Manual For Maintenance of Roads PDF

Diunggah oleh

Raj Bharath0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

24 tayangan55 halamanJudul Asli

manual for maintenance of roads.pdf

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

24 tayangan55 halamanManual For Maintenance of Roads PDF

Diunggah oleh

Raj BharathHak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

Anda di halaman 1dari 55

Ministry of Shipping & Traneport

Rv) pec | Bu

MANUAL FOR

MAINTENANCE

OF ROADS

(Roads Wing)

Ministry of Shipping,

‘end Transport (Rods Wing)

Copies can be had by V.P-P. from

the Secretary, Indian Roads Congress,

Jamnagar House, Shakjakan Road.

New Delhi-110 011

NEW DELHI 1989. Price Rs 48/-

Plus packing & po:

First published : December, 1983

Reprinted : September, 1989

Reprinted : February, 2000

(The Rights of Publication and Translation are Seserved)

Printed at DEE KAY PRINTERS, New Delhi-110015

(500 copies)

FOREWORD

There are no two opinions about the importance of proper

and timely maintenance in preserving the investments made on

road facilities and in providing safe transportation at a satisfactory

evel of service. This phase of operation has become all the more

important in recent years in the wake of the phenomenal growth

of traffic on the roads in the country accompanied by a steady

increase in the axle loads of commercial vebicles.

Maintenance of roads in the present day context can not there

fore just be limited to isolated actions like filling up potholes,

etc., but should follow a system approach involving a series of

sequential operations. is the precise assessment and codifica-

tion of the present fod condition, diagnosis of the problem

encountered, and ‘selection of the most appropriate treatment.

This would enable a clear understanding as to ‘when’, ‘what’ and

show’ to treat, the determination of priorities more objectively and

allotment of the available resources where they are most needed,

and formulation of a rational road maintenance programme.

Second is the effective improvement tn the quality of work and

productivity. Third is the adoption of an‘easy and quick report-

ing and recording system to check on the achievement of jobs

assigned to gangs or units, equipment, etc., employed on mainte-

nance in the field. Fourth is the observance of the duties and

responsibilities assigned to inspecting staff such as the periodicity

of inspection, a check list of items to be inspected, evaluation of

productivity and solving of any field problems in this regard,

Fifth is the training of all involved in the maintenance

methodology and operations. In performing all these activities in

the most efficient manner, the most important aspect is the human

clement, iie., the personal involvement of all concerned with

maintenance, right from the engineering supervisory staff down to

gangmen.

For providing guidance on all the above mentioned aspects

with the objective of putting the road maintenance activities in the

country.on a more rational footing with uniformity in approach, the

‘Ministry of Shipping & Transport (Roads Wing) have brought out

this ‘Manual for Maintenance of Roads’. The initial draft for this

document was prepared by Shri P.K. Lauria, .Chief Engineer and_

Shri MK. Saxena, Superintending Engineer, P.W.D. Rajasthan.

This was reviewed, amplified and finalised in the Roads Standards

Zone of the Ministry in consultation with a representative greup

of State Chief Engineers dealing with roads,

Tam sure this Manual will be useful to the Engineers in the

field as well as to those in the office dealing with planning, pro-

gramming and budgetting of maintenance activities. For more

positive impact in the different parts of the country, it will be

advantageous to translate the portions of this Manual dealing with

field activities into local language.

‘As is the case with any technical document, this Manual may

require improvementjrevision from time to time in light of the

feed-back from the various road construction departments in the

country. I do hope that this Ministry will get the necessary feed-

back in order to improve this document in the years to come.

