Bolt Torque Appendix-O

Diunggah oleh

Sachin5586Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Bolt Torque Appendix-O

Diunggah oleh

Sachin5586Hak Cipta:

Format Tersedia

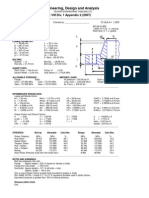

ASME-PCC-1 ASSEMBLY BOLT STRESS DETERMINATION

Remark

Maximum design pressure + static head Pmax 10 bar

Maximum design temperature T 80

Corrosion Allowance CA 3 mm

Size of bolt diameter d M20

Bolt area Ab 217.051 mm2

Number of bolt nb 24

Gasket ID GID 550 mm

Gasket OD GOD 576 mm

Pass partion gasket length GL 0 mm

width of pass partion gasket WL 0 mm

Gasket area Ag 22993.317 mm2

Nut factor K 0.2

MOC of flange SA-266 Gr. 2

Flange yield stress at assembly Sya 138 MPa SEC II D

Flange yield stress at operation Syo 138 MPa SEC II D

Maximum permissible bolt stress Sbmax 517.105 MPa pg-67

Minimum permissible bolt stress Sbmin 241.316 MPa pg-67

Target assembly gasket stress SgT 206.842 MPa pg-67

Maximum permissible bolts stress prior to flange damage Sfmax 507 MPa Table O-2

Selected assembly bolt stress Sbsel 912.99272 MPa O-1

Maximum permissible gasket stress Sgmax 275.789 MPa pg-67

Minimum gasket seating stress Sgmin-s 86.18 MPa pg-67

Minimum gaske operating stress Sgmin-o 41.3684 MPa pg-67

Bolt diameter b 20 mm

Assembly bolt torque Tb 792.66393 Nmm O-2

Sum of flange rotation at Sfmax,deg fmax 0.39 deg

Maximum permissible flange rotation for gasket at the

maximum operating temperature, deg gmax 1 deg

Fraction of gasket load remaining after relaxation b 0.7 As per appendixO-4.1 (i)

Step-1 Sbsel =min(Sbsel,Sbmax) 517.105 MPa O-4

Step-2 Sbsel =max(Sbsel,Sbmin) 912.993 MPa O-5

Step-3 Sbsel =min(Sbsel,Sfmax) 507.000 MPa O-6

Step-4 Sbsel Sgmin-s[Ag/(Abnb)] 380.395 MPa O-7

Step-5 Sbsel (Sgmin-o*Ag+/4*Pmax*G )/(g*Ab*nb)

ID

2

326.010 MPa O-8

Step-6 Sbsel Sgmax[Ag/(Ab*nb)] 1217.3222 MPa O-9

Step-7 Sbsel Sfmax(gmax/fmax) 1300.000 MPa O-10

Anda mungkin juga menyukai

- Asme Pcc-1 App O - 411-E-103 - Ch. Cover FLGDokumen12 halamanAsme Pcc-1 App O - 411-E-103 - Ch. Cover FLGVilas AndhaleBelum ada peringkat

- Blind flange design calculationDokumen4 halamanBlind flange design calculationmukesh100% (2)

- PCC1 - Addendum - 31210130 (Feb 2013) - GM1-001-G0000-MS-7880-00003Dokumen2 halamanPCC1 - Addendum - 31210130 (Feb 2013) - GM1-001-G0000-MS-7880-00003Abhay UpadhyayBelum ada peringkat

- Blind Flange Thickness Calculation Under 40 CharactersDokumen6 halamanBlind Flange Thickness Calculation Under 40 Charactersshazan0% (1)

- Assembly Bolt Stress As Per Asme Pcc-1 2013Dokumen12 halamanAssembly Bolt Stress As Per Asme Pcc-1 2013Anonymous RytT6uvX1Belum ada peringkat

- Bolt Torque Calculations 1 PDFDokumen1 halamanBolt Torque Calculations 1 PDFshazanBelum ada peringkat

- Blind Flange Calculation11Dokumen3 halamanBlind Flange Calculation11jaymuscatBelum ada peringkat

- Asme Viii D Table 2aDokumen16 halamanAsme Viii D Table 2aJohakim974100% (1)

- Ring Flange CalculationDokumen3 halamanRing Flange CalculationLuizBelum ada peringkat

