Magnesium Etching Procedure - 13 Steps Guide

Diunggah oleh

ZH_Etching100%(1)100% menganggap dokumen ini bermanfaat (1 suara)

1K tayangan2 halamanMagnesium Etching Procedure- 13 Steps Guide, photoengraving

Judul Asli

Magnesium Etching Procedure- 13 Steps Guide

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniMagnesium Etching Procedure- 13 Steps Guide, photoengraving

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

100%(1)100% menganggap dokumen ini bermanfaat (1 suara)

1K tayangan2 halamanMagnesium Etching Procedure - 13 Steps Guide

Diunggah oleh

ZH_EtchingMagnesium Etching Procedure- 13 Steps Guide, photoengraving

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

Anda di halaman 1dari 2

5.

POST DEVELOP - HYDRO-COAT

ZH Etching Materials Hydro-Coat plates should be post developed to

www.etchingmaterials.com enhance screen and fine line reproduction.

Scrub horizontally and vertically using a wet litho

pad. Follow with a clean water rinse and dry

MAGNESIUM ETCHING plate thoroughly using clean compressed air or

by blotting dry with a clean absorbent cloth.

PROCEDURE- 13 STEPS

BURN IN RED TOP (optional)

GUIDE Heat Red Top plates prior to etching to set Red

Top coating and prevent it from breaking down.

Burn in up to 10 minutes at 250°F / 121°C.

1. STORAGE

Store magnesium photoengraving plates in a 6. TOUCH UP

cool, dry place. Examine plate for flaws in the image areas

retained on the plate and touch up as needed

2. ARTWORK with Retouch Solution.

Inspect negative carefully and opaque pinholes

in the black areas. Pinholes result in pimply 7. WEIGH

etching if not opaqued. Record initial plate weight on your etching log

prior to etching. Scale must be capable of

3. EXPOSURE weighing to the nearest 1/4 ounce.

Expose using a Stouffer 21-Step Sensitivity

Guide. Expose Hydro-Coat to a step 8-10. 8. DESCUM

Red Top plates must be descummed using a

Expose Red Top to a step 6-8. Overexposure litho pad to remove residual chemical film.

causes excessive shadow-dot plugging and Failure to descum Red Top plates can cause

does not increase etching resistance of coating. erratic etching, pimples and scummy areas. Red

Underexposure causes wash-off in development Top Acid Descum Solution: 7% solution of

and etching failure. 42°Bé nitric acid with water. Hydro-Coat plates

should be descummed in a 3 - 5% 42°Bé nitric

4. DEVELOPING acid to water solution.

Mix one part of Heated or Cold Hydro-Coat

Developer with five parts water. Heated Hydro- 9. RINSE

Coat Developer should be used at 105°-115°F Rinse plates thoroughly with water after

(41°-46°C). Cold Hydro-Coat Developer can be descumming.

used at room temperature 70°-85°F (21°-29°C).

10. PLATE PROTECTOR

After developing in Magnesium developer, rinse An application of Express Guard Plate Protector

Red Top plates with a spray of water until image is recommended prior to etching to enhance

appears glossy. Dry plate thoroughly using clean performance of etching bath by preventing

compressed air or by blotting dry with a clean oxidation which can cause pimples.

absorbent cloth. DO NOT wipe or rub plate while

wet. 11. ETCH

Prepare bath according to additive instructions.

In case of evaporation loss when using Hydro- Refer to charts on last page. Follow

Coat Developer, water alone should be added manufacturer's instructions for etching machine

back to developer solution. DO NOT add back operation. When etching is complete, remove

concentrate Hydro-Coat Developer to plate, clean thoroughly to remove etch residue

compensate for evaporation loss. Heated Hydro- and dry.

