Designation: E2474 06

Diunggah oleh

Lupita RamirezJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Designation: E2474 06

Diunggah oleh

Lupita RamirezHak Cipta:

Format Tersedia

Designation: E2474 06

Standard Practice for

Pharmaceutical Process Design Utilizing Process Analytical

Technology1

This standard is issued under the fixed designation E2474; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon () indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Process design is the systematic conversion of information about needs for a product into

knowledge about how to manufacture this product. Products and manufacturing processes should be

designed using science- and risk-based design strategies to manage variation.

To attain this goal, integration of Process Analytical Technology (PAT) principles and tools during

process design will enhance opportunities to build, maintain, and expand science- and risk-based

process understanding throughout a product lifecycle. The product lifecycle includes the period in

production as well as development.

Process understanding will be the foundation to establish manufacturing (process selection,

methodology, implementation, and practice), process control (real-time control on the basis of

measured critical quality attributes), effective risk mitigation, and product release concepts.

Process understanding will also enable regulatory strategies in that the level of regulatory scrutiny

may reflect the demonstrated level of science- and risk-based process understanding.

1. Scope responsibility of the user of this standard to establish appro-

1.1 This practice covers process design, which is integral to priate safety and health practices and determine the applica-

process development as well as post-development process bility of regulatory limitations prior to use.

optimization. It is focused on practical implementation and

2. Referenced Documents

experimental development of process understanding.

2.1 Referenced Standards:

1.2 The term process design as used in this practice can

FDA Guidance for Industry: PATA Framework for Inno-

mean:

vative Pharmaceutical Development, Manufacturing, and

1.2.1 The activities to design a process (the process design),

Quality Assurance, September 20042

and/or

ICH Guidance: ICH Q8 Pharmaceutical Development, Step

1.2.2 The outcome of this activity (the designed process).

4 Document, November 20053

1.3 The principles in this practice are applicable to both ICH Guidance: ICH Q9 Quality Risk Management, Step 4

drug substance and drug product processes. For drug products, Document, November 20053

formulation development and process development are inter-

related and therefore the process design will incorporate 3. PAT Process Design Practices

knowledge from the formulation development. 3.1 Desired StateIn the desired state of a process, all

1.4 The principles in this practice apply during development sources of variation are defined and controlled, and end

of a new process or the improvement or redesign of an existing product variation is minimal. That implies that critical product

one, or both. attributes are controlled to target for all individual units of a

1.5 This standard does not purport to address all of the product. As a result, processes are capable of consistently

safety concerns, if any, associated with its use. It is the supplying, unit to unit and batch to batch, the desired quality.

2

Available from Food and Drug Administration (FDA), 5600 Fishers Ln.,

1

This practice is under the jurisdiction of ASTM Committee E55 on Manufac- Rockville, MD 20857, http://www.fda.gov.

3

ture of Pharmaceutical Products and is the direct responsibility of Subcommittee Available from International Conference on Harmonisation of Technical

E55.01 on PAT System Management, Implementation and Practice. Requirements for Registration of Pharmaceuticals for Human Use (ICH), ICH

Current edition approved Nov. 1, 2006. Published November 2006. DOI: Secretariat, c/o IFPMA, 15 ch. Louis-Dunant, P.O. Box 195, 1211 Geneva 20,

10.1520/E2474-06. Switzerland, http://www.ich.org.

Copyright ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

Copyright by ASTM Int'l (all rights reserved); 1

E2474 06

Philosophy and Principles 3.5.2.1 Process steps (unit operations) are evaluated as

connected operations, because outputs are inputs for subse-

3.2 Practice #1: Risk Assessment and MitigationProducts

quent steps.

and manufacturing processes should be designed to minimize

variation. Therefore, process design is a means to mitigate the 3.5.2.2 Measurements are focused on assessment(s) of criti-

risk of having product units with varying quality. The process cal quality attributes and/or factors associated with process

design requires the use of formal risk evaluation methodologies condition rather than on documenting compliance.

and mitigation assessments. 3.5.2.3 Measurements are discriminating (to account for the

multivariate process nature), rather than averaging (because

3.3 Practice #2: Continuous Improvement: information is lost through averaging of data).

3.3.1 Process design starts with the identification of first 3.5.2.4 Process performance-based optimization reduces to-

design options that reflect the desired process state and the tal variability (that is, input material, process, and analytical

desired product attributes. variability).

