The Task of 5-Axis Milling PDF

Diunggah oleh

Manikanda PrabhucDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

The Task of 5-Axis Milling PDF

Diunggah oleh

Manikanda PrabhucHak Cipta:

Format Tersedia

P. Pokorn et al.

Zadaa 5-osnog glodanja

ISSN 1330-3651

UDC/UDK 621.914.014

THE TASK OF 5-AXIS MILLING

Peter Pokorn, Jozef Peterka, tefan Vclav

Preliminary notes

The article deals with 5-axis milling. This milling method is currently used in manufacturing of complex shaped parts. The 5-axis milling achieves increased

accuracy of components because it is possible to mill a component from five sides at one clamp. The description of 5-axis milling machines structures is also

mentioned as well as the equations for the calculation of important parameters of a hemispherical milling cutter. These parameters are adjusted for 5-axis

milling. Finally, effective cutting speed and effective feed rates exploitation in practice are summarized.

Keywords: effective cutting speed, effective feed rat, 5-axis milling, structures of milling machines

Zadaa 5-osnog glodanja

Prethodno priopenje

lanak se bavi 5-osnim glodanjem. Ova se metoda glodanja koristi u proizvodnji sloenih oblikovanih dijelova. Njome se postie vea tonost elemenata jer se

element moe glodati s pet strana kod jednog stezanja. Daje se i opis konstrukcije strojeva za 5-osno glodanje kao i jednadbe za izraunavanje vanih

parametara polukuglastog glodala. Ovi parametri su podeeni za 5-osno glodanje. Na kraju se upuuje na uporabu uinkovite brzine rezanja i uinkovitog

posmaka u praksi.

Kljune rijei: uinkovita brzina rezanja, uinkovit posmak, 5-osno glodanje, konstrukcije glodalica

1 2

Introduction Structures of 5 axis milling centres

In the past, parts were produced from stock with simple All structures of machines are inventions which have

shape (cylinder, prism, etc.). Surfaces were machined on started according to the industrial needs [4]. Tool movement

conventional machine tools. This often required a simple in a space distinguishes two phases [9]:

linear linkage of the two movements, which could be 1) positioning it is the reference point displacement (e.g.

provided in a mechanical way (for example rotation and centre of gravity) from one spatial position to another,

translation in turning of a cylinder). Today complex shaped 2) directioning it is the spatial angular orientation of the

surfaces are also machined [7]. These shapes are known in tool eventually of the workpiece to a reference point.

the literature as FFS (Free Form Surfaces). These shapes

cannot be described analytically easily. Parts with FFS are

effectively produced by production technologies like

injection, blowing, precision casting, precision forming,

forging, pressing and other. For these technologies it is

necessary to produce tools. Those are: foundry models and

molds, forging dies, forming tools and injection molds.

FFS are now produced on CNC milling centers,

therefore it is possible to produce a whole shape on one

machine tool in one clamping. The most widely used are 5 -

axis milling centers. Components are designed in a CAD

system.

Designing a part according to the application methods

is important [5]. This relates to the possibility of component

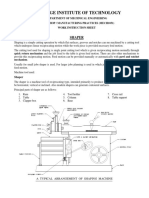

production, consequently to a tool moves during operation Figure 1 5D machine structure with swivel rotary table

[1]. A program for the CNC machine tool is generated in a

CAM system [6]. Machine tool, tools, or machined surface Universal structure of a machine tool has six degrees of

may be damaged, therefore the program must be simulated freedom [8]. It is possible to move the tool at any position in

and debugged [3]. Thanks to that it is possible to avoid space. When rotary tool is used in machining (milling), the

collisions. machine`s structure has five degrees of freedom. In practice

The basic structures of 5-axis milling centers as well as it means the control of five (5D) machine's axes. In general,

equations for the calculation of important parameters of a a 5D axis layout of the machine's structure can be realized in

hemispherical milling cutter are described in this article. three ways:

These parameters will be applied to the 5-axis milling. - translational movement provides tool positioning and