- Torque BoltDokumen1 halamanTorque Boltmuchamad yasin0% (1)

- Collar bolt sizing calculationDokumen2 halamanCollar bolt sizing calculationMohammad Zahid50% (2)

- Design Procedure For Aes He PDFDokumen30 halamanDesign Procedure For Aes He PDFRyan Goh Chuang HongBelum ada peringkat

- Pipe Thickness Calculation PDFDokumen1 halamanPipe Thickness Calculation PDFHeny Martha67% (3)

- Bolt Torque As Per ASME PCC-1 - MDokumen31 halamanBolt Torque As Per ASME PCC-1 - Mmechengg01100% (2)

- Blind Flange CalculationDokumen12 halamanBlind Flange CalculationrajarajanBelum ada peringkat

- Asme Sec 8 Div 1 - App 1-10Dokumen11 halamanAsme Sec 8 Div 1 - App 1-10BibinBabuBelum ada peringkat

- Vessel Allowable LoadingsDokumen50 halamanVessel Allowable LoadingsfahadfiazBelum ada peringkat

- Roark's - Max. Bending Stress at The Saddle Horn of Horizontal VesselDokumen1 halamanRoark's - Max. Bending Stress at The Saddle Horn of Horizontal VesselRey FiedacanBelum ada peringkat

- Flange Pad CalcsDokumen4 halamanFlange Pad CalcstomBelum ada peringkat

- Header Box Stress CalculationsDokumen2 halamanHeader Box Stress Calculationsrichward5Belum ada peringkat

- MD He Tema Asme v0.1Dokumen31 halamanMD He Tema Asme v0.1Sharon Lambert100% (1)

- My ASME VIII Div 2 Vessels Are at the End of Their Life! What NowDokumen56 halamanMy ASME VIII Div 2 Vessels Are at the End of Their Life! What NowRanjit Koshy Alexander100% (1)

- Branch Reinforcement Pad Requirement CalculationDokumen2 halamanBranch Reinforcement Pad Requirement CalculationAntoshal100% (4)

- Bolt Torque Calculation - Apr19Dokumen69 halamanBolt Torque Calculation - Apr19Raj SBelum ada peringkat

- Body Flange Bolt TorqueDokumen1 halamanBody Flange Bolt TorqueLcm Tnl100% (1)

- Flange Leakage CheckDokumen1 halamanFlange Leakage CheckPhornlert WanaBelum ada peringkat

- Flange Calculation Sheet..Dokumen2 halamanFlange Calculation Sheet..nguyenquoc198850% (2)

- Calculation of Target Torque for Bolts (ASME PCC-1Dokumen1 halamanCalculation of Target Torque for Bolts (ASME PCC-1daniel oliveiraBelum ada peringkat

- Asme b31 3 03 PDFDokumen3 halamanAsme b31 3 03 PDFAtallah BoufatahBelum ada peringkat

- ASME PCC-1 Bolt Stress and Torque CalculationDokumen11 halamanASME PCC-1 Bolt Stress and Torque Calculationndrarly100% (1)

- Pipe Wall Thickness Calculation @MechEngineersDokumen77 halamanPipe Wall Thickness Calculation @MechEngineersHeri KurniawanBelum ada peringkat

- API579 FSS AssesmentDokumen6 halamanAPI579 FSS AssesmentZvonimir OpicBelum ada peringkat

- Bolt Torque Calculation For FlangeDokumen1 halamanBolt Torque Calculation For Flangevishnudno1Belum ada peringkat

- New - Reinforcement of NozzleDokumen31 halamanNew - Reinforcement of Nozzlehardik5818Belum ada peringkat

- Tailing LugDokumen2 halamanTailing Lugjagannadha varmaBelum ada peringkat

- Shell and Tube HE CalculationDokumen16 halamanShell and Tube HE CalculationPradip ShindeBelum ada peringkat

- Standard Shoe Verification Rev - ADokumen19 halamanStandard Shoe Verification Rev - AballisnothingBelum ada peringkat

- Reinforcement Pad DesignDokumen3 halamanReinforcement Pad DesignAkshat JainBelum ada peringkat