3.3.2 Evaluation of the first and all following design options 3.5.2.5 Process measurements and controls are designed in.

should follow an iterative process of design improvement.

3.6 Practice #5: Manufacturing Strategy:

3.3.3 Design improvement is continued post-launch (con-

3.6.1 There is a mutual relationship between the develop-

tinuous improvement) to support management of process

ment of the manufacturing process and the risk mitigation

quality throughout the product lifecycle.

strategy for a given product, as the process is designed to

3.3.4 The iterative approach to continuous process design deliver the product with desired attributes.

improvement includes:

3.6.2 The design of the manufacturing process should form

3.3.4.1 Initiation of the design process based on information part of the risk mitigation strategy for a product. For example,

about product structure, composition, desired quality attributes, the risks to the patient for a low dose/high potency drug will be

and so forth, different from a high dose drug, and therefore the manufactur-

3.3.4.2 Definition of initial design concepts based on insti- ing process designed in each case will reflect those differences.

tutional knowledge, intuition, experience, first principles, and 3.6.3 This has the following implications:

so forth, 3.6.3.1 To achieve unit-to-unit consistent quality, all mate-

3.3.4.3 Generation of design options, rial transitions (that is, chemical, physical, or mechanical

3.3.4.4 Identification of feasible design options from devel- transformations) have to be the same for all units of the

opment studies, product.

3.3.4.5 Detailed process development, and 3.6.3.2 Since process scale is a risk factor, process design

3.3.4.6 Design review and learning from experience from should incorporate strategies to mitigate that risk through

development or implementation, or both, scaleable or scale-independent manufacturing operations. For

where quality risk management principles and methodology example, continuous processing technology is an approach to

are applied on each step, and information and learning is achieve scale-independency. Where a process is scaled-up,

fed-back and fed-forward between all steps. product quality and process robustness can be assured by

measuring the in-process material attributes and critical quality

3.4 Practice #3: Process Fitness for Purpose:

attributes, rather than the machine parameters and using these

3.4.1 The evaluation of process design options uses risk to ensure end product quality.

assessment to establish a process that will consistently deliver

the desired outputs. 3.7 Practice #6: Data Collection and Formal Experimental

3.4.2 Process fitness should be established regarding: DesignExperimental design tools (such as Design of Experi-

ments (DoE)) are used to ensure that data is collected through-

3.4.2.1 Product characteristics, product quality definition.

out the design space in a manner that minimizes the necessary

3.4.2.2 Process characteristics, for example, unit operation

experimental load and maximizes the information extracted

quality.

about the process. Several cycles of such experimental work,

3.4.2.3 Process systems (for example, control system, mea- each focusing more closely on the likely operating area, may

surement system). be required to establish initial production process conditions.

3.4.2.4 System components (for example, design elements,

modules, interfaces). Methodology

3.4.2.5 Commercial fitness for purpose. 3.8 Practice #7: Multivariate ToolsMultivariate tools are

3.5 Practice #4: Intrinsic Performance Assessment: used to generate predicted values for the critical quality

3.5.1 Processes should be designed with intrinsic process attributes, to generate values for factors directly or indirectly

assessments and control systems that are integral components linked to process condition, or to generate qualitative informa-

of the manufacturing operations. This approach is fundamen- tion about material. Multivariate tools can be used to under-

tally different from conventional design approaches that rely on stand and control process and product variability.

separation of process from process output assessment, for 3.9 Practice #8: Process AnalyzersIn-, on-, at-line pro-

example, by sampling, averaging, and off-line testing. cess analytical tools are used for rapid measurements which

3.5.2 This has the following implications for process de- can be used to evaluate material attributes and process perfor-

sign: mance and enable process control.