K.K. Samin

Director General (Road Development) and

New Delhi

‘Additional Secretary to the Govt. of India

December, 1983

CONTENTS

Scope

1.1. Basic Maintenance Objectives and

Policies

1.2. Definitions

‘Planning and Financing

21. Inventory of Road

2.2. Condition Survey

2.3. Programming and Planing

2.4, Annual Calendar of Road

Maintenance Activities

Inspection

3.1. Frequency

3.2. Duties

3.3, Identification of Defects

Maintenance Criteria

4.1. Criteria for Renewal

Execution of Maintenance Operations

5.1. Safety of Labour and Road User During

Maintenance

5.2 Symptoms, Causes and Treatment of

Surface Defects

. Output of Labour

Material Procurement

‘Mechanisation and Equipment Planning

Maintenance of Drains, Shoulders, Slopes

and CD Works

Page

29

40

4

4

47

48

5.7. Maintenance of Road Furniture

Organising Maintenapce Operations in Field

6.1. Preliminary Steps

6.2. Execution of Work

6.3. Work Report

Monitoring

‘Training in Maintenance Operations and

‘Management

Problems of Special Areas

9.1. Maintenance of Roads in Desert Areas

9.2. Special Problems and Techniques for

Maintenance of Roads in Hilly Terrain

in Heavy Rainfall Areas

9.3. Special Problems and Techniques for

Maintenance of Roads in High

Altitude Areas

APPENDICES

- Surface History of Road

Check List of Items reouired to be Inspected

during Lnspection for Maintenance of Roads

|. Routine Inspection Card (Recording Format)

. Annual Calendar of Road Maintenance Acti

. Field Procedure for Inspection and Planning

Maintenance Works

Action to be taken in case the Road is Breached

or Blocked s

. Duties and Responsibilities of Mate

8. Duties and Responsibilities of Store MunshijMunshi

9.

10.

Duties and Responsibilities of Mistry/SR Mistry

Recommended Norms for Task for Road Gangs

Page

55

39

61

6

63

65

69

B

78

18

8

85

86

88

89

90

92

95

56

7

|

|

nM

12,

13,

4

15.

Norms for work charged Staff Engaged on

‘Maintenance of Roads

Tools for Gangmen

Work Sheet

‘Work Report

Maintenance of Roads—Format of Performance

for Annual Maintenance in the Division

Page

100

tor

102

103

Scope

SCOPF.

1.1, Basle Maintenance Objectives and Policies

‘The basic objectives of maintenance function are to. maintain

and operate the highway system ina manner such that

(@) Confort, convenience and safety are afforded to public

(©) The investment inroads, ridges and appurtenances is preserved

(© The aesthetics and compactly of the highway system with the

environment is preserved

() The necessary expenditure of resuurces is accomplished with cont

‘ving emphasis on econoriy.

11.1, “Service to traveling public : The road system should

bbe maintained adequately at all times within the fiscal constraints

to enture safe and convenient travel considering the density and

nature of traffic being served. .

1.1.2. Employees on call: Emergent conditions may deve-

lop from time to time adversly affecting safe and convenient travel.

Persons dealing with maintenance of traffic are on call at all times

and should be ready to be of service in effective use of the roads.

1.1.3, Preservation of investment : Its the objective, as far

as possible, to maintain all roads, bridges and appurtenances in

originally constructed or subsequently improved condition, perfor-

ming work of such conclusive and restorative nature to ensure that

the investment of public funds in each road is preserved.

1.1.4, Preventive maintenance: Maintenance of a clearly

preventive nature (as opposed to waiting until correction is re-

quired) shail be performed by operating units. Planned work of

restorative nature (maintenance, replacements or reconstruction)

which will be done in a reasonable length of time, shall be the

only reason Yor deferring rovtine maintenance provided funds are

available.

Environmental considerations : Maintenance opera~

tions should be performed in such a manner as to preserve or

enhance the compatibility of the road system with environment,

4 Scope

The maintenance of roadside shall be directed towards the

preservation or enhancement of the natural beauty of the road

land. Special emphasis shall be directed towards the control of

roadside erosion,

1.1.6. Consistency of maintenance service : All roads pro-

Viding similar service should require equivalent maintenance care

based on needs and requirements of particular region and road,

1.1.7. Economy of operation and performance improvement :

It is the objective to constantly devote efforts towards impraving

the performance of the maintenance organisation through a process

‘of methods of research and analysis, management improvement and

training, the investigative research in the field of maintenance, equip-

ment, materials and technology and regular communication with

operating personnel to incorporate improvement as developed.