Finally, effective cutting speed and effective feed rates rotational movement provides the workpiece

exploitation in practice are summarised. positioning. The tool moves translationally in axes X,

Y, Z and the workpiece is rotated around two axes: A, C

(Fig. 1),

- rotational movement provides tool directioning and

translational movement provides workpiece

Tehniki vjesnik 19, 1(2012), 147-150 147

The task of 5-axis milling P. Pokorn et al.

positioning. The tool is rotated around two axes B, C move up or down. Longitudinal upward milling is shown in

and the workpiece moves translationally in axes X, Y, Z Fig. 5.

(Fig. 2),

- various combinations of the two previous cases (Fig. 3).

Figure 5 Longitudinal upward milling

Figure 2 5D machine structure with tool rotation in two axes The situation for longitudinal downward milling is

illustrated in Fig. 6.

Figure 3 5D machine structure with tool rotation and workpiece rotation

Figure 6 Longitudinal downward milling

The symbols in figures:

ap depth of cut, mm

R radius of the cutter, mm

vf feed rate, mm/min

a slope angle of milling surface,

Figure 4 Turbine wheel blades Ref1 effective radius of the cutter at machined surface, mm

n frequency of spindle rotation, 1/min

According to practice requirements, where more and Ref2 effective radius of the cutter at machined surface, mm

more FFS are machined, application machines with 5D ap,max maximum depth of cut, mm

structure are also increasing. Various shapes, for example ap,ident identical depth of cut, mm

engine rotors, turbine wheels with blades of various shapes ap,crit critical depth of cut, mm.

are produced on 5D machine tools (Fig. 4).

Equations for effective radius calculation were deduced

3 from [2, 8]. These equations are valid for 3-axis machining.

3 and 5 axis milling with hemispherical cutter Machined surface is sloped and tool is in vertical position.

Equation for calculation of Ref1 has the following form [10]:

When milling FFS, a combination of different surfaces

is machined. Surfaces form the final shape of the product. R ef1 = R sina (1)

Surfaces can be milled either upwards or downwards [2].

The most applied milling strategy in 5-axis milling is

where:

"constant Z". It is a longitudinal milling where the cutter can

Ref1 effective radius of the cutter at machined surface, mm

148 Technical Gazette 19, 1(2012), 147-150

P. Pokorn et al. Zadaa 5-osnog glodanja

R radius of the cutter, mm where:

a lead angle of milling surface, . vc,i instantaneous effective cutting speed, m/min

Ref,i instantaneous effective radius, mm

In 5-axis milling a problem occurs. That is why it is n frequency of spindle rotation, 1/min.

important to analyse the situation for longitudinal upward

milling with cutter lead angle (Fig. 7). In milling of FFS parts constant instantaneous effective

cutting speed vc,i is required. Hence we need to formulate

instantaneous frequency of spindle rotation ni from equation

(4). The equation is (5).

1000 . v c,i

ni = (5)

2 . R ef ,i

where:

vc,i instantaneous effective cutting speed, m/min

Ref,i instantaneous effective radius, mm

ni instantaneous frequency of spindle rotation, 1/min.

When programming the CNC machine tools in the NC

code the frequency of spindle rotation is presented as S. If

we know the value of instantaneous slope angle of milling

surface ai and lead angle from the vertical axis b, we can

calculate instantaneous frequency of spindle rotation ni that

will be used in the NC program. Thanks to that constant

cutting speed is achieved for whole surface milling and

consequently the constant surface roughness is ensured.

Figure 7 5 axes longitudinal upward milling Frequency of spindle rotation is closely related to the

feed rate, therefore it is possible to calculate required feed

Equation (1) for calculating Ref1 is not valid. It is rate at a moment according to equation:

necessary to add further parameters. It is lead angle from the

vertical axis milling b, and the contact angle of the cutter 1000 vc ,i

vf ,i = f z z (6)

with machined surface j. Contact angle is calculated from 2 Ref, i

the equation:

where:

j =a - b (2) vf,i instantaneous effective feed rate, mm/min

Ref,i instantaneous effective radius, mm

where: vc,i instantaneous effective cutting speed, m/min

j contact angle of the cutter with machined surface, fz feed per tooth, mm

a slope angle of milling surface, z number of teeth.

b lead angle from the vertical axis milling, .

