Astm e 1264

Diunggah oleh

asdrecvJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Astm e 1264

Diunggah oleh

asdrecvHak Cipta:

Format Tersedia

Designation: E1264 14

Standard Classification for

Acoustical Ceiling Products1

This standard is issued under the fixed designation E1264; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon () indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope E413 Classification for Rating Sound Insulation

1.1 This classification covers ceiling products that provide E795 Practices for Mounting Test Specimens During Sound

acoustical performance and interior finish in buildings. Prod- Absorption Tests

ucts used in performance spaces and other special applications E1110 Classification for Determination of Articulation Class

may require more detailed specification than provided by this E1111 Test Method for Measuring the Interzone Attenuation

classification. of Open Office Components

E1414 Test Method for Airborne Sound Attenuation Be-

1.2 This classification classifies acoustical ceilings by type, tween Rooms Sharing a Common Ceiling Plenum

pattern, and certain ratings for acoustical performance, light E1477 Test Method for Luminous Reflectance Factor of

reflectance, and fire safety. It does not cover the aspects of Acoustical Materials by Use of Integrating-Sphere Reflec-

acoustical ceilings when used as a component of a system or tometers

assembly tested for fire endurance or floor/ceiling sound

transmission. 3. Terminology

1.3 This classification does not include physical properties,

3.1 DefinitionsFor definitions of terms used in this

such as structural hardness, friability, sag, linear expansion and

classification, see Terminology C634.

contraction, and transverse strength, which may affect the

handling, installation, and use of acoustical ceiling products 3.2 Definitions of Terms Specific to This Standard:

(see Test Methods C367). 3.2.1 acoustical panela form of a prefabricated sound

1.4 The values stated in inch-pound units are to be regarded absorbing ceiling element used with exposed suspension sys-

as standard. The values given in parentheses are mathematical tems.

conversions to SI units that are provided for information only 3.2.2 acoustical tilea form of a prefabricated sound ab-

and are not considered standard. sorbing ceiling element used with concealed or semi-exposed

suspension systems, stapling, or adhesive bonding.

2. Referenced Documents

3.2.3 butta joint detail for acoustical tile, butt bevel, or

2.1 ASTM Standards:2 butt square edge, without kerfing of the edges, intended for

C367 Test Methods for Strength Properties of Prefabricated adhesive bonding to solid backing.

Architectural Acoustical Tile or Lay-In Ceiling Panels

C423 Test Method for Sound Absorption and Sound Absorp- 3.2.4 edge and joint detailvarious edge and joint details

tion Coefficients by the Reverberation Room Method are available in accordance with Table 1 and Fig. 1 for

C634 Terminology Relating to Building and Environmental acoustical ceiling products.

Acoustics 3.2.5 excelsiorlong, thin wood shavings.

E84 Test Method for Surface Burning Characteristics of 3.2.6 fissured patterna surface with irregular depressions

Building Materials of varying lengths, widths, and depths extending below the

basic product face.

1

This classification is under the jurisdiction of ASTM Committee E33 on 3.2.7 flush reveal edgeacoustical lay-in panels are in-

Building and Environmental Acoustics and is the direct responsibility of Subcom-

mittee E33.04 on Application of Acoustical Materials and Systems. tended for use in direct hung exposed suspension systems with

Current edition approved Oct. 1, 2014. Published January 2015. Originally a narrow exposed edge that is flush with the panel face.

approved in 1988. Last previous edition approved in 2008 as E1264 081. DOI:

10.1520/E1264-14. 3.2.8 glass fiber baseceilings composed principally of

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or glass in fiber form with appropriate binders.

--``,``,`````````,,,,,``,````,-`-`,,`,,`,`,,`---

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standards Document Summary page on 3.2.9 kerfed and rabbetedjoint detail for acoustical tile.

the ASTM website. Tile with kerfed and rabbeted edges on all four sides, with or

Copyright ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

Copyright ASTM International

Provided by IHS under license with ASTM

1Licensee=Enterprise Wide -rest of new locations/5940240048

No reproduction or networking permitted without license from IHS Not for Resale, 08/02/2017 06:57:26 MDT

E1264 14

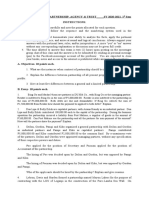

TABLE 1 Edge and Joint Detail, Types I, II, III, IV, VIII, IX, X, XI, 3.2.13 reveal edgeacoustical lay-in panels with step-down

and XII edge are intended for use in direct hung exposed suspension

Acoustical Unit Edge Detail Joint Detail systems.

