumented Protective Functions Test Procedure Revision1Anjani Prabhakar0% (1)

- Process Engineering HAZOP Procedure: Petroleum Development Oman L.L.CDokumen17 halamanProcess Engineering HAZOP Procedure: Petroleum Development Oman L.L.CAnjani PrabhakarBelum ada peringkat

- Petroleum Development Oman L.L.C.: Unrestricted Document ID: PR-1259 September 1999-09-12 Filing KeyDokumen43 halamanPetroleum Development Oman L.L.C.: Unrestricted Document ID: PR-1259 September 1999-09-12 Filing KeyAnjani PrabhakarBelum ada peringkat

- Process Engineering HAZOP Procedure: Petroleum Development Oman L.L.CDokumen17 halamanProcess Engineering HAZOP Procedure: Petroleum Development Oman L.L.CAnjani PrabhakarBelum ada peringkat

- Obele Ifenna PDFDokumen197 halamanObele Ifenna PDFGuomin JiBelum ada peringkat

- Structural Analysis of Pipelines PDFDokumen116 halamanStructural Analysis of Pipelines PDFAnjani PrabhakarBelum ada peringkat

- Role of Geotechnical Properties of Soil On Civil Engineering StructuresDokumen8 halamanRole of Geotechnical Properties of Soil On Civil Engineering StructuresAnjani PrabhakarBelum ada peringkat

- Ground Motion Prediction Equations 1964-2019Dokumen651 halamanGround Motion Prediction Equations 1964-2019Anjani PrabhakarBelum ada peringkat

- 966 Comparison Sheet PDFDokumen1 halaman966 Comparison Sheet PDFAnjani PrabhakarBelum ada peringkat

- MS-6.1 Piping SupportsDokumen19 halamanMS-6.1 Piping SupportsLe Thanh HaiBelum ada peringkat

- THERMOWELL VIBRATION ANALYSISDokumen6 halamanTHERMOWELL VIBRATION ANALYSISsheenBelum ada peringkat

- 9273E-300-CN-3531-613 - Attachment 3: About Upheaval and Lateral Buckling of Embedded PipelinesDokumen12 halaman9273E-300-CN-3531-613 - Attachment 3: About Upheaval and Lateral Buckling of Embedded PipelinesAnjani Prabhakar100% (1)

- Dissertation - Aqilah Abu Bakar - 13677Dokumen44 halamanDissertation - Aqilah Abu Bakar - 13677Anjani PrabhakarBelum ada peringkat

- IBP1941 14 Fatigue of Pipelines Subjecte PDFDokumen10 halamanIBP1941 14 Fatigue of Pipelines Subjecte PDFAnjani PrabhakarBelum ada peringkat

- PTC 19 3 TW Example ProblemDokumen10 halamanPTC 19 3 TW Example Problemrichardstorm100% (1)

- 966 Comparison Sheet PDFDokumen1 halaman966 Comparison Sheet PDFAnjani PrabhakarBelum ada peringkat

- A Comparative Study of Subsea Pipelines Lateral Buckling Due To Thermal Expansion in HTHP Environments PDFDokumen110 halamanA Comparative Study of Subsea Pipelines Lateral Buckling Due To Thermal Expansion in HTHP Environments PDFGaurav AgarwalBelum ada peringkat

- Tutorial Soil Overburden and Seismic in Autopipe v95 PDFDokumen56 halamanTutorial Soil Overburden and Seismic in Autopipe v95 PDFAnjani PrabhakarBelum ada peringkat

- Review of Pipeline Span Analyis-2019Dokumen78 halamanReview of Pipeline Span Analyis-2019Anjani PrabhakarBelum ada peringkat

- Ubc 2011 Fall Weerasekara LalindaDokumen294 halamanUbc 2011 Fall Weerasekara LalindaPHILIPPEBelum ada peringkat

- 965 Mathcad Test Roaks - Cased1 2 PDFDokumen6 halaman965 Mathcad Test Roaks - Cased1 2 PDFAnjani PrabhakarBelum ada peringkat

- Lecture 08 03 2012 Buried Piping by Dynaflow PDFDokumen14 halamanLecture 08 03 2012 Buried Piping by Dynaflow PDFhdphimxem100% (1)

