CW Quality Requirement - Rev.B

Diunggah oleh

Kalai SelvanJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

CW Quality Requirement - Rev.B

Diunggah oleh

Kalai SelvanHak Cipta:

Format Tersedia

Document No. Rev.

Demag Delaval Industrial Turbomachinery Pvt.Ltd. 1CYJ471211 B

Responsible Department: Take over Department: Document Type: Folder No.

I 24 I2 TD

Prepared: Checked: Released: Language Page:

28.08.2004 28.08.2004 28.08.2004 en 1/2

Valid for: Derived from: Replaces: E File no.:

I2 471211.doc

Technical Instruction for

Cooling Water Quality Requirement

B 18.02.2005 COOLING WATER REQUIREMENTS REVISED

A 28.08.2004 LOGO TYPE CHANGED

Rev.No. Date Description Prepared: Checked: Approved:

We reserve the rights in this document and in the information contained therein. Reproduction, use or disclosure to third parties without express

authority is strictly forbidden. Demag Delaval Industrial Turbomachinery Pvt.Ltd.

Format No.: DDIT3009

Rev./Date : - / 01.02.2004

Page: Document No. Rev.No.

2 1CYJ471211 B

REQUIREMENT OF COOLING WATER CHEMISTRY

For Condenser Tube Material specification SA249Tp304

The following cooling water chemistry needs to be mainatined for Condenser operation

Sl. No. Constituent Unit Analysis

1 PH 8.6

2 Conductivity Mhos/cm2 520

3 Suspended matters ppm 20

4 Dissolved solids ppm 370

5 Total hardness ppm as Caco3 152

6 Calcium hardness ppm as Caco3 104

7 Magnesium hardness ppm as Caco3 48

8 P - Alkalinity ppm as Caco3 16

9 M - Alkalinity ppm as Caco3 172

10 Chloride ppm as Caco3 50

11 Dissolved Silica ppm as Caco3 10

We strongly recommend the above cooling water chemistry. Any deviation shall be detrimental to the

tubes and condenser life.

The above cooling water chemistry is characterised by low salinity, high PH value and fairly low sus-

pended solids. The Tp304 tube material is very sensitive to crevice/pitting corrosion initiated by chlorides

and/or microbiological activity in general. The mentioned chlorides are to avoid crevice corrosion and the

elevated pH provide a certain buffer.

Following points have to be considered to keep the corrosion risk as low as possible:

Any MIC (microbiological introduced corrosion) should be avoided by appropriate cooling water

treatment.

The material is sensitive to oxidising agent e.g. chlorine, if used as biocide. A non-oxidising agent

should be selected instead.

Any fouling (by biological growth or inorganic precipitates) have to be excluded by adequate treat-

ment.

No chemical treatment with agents containing chlorides should be allowed. (e.d calcium carbonate,

pH control by hydrochoric acid)

A preservation concept is needed to avoid standstill corrosion

Cathodic Protection

Zinc anodes are provided in the Condenser waterbox. Due to high ph Value, the anode may passivate

and they have to be deactivated once in a while. A check of the waterbox potential by periodic measure-

ment should be done.

Format No.: DDIT3009

Rev./Date : - / 01.02.2004

Anda mungkin juga menyukai

- MODULE 1-Chemistry-Dr - HariharaDokumen100 halamanMODULE 1-Chemistry-Dr - HariharaKartik KaushikBelum ada peringkat

- 100-T-1100 Methanol Tank SampleDokumen3 halaman100-T-1100 Methanol Tank SampleSachinl PatelBelum ada peringkat

- BS For Chemicals To Water TreatmentDokumen18 halamanBS For Chemicals To Water TreatmentKalinda0% (1)

- Calculation V-Notch For Sedimentation TankDokumen34 halamanCalculation V-Notch For Sedimentation TankDavid LambertBelum ada peringkat

- Quality of WaterDokumen48 halamanQuality of WaterAbhishek KoulBelum ada peringkat

- Saudi Pak TowerDokumen8 halamanSaudi Pak TowerHamza EllahiBelum ada peringkat

- Salt Pumps Data Sheet Xi'An Space Huawei Chemical & Biological Engineering Co - LTDDokumen3 halamanSalt Pumps Data Sheet Xi'An Space Huawei Chemical & Biological Engineering Co - LTDkayaltharanBelum ada peringkat