Tile Beveled Kerfed and Rabbeted or Tongue

and Groove or Butt

3.2.14 square edgeacoustical lay-in panels with square

Square Kerfed and Rabbeted or Tongue edges are intended for use in direct hung exposed suspension

and Groove or Butt systems.

Beveled Long Edges, Kerfed and Rabbeted Long

Square Edge Trimmed on Edges Only, Ends Trimmed. 3.2.15 DiscussionReveal, flush reveal, and square edged

Ends (For Semi-concealed System) panels are laid in place and can easily be pushed upward for

Panels Square removal or access to the plenum above.

Reveal 3.2.16 textured patterngranular or raised (fine, coarse, or

Flush Reveal

Narrow Reveal a blend), felted or matted surface as an integral part of the basic

Narrow Flush Reveal product or superimposed on the product surface.

Metal Pan Square

Reveal 3.2.17 tongue and groovejoint detail for acoustical tile.

Flush Reveal Tile with tongue and groove edges are intended for stapling,

Narrow Reveal concealed suspension system, or adhesive bonding.

Narrow Flush Reveal

Metal Strip Varies with Manufacturer

4. Significance and Use

4.1 This classification is used to classify and aid in the

selection of acoustical ceiling products.

5. Basis of Classification

5.1 Acoustical ceiling products described using this classi-

fication may be of one or more of the following types, forms,

patterns, acoustical ratings, light reflectance values, and fire

classes, as specified.

5.2 Ceiling Types:

5.2.1 Type ICellulose base with painted finish.

5.2.2 Type IICellulose base with membrane-faced over-

lay.

5.2.3 Type IIIMineral base with painted finish.

5.2.3.1 Form 1Nodular.

5.2.3.2 Form 2Water felted.

5.2.3.3 Form 3Dry felted.

5.2.3.4 Form 4Cast or molded.

5.2.3.5 Form 5Other (describe).

5.2.4 Type IVMineral base with membrane-faced overlay.

5.2.4.1 Form 1Nodular.

5.2.4.2 Form 2Water felted.

5.2.4.3 Form 3Dry felted.

5.2.4.4 Form 4Cast or molded.

5.2.4.5 Form 5Other (describe).

FIG. 1 Edge and Joint Details 5.2.5 Type VPerforated steel facing (pan) with mineral or

glass fiber base backing.

without beveled edges, are intended for concealed suspension 5.2.6 Type VIPerforated stainless steel facing (pan) with

system or adhesive bonding. mineral or glass fiber base backing.

5.2.7 Type VIIPerforated aluminum facing (pan) with

3.2.10 kerfed and rabbeted long edges, ends trimmed

mineral or glass fiber base backing.

acoustical tile, 2 ft (609.6 mm) or longer, is intended for

5.2.8 Type VIIICellulose base with scrubbable pigmented

installation in semi-exposed, or semi-exposed direct hung

or clear finish.

--``,``,`````````,,,,,``,````,-`-`,,`,,`,`,,`---

suspension systems.

5.2.9 Type IXMineral base with scrubbable pigmented or

3.2.11 metal facings (pans)metal facing (pan) ceiling clear finish.

systems with mineral or glass fiber base backings are intended 5.2.9.1 Form 1Nodular.

for use where sound absorption is needed and where durable 5.2.9.2 Form 2Water felted.

and easily maintainable surfaces are a necessity. 5.2.9.3 Form 3Dry felted.

3.2.12 mineral baseceilings composed principally of min- 5.2.9.4 Form 4Cast or molded.

eral materials such as fibers manufactured from rock or slag, 5.2.10 Type XMineral base with plastic or aluminum

with or without binders. membrane-faced overlay, or both.