- NozzlePRO PDFDokumen185 halamanNozzlePRO PDFIan CarrBelum ada peringkat

- Design of Flanges - Full-Face Gasket 2010Dokumen29 halamanDesign of Flanges - Full-Face Gasket 2010bakelly100% (2)

- Mechanical design calculation for inspection hatch reinforcementDokumen14 halamanMechanical design calculation for inspection hatch reinforcementRaghBelum ada peringkat

- Platform Weight Calculator (Vertical Vessel)Dokumen11 halamanPlatform Weight Calculator (Vertical Vessel)Sky LarksBelum ada peringkat

- Load Check For Shoe Welded SupportDokumen313 halamanLoad Check For Shoe Welded Supportscrbdgharavi100% (2)

- PTB E4.18.5 Fixed TubesheetDokumen83 halamanPTB E4.18.5 Fixed TubesheetNicolaSaviliBelum ada peringkat

- Tube Sheet ProceduresDokumen20 halamanTube Sheet ProceduresLcm TnlBelum ada peringkat

- Minimum Distance Between Two Circumferential PipeDokumen7 halamanMinimum Distance Between Two Circumferential PipeAbdulrahmanBelum ada peringkat

- MDMT Calculations For A Pressure Vessel - Abdel Halim GalalaDokumen12 halamanMDMT Calculations For A Pressure Vessel - Abdel Halim Galalabego00Belum ada peringkat

- Sight Glass Flange AnalysisDokumen4 halamanSight Glass Flange AnalysisOmil Rastogi0% (2)

- Bolt TorqueDokumen3 halamanBolt TorqueHeri KurniawanBelum ada peringkat

- Shell Thickness CalculationsDokumen2 halamanShell Thickness CalculationsskocogluBelum ada peringkat

- Narrow Face Flange - Slip On Hub TypeDokumen17 halamanNarrow Face Flange - Slip On Hub TypeEng-CalculationsBelum ada peringkat

- ASME PCC-1 APP O - 411-E-103 - Shell Cov. FLGDokumen12 halamanASME PCC-1 APP O - 411-E-103 - Shell Cov. FLGmohamed.eldesouky9120Belum ada peringkat

- ASME PCC-1 APP O - 411-E-103 - TS FLGDokumen56 halamanASME PCC-1 APP O - 411-E-103 - TS FLGmohamed.eldesouky9120Belum ada peringkat

- ENG K22014 H-072 DR A 05 Rev A - Torque TighteningDokumen10 halamanENG K22014 H-072 DR A 05 Rev A - Torque TighteningQuraisy AmriBelum ada peringkat

- Job No. Item No: Doc. No. Tag No. Client Fine Filter Skid FD-38063A/B Bharat Heavy Electricals LimitedDokumen3 halamanJob No. Item No: Doc. No. Tag No. Client Fine Filter Skid FD-38063A/B Bharat Heavy Electricals LimitedgauravBelum ada peringkat

- ASME B31.4-Wall Thickness CalDokumen2 halamanASME B31.4-Wall Thickness CalBagus Sukoco Koco100% (1)

- Flange Excel NewDokumen26 halamanFlange Excel NewvikasBelum ada peringkat

- Rectangular Flange 070122Dokumen4 halamanRectangular Flange 070122bytestefBelum ada peringkat

- ASME B31.4-Wall Thickness Calc For 6 InchDokumen2 halamanASME B31.4-Wall Thickness Calc For 6 InchBagus Sukoco KocoBelum ada peringkat

- Input EchoDokumen6 halamanInput EchohgagBelum ada peringkat

- (Reaffirmed 2018) : QPR 9u TFK#JT Stainless Steel Wire - Specification (First Revision)Dokumen9 halaman(Reaffirmed 2018) : QPR 9u TFK#JT Stainless Steel Wire - Specification (First Revision)shamrajjBelum ada peringkat

- English Grammar Rules Mistakes Learn All of The EssentialsDokumen229 halamanEnglish Grammar Rules Mistakes Learn All of The EssentialsDaniel Duarte100% (11)

- Test Taker Handbook: Illustration by Nathalie LeesDokumen20 halamanTest Taker Handbook: Illustration by Nathalie LeesSachin5586Belum ada peringkat

- Plate Design Data ParametersDokumen2 halamanPlate Design Data ParametersSachin5586Belum ada peringkat