- Level Transmitter MSPLDokumen6 halamanLevel Transmitter MSPLPratap ShettyBelum ada peringkat

- CWT-NIT For 2015 Tech. PartDokumen22 halamanCWT-NIT For 2015 Tech. Partpsk.pranesh5520Belum ada peringkat

- 001.17056.000028-AK008-01 1st Stage PreheaterDokumen5 halaman001.17056.000028-AK008-01 1st Stage PreheaterQuy RomBelum ada peringkat

- Tech Part of CWT-NITDokumen22 halamanTech Part of CWT-NITBanvari GurjarBelum ada peringkat

- MP/LP Let Down and Desuperheating Station (DS-721-02 A/B) : Process Data SheetDokumen4 halamanMP/LP Let Down and Desuperheating Station (DS-721-02 A/B) : Process Data SheetZeynab HazratiBelum ada peringkat

- Daharki Combined Cycle Power PlantDokumen77 halamanDaharki Combined Cycle Power Plantmuhammad abdulrehmanBelum ada peringkat

- 07-3116 333 PID 28 - 33 Temperature Iss - 0Dokumen1 halaman07-3116 333 PID 28 - 33 Temperature Iss - 0rajuBelum ada peringkat

- Revised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedDokumen10 halamanRevised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedAnonymous bHh1L1Belum ada peringkat

- Technical Specifications-CombinedDokumen12 halamanTechnical Specifications-CombinedsaravananBelum ada peringkat

- 001.17056.000028-AK007-01 Cartridge FilterDokumen5 halaman001.17056.000028-AK007-01 Cartridge FilterQuy RomBelum ada peringkat

- 000 Pe DS 0001Dokumen5 halaman000 Pe DS 0001Dar FallBelum ada peringkat

- JI2048-977-MS-DAT-0041 - Rev002 (T-1020)Dokumen9 halamanJI2048-977-MS-DAT-0041 - Rev002 (T-1020)Tech DesignBelum ada peringkat

- General Description: Coupling: Yellow, Yellow, Orange Pipe Body: Yellow, Yellow, OrangeDokumen5 halamanGeneral Description: Coupling: Yellow, Yellow, Orange Pipe Body: Yellow, Yellow, OrangesunnyBelum ada peringkat

- Project Title: Detailed Engineering of Methanol Export Line To New Liquid JettyDokumen2 halamanProject Title: Detailed Engineering of Methanol Export Line To New Liquid JettypavanBelum ada peringkat

- Item Location Flowing Conditions Design Conditions Instrument Characteristics RemarksDokumen2 halamanItem Location Flowing Conditions Design Conditions Instrument Characteristics RemarksrajuBelum ada peringkat

- WPS 7018+70S2Dokumen5 halamanWPS 7018+70S2rajuBelum ada peringkat

- Technical OfferDokumen10 halamanTechnical OfferNishantBelum ada peringkat

- 6700-EQS-2800-EC-0004 - EC 2802 - Flash Cooler Condenser - R01Dokumen9 halaman6700-EQS-2800-EC-0004 - EC 2802 - Flash Cooler Condenser - R01balajiBelum ada peringkat

- Standard 1103Dokumen27 halamanStandard 1103Sulist N WahyudieBelum ada peringkat

- 32LN5400 Esquema Da FonteDokumen73 halaman32LN5400 Esquema Da Fonteerick100% (1)

- Manual de Servicio Fuente de Poder PK101V3280I PDFDokumen73 halamanManual de Servicio Fuente de Poder PK101V3280I PDFpablor6Belum ada peringkat

- 100-T-1150 IPA Tank SampleDokumen3 halaman100-T-1150 IPA Tank SampleSachinl PatelBelum ada peringkat

- MC-001-DS-M-004-110 DS For Liquor Filter Rev ADokumen4 halamanMC-001-DS-M-004-110 DS For Liquor Filter Rev AHeldiyan RamdhanBelum ada peringkat

- Panasonic BGA IC Seminar 2013 - Resolder, Scule Si Cum Se Face PDFDokumen45 halamanPanasonic BGA IC Seminar 2013 - Resolder, Scule Si Cum Se Face PDFCristea GabrielBelum ada peringkat

- Abbott DI ProposalDokumen17 halamanAbbott DI ProposalFaiqMullaBelum ada peringkat