Copyright ASTM International

Provided by IHS under license with ASTM

2Licensee=Enterprise Wide -rest of new locations/5940240048

No reproduction or networking permitted without license from IHS Not for Resale, 08/02/2017 06:57:26 MDT

E1264 14

5.2.11 Type XIMineral base with fabric-faced overlay. space dividers. AC is the preferred rating scheme for selecting ceiling

5.2.11.1 Form 1Nodular. products for open-plan in lieu of the NRC rating scheme. (The addition of

hard surfaced elements in the ceiling, such as surface mounted or recessed

5.2.11.2 Form 2Water felted. lighting fixtures can impair the AC rating, depending upon the area of the

5.2.11.3 Form 3Dry felted. hard surface and its location relevant to occupants in the space.)

5.2.11.4 Form 4Cast or molded.

7.1.3 Ceiling Attenuation Class (CAC)An acoustical ceil-

5.2.12 Type XIIGlass fiber base with membrane-faced

ing may meet a CAC rating, derived in accordance with Test

overlay.

Method E1414 and Classification E413. Typical CAC values

5.2.12.1 Form 1Plastic.

may range from 5 to 55.

5.2.12.2 Form 2Cloth.

5.2.12.3 Form 3Other. NOTE 4Ceiling Attenuation Class (CAC) is a single number rating

5.2.13 Type XIIIAluminum or steel strip with mineral or obtained according to Test Method E1414 and Classification E413. The

glass fiber base backing. Normalized Ceiling Attenuation (Dn,c) values, obtained according to

E1414 are used instead of Transmission Loss (TL) values in Classification

5.2.13.1 Form 1Perforated. E413. Test Method E1414 is a two-room method of test in which a

5.2.13.2 Form 2Non-perforated. suspended ceiling and common plenum space overlay a two-room suite

5.2.14 Type XIVExcelsior bonded with inorganic binders. separated by a massive dividing wall. Sound must travel up through the

5.2.14.1 Form 1No backing. source room ceiling, across the plenum, and down through the receive

5.2.14.2 Form 2Backed with mineral or glass fiber base room ceiling. Modifications to the plenum space such as overlays and

barriers must be specified. STC ratings obtained from Test Method E90 or

backing. E336 data are not acceptable.

5.2.15 Type XXOther types (describe).

7.2 Light Reflectance (LR) CoeffcientAn acoustical ceil-

NOTE 1The facings specified in Type II, Type IV, Type X, Type XI, ing may meet a LR coefficient, measured in accordance with

and Type XII shall be separate overlays and not coatings similar to paint.

Test Method E1477. Typical values may range from 0.60 to

NOTE 2The minimum thickness of metallic facings (pans) specified in

Type V, Type VI, and Type VII shall be sufficient to support the length of 0.80.

the facing, or instead thereof, stiffeners or ribs may be provided to ensure 7.3 Fire Class/Surface Burning Characteristics

rigidity.

Acoustical ceiling products may be classified by flame spread

6. Ceiling Pattern and smoke developed indexes, tested in accordance with Test

Method E84, as follows:

6.1 Acoustical ceilings may be one of or a combination of 7.3.1 Class AThe flame spread rating of Class A ceiling

two or more of the following patterns: products shall not exceed 25, nor shall the material show

Pattern Designation Pattern Description evidence of continued progressive combustion after the test

A Perforated, regularly spaced large holes

B Perforated, randomly spaced large holes

flame has been extinguished. All surfaces, including those that

C Perforated, small holes would be exposed by cutting through the material in any way,

D Fissured shall meet these requirements. In addition, Class A ceiling

E Lightly textured

products shall have a smoke developed rating not to exceed 50.

--``,``,`````````,,,,,``,````,-`-`,,`,,`,`,,`---

F Heavily textured

G Smooth 7.3.2 Class BThe flame spread of Class B ceiling products

H Printed shall not exceed 75 on the face side.

I Embossed

J Embossed-in-register 7.3.3 Class CThe flame spread of Class C Ceiling prod-

K Surface scored ucts shall not exceed 200 on the face side.

L Random swirl

Z Other patterns (describe) NOTE 5Classes A, B, and C are equivalent, respectively, to Classes I,

II, and III of various building code authorities.