1.2. Definitions

‘The maintenance of highways can be broadly-classified ander

the following three sub-heads.

1.2.1. Ordinary repairs/routine maintenance : ‘The ordinary

repairs include the following nature of works :

( Upkeep of road pavements and side shoulders

Ail) Upkeep of roadside drain system

(it) Upkeep of culverts and bridges, and earth retaining structures and

parapets

(Gv) Keeping the sign boards, km stones and other trafic aids and furni-

ture in good shape and condition

(©) Maintenance of réadside arboriculture

(vi) Upkeep and maintenance of rest houses, inspection bungalows and

‘sag buts,

1.2.2, Periodic maintenance : It covers periodic renewalé to

the carriageway whether it is gravelled road, metalled road or

black topped road to ensure that adequate level of services

maintained,

1.2.3, Special repairs and flood damage repairs

Planning and Financing §

2

Planning and

Financing

2. PLANNING AND FINANCING

2.1. Inventory of Road

The first step to planning of maintenance operation is the

evaluation of the existing road in terms of its physical condition,

structural capacity and surface profile (roughness) etc. For this

purpose, basic road inventory containing all details of the existing

highway should be available. The following data are required to

have a coniplete inventory.

2.1, District map (Fig. 2.1.) : District map on the scale of

1000 shoilld be available with the following details :

(a) Classifcationjcategory width of roads

(b) Location of streams and C.D. works

(© Type of surfaces

(@ Lane width of road

(@) Traffic intensity and volume

(©) Urban limits.

2.1.2. Strip maps (Fig. 2.2.): Strip map of particular

section of the road must have the following details:

(a) Kilometerags, road geometries vs. road width, steep aradints, i

‘ny, colverth with Bre particular, crossings et,

(availability of materials and location st quarries

(© Availability of T & P, existence of stores and. department

workshops, gang huts

(8) Any other features suchas sections which require special attention

cr substandard geometric, eq. inadequate tight distance,

forizonal or vertical alisnment, arrow width, inadequate super.

elevation, weak bridges

(© Broad soil types

2.1.3. Surface history : Surface history of the road should

be compiled in format given in Appendix I. It will contain the

summary of information available in the road register maintained

on ‘the lines prescribed by M.O.S. & T. The information should be

as accurate as possible and collected from the available records.

Planning and Financing

Planning and Financing 9

Rees,

|

| |

| ade omavecun

|

Wee ee

Fig 2.1, Dist map Fig.2.2,, Road inventory chart,

10 Planning and Financing

2.2, Condition Survey

When all the inventory data of the road are available,

condition survey can be carried out :

(@) By visual inspection

(©) By mechanical evaulation

Condition surveys by visual inspection/assessment of the

pavement, cover the type, magnitude and location of the deficiency

or distress. Necessary information about the routine maintenance

‘can be had by simply going along the rond-both past and_ present

and the likely causes of distress.

Pavement surface evaulation based on surface condition

(cracking, patching) riding quality (j.e. road roughness) and skid

resistance would form basis for taking periodic maintenance

decisions. Condition surveys at fixed frequency are necessary for

determining periodic renewal requirements and long term main=

tenance strategy. For that purpose, the condition surveys should

be conducted for each stretch of the road as per frequency

prescribed in para 3.1.

Generally, the condition’ surveys are. cirtied out from a

Vehicle travelling at slow speed supplemented by inspection of

more critical spots on foot. The data collected should be recorded

methodically kilometre-wise. It is desirable that these condition

surveys be carried out by the Junior Engineer/Assistant Engineer.

While carrying out inspections, the check list of items given in

Appendix 2 should be kept in mind. The findings of condition

survey should be recorded in format given in Appendix 3.