Copyright by ASTM Int'l (all rights reserved); 2

E2474 06

3.10 Practice #9: Process Control: 3.10.2 Process endpoints are based on achieving desired

3.10.1 The combination of univariate and multivariate data critical quality attributes.

derived in real-time from the process is used to evaluate effects

on process critical quality attributes. These in turn are used to 4. Keywords

evaluate the necessary process parametric settings to ensure

4.1 design space; desired state; manufacturing; PAT ; phar-

both the desired process trajectory and end product quality or

maceutical process design; process analytical technology; pro-

desired state. This feedback loop, and any associated feed-

forward and feed-back of data from stage-to-stage, comprises cess understanding; quality risk management

the process control.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the ASTM website (www.astm.org/

COPYRIGHT/).

Copyright by ASTM Int'l (all rights reserved); 3

Anda mungkin juga menyukai

- ICH Quality Guidelines: An Implementation GuideDari EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleBelum ada peringkat

- Pharmaceutical Quality Management System (QMS) Questions and AnswersDari EverandPharmaceutical Quality Management System (QMS) Questions and AnswersBelum ada peringkat

- Process Validation Article 1Dokumen12 halamanProcess Validation Article 1baluchakpBelum ada peringkat

- TRS961 Annex7Dokumen25 halamanTRS961 Annex7Tahir KhanBelum ada peringkat

- Process validation of Benazepril HCl 5 mg tabletDokumen16 halamanProcess validation of Benazepril HCl 5 mg tabletCamila Flórez IdárragaBelum ada peringkat

- Establishing A CGMP Laboratory Audit System: A Practical GuideDari EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideBelum ada peringkat

- Techniques for Downstream process for Biologic Drugs and VaccinesDari EverandTechniques for Downstream process for Biologic Drugs and VaccinesBelum ada peringkat

- Risk Management Applications in Pharmaceutical and Biopharmaceutical ManufacturingDari EverandRisk Management Applications in Pharmaceutical and Biopharmaceutical ManufacturingHamid MollahBelum ada peringkat

- Process Capability EngDokumen11 halamanProcess Capability EngApoloTrevinoBelum ada peringkat

- Module - 5 - PPPQMS - Lifecycle Management 2018Dokumen11 halamanModule - 5 - PPPQMS - Lifecycle Management 2018Indra Maghfurin100% (1)

- Risk-Based Reduced Robustness TestingDokumen8 halamanRisk-Based Reduced Robustness TestingMostafa AfifyBelum ada peringkat

- Introduction To Science and Risk Based Cleaning Validation Using ASTM E3106 E3219Dokumen9 halamanIntroduction To Science and Risk Based Cleaning Validation Using ASTM E3106 E3219nsk79inBelum ada peringkat

- Projects in Contemporary OrganizationsDokumen17 halamanProjects in Contemporary OrganizationssurapolBelum ada peringkat

- E3051 16Dokumen10 halamanE3051 164romi89Belum ada peringkat

- Aseptic and Sterile Processing: Control, Compliance and Future TrendsDokumen2 halamanAseptic and Sterile Processing: Control, Compliance and Future TrendsTim Sandle100% (1)

- Posterior Probability of Passing Compendial TestDokumen47 halamanPosterior Probability of Passing Compendial Testvg_vvgBelum ada peringkat

- Manufacturer Qualification in JakartaDokumen15 halamanManufacturer Qualification in JakartaMillicent SongsterBelum ada peringkat

- Validation Req. in CTD & ProcessDokumen38 halamanValidation Req. in CTD & ProcessOula HatahetBelum ada peringkat

- Sample Size Selection-USP - FDA - ASTMDokumen27 halamanSample Size Selection-USP - FDA - ASTMvg_vvg100% (1)

- Determining Probability of Passing USP Tests with CuDAL-ExcelDokumen6 halamanDetermining Probability of Passing USP Tests with CuDAL-Excellhthang1990Belum ada peringkat

- In Use StabilityDokumen6 halamanIn Use Stabilitytantri ayu lestariBelum ada peringkat