7. Ratings

7.1 Acoustical Ratingsan acoustical ceiling shall meet one 8. Test Methods

or more of the following acoustical performance requirements: 8.1 Acoustical Performance Ratings:

7.1.1 Noise Reduction Coeffcient (NRC)An acoustical 8.1.1 Noise Reduction Coeffcient (NRC)Test according to

ceiling may meet a NRC rating measured in accordance with Test Method C423 using Type E-400 mounting as defined in

Test Method C423. NRC values are to be expressed in Practices E795 unless special means of installation are re-

increments of 0.05 as specified by Test Method C423. Typical quired. Special means of installation shall be explicitly noted in

values may range from 0.40 to 1.00. test reports and in publications of test data.

7.1.2 Articulation Class (AC)An acoustical ceiling may

meet the minimum AC rating derived in accordance with Test NOTE 6Plenum: The depth of air space has considerable effect on

NRC using mechanically mounted acoustical tiles and panels. Because

Method E1111 and Classification E1110. AC values are to be there are unlimited variations that are possible, it has been established that

expressed to the nearest multiple of 10 as specified by the Practices E795 mounting Type E-400 (formerly AMA Mounting No. 7) is

Classification E1110. Typical values may range from 150 to most consistent with normal usage and existing technology of testing.

250. Some manufacturers publish data for depths of mountings other than 400

mm, designated by an E, followed by numbers which indicate the

NOTE 3Specify AC rating only when rating the acoustical perfor- mounting depth in millimeters. For selecting NRC for mechanically

mance of ceilings designed to accommodate open-plan areas. AC is mounted acoustical tiles and panels, mounting Type E-400 is preferred. If

applicable for any ceiling material used as part of an acoustically designed a plenum will not be used, a report of how the product performs with the

system incorporating background sound masking and speech privacy appropriate mounting shall be described.

Copyright ASTM International

Provided by IHS under license with ASTM

3Licensee=Enterprise Wide -rest of new locations/5940240048

No reproduction or networking permitted without license from IHS Not for Resale, 08/02/2017 06:57:26 MDT

E1264 14

8.1.2 Articulation Class (AC)Test according to Test Classification E413. Special plenum details or additions shall

Method E1111 and determine AC rating according to Classi- be explicitly noted in test reports and publications of test data.

fication E1110, subject to the following: 8.2 Light Reflectance (LR) CoeffcientTest according to

8.1.2.1 The reported AC rating shall be the minimum Test Method E1477.

articulation class as defined in Test Method E1111, for a space

divider height of 1.52 m (60 in.) and no other heights. 8.3 Fire ClassTest according to Test Method E84.

NOTE 7The space divider height has considerable effect on the AC 9. Format of Classification

rating of acoustical tiles and panels. Because there are unlimited heights

that could be tested, it has been established that 1.52 m (60 in.) space

9.1 The ceiling classification shall conform to the following

divider height is consistent with normal practices and usages. Test Method format, when applicable:

9.1.1 Type [Form]; Pattern; NRC, SAA, or AC (1.5) min.

--``,``,`````````,,,,,``,````,-`-`,,`,,`,`,,`---

E1111 requires that the AC for the 1.52 m (60 in.) high screen be reported.

8.1.2.2 The ceiling to be tested shall be installed as normally (specify); CAC; LR; Fire Class.

used with its recommended means of installation, no less than NOTE 8For example, a lightly textured, water felted mineral base

8 ft and no more than 9 ft above the floor, or as otherwise ceiling with painted finish, having an NRC 0.65, AC (1.5) min. 180, CAC

specified and explicitly noted in test reports and in publications 42, LR 0.75, and a flame spread rating of 50 would be designated as either:

Type III, Form 2; Pattern E; NRC 0.65; CAC 42; LR 0.75; Fire Class

of test data. B, or

8.1.2.3 The plenum depth measured from the specimen Type III, Form 2; Pattern E; AC (1.5) min. 180; CAC 42; LR 0.75; Fire

surface to the underside of the deck above shall be 2 ft, 6 in. Class B.