2.3. Programming and Planning

Based on the condition evaulation, the causes for the various

defects observed should be examined in detail and a decision taken

whether to initiate a particular maintenance activity, or to go in for

more detailed investigations to determine the maintenance/rebabi-

Imation needs precisely. Whenever distress on the pavement has

reached the stage which affects the smooth operation of traffic, it

should be rectified straightaway. For other defects like cracking,

ravelling etc., the optimal strategy should be determined having

regard to the various factors involved and a decision taken whether

Planning and Financing "

to go in for measures like seal/renewal coat or to strengthen/recon-

struct the pavement. If the latter appears necessary, further

investigations about structural deficiencies must be takea up. In

other words, the planning of the various maintenance operations

should be correlated and looked upon as a total system rather

than each activity being considered in isolation. The criteria. for

maintenance priorities/rebabilitation needs would be as per

Chapter 4.

‘Once the overall maintenance plan has been drawn up,

attention should be-given to the proper organisation and manage-

ment of the whole programme including deployment of various

resources ie, men, materials and equipment, in an efficient

manner. For each maintenance activity, the work at site should

be carefully controlled so that the optimum out-put and quality

are achieved.

2.4, Annual Calender of Road Maintenance Acti

The planning and programming of various maintenance acti=

vities throughout the year should be done in advance keeping in

view the climatic condition and periods available for carrying out

different activities, A suggested programme with regard to various

activities involved in respect of maintenance is given.in Appendix 4.

Inspection

3

Inspection

INSPECTION

1. Frequency

‘The minimum frequency of inspections for condition is

suggested in Table 3.1.

‘Tame 3

Section |e.

road

pee est | ee a (oe |

L NH Twisein Before Once in Before Oncea Every

&.ayear and and month week

SH (Aphl& after after

{Oaober) ‘mon- mon

twice

during

‘The inspection should_ be carried out not only to check the

conditions of works but also for planning future strategies. Senior

officers should make it a point to note and communicate the

instructions to the subordinates. While on inspection, the senior

officer should go through the notes of Junior colleagues and make

suitable suggestions so that inspections are meaningful.

3.2. Dates

‘The duties of supervisory staffisuch as mates-and civil mis-

tries nave been defined elsewhere under the sub-head “Out-put of

labour”. The duties of Engineering subordinates, Assistant

Engineers and Executive Engineers are as follows :

3.2.1. Duties of engineering subordinates

{i Inspection and supervision of works as per prescribed norms

Gi) Reporting observations to higher authorities

16

Inspection

fer conducting condition surveys of

Gi) Preparing estimates for repair

road

Reporting about closure of roadjobstructions due to any of the

following reasons :

(2) Over toppingybreach

(®) Landslides

(© Earthquake

(a) Accident

(©) Any other reason (specify)

() Arranging for removal of obstructions, dead animals and other

debris wing on road

(wi Enumeratine ssrery measures and restoration works in case of flood

damages and erehches and reports on opening of tafe/completion

restoration

3.2.2. Duties of Assistant Engineers

44) Inspection and supervision of workk a8 per norms

i) Reporting observations with suggestion for ren

authorities

) Getting estimates: prepared and’ checked after conducting surveys

and site investigations

Gv) Reporting about heavy rainfalls in the area and consequent rain

damage

(¥) Enumerating action oa the report of engineering subordinates

regarding obstructions, accidents etc

(vi) Boumerating safety measures and restoration of (both temporary and

permanent) works in case of flood damages and brea

il action to higher

3.2.3, Duties of Executive Engineers

(@ Inspection and recording of observations as per prescribed-norms

i) Planning and finalisation of nature of maintenance activity eg.

‘surface cemoval, repair to CD works ete.

(Gi) Arranging men, materiats and machinery in advance s per require-

jing action on reports of Assistant Engineers and also on safety

‘measures, diversion in case of breaches and flood damages

(9) Coordination with various ageticies like trafic police, local adminis

tration, publicity mediaretc., in case of emergent repairs interruption

to traffic by road blockage, ete.