- Statistical Approach For CU Testing CPV Batches & Comparison With USP UDU - Pharmaceutical EngineeringDokumen12 halamanStatistical Approach For CU Testing CPV Batches & Comparison With USP UDU - Pharmaceutical EngineeringJohn PerezBelum ada peringkat

- E3060 16Dokumen14 halamanE3060 164romi89Belum ada peringkat

- Process ValidationDokumen883 halamanProcess Validationjaime manciaBelum ada peringkat

- Pharma Change Control Peither ExecSeries PDFDokumen55 halamanPharma Change Control Peither ExecSeries PDFHamid HamidBelum ada peringkat

- Development and Validation of Dissolution ProceduresDokumen7 halamanDevelopment and Validation of Dissolution ProceduresVenkatesh KoppuBelum ada peringkat

- Establishing Scientifically Justified Acceptance Criteria For The Cleaning Validation of Apis (Active Pharmaceutical Ingredients) (Le Blanc)Dokumen6 halamanEstablishing Scientifically Justified Acceptance Criteria For The Cleaning Validation of Apis (Active Pharmaceutical Ingredients) (Le Blanc)jorgeBelum ada peringkat

- PDA Journal SeptemberDokumen19 halamanPDA Journal SeptemberZia100% (2)

- PDA TR 80 《制药实验室数据完整性管理体系》中英文对照版Dokumen98 halamanPDA TR 80 《制药实验室数据完整性管理体系》中英文对照版于天一100% (1)

- 3rd Annual QBD ConferenceDokumen582 halaman3rd Annual QBD Conferencesumit_waghmareBelum ada peringkat

- Nvironmental Onitoring: Omprehensive AndbookDokumen7 halamanNvironmental Onitoring: Omprehensive Andbookdavincicode888Belum ada peringkat

- Validation of Sterile Water For Injection in PharmDokumen12 halamanValidation of Sterile Water For Injection in PharmSehrish KanwalBelum ada peringkat

- VMP TheoryDokumen34 halamanVMP Theoryparam540Belum ada peringkat

- CPV Case Study - Print VersionDokumen102 halamanCPV Case Study - Print VersionMatíasBelum ada peringkat

- APIC Guideline Technical Change Control Revised Nov2018 PDFDokumen8 halamanAPIC Guideline Technical Change Control Revised Nov2018 PDFPhr Aashish KhadkaBelum ada peringkat

- 20th ISPE International Conference On Concurrent EngineeringDokumen620 halaman20th ISPE International Conference On Concurrent EngineeringHadiBiesBelum ada peringkat

- A History of The OOS ProblemDokumen10 halamanA History of The OOS Problemjljimenez1969Belum ada peringkat

- Preventing of Cross ContaminationDokumen27 halamanPreventing of Cross ContaminationOmar FaruqBelum ada peringkat

- Cleaning Validation for Developmental, Stability and Clinical LotsDokumen7 halamanCleaning Validation for Developmental, Stability and Clinical Lotszer-otakuBelum ada peringkat

- Pub PHEUR-SE04 PDFDokumen357 halamanPub PHEUR-SE04 PDFSantiago IbañezBelum ada peringkat

- Day 1 Session 2 - QRM Applied To CQVDokumen42 halamanDay 1 Session 2 - QRM Applied To CQVBerna Saefullah100% (1)

- Presentation Cleaning ValidationDokumen38 halamanPresentation Cleaning ValidationNishit SuvaBelum ada peringkat

- Statistical Tools For Development and C... in The FDA Process Validation GuidanceDokumen6 halamanStatistical Tools For Development and C... in The FDA Process Validation GuidanceGaoussou TimitéBelum ada peringkat

- Introduction To The ASTM E3106 Standard Guide To Science-Based and Risk-Based Cleaning Process Developmentand ValidationDokumen14 halamanIntroduction To The ASTM E3106 Standard Guide To Science-Based and Risk-Based Cleaning Process Developmentand Validationnsk79in100% (1)

