Monthly Highlights July 2017 Workshop - Garage - Craft

Diunggah oleh

HamzaNouman0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

18 tayangan3 halamanhighlights

Hak Cipta

© © All Rights Reserved

Format Tersedia

DOCX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Inihighlights

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

18 tayangan3 halamanMonthly Highlights July 2017 Workshop - Garage - Craft

Diunggah oleh

HamzaNoumanhighlights

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 3

Maintenance and E & I

Monthly highlights for the Month: July 2017

Workshop / Garage / Craf

Safety Initiatives:

1. Seat belts installed in Vehicles in which previously no safety belt

was installed (80% completed)

2. Raised concern for high ratio of fire hoses failure due to too high

pressure. Most of the hoses fail above 12~13 kg/cm2. Suggested

to reduce the test pressure to save huge cost of fire hoses.

Trainings:

Section: Workshop/ Garage / Craft

IPP - INJURY PREVENTION PLAN : UTC & OTHERS :

1. Harards Of Tyre Inflation (Specially 1. Load Chart / Rigging Plan

On Lock Type Rims) 2. Scaffolding Erection

3. Installation of Taper Bore Bearing with adapter

2. Hazards of Grinding / Cutting sleeve (practical demonstration)

3. Hazards While Scaffoldindg Erection

4. Safe Crane Operation

Major Jobs attended during month:

1. Overhauling of 108-J pump due to shaft breakage (Started in end

July-2017).

2. Overhauling of following equipment:

a. Balancing of HT Cold Water Pump Motor and Balcke pump

motor of UTY East

b. Balcke Cooling Water Pump (940-1124)

c. Cold Brine Pump 40-1185 NP plant.

d. Phosphate solution pump 40-1182 of NP

e. Motor of Compressor of LCO2 Plant (machining / balancing

done)

f. 02 No. Repulpar Pumps (40-108/88)

g. Portable disposal pumps (02 No.)

h. 2207-JS pump of UTY East plant.

i. NP Melt pump ( 01 Nos.) 40-1193

j. Vacuum Bed Filter Roller (02 No.)

k. BD # 01 Komatsu Bulldozer D80A New Coolant Radiator

Replaced for CAN Handling Plant)

l. FLT # 07 Fork Lift New Overhauled Engine Replaced for

Material Warehouse.

m.Prilling bucket assembly of NP Plant (03 No.)

n. CR # 01 Manitowoc Crane Boom Hoist Lowering and Steering

turning problem rectification. (Craft Section)

o. 06 Nos. Vehicles 250 Running Hrs. Preventive Maintenance

Done.

p. NAST Structure Painting (in progress)

Cost Saving Activities:

1. Manufacturing of new shaft of 108-J pump in Workshop from

provided raw material. (Cost Saving: approx. 2 million)

2. Fabrication of square flange for Vacuum pump of CAN Plant.

(Cost Saved: 20K)

3. Manufacturing of labyrinth seal rings for 108-J pump of NH3

plant. (Cost Saving: 0.175 Million)

4. Manufacturing of shaft for 02-1108 pump of HNO3 plant &

sleeve for 15-1112 pump of can plant (Cost Saving: 75K)

5. Refurbishment of Impeller, Partition Plates and Volute Casing

for wash acid pump NP plant. (Cost Saving: 0.1 Million)

Support services to FF/FFL:

Hydro-jetting machines & maintenance manpower support for forced

emergency shutdown of FFCL

1. Any Other Initiative:

1. Template made for painting of No welding permitted on this

vessel for painting on critical vessels at Plant.

++++++++++++++ the end +++++++++++++++

Anda mungkin juga menyukai

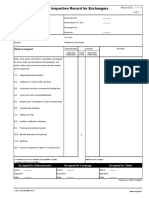

- Balance Plot FormDokumen1 halamanBalance Plot FormHamzaNoumanBelum ada peringkat

- Helium Leak Detector vs Pressure Decay Leak Testing MethodsDokumen2 halamanHelium Leak Detector vs Pressure Decay Leak Testing MethodsHamzaNoumanBelum ada peringkat

- Best Practices in Machinery InstallationDokumen2 halamanBest Practices in Machinery InstallationHamzaNoumanBelum ada peringkat