(vi) Tnitiate steps for finalising permanent restoration work.

Inspection 7

3.3, Wentification of Defects :

Itis important to identify and locate the defects of surface,

shoulders, side drains and cross drainage during the inspection of

the road by various officers. Reference should be made to IRC : 82

“Code of Practice for Maintenance of Bituminous Surfaces of

hways” to help in identifying the various surface defects such

as bleeding, streaking, cracking, ravelling, edge subsidence, edge

fretting, rutting, shoving, pot holes ete. Common defects and

deficiencies of shoulder draining and cross drainage works have

been indicated in para 5.6, A brie note'on field procedure for

inspection and planning maintenance works is given in Appendix 5.

He The / 82

Maintenance Criteria 19

4

Maintenance

Criteria

4. MAINTENANCE CRITERIA

4.1. Once the inspection of road for condition survey has

been carried out and its findings recorded in the prescribed format

given in Appendix 3 in accordance with the instructions

‘contajned in para 2.2, the priorities for the required maintenance

operations are required to be fixed. These priorities are to be

assigned judiciously looking to. the urgency of the -work. The

urgency is governed by factors like (a) safe and unobstructed flow

of traffic (b) preservation of the assets in the form of roadway and

its appurtenances and (c) preventive maintenance to avoid any

further deterioration. Guidance regarding assignment of priorities

is given. in table 4.1 which indicates the priorities for various

operations as (a) urgent for jobs requiring top priority (b) spe

for jobs which are in next order of priority (c) recurrent-for

jobs which occur recurrently and are next to special in order of

prioriij=and (d) routine—for jobs which are to be attended to

in-a routine manner. In case road is breached or blocked, urgent

action sbull be taken. by Mate/Scction Officer/Assistant Engineer

and others as per steps indicated in Appendix 6.

4.2. Criteria for Renewal

Generally, the renewal cycle of bituminous surfacing would

be dependent on the traffic density, rainfall and lane width.

Table 4.2. gives the guidelines recommended in IRC : 82 “Code

of Practice for Maintenance of Bituminous Surfaces of Highways”

for National and State Highways.

aryoy

29quuv9 sndoud 0} Banas

2

a

-susad 1301109 PUE AP3K) ape Kay

sppinous at

syedos pure 98p2 peo! Ysted, apo Ay ue souspisqns 38pq 1-4.

day

28 syp819 UONDDyU

sou ed

{eur810 50 330

10 Soryot

repods Zoo war 9g wre TC

§ sunnoy ee

3 reads

8 uno sopetd om

e

§

é

2

£

s ory e129 sumneoa

7

® ‘eaze e101 a4 Jo 039 Jo 52

5 sunnow tuyeas roo} dary" Buypasoua sease reo0r ST) sodas ca

= eats fei0) 24)

é sonmanerepads ue repute oe 4J9 iso saz Butpaox

8 soiimieriapegng et. ene ae Suh (@)

& Some ot

e ay

2 J0.sw/84 STB pa (@). —_twI69 amp Jo 3429 20d sz

& ne trot 20.01 ens

s eupnow 24940 Buty 20 Boyes 201 seate eso] a ButyaEs (8)