- Visual Inspection of Inject Able Products More Than Just Sorting Good From BadDokumen44 halamanVisual Inspection of Inject Able Products More Than Just Sorting Good From BadEngy Hany Moustafa50% (2)

- 2.8 Science and Risk-BasedDokumen19 halaman2.8 Science and Risk-BasedJorge Humberto HerreraBelum ada peringkat

- Quality Risk Management GuideDokumen48 halamanQuality Risk Management GuideEdy TeranBelum ada peringkat

- Risk Assessment and Management For Healthcare Manufacturing: Practical Tips and Case StudiesDokumen14 halamanRisk Assessment and Management For Healthcare Manufacturing: Practical Tips and Case StudiesTim SandleBelum ada peringkat

- The Future of Systems Validation ACF1D6Dokumen3 halamanThe Future of Systems Validation ACF1D6Mitchel JammalBelum ada peringkat

- Leak Testing PDFDokumen130 halamanLeak Testing PDFఝాన్సీ పుత్ర సతీష్Belum ada peringkat

- Day 2-Session 5 - Introduction To Lean CQVDokumen16 halamanDay 2-Session 5 - Introduction To Lean CQVFikri Firmansah Musa100% (1)

- Pharma Quality WorkDokumen26 halamanPharma Quality WorkBhagwan YadavBelum ada peringkat

- Estimating Number of PPQ Batches: Various Approaches: Journal of Pharmaceutical InnovationDokumen9 halamanEstimating Number of PPQ Batches: Various Approaches: Journal of Pharmaceutical Innovationlhthang1990Belum ada peringkat

- Tim Sandle White Paper EU - GMP - Annex - 1 - The - New - Draft - and - Implications 2020Dokumen15 halamanTim Sandle White Paper EU - GMP - Annex - 1 - The - New - Draft - and - Implications 2020Supriya KapasBelum ada peringkat

- Who Hold Time Studies Rev1 CommentDokumen4 halamanWho Hold Time Studies Rev1 CommentschumonBelum ada peringkat

- Retrofitting Existing Lines with RABSDokumen28 halamanRetrofitting Existing Lines with RABSsteven correaBelum ada peringkat

- ISPE Print PageDokumen1 halamanISPE Print Pagesmallik3Belum ada peringkat

- A Pocket Guide To AuditingDokumen10 halamanA Pocket Guide To Auditingmanojdhamne5802Belum ada peringkat

- SOP-000182638 Phase 1b Investigation ChecklistDokumen3 halamanSOP-000182638 Phase 1b Investigation ChecklistSebastian LopezBelum ada peringkat

- ISPE CCChUSPH2OSuccessDokumen58 halamanISPE CCChUSPH2OSuccessAdam MazurekBelum ada peringkat

- Water Permeability of Geotextiles by Permittivity: Standard Test Methods ForDokumen6 halamanWater Permeability of Geotextiles by Permittivity: Standard Test Methods ForLupita RamirezBelum ada peringkat

- Menu Room Service 2.0Dokumen26 halamanMenu Room Service 2.0Lupita RamirezBelum ada peringkat

- Sampling of Geosynthetics For TestingDokumen3 halamanSampling of Geosynthetics For TestingLupita RamirezBelum ada peringkat

- D 7002 Â " 03 RDCWMDIDokumen6 halamanD 7002 Â " 03 RDCWMDILeón SuárezBelum ada peringkat

- Geosynthetics: Standard Terminology ForDokumen5 halamanGeosynthetics: Standard Terminology ForEdmundo Jaita CuellarBelum ada peringkat

- Non Reinforced PVC (Polyvinyl Chloride) Geomembrane Seams: Standard Specification ForDokumen5 halamanNon Reinforced PVC (Polyvinyl Chloride) Geomembrane Seams: Standard Specification ForLupita RamirezBelum ada peringkat

- Dma PDFDokumen9 halamanDma PDFkrishna saiBelum ada peringkat

- Astm D-4437Dokumen2 halamanAstm D-4437VIDAL AMAU RUIZBelum ada peringkat

- Alkaline Stabilization of Wastewater Treatment Plant ResidualsDokumen6 halamanAlkaline Stabilization of Wastewater Treatment Plant ResidualsLupita RamirezBelum ada peringkat