5

Then we can calculate the effective radius of the cutter at Conclusion

machined surface from equation:

In the paper we have described the task of 5-axis milling.

R ef 1 = R sin j (3 ) The 5-axis milling is a very wide topic. The structures of

existing machine tools, calculation of effective radius of the

where: cutter at machined surface and using of effective cutting

Ref1 effective radius of the cutter at machined surface, mm speed and feed rates in practice are described. The next

R radius of the cutter, mm research will be focused on derivation of the equations for

j contact angle of the cutter with machined surface, . effective radius of the cutter in machined surface

calculating. The current project will solve the impact of lead

angle from the vertical axis milling on dynamic

4 characteristics of the cutting process: cutting force and its

Effective cutting speed and effective feed rate in practice components and vibration generated in the process of 5-axis

milling. The result will be the derivation and experimental

In technical practice it is common that parts have verification of equations for cutting forces calculation. We

different surfaces, thus the value of effective radius will also will also study the issues of structures of milling machines,

change. This also changes the value of instantaneous CAM milling strategies and their impact on the accuracy

effective cutting speed. We calculate this value from the and roughness of machined surfaces. Our research is

equation: realized in the "Centre of Excellence of 5-axis machining",

(Fig. 8) where necessary machine tools and devices are

2 Ref i n located.

vc ,i = (4)

1000

Tehniki vjesnik 19, 1(2012), 147-150 149

The task of 5-axis milling P. Pokorn et al.

Authors' addresses

Pokorn Peter, Assoc. Prof., PhD.

Address: Slovak University of Technology

Faculty of Materials Science and Technology

Bottova 25, 917 24, Trnava, Slovak Republic

Contact: Tel. +421 906 068 386

e-mail: peter.pokorny@stuba.sk

Peterka Jozef, Prof. Dr.

Address: Slovak University of Technology

Faculty of Materials Science and Technology

Bottova 25, 917 24, Trnava, Slovak Republic

Contact: Tel. +421 905 930 245

Figure 8 Centre of Excellence of 5-axis machining e-mail: jozef.peterka@stuba.sk

Vclav tefan, MSc, PhD.

Acknowledgements Address: Slovak University of Technology

Faculty of Materials Science and Technology

The article was written within the project of the Bottova 25, 917 24, Trnava, Slovak Republic

Contact: Tel. +421 906 068 386

European Union Structural Funds: "Centre of Excellence of e-mail: stefan.vaclav@stuba.sk

5-axis machining".

6

References

[1] Valentovic, E. Machining Strategy. Bratislava: STU 2007.

[2] Pokorn, P. Technological factors of CNC milling of free

form surfaces Habilitation work, Trnava, STU v Bratislave,

2009., 94.

[3] Jurko, J.; Dupon, M.; Panda, A.; Gajdo, M.; Pandov, I.

Deformation of Material Under the Machined Surface in the

Manufacture of Drilling Holes in Austenitic Stainless Steel. //

Chemick listy, 105, (S)(2011), 600-602.

[4] Pokorn, P.; Valentovic, E. What are hybrid structures? //

Strojrstvo, Strojrenstv, Februr 2004., str. 52.

[5] Sendersk, K.; Mare, A.; Fabian, M. Practical application of

ergonomic CATIA modules for the analysis of manual

assembly workplaces. // IT CAD, 18, 2(2008), 18-19.

[6] Fabian, M.; Iol, P.; Spik, E. CAM a CNC: Theory of

machining based on the virtual model. // Computer Design,

4(2006), 22-25.