- VDRLDokumen4 halamanVDRLfarazhussainkhanBelum ada peringkat

- T-25-2018-00-Pe-Das-1048 - Rev-2 - Datasheet For Sight GlassDokumen3 halamanT-25-2018-00-Pe-Das-1048 - Rev-2 - Datasheet For Sight Glassvinoj chandranBelum ada peringkat

- Annex HDPE SpecificationDokumen20 halamanAnnex HDPE SpecificationKengaiah Pothi RaajaBelum ada peringkat

- 07-3116 333 PID 24 - 33 Temperature Iss - 0Dokumen1 halaman07-3116 333 PID 24 - 33 Temperature Iss - 0rajuBelum ada peringkat

- !!!chlorate Cell PDFDokumen20 halaman!!!chlorate Cell PDFSlava75Belum ada peringkat

- Utility Requirement: SiemensDokumen3 halamanUtility Requirement: SiemensKalai SelvanBelum ada peringkat

- Sample Testing Performa: Total Parco Pakistan LTDDokumen1 halamanSample Testing Performa: Total Parco Pakistan LTDAdnanBelum ada peringkat

- EDOPEC Cathodic Protection PDFDokumen17 halamanEDOPEC Cathodic Protection PDFocayliBelum ada peringkat

- 5 m3 For STP ProposalDokumen15 halaman5 m3 For STP ProposalShah Newaz KabirBelum ada peringkat

- Imp 00018 Part of Corrosion InhDokumen9 halamanImp 00018 Part of Corrosion InhAntonio BarbaBelum ada peringkat

- Used Oil Analysis ReportDokumen2 halamanUsed Oil Analysis ReportZishu DasBelum ada peringkat

- Tca 8039772Dokumen2 halamanTca 8039772teckhuiBelum ada peringkat

- N2 Regulator and Gauges DatasheetDokumen4 halamanN2 Regulator and Gauges DatasheetpavanBelum ada peringkat

- MC-001-DS-M-005-110 DS For Liquor Filter Rev ADokumen4 halamanMC-001-DS-M-005-110 DS For Liquor Filter Rev AHeldiyan RamdhanBelum ada peringkat

- Detail Engineering Services For Engen Tank X368 RebuildDokumen9 halamanDetail Engineering Services For Engen Tank X368 RebuildpavanBelum ada peringkat

- CH BB SLD El 04 04Dokumen2 halamanCH BB SLD El 04 04Ahmed MarzokBelum ada peringkat

- AMI Organics LTD Unit II 100 TRDokumen18 halamanAMI Organics LTD Unit II 100 TRVatsal VermaBelum ada peringkat

- Welding Procedure B69AWDokumen2 halamanWelding Procedure B69AWMastram HatheshBelum ada peringkat

- Abbott DI Proposal PDFDokumen17 halamanAbbott DI Proposal PDFFaiqMullaBelum ada peringkat

- K-RD-DT-28, Rev 5 (Indoor - Outdoor Dist Trafo) .Dokumen21 halamanK-RD-DT-28, Rev 5 (Indoor - Outdoor Dist Trafo) .Muhammad KashifBelum ada peringkat

- PDE-EQS-3120-EC-00006 - 00 Technical Specification of Ammonia SeparatorDokumen8 halamanPDE-EQS-3120-EC-00006 - 00 Technical Specification of Ammonia Separatorhgag selimBelum ada peringkat

- 150 MW Reheat LP-A1Dokumen4 halaman150 MW Reheat LP-A1DeepikaBelum ada peringkat

- Electrochlor Ination System Operating and MaintenanceDokumen50 halamanElectrochlor Ination System Operating and MaintenanceDwi Mulyanti DwimulyantishopBelum ada peringkat

- Submersible PumpDokumen105 halamanSubmersible PumpRamKS80100% (1)

- Eax64905701 Mreza LG PDFDokumen78 halamanEax64905701 Mreza LG PDFmiharkukBelum ada peringkat

- 7T04-EL-22-LI-080 - Hazardous - Source - List - (Unit - 22 DCU) - RevDokumen9 halaman7T04-EL-22-LI-080 - Hazardous - Source - List - (Unit - 22 DCU) - RevYaser AhmadBelum ada peringkat

- API Heat Exchanger Spec RequiremenDokumen11 halamanAPI Heat Exchanger Spec RequiremenElias EliasBelum ada peringkat