Coat Developer should be changed when

developing times exceed 90 seconds. 12. REPLENISH BATH

Record plate weight after etching to determine

Cold Hydro-Coat Developer used in trays should proper acid replenishment. Replenish acid at a

be changed daily. rate of 200 milliliters of 42°Bé nitric acid per

ounce of magnesium dissolved into bath (6,7

Copyright © 2010 ZH Etching Materials Co.,Ltd. All rights reserved.

milliliters of acid per gram). Refer to acid

addition chart on last page. Use the following

formula to calculate replenishment:

Initial plate weight - Post etching plate weight =

amount of Mg dissolved.

Example: 16.90 - 15.40 = 1.5 ozs. Magnesium

dissolved. Acid addition = 300 mls of acid are

added to bath.

Check dip gauge and restore proper level in

bath by adding water or draining excess.

13. TOP REMOVAL (optional)

Use Hydro-Coat Top Remover II according to

directions on label. Red Top plates - Remove

top using a pumice and rotary brush or with

various chemicals.

Copyright © 2010 ZH Etching Materials Co.,Ltd. All rights reserved.

Anda mungkin juga menyukai

- Animate SketchUp Models with Plugin Proper AnimationDokumen11 halamanAnimate SketchUp Models with Plugin Proper Animationsyndicate_mauliBelum ada peringkat

- Ficha Tecnica de Pimtas PDFDokumen16 halamanFicha Tecnica de Pimtas PDFLorena LlerenaBelum ada peringkat

- Teriostar 1020 Scanner A ColorDokumen2 halamanTeriostar 1020 Scanner A ColorLuis Oscar Barrios0% (1)

- "S" and "As" Series Self-Cleaning Micro Oil Valve: InstructionsDokumen7 halaman"S" and "As" Series Self-Cleaning Micro Oil Valve: InstructionssergioBelum ada peringkat

- ZINC Etching ProcedureDokumen3 halamanZINC Etching ProcedureAnderson100% (1)

- Application Procedure For Carbothane 1345 To Concrete FloorsDokumen1 halamanApplication Procedure For Carbothane 1345 To Concrete FloorsJASONBelum ada peringkat

- Coating Defects With Illustrations.Dokumen23 halamanCoating Defects With Illustrations.Yousab CreatorBelum ada peringkat

- Black Oxide InstructionsDokumen1 halamanBlack Oxide InstructionsduggybBelum ada peringkat

- ZP 14a Pds July17Dokumen3 halamanZP 14a Pds July17aravindanBelum ada peringkat

- X-Ray Film Film Processing H& D Curves Reduction of Scatter Single Wall & Double Wall Techniques Multi Film Techniques EtcDokumen23 halamanX-Ray Film Film Processing H& D Curves Reduction of Scatter Single Wall & Double Wall Techniques Multi Film Techniques EtcVIBHAV100% (2)

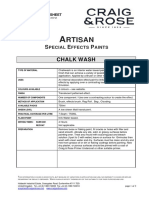

- TDS Artisan Chalkwash V1Dokumen2 halamanTDS Artisan Chalkwash V1Mihail BurlacBelum ada peringkat

- 9-4 DIGE Basic Course ManualDokumen24 halaman9-4 DIGE Basic Course Manualsankarmalayandi4173Belum ada peringkat

- Acriglaze 2020 Info SheetDokumen1 halamanAcriglaze 2020 Info SheetValerio GalieniBelum ada peringkat

- Reversal Processing: Application SheetDokumen4 halamanReversal Processing: Application SheetTrương TrườngBelum ada peringkat

- Cee Bee Cleaner 280Dokumen3 halamanCee Bee Cleaner 280Jimmy SteepBelum ada peringkat

- R 50 CP TDSDokumen2 halamanR 50 CP TDSVenkatesh KumarBelum ada peringkat

- Quick Dry SatinwoodDokumen3 halamanQuick Dry SatinwoodAMER SALEEMBelum ada peringkat

- Berger: Product SpecificationsDokumen2 halamanBerger: Product SpecificationsAabhas UpadhyayaBelum ada peringkat