(762.0 mm) unless specified otherwise. The extended surface

of the underside of the deck shall be acoustically hard. 10. Keywords

8.1.3 Ceiling Attenuation Class (CAC)Test according to 10.1 acoustical ceilings; acoustical ratings; acoustical tile;

Test Method E1414 and determine CAC rating according to light reflectance

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the Copyright Clearance Center, 222

Rosewood Drive, Danvers, MA 01923, Tel: (978) 646-2600; http://www.copyright.com/

Copyright ASTM International

Provided by IHS under license with ASTM

4Licensee=Enterprise Wide -rest of new locations/5940240048

No reproduction or networking permitted without license from IHS Not for Resale, 08/02/2017 06:57:26 MDT

Anda mungkin juga menyukai

- AAMA WDMA CSA 101 I S 2 A440 11 (Standard Specification For Windows, Doors and Skylights)Dokumen8 halamanAAMA WDMA CSA 101 I S 2 A440 11 (Standard Specification For Windows, Doors and Skylights)siddique27Belum ada peringkat

- Astm C 636Dokumen5 halamanAstm C 636asdrecvBelum ada peringkat

- Astm d4101Dokumen17 halamanAstm d4101asdrecvBelum ada peringkat

- Astm C926Dokumen14 halamanAstm C926asdrecv75% (4)

- Astm E547-00Dokumen5 halamanAstm E547-00ELENA NAVAS100% (1)

- C636-Installation of Metal Ceiling Suspension SystemsDokumen4 halamanC636-Installation of Metal Ceiling Suspension SystemswahyuniarsihBelum ada peringkat

- ASTM C1063-12a - Standard Specification For Installation of Lathing and Furring To Receive Interior and Exterior Portland Cement Based Plaster PDFDokumen12 halamanASTM C1063-12a - Standard Specification For Installation of Lathing and Furring To Receive Interior and Exterior Portland Cement Based Plaster PDFibrahim100% (2)

- 2605-20 Errata 2022Dokumen20 halaman2605-20 Errata 2022Aluminio KingtomBelum ada peringkat

- Earthquake Code For TurkeyDokumen161 halamanEarthquake Code For Turkeywpchen2Belum ada peringkat

- 524R 04 PDFDokumen40 halaman524R 04 PDFFred PrzBelum ada peringkat

- TORTS Case DigestDokumen4 halamanTORTS Case DigestfaithimeeBelum ada peringkat

- Astm C90Dokumen4 halamanAstm C90carlos100% (1)

- E 580Dokumen10 halamanE 580cokecokeBelum ada peringkat

- ASQ-Certified Quality EngineerDokumen90 halamanASQ-Certified Quality EngineerHosam Abd El-Galeil40% (25)

- Aashto M294Dokumen19 halamanAashto M294asdrecv100% (1)

- Aashto M294Dokumen19 halamanAashto M294asdrecv100% (1)

- Astm A143Dokumen4 halamanAstm A143asdrecv100% (1)

- Astm C 841-03 Standard Specifications For The Installation PDFDokumen10 halamanAstm C 841-03 Standard Specifications For The Installation PDFCharwin PicaoBelum ada peringkat

- Astm E699Dokumen8 halamanAstm E699AlbertoBelum ada peringkat

- A1003Dokumen6 halamanA1003hamidharvardBelum ada peringkat

- Quality Audit Handbook PDFDokumen59 halamanQuality Audit Handbook PDFmadmaxjune17557Belum ada peringkat

- Quality Audit Handbook PDFDokumen59 halamanQuality Audit Handbook PDFmadmaxjune17557Belum ada peringkat

- Astm E783-02Dokumen6 halamanAstm E783-02ELENA NAVASBelum ada peringkat

- ASTM E 90 09 StandardsDokumen15 halamanASTM E 90 09 StandardsNagwan Qassem100% (2)

- Astm d5361Dokumen3 halamanAstm d5361asdrecvBelum ada peringkat

- Astm E1105 Water Intrusion TestDokumen21 halamanAstm E1105 Water Intrusion TestCristian DandresBelum ada peringkat

- DIN 1164-2000-EnDokumen8 halamanDIN 1164-2000-EnasdrecvBelum ada peringkat

- Ansi Asq Z1.9-2008Dokumen117 halamanAnsi Asq Z1.9-2008AlvaroZava88% (8)

- Ansi Asq Z1.9-2008Dokumen117 halamanAnsi Asq Z1.9-2008AlvaroZava88% (8)

- Ansi Asq Z1.9-2008Dokumen117 halamanAnsi Asq Z1.9-2008AlvaroZava88% (8)