- The ABC of NDTDokumen5 halamanThe ABC of NDTHamzaNoumanBelum ada peringkat

- H Hole MesaurmentDokumen2 halamanH Hole MesaurmentHamzaNoumanBelum ada peringkat

- 2005 Nondestructive Testing Guide Equipment Condition AssessmentDokumen8 halaman2005 Nondestructive Testing Guide Equipment Condition AssessmentHamzaNoumanBelum ada peringkat

- Acceptance Criteria of Weld Defects As Per Different CodesDokumen17 halamanAcceptance Criteria of Weld Defects As Per Different CodesShubham ShuklaBelum ada peringkat

- Shift 2 Schedule (Sept 12 - Sept 20 '22)Dokumen1 halamanShift 2 Schedule (Sept 12 - Sept 20 '22)HamzaNoumanBelum ada peringkat

- Onboarding Checklist: Best Practices for a Smooth StartDokumen1 halamanOnboarding Checklist: Best Practices for a Smooth StartHamzaNoumanBelum ada peringkat

- Nbo-Tc NewDokumen24 halamanNbo-Tc NewHamzaNoumanBelum ada peringkat

- Bayyinat ArticleDokumen4 halamanBayyinat ArticleHamzaNoumanBelum ada peringkat

- MC LiftRigBestPractices Poster 11X17Dokumen1 halamanMC LiftRigBestPractices Poster 11X17HamzaNoumanBelum ada peringkat

- Certificate of Completion: Hafiz NomanDokumen1 halamanCertificate of Completion: Hafiz NomanHamzaNoumanBelum ada peringkat

- Fluid Handling System PriceDokumen2 halamanFluid Handling System PriceHamzaNoumanBelum ada peringkat

- Confirmation - Check-InDokumen1 halamanConfirmation - Check-InHamzaNoumanBelum ada peringkat

- Calculate your daily water intake based on weightDokumen7 halamanCalculate your daily water intake based on weightSuyenthan SathishBelum ada peringkat

- 7 22 2022 Mech - 19596Dokumen1 halaman7 22 2022 Mech - 19596HamzaNoumanBelum ada peringkat

- Congratulations On Your Completion: Hamza NomanDokumen1 halamanCongratulations On Your Completion: Hamza NomanHamzaNoumanBelum ada peringkat

- Scaffolding: Submitted By, Akhilesh.A Production Operator (TR), Forbes Bumiarmada LimitedDokumen42 halamanScaffolding: Submitted By, Akhilesh.A Production Operator (TR), Forbes Bumiarmada LimitedHamzaNoumanBelum ada peringkat

- Cylinder Test-Certification-ProceduresDokumen3 halamanCylinder Test-Certification-ProceduresHamzaNoumanBelum ada peringkat

- Sr. No. Description Unit: Workshop / Garage Craft IssuesDokumen14 halamanSr. No. Description Unit: Workshop / Garage Craft IssuesHamzaNoumanBelum ada peringkat

- D Level Safety Meeting Quality Checklist - RevisedDokumen1 halamanD Level Safety Meeting Quality Checklist - RevisedHamzaNoumanBelum ada peringkat

- Contract Extension of Hafiz Hussain 2021Dokumen2 halamanContract Extension of Hafiz Hussain 2021HamzaNoumanBelum ada peringkat

- Manpower Workshop Garage CraftDokumen7 halamanManpower Workshop Garage CraftHamzaNoumanBelum ada peringkat

- Advance Cash For Cricket PitchDokumen1 halamanAdvance Cash For Cricket PitchHamzaNoumanBelum ada peringkat

- JSA For Woma Jet TestingDokumen2 halamanJSA For Woma Jet TestingHamzaNoumanBelum ada peringkat

- Mechanical Workshop: Inspection & Test PlanDokumen4 halamanMechanical Workshop: Inspection & Test PlanHamzaNoumanBelum ada peringkat

- Incident / Injury Occurrence Report Part A:: Form No: SAF/2/001 Date Prepared: 29 / 09 / 08 Revision: 00Dokumen2 halamanIncident / Injury Occurrence Report Part A:: Form No: SAF/2/001 Date Prepared: 29 / 09 / 08 Revision: 00HamzaNoumanBelum ada peringkat

- MCBU - Lifting & Rigging Questions and AnswersDokumen15 halamanMCBU - Lifting & Rigging Questions and AnswersBhaiJan59Belum ada peringkat