- Hi Pon90 01EpoxyGlassFlakeHB95 - TDS 1Dokumen3 halamanHi Pon90 01EpoxyGlassFlakeHB95 - TDS 1Saranik DattaBelum ada peringkat

- Dry WallDokumen3 halamanDry WallJuan Manuel Eirin VarelaBelum ada peringkat

- Epoxy Mastic Primer Epiplus 556Dokumen2 halamanEpoxy Mastic Primer Epiplus 556rh decoratorsBelum ada peringkat

- AI Hempadur 35560Dokumen4 halamanAI Hempadur 35560MUTHUBelum ada peringkat

- 4 Rockgrip 27 en Prep Plaster Primer WB 2022 Rev1Dokumen5 halaman4 Rockgrip 27 en Prep Plaster Primer WB 2022 Rev1yoxan25808Belum ada peringkat

- Micron Extra 2 AP Eng A4 20200720Dokumen2 halamanMicron Extra 2 AP Eng A4 20200720Wesley KiplingBelum ada peringkat

- Problem Solving Guide 1-15Dokumen16 halamanProblem Solving Guide 1-15Sekson LapcharoensinBelum ada peringkat

- SPC-15 Specialty Tub Tile Refinishing Kit TDS 1Dokumen2 halamanSPC-15 Specialty Tub Tile Refinishing Kit TDS 1Tom CatBelum ada peringkat

- PDS HEMPATHANE FAST DRY 55750 en-GBDokumen2 halamanPDS HEMPATHANE FAST DRY 55750 en-GBEli KhawBelum ada peringkat

- Cerami-Shield Label and Direction PanelDokumen1 halamanCerami-Shield Label and Direction PanelheeenriiiiiBelum ada peringkat

- Dunlop Builder's Bond 0114Dokumen2 halamanDunlop Builder's Bond 0114marklaforestBelum ada peringkat

- Berger: Product SpecificationsDokumen2 halamanBerger: Product SpecificationsMuthuKumarBelum ada peringkat

- HEMPADUR MULTI-STRENGTH GF 35870 Product Data SheetDokumen3 halamanHEMPADUR MULTI-STRENGTH GF 35870 Product Data SheetAnuar SalehBelum ada peringkat

- Revelador FluorescenteDokumen2 halamanRevelador FluorescenteEric Figueroa UribeBelum ada peringkat

- Underwater Epoxy Patching CompoundDokumen3 halamanUnderwater Epoxy Patching CompoundMohindra Persad100% (1)

- GelCode Blue Stain ReagentDokumen4 halamanGelCode Blue Stain ReagentAhammed Abu DilBelum ada peringkat

- Technical Bulletin: Proteosilver Silver Stain KitDokumen4 halamanTechnical Bulletin: Proteosilver Silver Stain KitAjeng FadillahBelum ada peringkat

- Silasec DATASHEETSDokumen6 halamanSilasec DATASHEETSestyBelum ada peringkat

- Painting Specification & Procedure GuideDokumen2 halamanPainting Specification & Procedure Guidesabir hussainBelum ada peringkat

- All Purpose Primer - TDS PDFDokumen2 halamanAll Purpose Primer - TDS PDFaboali8686Belum ada peringkat

- Royale Play Ironic: Product FeaturesDokumen2 halamanRoyale Play Ironic: Product FeaturesAcro PaintsBelum ada peringkat

- HEMPADUR 47182 47182 en-GB PDFDokumen3 halamanHEMPADUR 47182 47182 en-GB PDFwilfran villegasBelum ada peringkat

- DSP Waterplug Sealocrete - Methodology AspireDokumen1 halamanDSP Waterplug Sealocrete - Methodology AspireJM SubionBelum ada peringkat

- Floor Patch Fast CureDokumen2 halamanFloor Patch Fast CureStevenFerrelBelum ada peringkat

- Kansai Neoshield Plus Matt Exterior Paint Protects From MoldDokumen2 halamanKansai Neoshield Plus Matt Exterior Paint Protects From Moldaboali8686Belum ada peringkat