= suoppeos ys pus Keastouie “g

Soupnos 2380

13g sou0 Jat weg oe set

uuonwone reeds 4J0 19p10 oF 39 U9 pury cay We Soon yo MME EV

ours

29 Koyo satupe> an

asytdat in om 1089 onasgo Aspfduios Yow

wuslin pee pasouiarsaperoo(a 2D Op Hotum s9peyaO!a 10 ND

owen

39 ou ot coponsnge snes

sapuadde pie awe Jo 49 Konpsor

matin upon secomm ag ot saaig Stam ed jose May aM ULSAUERIG IONE IV

agen Jo Gpyes uta pourss009 sammeeg “y

suo wopoy a | amivaa

a

a

{YRURLEND ONYNELNIVI “TP SEV,

Maintenance Criteria

fal attention

Special attention

Special attention

Special attention

‘Special attention

Routine

‘Special attention

‘Special attention

‘Special attention

Routine

‘Action

Bo texraveing

Fill and compact and tring its | Rovtine

Eirtecsto deur camber™

Clean out he drains

\ Reconsrt to adequate

Bape and see

Repair by filing

Repair

epalaReplce

Fak mw one

rectly

Repair

Clean and repair replace

Investigate the cause and

‘Any extent

Any extent

Any extent

‘Any exteat

|

z

é

‘Any extent

Any extent

‘Any

Any extedt

Any

‘in paved

(o) Erosion at aletfoutlet

)

Guide posts/ood

? ange musing

Feature

D2 Culverts

surface

(© Settlement cracks

E. Othe Works 7

‘shoulder

C2 Sing of side drains

G3 Damage or scour

Cees

@) Pot

8

‘anlng diy or corroded

‘Sr dammed ning

2 Mining road signs

B oaba at inesy

‘unpaved road

C. Shoulders—side dralas

BS Undulations

‘B-10 Loss of materia frous

C1 Deformation or scour

D. CD. Works

DI ca

EAL Road farnitare and

Maintenance Criteria 26

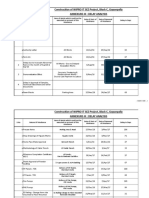

awe 4.2,

|

Lane | Trafic commercial | Type of renewal and periodicity

width | vehicles per day)” | ‘ofthe renewal treatment for

Class of

road

| tow | atedium | sigh

| rainfall | rainfall" rainfall

150.300 | above

| Se

| 150m | cm per | 300 cm

I per year | year | pee year

National ‘Singk = Lessthan 450 SD SSD

Highways 4 4 7

and State (430-1500 ep

Highways + a 3

iy More than 1300 PC PCB

6 3 i

Mos as

3 iu .

Double) Lessthan 450, SD SDS

3 4 cs

(i) 430-1500 sD sD SD

4 3 ‘S

Gi) Morethan 1500 PEPE

6 3 ‘

ashes

5 TO &

Notes

(1) SD = Single coat of uric desig with 3 ct, of chips and 25 1 of

‘itnee

PC = 20 mm premix chipping carpet as per IRC : 14

MS ~ Mix sal surfacing at pet Minitry of Shiping and “Transport

‘Goads Wing Speciation for Roads & Bridge Works cause 508

(2) The denomfaator retro the perodicy of renewal io year

G) For areas subject to snowfall and hilly areas with steep side slopes and heavy

rainfall the priodiey of renewal maybe at ose teva

(© Theperiodbty of he renewal indicated in the table above should only

bétaken asa general guideline forthe purpose of Budgeting and’ deer

mining the extent of renewal programme. It does not india ether the

‘xpected life ofthe parteular typeof treatment or the imperative need for

‘enewals after the period india. :

Execution of 27

Maintenance Operations

Execution of

Maintenance

Operations

5. EXECUTION OF MAINTENANCE OPERATIONS

5.1. Safety of Labour and Road User During Maintenance

S.1.1. Principles : In the implementation of maintenance

‘operations, the road user and personnel involved in the work

should not be exposed to hazards. Besides, delay and inconve-

rience to the traffic should be reduced to the minimum. Road

user, even when fully aware that maintenance is for his ultimate

good and safety, does not take it kindly if it is not done in a proper

manner.

Traffic hazards and inconvenience can be minimised by use

of temporary road signs and controlling/guiding of the traffic,

while keeping in mind the positioning of road signs as follows:

The standard signs in good and clear condition should be

displayed in a proper and standard layout, so as to give the drivers

sufficient time to ‘understand and react to the information on the

sign.’ The signs to be used should be as per IRC: 67 “Code of

Practice for Road Signs”, some of which are shown in Fig. 5.1.