- Astm D4355 PDFDokumen5 halamanAstm D4355 PDFgadBelum ada peringkat

- Astm D7466Dokumen3 halamanAstm D7466Nhuận PhạmBelum ada peringkat

- ASTM Designation: D517 98 (Reapproved 2008)Dokumen3 halamanASTM Designation: D517 98 (Reapproved 2008)Lupita RamirezBelum ada peringkat

- Astm C1707Dokumen3 halamanAstm C1707Jino LegastoBelum ada peringkat

- Biological Clogging of Geotextile or Soil/Geotextile FiltersDokumen6 halamanBiological Clogging of Geotextile or Soil/Geotextile FiltersLupita RamirezBelum ada peringkat

- Lime and Limestone (As Used by The Industry) : Standard Terminology Relating ToDokumen3 halamanLime and Limestone (As Used by The Industry) : Standard Terminology Relating Toasemamaw damtieBelum ada peringkat

- GoodReader - Getting StartedDokumen10 halamanGoodReader - Getting StartedAditya WaliyantoBelum ada peringkat

- Masonry Cement: Standard Specification ForDokumen4 halamanMasonry Cement: Standard Specification ForLupita RamirezBelum ada peringkat

- ASTM Designation: C 1305 - 08Dokumen3 halamanASTM Designation: C 1305 - 08Lupita RamirezBelum ada peringkat

- ASTM Designation: D4469 11Dokumen4 halamanASTM Designation: D4469 11Lupita RamirezBelum ada peringkat

- Index of Aggregate Particle Shape and Texture: Standard Test Method ForDokumen4 halamanIndex of Aggregate Particle Shape and Texture: Standard Test Method ForLupita RamirezBelum ada peringkat

- Designation: E1530 11Dokumen9 halamanDesignation: E1530 11Lupita RamirezBelum ada peringkat

- Designation: D7175 08Dokumen16 halamanDesignation: D7175 08Lupita RamirezBelum ada peringkat

- Astm E1448/e1448m 09Dokumen9 halamanAstm E1448/e1448m 09Lupita RamirezBelum ada peringkat

- ASTM Designation: E1166 00 (Reapproved 2009)Dokumen2 halamanASTM Designation: E1166 00 (Reapproved 2009)Lupita RamirezBelum ada peringkat

- ASTM Designation: D6723 12Dokumen13 halamanASTM Designation: D6723 12Lupita RamirezBelum ada peringkat

- Designation: D7404 07 (Reapproved 2012)Dokumen3 halamanDesignation: D7404 07 (Reapproved 2012)Lupita RamirezBelum ada peringkat

- Designation: D7404 07 (Reapproved 2012)Dokumen3 halamanDesignation: D7404 07 (Reapproved 2012)Lupita RamirezBelum ada peringkat

- Innovations in Concrete Pavement ConstructionDokumen34 halamanInnovations in Concrete Pavement ConstructionLupita RamirezBelum ada peringkat

- ASTM Designation: D3142/D3142M 11Dokumen4 halamanASTM Designation: D3142/D3142M 11Lupita RamirezBelum ada peringkat

- Designation: D7175 08Dokumen16 halamanDesignation: D7175 08Lupita RamirezBelum ada peringkat

- Accounting Postulates, Concepts and PrinciplesDokumen4 halamanAccounting Postulates, Concepts and PrinciplesKkaran ShethBelum ada peringkat

- International Aspects of Trade SecretDokumen8 halamanInternational Aspects of Trade Secrety500Belum ada peringkat

- Swot AnalysisDokumen4 halamanSwot AnalysisMariel TinolBelum ada peringkat

- Measure HR's Impact on Business GoalsDokumen11 halamanMeasure HR's Impact on Business Goalskartik bharadwajBelum ada peringkat

- Cambodia Garment Sector Main Report NathanDokumen68 halamanCambodia Garment Sector Main Report Nathanaman.4u100% (1)