[7] Valentovic, E.; Peterka, J.; Pokorn, P. The machining of the

most complicated shapes. // MATAR Praha 2004 -

Proceedings of Sections 2, 3, 4. Forming machines and

forming production systems. Industrial robots and

automation. Machining and forming processes / International

Congres. Praha, Brno, 21.-23.9.2004. - Praha : Cesk vysok

ucen technick v Praze, 2004., 225-228.

[8] Peterka, J. 3D copy milling with copy cutter. Cutting process.

// CO-MAT-TECH, 1996., 281-258.

[9] Valentovic, E.; Pokorn, P. The serial ortogonal structures of

the tool machines. // CO-MAT-TECH, 2001., 391-396.

[10] Peterka, J. Analysis of the geometry and kinematics of copy

milling. // Vedeck prce MtF STU v Trnave, zvzok 5, 1997.,

53-58.

150 Technical Gazette 19, 1(2012), 147-150

Anda mungkin juga menyukai

- Production Engineering: Jig and Tool DesignDari EverandProduction Engineering: Jig and Tool DesignPenilaian: 4 dari 5 bintang4/5 (9)

- JigDokumen13 halamanJigJunaid YBelum ada peringkat

- Patrick Meyer Reliability Understanding Statistics 2010Dokumen160 halamanPatrick Meyer Reliability Understanding Statistics 2010jcgueinj100% (1)

- Evolution Army 3 R DadDokumen341 halamanEvolution Army 3 R DadStanisław DisęBelum ada peringkat

- The Task of 5-Axis Milling: Peter Pokorný, Jozef Peterka, Štefan VáclavDokumen4 halamanThe Task of 5-Axis Milling: Peter Pokorný, Jozef Peterka, Štefan VáclavNatalie WyattBelum ada peringkat

- 20 Shaping, Planing and Slotting Machines.Dokumen16 halaman20 Shaping, Planing and Slotting Machines.PRASAD326100% (2)

- 5-Axis Milling Machine For Drilling Inclined Holes in PartsDokumen9 halaman5-Axis Milling Machine For Drilling Inclined Holes in PartsMido MoussaBelum ada peringkat

- Machine Tools (Workshop Technology) PDFDokumen11 halamanMachine Tools (Workshop Technology) PDFvenkateshyadav2116100% (1)

- Pressed PDFDokumen8 halamanPressed PDFShantanu SinghBelum ada peringkat

- 19 Kinematic System and Operations of Milling Machines.Dokumen23 halaman19 Kinematic System and Operations of Milling Machines.PRASAD326100% (5)

- Five Axis MachinesDokumen9 halamanFive Axis Machinesacalderab5377Belum ada peringkat

- Module 2 - MC TOOLS, CNC & 3D PRINTINGDokumen27 halamanModule 2 - MC TOOLS, CNC & 3D PRINTINGSHARATH RBelum ada peringkat

- A Review of Usability of Portable Milling Machine From Micro To Macro PartsDokumen6 halamanA Review of Usability of Portable Milling Machine From Micro To Macro PartsajayBelum ada peringkat

- Me 8451MT Ii MT 5 AnswerDokumen4 halamanMe 8451MT Ii MT 5 AnswerJayaram R S [MECH]Belum ada peringkat

- Journal Pre-ProofDokumen16 halamanJournal Pre-ProofMido MoussaBelum ada peringkat

- Lathe Machine AttachmentDokumen15 halamanLathe Machine Attachmentgajanan maharajBelum ada peringkat

- 3D Surface Topography Analysis in 5-Axis Ball-End MillingDokumen4 halaman3D Surface Topography Analysis in 5-Axis Ball-End MillingBrahim BenmohammedBelum ada peringkat

- Assignment 2Dokumen3 halamanAssignment 2Amer KhayyatBelum ada peringkat

- Machine Shop Theory and Practi Ce: Mechanical EngineeringDokumen14 halamanMachine Shop Theory and Practi Ce: Mechanical EngineeringJohn BorjaBelum ada peringkat

- Application of Incremental Sheet FormingDokumen5 halamanApplication of Incremental Sheet FormingSaif RezguiBelum ada peringkat