- Pa001 07Dokumen3 halamanPa001 07Christian Linares AbreuBelum ada peringkat

- Aqua Stop+TDS+25kg+TubDokumen4 halamanAqua Stop+TDS+25kg+Tubshess1Belum ada peringkat

- Weberbloc Fix NDokumen2 halamanWeberbloc Fix NCharbel AchkoutyBelum ada peringkat

- High Build Epoxy Coating for Steel and ConcreteDokumen2 halamanHigh Build Epoxy Coating for Steel and ConcreteTejinder KumarBelum ada peringkat

- HEMPADUR MULTI-STRENGTH 35530 BlackDokumen2 halamanHEMPADUR MULTI-STRENGTH 35530 BlackRuby Faith EspinosaBelum ada peringkat

- Distemper HiteshDokumen12 halamanDistemper Hiteshbazingaa aBelum ada peringkat

- INTERIOR MATT EMULSION GUIDEDokumen2 halamanINTERIOR MATT EMULSION GUIDElongBelum ada peringkat

- Autotype Indirect Photostencil Films GuideDokumen4 halamanAutotype Indirect Photostencil Films GuideTitus MendezBelum ada peringkat

- Tabloid Fine Grain DeveloperDokumen2 halamanTabloid Fine Grain DeveloperntrscribeBelum ada peringkat

- Encap Brite SRDokumen1 halamanEncap Brite SRBenBelum ada peringkat

- PDS Hempadur 35560 en-GBDokumen2 halamanPDS Hempadur 35560 en-GBErwin MalmsteinBelum ada peringkat

- Decor Texture - TDSDokumen2 halamanDecor Texture - TDSaboali8686Belum ada peringkat

- Insl-X Epoxy Pool Paint Pool Painting GuideDokumen2 halamanInsl-X Epoxy Pool Paint Pool Painting GuideJean-Baptiste VenturiniBelum ada peringkat

- Customer Information Manual - Kodak Thermal Platinum Digital Plates - Dec08Dokumen17 halamanCustomer Information Manual - Kodak Thermal Platinum Digital Plates - Dec08Giza JupolliBelum ada peringkat

- PDS en-GB 45751Dokumen2 halamanPDS en-GB 45751Anuar SalehBelum ada peringkat

- Clopay Steel Garage Door InstallDokumen20 halamanClopay Steel Garage Door Installjrrjr71Belum ada peringkat

- Shine Repair Light TDS EN Rev1.0Dokumen2 halamanShine Repair Light TDS EN Rev1.0Adrian ZawodnyBelum ada peringkat

- Zinc Etching Procedure - 12 Steps GuideDokumen1 halamanZinc Etching Procedure - 12 Steps GuideZH_EtchingBelum ada peringkat

- Zinc Plate For Photoengraving DatasheetDokumen1 halamanZinc Plate For Photoengraving DatasheetZH_EtchingBelum ada peringkat

- Magnesium Plate For Photoengraving DatasheetDokumen1 halamanMagnesium Plate For Photoengraving DatasheetZH_EtchingBelum ada peringkat

- Copper Plate For Photoengraving DatasheetDokumen1 halamanCopper Plate For Photoengraving DatasheetZH_EtchingBelum ada peringkat

- Boysen Paints PDFDokumen15 halamanBoysen Paints PDFHale100% (2)

- AMS 2649 - Rev - CDokumen7 halamanAMS 2649 - Rev - CRathnakumara Kemmara100% (1)

- Buehler Electromet 4Dokumen24 halamanBuehler Electromet 4Sileno DiasBelum ada peringkat

- Books: Rembrandt. The New Hollstein Dutch & Flemish Etchings, Engravings and Woodcuts 1450-1700. by ErikDokumen2 halamanBooks: Rembrandt. The New Hollstein Dutch & Flemish Etchings, Engravings and Woodcuts 1450-1700. by Erik77bgfaBelum ada peringkat