- Ublox - 2007 - ANTARIS 4 GPS Modules System Integration Manual PDFDokumen187 halamanUblox - 2007 - ANTARIS 4 GPS Modules System Integration Manual PDFCenascenascenascenasBelum ada peringkat

- Astm C578Dokumen7 halamanAstm C578almadar12100% (1)

- Astm E330Dokumen7 halamanAstm E330Lupita Ramirez100% (1)

- Astm E989 IicDokumen3 halamanAstm E989 IicWilson Javier Garcia V.Belum ada peringkat

- Astm A615Dokumen6 halamanAstm A615Muhammad sheryarBelum ada peringkat

- ASTM E331-00 (Reapproved 2016)Dokumen5 halamanASTM E331-00 (Reapproved 2016)داروین پرز100% (3)

- Certified Quality Engineer (Cqe) Body of KnowledgeDokumen12 halamanCertified Quality Engineer (Cqe) Body of Knowledgemehdi810Belum ada peringkat

- Astm c1202Dokumen8 halamanAstm c1202asdrecv100% (1)

- 1.2 Astm-C503Dokumen3 halaman1.2 Astm-C503Glexer Dazo Corrales100% (1)

- Astm C270Dokumen14 halamanAstm C270asdrecv100% (4)

- D449Dokumen2 halamanD449Rangga Adi100% (2)

- Use of Sealants in Acoustical Applications: Standard Practice ForDokumen4 halamanUse of Sealants in Acoustical Applications: Standard Practice ForRufo CascoBelum ada peringkat

- ASTM E 736 - 00 Standard Test Method For Cohesion-Adhesion of Sprayed Fire-Resistve Maaterials Applied To Structural Members PDFDokumen3 halamanASTM E 736 - 00 Standard Test Method For Cohesion-Adhesion of Sprayed Fire-Resistve Maaterials Applied To Structural Members PDFKanapol KaewdangBelum ada peringkat

- Boie-Takeda vs. de La SernaDokumen2 halamanBoie-Takeda vs. de La Sernazhengxiong100% (3)

- ASTM E119-16aDokumen36 halamanASTM E119-16asalagto60% (5)

- Aci 211.3RDokumen26 halamanAci 211.3Rasdrecv100% (1)

- Astm D1751-18 PDFDokumen2 halamanAstm D1751-18 PDFAnonymous SBjNS7Gw0qBelum ada peringkat

- Astm A194 A194m - 13Dokumen12 halamanAstm A194 A194m - 13Danilo YamaguchiBelum ada peringkat

- Criminology and Criminal Justice AdministrationDokumen167 halamanCriminology and Criminal Justice AdministrationRahulAbHishekBelum ada peringkat

- D7425D7425M 13Dokumen3 halamanD7425D7425M 13diego rodriguez100% (1)

- Astm C635Dokumen8 halamanAstm C635Buildcraft InteriorsBelum ada peringkat

- Midterm Exam Partnership, Agency & Trust - Sy 2020-2021. 1 Sem InstructionsDokumen2 halamanMidterm Exam Partnership, Agency & Trust - Sy 2020-2021. 1 Sem InstructionsPat RañolaBelum ada peringkat

- Astm C90Dokumen5 halamanAstm C90asdrecv100% (1)

- E413 - 16Dokumen4 halamanE413 - 16ahmad Yaghi100% (2)

- ASTM E 283 Standard Test Method For Determining Rate of Air Leakage Through Exterior Windows CurDokumen6 halamanASTM E 283 Standard Test Method For Determining Rate of Air Leakage Through Exterior Windows CurNitson AmitsuBelum ada peringkat

- Structural Sealant Glazing: Standard Guide ForDokumen52 halamanStructural Sealant Glazing: Standard Guide ForĐường Nguyễn ThừaBelum ada peringkat

- Astm d2950Dokumen4 halamanAstm d2950asdrecv100% (1)

- Astm D6164Dokumen3 halamanAstm D6164tenBelum ada peringkat

- Behavior of Materials in A Tube Furnace With A Cone-Shaped Airflow Stabilizer, at 750°CDokumen11 halamanBehavior of Materials in A Tube Furnace With A Cone-Shaped Airflow Stabilizer, at 750°CAhmad Zubair RasulyBelum ada peringkat