- Petition for review of CA decision reversing CTA ruling on tax assessmentsDokumen16 halamanPetition for review of CA decision reversing CTA ruling on tax assessmentscarl dianneBelum ada peringkat

- Maryland Open Meetings Act Manual CompleteDokumen97 halamanMaryland Open Meetings Act Manual CompleteCraig O'DonnellBelum ada peringkat

- Canary Wharfian PDFDokumen1 halamanCanary Wharfian PDFGleb PilipenkoBelum ada peringkat

- Tax Case AssignmentDokumen3 halamanTax Case AssignmentChugsBelum ada peringkat

- Jakarta Property Market Research Report Q3 2019Dokumen16 halamanJakarta Property Market Research Report Q3 2019Deni MuliyawanBelum ada peringkat

- Auditing Trs by IcapDokumen53 halamanAuditing Trs by IcapArif AliBelum ada peringkat

- Tabangao Shell Refinery Employees Association v. Pilipinas Shell Petroleum CorporationDokumen26 halamanTabangao Shell Refinery Employees Association v. Pilipinas Shell Petroleum CorporationAnnie Herrera-LimBelum ada peringkat

- Buyer Receipt for Used Toyota CorollaDokumen1 halamanBuyer Receipt for Used Toyota CorollaMoisés BoquinBelum ada peringkat

- Assignment - MQC708Dokumen16 halamanAssignment - MQC708Eng Abdulkadir MahamedBelum ada peringkat

- Study on inventory management at Micon EngineersDokumen39 halamanStudy on inventory management at Micon EngineersAnbalagan AnbaBelum ada peringkat

- G Ym 6 F 8 HEtoev 4 GEbDokumen6 halamanG Ym 6 F 8 HEtoev 4 GEbPrakhar AgarwalBelum ada peringkat

- OHSAS 18001 GuideDokumen10 halamanOHSAS 18001 Guidevij2009Belum ada peringkat

- Sukuk Al-IstithmarDokumen3 halamanSukuk Al-IstithmarethicalbankerBelum ada peringkat

- 2017 Fall 179 HimelsteinDokumen4 halaman2017 Fall 179 HimelsteinZaki AlattarBelum ada peringkat

- More Than A School A Way of Life: 2020 Fee ScheduleDokumen1 halamanMore Than A School A Way of Life: 2020 Fee ScheduleRoss SaundersBelum ada peringkat

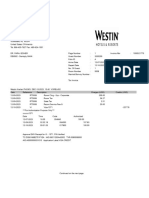

- Westin Hotels & Resorts - 2023-12-10 - 257.78Dokumen2 halamanWestin Hotels & Resorts - 2023-12-10 - 257.78rahul.transcountsBelum ada peringkat

- PVAI VPO - Membership FormDokumen8 halamanPVAI VPO - Membership FormRajeevSangamBelum ada peringkat

- Ece TrainingDokumen95 halamanEce TrainingAyush MittalBelum ada peringkat

- Business Model Canvas: Gujarat Technological UniversityDokumen6 halamanBusiness Model Canvas: Gujarat Technological UniversityD VBelum ada peringkat

- DUPA - 15 StoreyDokumen45 halamanDUPA - 15 StoreyMark Christian FloresBelum ada peringkat

- Global Forecast For Machine Tools - OXFORD ECONOMICS (November 2018)Dokumen132 halamanGlobal Forecast For Machine Tools - OXFORD ECONOMICS (November 2018)Sa RaBelum ada peringkat

- The Family Finance WorkshopDokumen40 halamanThe Family Finance WorkshopPierre PucheuBelum ada peringkat

- Mock Test No. 4 ReviewDokumen5 halamanMock Test No. 4 ReviewFTU.CS2 Nghiêm Mai Yến NhiBelum ada peringkat

- Make My TripDokumen4 halamanMake My TripAhmad NoorBelum ada peringkat

- Arbitration Role Playing ScriptDokumen18 halamanArbitration Role Playing ScriptClimz Aether100% (1)