- Unit V PDFDokumen28 halamanUnit V PDFChandran PandiyanBelum ada peringkat

- Unit Iii Other Machine ToolsDokumen41 halamanUnit Iii Other Machine Toolsrkscad11Belum ada peringkat

- Advanced Control Technologies For 5-Axis Machining: Masako SudoDokumen2 halamanAdvanced Control Technologies For 5-Axis Machining: Masako SudoThirugnanam DhandayuthapaniBelum ada peringkat

- Power Skiving PDFDokumen11 halamanPower Skiving PDFmadhavikBelum ada peringkat

- Aug2001 - Mechanistic Modeling of The Ball End Milling Process For Multi-Axis Machining of Free-Form SurfacesDokumen11 halamanAug2001 - Mechanistic Modeling of The Ball End Milling Process For Multi-Axis Machining of Free-Form SurfacesusamaumerBelum ada peringkat

- Karpuschewski2018 ReferenceWorkEntry GearGrindingDokumen9 halamanKarpuschewski2018 ReferenceWorkEntry GearGrindingسید مرتضی حسینیBelum ada peringkat

- Government Polytechnic, Sirsa: Branch: Mechanical Engineering Subject: Workshop Technology - Iii Semester: 5ThDokumen168 halamanGovernment Polytechnic, Sirsa: Branch: Mechanical Engineering Subject: Workshop Technology - Iii Semester: 5ThJay YadavBelum ada peringkat

- Me 330 Lab ManualDokumen43 halamanMe 330 Lab ManualberhaneBelum ada peringkat

- Topic 3: Machining Process: 3.4: Lathe MachineDokumen41 halamanTopic 3: Machining Process: 3.4: Lathe MachineAnti SugarBelum ada peringkat

- QB114433Dokumen12 halamanQB114433Saravanan ShriBelum ada peringkat

- Workshop Practice Lecture Week 01-ADokumen34 halamanWorkshop Practice Lecture Week 01-AArham AmjadBelum ada peringkat

- Comparison of Manufacturing Data Analysis For 5 3Dokumen6 halamanComparison of Manufacturing Data Analysis For 5 3Joss JossBelum ada peringkat

- LABORATORY MANUAL For TA202PDokumen42 halamanLABORATORY MANUAL For TA202Pप्रखर गुप्ताBelum ada peringkat

- Cutting MethodsDokumen9 halamanCutting MethodsGomez Eider100% (1)

- Shaper Planer N SlotterDokumen23 halamanShaper Planer N SlotterAtif WahidBelum ada peringkat

- Metal Cutting: Machining & Machining Tools Unit-1Dokumen90 halamanMetal Cutting: Machining & Machining Tools Unit-1Joao PedroBelum ada peringkat

- Milling MachineDokumen20 halamanMilling MachineBrent Neil SobrepeñaBelum ada peringkat

- Klocke 2014Dokumen56 halamanKlocke 2014ashoku24007Belum ada peringkat

- G7 Shaper MachinesDokumen18 halamanG7 Shaper MachinesAchal SakyaBelum ada peringkat

- Simulation and Experimental of 5 - Axis MillingDokumen13 halamanSimulation and Experimental of 5 - Axis MillingVladimir TsargenzkiBelum ada peringkat

- Jig and FixtureDokumen24 halamanJig and FixtureprabhjotbhangalBelum ada peringkat

- Surface Swept by A Toroidal Cutter During 5-Axis MachiningDokumen10 halamanSurface Swept by A Toroidal Cutter During 5-Axis MachiningJulen MartinezBelum ada peringkat

- CH 6 Machining ProcessesDokumen32 halamanCH 6 Machining ProcessesjssrikantamurthyBelum ada peringkat

- Okuma OSP 5 Axis TrainingDokumen49 halamanOkuma OSP 5 Axis TrainingRick WilliamsBelum ada peringkat

- Module-2 Machining Process: Lesson ContentsDokumen20 halamanModule-2 Machining Process: Lesson ContentsYashas KattemaneBelum ada peringkat