- Timesheet tracking for December 2019Dokumen1 halamanTimesheet tracking for December 2019Sachin5586Belum ada peringkat

- 20.360.133 2 Effects Sketch EV-21 HE-21 3Dokumen1 halaman20.360.133 2 Effects Sketch EV-21 HE-21 3Sachin5586Belum ada peringkat

- Jd-Piping EngineerDokumen1 halamanJd-Piping EngineerSachin5586Belum ada peringkat

- Rough WorkDokumen1 halamanRough WorkSachin5586Belum ada peringkat

- Jd-Phe & FF EngineerDokumen1 halamanJd-Phe & FF EngineerSachin5586Belum ada peringkat

- Mantralaya - Bulletin - Warning 18 July 2021 1400 HRSDokumen3 halamanMantralaya - Bulletin - Warning 18 July 2021 1400 HRSImran FarooquiBelum ada peringkat

- Heat ExchangerDokumen2 halamanHeat ExchangerSachin5586Belum ada peringkat

- Analysis of Vertical Vessels Supported on LegsDokumen6 halamanAnalysis of Vertical Vessels Supported on Legssonali panditBelum ada peringkat

- Notes 1 PDFDokumen261 halamanNotes 1 PDFSachin5586100% (3)

- TANK BLANK FORMAT-1-merged PDFDokumen8 halamanTANK BLANK FORMAT-1-merged PDFSachin5586Belum ada peringkat

- V-340 & 380 - 08-12-2019Dokumen1 halamanV-340 & 380 - 08-12-2019Sachin5586Belum ada peringkat

- Blind Flange DesignDokumen1 halamanBlind Flange DesignSachin5586Belum ada peringkat

- TANK BLANK FORMAT-1-merged PDFDokumen8 halamanTANK BLANK FORMAT-1-merged PDFSachin5586Belum ada peringkat

- V-340 OutDokumen14 halamanV-340 OutSachin5586Belum ada peringkat

- API 660 Vs TEMADokumen5 halamanAPI 660 Vs TEMAALONSO GOMEZBelum ada peringkat

- Design Calculations For Slurry Agitators: Method To Arrive at Motor RatingDokumen21 halamanDesign Calculations For Slurry Agitators: Method To Arrive at Motor RatingSachin5586Belum ada peringkat

- WRC For NozzleDokumen43 halamanWRC For NozzleSachin55860% (1)

- ACHE Tube Sheet PDFDokumen1 halamanACHE Tube Sheet PDFSachin5586Belum ada peringkat

- Min. Req. Nozzle Loads 200-V-1071 - RevADokumen5 halamanMin. Req. Nozzle Loads 200-V-1071 - RevASachin5586Belum ada peringkat

- Design Calc Hast ReactorDokumen24 halamanDesign Calc Hast ReactorSachin5586Belum ada peringkat

- API 660 Vs TEMA RequirementsDokumen1 halamanAPI 660 Vs TEMA RequirementsSachin5586Belum ada peringkat

- 618ti PDFDokumen8 halaman618ti PDFpeach5Belum ada peringkat

- Duplex Stainless BrochureDokumen20 halamanDuplex Stainless BrochureFelipe ArceBelum ada peringkat

- External Pressure CalculationsDokumen40 halamanExternal Pressure Calculationsmisterdavi50% (2)

- SEISMIC ASSESSMENT OF STEEL CHEMICAL STORAGE TANKSDokumen10 halamanSEISMIC ASSESSMENT OF STEEL CHEMICAL STORAGE TANKSSachin5586Belum ada peringkat

- Zick AnalysisDokumen12 halamanZick AnalysisrksahayBelum ada peringkat

- System Software Module 3: Machine-Dependent Assembler FeaturesDokumen28 halamanSystem Software Module 3: Machine-Dependent Assembler Featuresvidhya_bineeshBelum ada peringkat

- Eports: India's Defiance of Religious Freedom: A Briefing On Anti-Conversion' LawsDokumen16 halamanEports: India's Defiance of Religious Freedom: A Briefing On Anti-Conversion' LawsGabriela StevensBelum ada peringkat

- Principles of CHN New UpdatedDokumen4 halamanPrinciples of CHN New Updatediheart musicBelum ada peringkat