- OP0013477 - Crude Oil Convection Heater Budgetary Proposal PDFDokumen16 halamanOP0013477 - Crude Oil Convection Heater Budgetary Proposal PDFShiloh TonyBelum ada peringkat

- RT 02A 13B 21 23709 00 (Material Selection Report)Dokumen44 halamanRT 02A 13B 21 23709 00 (Material Selection Report)gharsallah mouna100% (1)

- The Electrochemistry and Characteristics of Embeddable Reference Electrodes for ConcreteDari EverandThe Electrochemistry and Characteristics of Embeddable Reference Electrodes for ConcreteBelum ada peringkat

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceDari EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceBelum ada peringkat

- Mucg06m1tw - List of DocumentsDokumen62 halamanMucg06m1tw - List of DocumentsKalai SelvanBelum ada peringkat

- Amendment No. 2ererDokumen345 halamanAmendment No. 2ererKalai SelvanBelum ada peringkat

- Panki FGD Gds r00 1600398998Dokumen120 halamanPanki FGD Gds r00 1600398998Kalai SelvanBelum ada peringkat

- 22.1 Itp Rot 001 PDFDokumen3 halaman22.1 Itp Rot 001 PDFAdades Safede EfdBelum ada peringkat

- 2 Instructions To Bidders (ITB)Dokumen265 halaman2 Instructions To Bidders (ITB)Saurabh Kumar SharmaBelum ada peringkat

- 03c EIL MR 3002 dd1059Dokumen146 halaman03c EIL MR 3002 dd1059Kalai Selvan100% (1)

- DSR PuneDokumen298 halamanDSR PuneAsif KhanBelum ada peringkat

- FL Flywheel Coupling/ Guardex Type FLD Pulley Coupling: Altra Industrial MotionDokumen8 halamanFL Flywheel Coupling/ Guardex Type FLD Pulley Coupling: Altra Industrial MotionKalai SelvanBelum ada peringkat

- Deluge System ManualDokumen64 halamanDeluge System ManualAsman Ahmad100% (3)

- Engineering Consultancy Services: Tender Document FORDokumen69 halamanEngineering Consultancy Services: Tender Document FORKalai SelvanBelum ada peringkat

- Full TextDokumen341 halamanFull Textcevapcic100Belum ada peringkat

- A133 3211 1062 MR 0Dokumen49 halamanA133 3211 1062 MR 0Kalai SelvanBelum ada peringkat

- Oil IndiaDokumen445 halamanOil IndiaJayadevDamodaranBelum ada peringkat

- Mohitdhullprojectreport12162035 141124013553 Conversion Gate01Dokumen53 halamanMohitdhullprojectreport12162035 141124013553 Conversion Gate01Kalai SelvanBelum ada peringkat

- Hood Design Data - Range of Capture VelocitiesDokumen3 halamanHood Design Data - Range of Capture VelocitieszshehadehBelum ada peringkat

- TS For NML Supply of ValvesDokumen19 halamanTS For NML Supply of ValvesKalai SelvanBelum ada peringkat

- Flywheel Drive Couplings & Engine Pump Mounts: Altra Industrial MotionDokumen4 halamanFlywheel Drive Couplings & Engine Pump Mounts: Altra Industrial MotionKalai SelvanBelum ada peringkat

- A133 3211 1062 MR 0Dokumen49 halamanA133 3211 1062 MR 0Kalai SelvanBelum ada peringkat

- 5.4 Design Basis For Co2 Recovery PlantDokumen41 halaman5.4 Design Basis For Co2 Recovery PlantBao KimBelum ada peringkat

- GDN 145Dokumen123 halamanGDN 145pandyatushar100% (1)

- Norsok StandardDokumen58 halamanNorsok StandardstephlyonBelum ada peringkat

- Engineering Layout of Fuel Tanks in A Tank Farm - J of LPDokumen7 halamanEngineering Layout of Fuel Tanks in A Tank Farm - J of LPthawdarBelum ada peringkat

- Cat CSVDokumen36 halamanCat CSVaqhammamBelum ada peringkat

- CDQDokumen2 halamanCDQKalai SelvanBelum ada peringkat

- Fan Laws PDFDokumen3 halamanFan Laws PDFKalai SelvanBelum ada peringkat

- Astrum BrochureDokumen22 halamanAstrum BrochureKalai SelvanBelum ada peringkat

- RivSol Article 2 - Engineering ProcessDokumen1 halamanRivSol Article 2 - Engineering ProcessKalai SelvanBelum ada peringkat