- Enamel Etching and Dentine ConditionerDokumen1 halamanEnamel Etching and Dentine ConditionerTracie YW100% (4)

- CopperPlatesHistory JeanStephenGalleries020711Dokumen4 halamanCopperPlatesHistory JeanStephenGalleries020711Matthew Phillips0% (1)

- Etching and Pedal Finishing Tutorial!: 1. Warnings!Dokumen18 halamanEtching and Pedal Finishing Tutorial!: 1. Warnings!Jesse BélangerBelum ada peringkat

- Electro-Etching Made EasyDokumen52 halamanElectro-Etching Made Easyedhykoes100% (1)

- Rembrandt's Genius Explored in Essay on the Famous Painting "Night WatchDokumen6 halamanRembrandt's Genius Explored in Essay on the Famous Painting "Night WatchpaulacotoiBelum ada peringkat

- Astm e 1417 PDFDokumen12 halamanAstm e 1417 PDFJunior C. Ho100% (2)

- Etching OpperDokumen8 halamanEtching OpperAnil SharmaBelum ada peringkat

- Cassels Cyclopaedia of Mechanics - Paul HasluckDokumen396 halamanCassels Cyclopaedia of Mechanics - Paul Hasluckhbpr9999Belum ada peringkat

- Intaglio Printmaker Catalogue 2017Dokumen36 halamanIntaglio Printmaker Catalogue 2017Kath Glover100% (1)

- Impress'09: CatalogueDokumen92 halamanImpress'09: Cataloguelovelly.com100% (2)

- Module 6Dokumen33 halamanModule 6cebila9115Belum ada peringkat

- Print MakingDokumen17 halamanPrint MakingJunardCabicoBelum ada peringkat

- The Prints of Brice Marden 1992Dokumen5 halamanThe Prints of Brice Marden 1992Danny100% (1)

- Hyundai-Cat 3533270 PDFDokumen22 halamanHyundai-Cat 3533270 PDFastwan81Belum ada peringkat

- Instr-Tes200 en PDFDokumen2 halamanInstr-Tes200 en PDFDaniel IliescuBelum ada peringkat

- Foilography Printmaking: Cmorgan@uvic - CaDokumen73 halamanFoilography Printmaking: Cmorgan@uvic - Cacetakasyraf100% (1)

- Large Hot Plate Safety GuideDokumen2 halamanLarge Hot Plate Safety GuideGiniung AugieBelum ada peringkat

- Laboratory Activities Computer Engineering Drafting and DesignDokumen74 halamanLaboratory Activities Computer Engineering Drafting and DesignPaul Santos Nonat75% (4)

- STM Tip PrepDokumen9 halamanSTM Tip Prephermas67Belum ada peringkat

- Art and the French Revolution: An Exhibition at the Musée CarnavaletDokumen24 halamanArt and the French Revolution: An Exhibition at the Musée CarnavaletArchana BhartiBelum ada peringkat

- Discovery Featuring Studio Paintings & Country Americana - Skinner Auction 2686MDokumen80 halamanDiscovery Featuring Studio Paintings & Country Americana - Skinner Auction 2686MSkinnerAuctionsBelum ada peringkat

- Aquatints and EngravingDokumen512 halamanAquatints and EngravingAndrew Olsen100% (5)

- Hockney Large Print LabelsDokumen77 halamanHockney Large Print LabelsEtab BarakatBelum ada peringkat

- Optical Drive: Sarah Lehrer-Graiwer Talks With Laura OwensDokumen6 halamanOptical Drive: Sarah Lehrer-Graiwer Talks With Laura OwensKenneth HeyneBelum ada peringkat

- Luxaprime1500 Etching Wash PrimerDokumen2 halamanLuxaprime1500 Etching Wash PrimerGurdeep Sungh AroraBelum ada peringkat

- LDC Discontinued Products 2017 - 2nd Comm 1Dokumen1 halamanLDC Discontinued Products 2017 - 2nd Comm 1KRBelum ada peringkat