- Pakarab Fertilizers IT Help Desk FormDokumen1 halamanPakarab Fertilizers IT Help Desk FormHamzaNoumanBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Essential v13.2Dokumen11 halamanThe Essential v13.2Beatriz ponferradaBelum ada peringkat

- Health Hazards of WeldingDokumen10 halamanHealth Hazards of Weldingapi-312547050Belum ada peringkat

- Chemical Tests: CementDokumen9 halamanChemical Tests: Cementjoe briffaBelum ada peringkat

- Horrock Ortho Toludine Water SamplingDokumen12 halamanHorrock Ortho Toludine Water SamplingHarshal Sabane100% (1)

- Ad. and Disad. of AutomationDokumen4 halamanAd. and Disad. of AutomationKumar Buddhi PrakashBelum ada peringkat

- Inspection Checklist Solar Water HeatersDokumen4 halamanInspection Checklist Solar Water HeatersREMYABelum ada peringkat

- R410A Non Inverter Ceiling Concealed SeriesDokumen2 halamanR410A Non Inverter Ceiling Concealed SeriesAyda Johari100% (1)

- Make a castable lab test mixDokumen16 halamanMake a castable lab test mixthaituan237Belum ada peringkat

- Rod Extensometer Monitoring Ground DeformationDokumen2 halamanRod Extensometer Monitoring Ground DeformationKristina LanggunaBelum ada peringkat

- Air Products Cryogenics SafetyDokumen6 halamanAir Products Cryogenics Safetyvermaravi11449922Belum ada peringkat

- Eaton DatasheetDokumen184 halamanEaton DatasheetJamesHorganBelum ada peringkat

- Analyzer Best Practices SRU TGTUDokumen25 halamanAnalyzer Best Practices SRU TGTUoujda1977Belum ada peringkat

- GQ Patrol Service Manual - Y60Dokumen1.038 halamanGQ Patrol Service Manual - Y60Jan Antonius Djunaedi77% (13)

- Cooling Water Treatment PDFDokumen2 halamanCooling Water Treatment PDFvjBelum ada peringkat

- Assignment 3 - Application of FactSageDokumen2 halamanAssignment 3 - Application of FactSagesyedalubabahrehanBelum ada peringkat

- Mohrs CircleDokumen19 halamanMohrs Circlemch77014Belum ada peringkat

- CIVL 2510 - LAB3 - Venturi Meter PDFDokumen8 halamanCIVL 2510 - LAB3 - Venturi Meter PDFmaxBelum ada peringkat

- Safety Data Sheet: Polytrol FL 32Dokumen9 halamanSafety Data Sheet: Polytrol FL 32melvinkuriBelum ada peringkat

- Cat 1600HDokumen20 halamanCat 1600HGustavoBelum ada peringkat

- 30 Pratt CatalogDokumen8 halaman30 Pratt CatalograolyjBelum ada peringkat

- Mil C 9084CDokumen20 halamanMil C 9084CNick AlanenBelum ada peringkat

- Experience With In-Field Assessment of Water Contamination ofDokumen19 halamanExperience With In-Field Assessment of Water Contamination ofmayur3dhandeBelum ada peringkat

- 6299 Chapter 4Dokumen61 halaman6299 Chapter 4Kamlesh KumarBelum ada peringkat

- Offer - Armour Steel Salem SiteDokumen1 halamanOffer - Armour Steel Salem SiteVijayKumarBelum ada peringkat

- STABURAGS NBU 12-300 KP 017062 PI GB enDokumen2 halamanSTABURAGS NBU 12-300 KP 017062 PI GB enmuhammad saputraBelum ada peringkat

- Clampco CatalogueDokumen39 halamanClampco CatalogueMisaghBelum ada peringkat

- Accesorii Cubicles 13mm InoxDokumen5 halamanAccesorii Cubicles 13mm InoxRaul IlieșBelum ada peringkat

- Air Filter Alarm SystemDokumen6 halamanAir Filter Alarm Systemhima012100% (1)

- Technical Service Information: Automatic Transmission Service GroupDokumen2 halamanTechnical Service Information: Automatic Transmission Service GroupLojan Coronel José HumbertoBelum ada peringkat