Maintenance operations should at a time be confined to small

lengths, say 30 m in half the pavement width, leaving the other

half for use by traffic. However, some times this may not be

possible and in such a case, maintenance work can be divided in

the following four categories from the point of view of safety and

traffic control :

(@ Repairing the edges of the carriageway, shoulders, cleaning out

rains, cutting grass ec, where carriageway is not affected

Repairing. the carriageway restricting to one lane while trafic can

be allowed on the other lane

(ii) White working on the centre line such as centre line marking!

painting necessitating the trafic to se restricted width on ether side

Total closure ofthe road necessitating use of diversion due to

‘widening[reconstruction ofan existing CD work or construction of a

new structure or ue to breach or damage 10:

works. The detailed instru

Follows:

«

30 Execution of Maintenance Operations

eines af

RESTRICTION ENOS MEN AT WORK

ary

‘40

4

Pope

ne t00

NARROW ROAD AHEAD SPEED LIMIT

Hiook

Fig 5.1

5.1.2. Works on edges and shoulders : The positioning of

the cautionary signs for this category are illustrated in Fig. 5.2

Before starting the work, all warning signs should be installed in

the following manner. “Men at Work” should be placed 200 m

before approaching the work area and “Restriction Ends” sign

should be displyed 200-m béyond the work area. When the work

is completed, these'signs should be removed in the reverse order.

Execution of Maintenance Operations 31

Fig. 5.2. Arrangements of signs for work on edges and shoulders

5.1.3, Restricting the traffic to one lane: At times, the

trafic is to be restricted to one lane only due to repairs being

carried out in the other lane such as major patch repairs, etc. The

position of various cautionary and warning signs are illustrated in

Fig. 5.3, which are to be installed before start of the work in the

following sequence :

() “Men at Work

work

Anda mungkin juga menyukai

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- NPS Transaction Statement For Tier I Account: Current Scheme PreferenceDokumen2 halamanNPS Transaction Statement For Tier I Account: Current Scheme PreferenceRaj Bharath33% (3)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- AsanSM IIIDokumen18 halamanAsanSM IIIRaj BharathBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Monthly DDO Reconciliation For Receipts For June, 2021 Ifmis Government of TelanganaDokumen1 halamanMonthly DDO Reconciliation For Receipts For June, 2021 Ifmis Government of TelanganaRaj BharathBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Stress Management: Unit-IV Pranayama and StressDokumen16 halamanStress Management: Unit-IV Pranayama and StressRaj BharathBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Stress Management: Ashtanga YogaDokumen29 halamanStress Management: Ashtanga YogaRaj BharathBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Hindrance RegisterDokumen14 halamanHindrance RegisterRaj Bharath88% (8)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Block C: Concrete Abstract UOMDokumen8 halamanBlock C: Concrete Abstract UOMRaj BharathBelum ada peringkat

- Stress Management: Unit - V Dhyana and StressDokumen31 halamanStress Management: Unit - V Dhyana and StressRaj BharathBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Ac Exam PDF 2019 - Jan To MayDokumen99 halamanAc Exam PDF 2019 - Jan To MayRaj Bharath100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Fuel Safety PDFDokumen12 halamanFuel Safety PDFRaj BharathBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Railconstruction0714 PDFDokumen1 halamanRailconstruction0714 PDFRaj BharathBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Cpwd-6 For E-Tendering 1Dokumen8 halamanCpwd-6 For E-Tendering 1Raj BharathBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Rate AnalysisDokumen6 halamanRate AnalysisRaj BharathBelum ada peringkat

- Cpwd-6 For E-Tendering 2Dokumen7 halamanCpwd-6 For E-Tendering 2Raj BharathBelum ada peringkat

- Basic Finance - Day1Dokumen72 halamanBasic Finance - Day1Raj BharathBelum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Important Words For Interview Business-To-Business (B2B) Describes Commerce Transactions Between Businesses, Such As Between ADokumen1 halamanImportant Words For Interview Business-To-Business (B2B) Describes Commerce Transactions Between Businesses, Such As Between ARaj BharathBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1091)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)