- Application of Gypsum Veneer Plaster: Standard Specification ForDokumen5 halamanApplication of Gypsum Veneer Plaster: Standard Specification ForINARQ1979Belum ada peringkat

- Licensure Exams Criminologist ReviewDokumen34 halamanLicensure Exams Criminologist ReviewKulot SisonBelum ada peringkat

- Astm D7234-12Dokumen9 halamanAstm D7234-12EdwinMauricioMacabeo100% (1)

- Astm e 136Dokumen10 halamanAstm e 136Zahoor Ahmed MohsanBelum ada peringkat

- Astm c717 - SelantesDokumen13 halamanAstm c717 - SelantesJavier VianaBelum ada peringkat

- Astm C 1201-09Dokumen4 halamanAstm C 1201-09kishor150688Belum ada peringkat

- Astm d4429 RevaDokumen7 halamanAstm d4429 Revaasdrecv0% (1)

- Astm d4429 RevaDokumen7 halamanAstm d4429 Revaasdrecv0% (1)

- Non-Asbestos Fiber-Mat Reinforced Cement Substrate Sheets: Standard Specification ForDokumen4 halamanNon-Asbestos Fiber-Mat Reinforced Cement Substrate Sheets: Standard Specification ForNicolas FernandezBelum ada peringkat

- Astm E119 PDFDokumen24 halamanAstm E119 PDFRoly David Rodriguez Castro100% (3)

- Practise Exam CBA PDFDokumen11 halamanPractise Exam CBA PDFasdrecvBelum ada peringkat

- Astm E119-19Dokumen37 halamanAstm E119-19Rodrigo Jeldes100% (2)

- Astm C117Dokumen4 halamanAstm C117asdrecvBelum ada peringkat

- C90Dokumen5 halamanC90Rufo CascoBelum ada peringkat

- E413-10 Classification For Rating Sound InsulationDokumen4 halamanE413-10 Classification For Rating Sound Insulationمحمود البقاعيBelum ada peringkat

- C88 2013Dokumen5 halamanC88 2013manil_5Belum ada peringkat

- 14411Dokumen70 halaman14411Ayman S. AshourBelum ada peringkat

- Astm d2486Dokumen4 halamanAstm d2486mtnguyenns100% (1)

- ASTM C91 C91M-12 Standard Specification For Masonry CementDokumen4 halamanASTM C91 C91M-12 Standard Specification For Masonry Cementbastian100% (2)

- ASTM E119 Standard Test Methods ForDokumen35 halamanASTM E119 Standard Test Methods ForAlineMeirelesBelum ada peringkat

- Strength of Power-Actuated Fasteners Installed in Structural MembersDokumen6 halamanStrength of Power-Actuated Fasteners Installed in Structural MembersROHITBelum ada peringkat

- C367Dokumen5 halamanC367dinhtung2210Belum ada peringkat

- D1187 PDFDokumen2 halamanD1187 PDFArnold RojasBelum ada peringkat

- ANSI/BHMA A156.18 Materials Finishes StandardDokumen1 halamanANSI/BHMA A156.18 Materials Finishes StandardRey Eduard Q. UmelBelum ada peringkat

- Spray-Applied Rigid Cellular Polyurethane Thermal InsulationDokumen4 halamanSpray-Applied Rigid Cellular Polyurethane Thermal InsulationsabinBelum ada peringkat

- Astm E736Dokumen3 halamanAstm E736Diego NeiraBelum ada peringkat

- Mineral Wool Roof Insulation Board: Standard Specification ForDokumen4 halamanMineral Wool Roof Insulation Board: Standard Specification ForMina RemonBelum ada peringkat

- Astm C473 03Dokumen72 halamanAstm C473 03DhritiBelum ada peringkat

- Conducting Exterior Exposure Tests of Paints On Wood: Standard Practice ForDokumen7 halamanConducting Exterior Exposure Tests of Paints On Wood: Standard Practice Formanox007Belum ada peringkat

- F 2247 - 03Dokumen14 halamanF 2247 - 03Francisco GuerraBelum ada peringkat

- Astm C-1178-1 PDFDokumen3 halamanAstm C-1178-1 PDFibrahim0% (1)