- Jig ManufacturingDokumen13 halamanJig ManufacturingAnurag JoshiBelum ada peringkat

- Me6411 Manufacturing Technology-II Lab ManualDokumen35 halamanMe6411 Manufacturing Technology-II Lab ManualdibyenindusBelum ada peringkat

- Milling Introduction Types of Milling MachineDokumen21 halamanMilling Introduction Types of Milling MachineHUyBelum ada peringkat

- Milling Introduction Types of Milling MachineDokumen21 halamanMilling Introduction Types of Milling MachineHUyBelum ada peringkat

- Milling Introduction Types of Milling MachineDokumen21 halamanMilling Introduction Types of Milling Machineboanerges wino pattyBelum ada peringkat

- 05 - Machine Shop - Milling - and - ShaperDokumen10 halaman05 - Machine Shop - Milling - and - ShaperAnurag MukherjeeBelum ada peringkat

- Me6411 Manufacturing Technology-II Lab ManualDokumen35 halamanMe6411 Manufacturing Technology-II Lab ManualRamanvlrBelum ada peringkat

- Performance-Based Gear Metrology: Kinematic - Transmission - Error Computation and DiagnosisDari EverandPerformance-Based Gear Metrology: Kinematic - Transmission - Error Computation and DiagnosisBelum ada peringkat

- Traditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingDari EverandTraditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingPenilaian: 5 dari 5 bintang5/5 (2)

- Planar Linkage Synthesis: A modern CAD based approachDari EverandPlanar Linkage Synthesis: A modern CAD based approachBelum ada peringkat

- Bearings: A Tribology HandbookDari EverandBearings: A Tribology HandbookM. J. NealePenilaian: 3 dari 5 bintang3/5 (8)

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheDari EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LathePenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Dynamics of the Rigid Solid with General Constraints by a Multibody ApproachDari EverandDynamics of the Rigid Solid with General Constraints by a Multibody ApproachBelum ada peringkat

- Matrix Approach To Variance AnalysisDokumen5 halamanMatrix Approach To Variance AnalysisManikanda PrabhucBelum ada peringkat

- Variance Analysis Worksheet/Template: Overview & PurposeDokumen2 halamanVariance Analysis Worksheet/Template: Overview & PurposeManikanda PrabhucBelum ada peringkat

- 828D Hardware Man en-US en-USDokumen270 halaman828D Hardware Man en-US en-USManikanda Prabhuc50% (2)

- WakeForestUniversity SS 111715 Web USDokumen4 halamanWakeForestUniversity SS 111715 Web USManikanda PrabhucBelum ada peringkat

- Geometric Tolerance Analysis: Abstract This Chapter Focuses On Five Main Literature Models of Geometric TolerDokumen31 halamanGeometric Tolerance Analysis: Abstract This Chapter Focuses On Five Main Literature Models of Geometric TolerManikanda PrabhucBelum ada peringkat

- Bosch Rexroth Case StudyDokumen4 halamanBosch Rexroth Case StudyManikanda PrabhucBelum ada peringkat

- AutoCAD Electrical Having The Manufacturer Catalog InformationDokumen1 halamanAutoCAD Electrical Having The Manufacturer Catalog InformationManikanda PrabhucBelum ada peringkat

- Lecture2 GranulopoiesisDokumen9 halamanLecture2 GranulopoiesisAfifa Prima GittaBelum ada peringkat

- 7TH Maths F.a-1Dokumen1 halaman7TH Maths F.a-1Marrivada SuryanarayanaBelum ada peringkat

- Scholastica: Mock 1Dokumen14 halamanScholastica: Mock 1Fatema KhatunBelum ada peringkat

- Week-3-Q1-Gen Chem-Sep-11-15-DllDokumen12 halamanWeek-3-Q1-Gen Chem-Sep-11-15-DllJennette BelliotBelum ada peringkat