- Prperman 2016 14 3 (Spec. 14Dokumen8 halamanPrperman 2016 14 3 (Spec. 14celia rifaBelum ada peringkat

- EA Flora 1Dokumen3 halamanEA Flora 1A. MagnoBelum ada peringkat

- Karan Chawla and Joshua Lee November 21, 2016 MEDS 3020 - Fall 2016 Dr. Rosevear, Dr. Cartwright, Dr. LiebermanDokumen2 halamanKaran Chawla and Joshua Lee November 21, 2016 MEDS 3020 - Fall 2016 Dr. Rosevear, Dr. Cartwright, Dr. LiebermanJeremy DelaneyBelum ada peringkat

- Pahang JUJ 2012 SPM ChemistryDokumen285 halamanPahang JUJ 2012 SPM ChemistryJeyShida100% (1)

- Adventures in PioneeringDokumen202 halamanAdventures in PioneeringShawn GuttmanBelum ada peringkat

- Frozen DessertDokumen3 halamanFrozen DessertcsqueilBelum ada peringkat

- PLC of MaggiDokumen19 halamanPLC of Maggikrati agarwalBelum ada peringkat

- Roxas Avenue, Isabela City, Basilan Province AY: 2018-2019: Claret College of IsabelaDokumen2 halamanRoxas Avenue, Isabela City, Basilan Province AY: 2018-2019: Claret College of IsabelaJennilyn omnosBelum ada peringkat

- Safety Data Sheet for Instant AdhesiveDokumen6 halamanSafety Data Sheet for Instant AdhesiveDiego S. FreitasBelum ada peringkat

- Footprints 080311 For All Basic IcsDokumen18 halamanFootprints 080311 For All Basic IcsAmit PujarBelum ada peringkat

- Scientific Passage English TestDokumen57 halamanScientific Passage English TestAb HadiBelum ada peringkat

- Fancy YarnsDokumen7 halamanFancy Yarnsiriarn100% (1)

- Mega Goal 4Dokumen52 halamanMega Goal 4mahgoubkamel0% (1)

- 60Hz Axial-Fan Centrifugal-Fan AC EN (2009) PDFDokumen136 halaman60Hz Axial-Fan Centrifugal-Fan AC EN (2009) PDFRodrigo GonçalvesBelum ada peringkat

- Albert PikeDokumen6 halamanAlbert Pikeapi-302575383Belum ada peringkat

- VANSINA, Jan. Art History in AfricaDokumen250 halamanVANSINA, Jan. Art History in AfricaRaphaelTim100% (1)

- V60 Ventilator Specifications PDFDokumen4 halamanV60 Ventilator Specifications PDFJonathan Issac Dominguez RamirezBelum ada peringkat

- ECE 4400 Performance Analysis Local Computer Networks HomeworkDokumen2 halamanECE 4400 Performance Analysis Local Computer Networks HomeworkNguyen Phi HungBelum ada peringkat

- Understanding The Self Metacognitive Reading Report 1Dokumen2 halamanUnderstanding The Self Metacognitive Reading Report 1Ako Lang toBelum ada peringkat

- Motor Electrico Bojin J4103 - B User ManualDokumen6 halamanMotor Electrico Bojin J4103 - B User ManualJordan BonnettBelum ada peringkat

- Tos IcuDokumen1 halamanTos IcuMary Cris RombaoaBelum ada peringkat

- Predictive Analytics: QM901.1x Prof U Dinesh Kumar, IIMBDokumen36 halamanPredictive Analytics: QM901.1x Prof U Dinesh Kumar, IIMBVenkata Nelluri PmpBelum ada peringkat

- The Golden HarvestDokumen3 halamanThe Golden HarvestMark Angelo DiazBelum ada peringkat

- De HSG Lay Cau - Ban WordDokumen124 halamanDe HSG Lay Cau - Ban WordNguyễn Hải YếnBelum ada peringkat

- SBFP Timeline 2019Dokumen1 halamanSBFP Timeline 2019Marlon Berjolano Ere-erBelum ada peringkat

- Bhajan Songs PDFDokumen36 halamanBhajan Songs PDFsilphansi67% (6)

- Thank you for purchasing your remap from HDI Tuning LtdDokumen2 halamanThank you for purchasing your remap from HDI Tuning LtdMaks LebanBelum ada peringkat