- Selection of Standards On Environmental Acoustics: Standard Guide ForDokumen11 halamanSelection of Standards On Environmental Acoustics: Standard Guide ForAhmad Zubair RasulyBelum ada peringkat

- Astm e 477 Rev A 2006 PDFDokumen11 halamanAstm e 477 Rev A 2006 PDFJORGE ARTURO TORIBIO HUERTABelum ada peringkat

- Astmd16 16Dokumen10 halamanAstmd16 16asdrecv100% (1)

- Innovation Imperative Embracing ChangeDokumen2 halamanInnovation Imperative Embracing ChangeasdrecvBelum ada peringkat

- DocsssDokumen4 halamanDocsssAnne DesalBelum ada peringkat

- Doctrine of Ultra ViresDokumen6 halamanDoctrine of Ultra ViresAbir N ZainBelum ada peringkat

- Audit SoalDokumen4 halamanAudit SoalRukmayanti MunteBelum ada peringkat

- Safety data sheet for TL 011 lubricantDokumen8 halamanSafety data sheet for TL 011 lubricantXavierBelum ada peringkat

- JIRA Issue-Bug March OnwardsDokumen10 halamanJIRA Issue-Bug March OnwardsMoses RashidBelum ada peringkat

- CH7 Lecture SlidesDokumen30 halamanCH7 Lecture SlidesRomeo BalingaoBelum ada peringkat

- Denmark Trans Fats LawDokumen2 halamanDenmark Trans Fats LawPerwaiz KhanBelum ada peringkat

- Socrates vs. Commission On Elections, G.R. No. 154512 - Case DigestDokumen2 halamanSocrates vs. Commission On Elections, G.R. No. 154512 - Case DigestAlena Icao-AnotadoBelum ada peringkat

- SOP For OLDokumen9 halamanSOP For OLTahir Ur RahmanBelum ada peringkat

- Mary Rieser "Things That Should Not Be"Dokumen22 halamanMary Rieser "Things That Should Not Be"Tony OrtegaBelum ada peringkat

- October 2012 Bulletin of TSTIDokumen16 halamanOctober 2012 Bulletin of TSTIDan CohenBelum ada peringkat

- Cloud Control Basic Installation GuideDokumen184 halamanCloud Control Basic Installation GuidesoftdesireBelum ada peringkat

- Administrative DisciplineDokumen27 halamanAdministrative DisciplineSeven De Los ReyesBelum ada peringkat

- Follow Up of DCPS Emergency Response Planning and ReadinessDokumen12 halamanFollow Up of DCPS Emergency Response Planning and ReadinessABC7NewsBelum ada peringkat

- Punishment For Offences Against The StateDokumen3 halamanPunishment For Offences Against The StateMOUSOM ROYBelum ada peringkat

- Trinity College - Academic Calendar - 2009-2010Dokumen3 halamanTrinity College - Academic Calendar - 2009-2010roman_danBelum ada peringkat

- UT Dallas Syllabus For Hist4344.001.09f Taught by Debra Pfister (DHPF)Dokumen8 halamanUT Dallas Syllabus For Hist4344.001.09f Taught by Debra Pfister (DHPF)UT Dallas Provost's Technology GroupBelum ada peringkat

- Block Class Action LawsuitDokumen53 halamanBlock Class Action LawsuitGMG EditorialBelum ada peringkat

- Tax 3 Mid Term 2016-2017 - RawDokumen16 halamanTax 3 Mid Term 2016-2017 - RawPandaBelum ada peringkat

- MC No. 005.22Dokumen5 halamanMC No. 005.22raymund pabilarioBelum ada peringkat

- Manifesto: Manifesto of The Awami National PartyDokumen13 halamanManifesto: Manifesto of The Awami National PartyonepakistancomBelum ada peringkat

- Understanding Symbols of Peace & War in International OrganizationsDokumen3 halamanUnderstanding Symbols of Peace & War in International OrganizationsNouha MezlougBelum ada peringkat

- Annual ReportDokumen110 halamanAnnual ReportSarwan AliBelum ada peringkat

- Beacons and BoundariesDokumen2 halamanBeacons and BoundariesDonald MolaiBelum ada peringkat