- Software Engineering Chapter 6 ExercisesDokumen4 halamanSoftware Engineering Chapter 6 Exercisesvinajanebalatico81% (21)

- A.No.360of19 14.07.21Dokumen133 halamanA.No.360of19 14.07.21Bhupendra CharanBelum ada peringkat

- Effect of Organization Climate On Innovative Work BehaviourDokumen8 halamanEffect of Organization Climate On Innovative Work BehaviourRaja .SBelum ada peringkat

- CMC Internship ReportDokumen62 halamanCMC Internship ReportDipendra Singh50% (2)

- Etl Ab Initio PDFDokumen2 halamanEtl Ab Initio PDFDustin0% (1)

- Inbound 6094510472110192055Dokumen2 halamanInbound 6094510472110192055MarielleBelum ada peringkat

- What Digital Camera - May 2016Dokumen100 halamanWhat Digital Camera - May 2016Alberto ChazarretaBelum ada peringkat

- Dleg0170 Manual PDFDokumen20 halamanDleg0170 Manual PDFEmmanuel Lucas TrobbianiBelum ada peringkat

- 41.2.02 Operational PursuitDokumen14 halaman41.2.02 Operational PursuitNewsChannel 9 StaffBelum ada peringkat

- IM-100 IM-202 IM-300 IM-400 IM-500 Operating and Programming - TOCDokumen6 halamanIM-100 IM-202 IM-300 IM-400 IM-500 Operating and Programming - TOCRudinHarianto0% (1)

- Data SheetddddDokumen31 halamanData SheetddddEm GomezBelum ada peringkat

- 43 CSeT F Mock - 240818 PDFDokumen26 halaman43 CSeT F Mock - 240818 PDFben romdhane ahmedBelum ada peringkat

- IIM Kozhikode Senior Management ProgrammeDokumen14 halamanIIM Kozhikode Senior Management ProgrammeGupta KanBelum ada peringkat

- Project Report On Recruitment and Selection by PreetiDokumen85 halamanProject Report On Recruitment and Selection by Preetipritothegreat86% (7)

- A Tidy GhostDokumen13 halamanA Tidy Ghost12345aliBelum ada peringkat

- Johannes GutenbergDokumen6 halamanJohannes GutenbergMau ReenBelum ada peringkat

- Assessment of Cellular Planning Methods for GSMDokumen5 halamanAssessment of Cellular Planning Methods for GSMradebasicBelum ada peringkat

- 7 - Cold Handling Operation Manual - Version ADokumen355 halaman7 - Cold Handling Operation Manual - Version ARangga Sena PutraBelum ada peringkat

- Grasshopper VB Scripting Primer IntroductionDokumen28 halamanGrasshopper VB Scripting Primer Introductionfagus67Belum ada peringkat

- City Profil Addis AbabaDokumen33 halamanCity Profil Addis AbabaEyuale TBelum ada peringkat

- Banking Fundamentals QuizDokumen5 halamanBanking Fundamentals QuizPhương Nghi LêBelum ada peringkat

- China Identity Verification (FANTASY TECH)Dokumen265 halamanChina Identity Verification (FANTASY TECH)Kamal Uddin100% (1)

- Student Boarding House Quality in Term of Health DDokumen11 halamanStudent Boarding House Quality in Term of Health DPauline Valerie PacturanBelum ada peringkat

- 6Tdvfutfrfr-S: of ofDokumen2 halaman6Tdvfutfrfr-S: of ofhim vermaBelum ada peringkat

- Positive Behavioral Interventions and SupportsDokumen32 halamanPositive Behavioral Interventions and SupportsAbhimanyu SinghBelum ada peringkat

- Alternate Sources OF Finance: FOR RBI Grade B ExamDokumen9 halamanAlternate Sources OF Finance: FOR RBI Grade B ExamAadeesh JainBelum ada peringkat

- 00 2 Physical Science - Zchs MainDokumen4 halaman00 2 Physical Science - Zchs MainPRC BoardBelum ada peringkat

- Ausat Final Set 1Dokumen13 halamanAusat Final Set 1Rajiv RanjanBelum ada peringkat

- Homework 7 Traffic Accident Data AnalysisDokumen5 halamanHomework 7 Traffic Accident Data AnalysisRagini P0% (1)