- Quarter 1-Week 2 - Day 2.revisedDokumen4 halamanQuarter 1-Week 2 - Day 2.revisedJigz FamulaganBelum ada peringkat

- Sakui, K., & Cowie, N. (2012) - The Dark Side of Motivation - Teachers' Perspectives On 'Unmotivation'. ELTJ, 66 (2), 205-213.Dokumen9 halamanSakui, K., & Cowie, N. (2012) - The Dark Side of Motivation - Teachers' Perspectives On 'Unmotivation'. ELTJ, 66 (2), 205-213.Robert HutchinsonBelum ada peringkat

- Eggermont 2019 ABRDokumen15 halamanEggermont 2019 ABRSujeet PathakBelum ada peringkat

- Leadership Styles-Mckinsey EdDokumen14 halamanLeadership Styles-Mckinsey EdcrimsengreenBelum ada peringkat

- ASHRAE Journal - Absorption RefrigerationDokumen11 halamanASHRAE Journal - Absorption Refrigerationhonisme0% (1)

- RFID Seminar AbstractDokumen2 halamanRFID Seminar Abstractanushabhagawath80% (5)

- Antena TelnetDokumen4 halamanAntena TelnetMarco PiambaBelum ada peringkat

- CHAPTER 1 SBL NotesDokumen13 halamanCHAPTER 1 SBL NotesPrieiya WilliamBelum ada peringkat

- Chapter 2Dokumen13 halamanChapter 2Kumkumo Kussia KossaBelum ada peringkat

- CL57T V4.0Dokumen14 halamanCL57T V4.0dimitriBelum ada peringkat

- Science 4 Diagnostic/Achievement TestDokumen5 halamanScience 4 Diagnostic/Achievement TestGe PebresBelum ada peringkat

- Z-Purlins: Technical DocumentationDokumen11 halamanZ-Purlins: Technical Documentationardit bedhiaBelum ada peringkat

- ISO 27001 Introduction Course (05 IT01)Dokumen56 halamanISO 27001 Introduction Course (05 IT01)Sheik MohaideenBelum ada peringkat

- Sample Monologues PDFDokumen5 halamanSample Monologues PDFChristina Cannilla100% (1)

- The cardioprotective effect of astaxanthin against isoprenaline-induced myocardial injury in rats: involvement of TLR4/NF-κB signaling pathwayDokumen7 halamanThe cardioprotective effect of astaxanthin against isoprenaline-induced myocardial injury in rats: involvement of TLR4/NF-κB signaling pathwayMennatallah AliBelum ada peringkat

- Lecture 2 Effects of Operating Conditions in VCCDokumen9 halamanLecture 2 Effects of Operating Conditions in VCCDeniell Joyce MarquezBelum ada peringkat

- National Anthems of Selected Countries: Country: United States of America Country: CanadaDokumen6 halamanNational Anthems of Selected Countries: Country: United States of America Country: CanadaHappyBelum ada peringkat

- Enochian Dragon Ritual PDFDokumen4 halamanEnochian Dragon Ritual PDFDenis NantelBelum ada peringkat

- Apexi Powerfc Instruction ManualDokumen15 halamanApexi Powerfc Instruction ManualEminence Imports0% (2)

- Clark SM 616 Service ManualDokumen20 halamanClark SM 616 Service Manualenid100% (55)

- Jackson V AEGLive - May 10 Transcripts, of Karen Faye-Michael Jackson - Make-up/HairDokumen65 halamanJackson V AEGLive - May 10 Transcripts, of Karen Faye-Michael Jackson - Make-up/HairTeamMichael100% (2)

- SachinDokumen3 halamanSachinMahendraBelum ada peringkat

- Music CG 2016Dokumen95 halamanMusic CG 2016chesterkevinBelum ada peringkat

- Inside:: Issue 4 - February 2004 Bi-Monthly Warhammer E-ZineDokumen40 halamanInside:: Issue 4 - February 2004 Bi-Monthly Warhammer E-ZineJoe BloggsBelum ada peringkat