- Apt 60928 Evs TM 08 1Dokumen108 halamanApt 60928 Evs TM 08 1Mohan JhaBelum ada peringkat

- HPCL - Palanpur Terminal EIADokumen130 halamanHPCL - Palanpur Terminal EIAKalai SelvanBelum ada peringkat

- File20 PDFDokumen1 halamanFile20 PDFKalai SelvanBelum ada peringkat

- Kendriya Vidyalaya Ongc Panvel: Chemistry Investigatory Project SESSION 2018-2019Dokumen14 halamanKendriya Vidyalaya Ongc Panvel: Chemistry Investigatory Project SESSION 2018-2019tlgBelum ada peringkat

- AEG LAVW1441 ΕΓΧΕΙΡΙΔΙΟDokumen52 halamanAEG LAVW1441 ΕΓΧΕΙΡΙΔΙΟFani MarkopoulouBelum ada peringkat

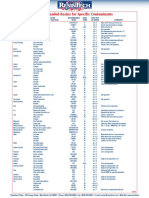

- Recommended Resins (ResinTech)Dokumen1 halamanRecommended Resins (ResinTech)dyarifinBelum ada peringkat

- Water: Engineering Chemistry-I Unit-6Dokumen70 halamanWater: Engineering Chemistry-I Unit-6Abhyudaya Rajput an idiotBelum ada peringkat

- ALBATEX AD - Protective ColloidDokumen5 halamanALBATEX AD - Protective Colloid郭哲宏0% (1)

- Low Cost Multi Bed Filter For Rainwater Harvesting System in India-IJRASETDokumen9 halamanLow Cost Multi Bed Filter For Rainwater Harvesting System in India-IJRASETIJRASETPublicationsBelum ada peringkat

- OFR 2013-11 Maps of Fresh Groundwater Chemistry, Edmonton-Calgary Corridor, Alberta: V - Bearpaw AquiferDokumen23 halamanOFR 2013-11 Maps of Fresh Groundwater Chemistry, Edmonton-Calgary Corridor, Alberta: V - Bearpaw AquiferAlberta Geological SurveyBelum ada peringkat

- TDS Nipaguard CG EnglishDokumen3 halamanTDS Nipaguard CG EnglishMaximiliano MackeviciusBelum ada peringkat

- Tasting The Hardness of Water PDFDokumen4 halamanTasting The Hardness of Water PDFAnonymous XcoRUnFBelum ada peringkat

- Hydrogen: Position in The Periodic TableDokumen5 halamanHydrogen: Position in The Periodic TableAura WaxBelum ada peringkat

- Catalog HI 83099Dokumen2 halamanCatalog HI 83099Ốc TiêuBelum ada peringkat

- Chapter 4.1 Water Supply TreatmentDokumen48 halamanChapter 4.1 Water Supply TreatmentNur HazimahBelum ada peringkat

- Waste WaterDokumen60 halamanWaste Waterbarhooom100% (1)

- Chemistry Da1Dokumen6 halamanChemistry Da1Vijayaraj MBelum ada peringkat

- Aeg Fav40750Dokumen40 halamanAeg Fav40750gabi chisBelum ada peringkat

- Hellenbrand Residential Water Softener Promate6 Consumers Manual PDFDokumen16 halamanHellenbrand Residential Water Softener Promate6 Consumers Manual PDFsteve_vtBelum ada peringkat

- Cooling Tower Problems and Chemical DosingDokumen2 halamanCooling Tower Problems and Chemical Dosingvela vanBelum ada peringkat

- Steam SystemsDokumen32 halamanSteam SystemsYoussry Elsayed MohamedBelum ada peringkat

- Watts Fmro5m Owners ManualDokumen22 halamanWatts Fmro5m Owners Manualthe_tapBelum ada peringkat

- 374 Demin Water TreatmentDokumen8 halaman374 Demin Water Treatmentnailulfalah17Belum ada peringkat

- Installation, Operation and Maintenance of Airflex® WCB Water Cooled Tensioners Ref.: Parts List #'S 146246A Thru 146298JDokumen42 halamanInstallation, Operation and Maintenance of Airflex® WCB Water Cooled Tensioners Ref.: Parts List #'S 146246A Thru 146298JMahmoud FawzyBelum ada peringkat

- 04 Installation ManualDokumen18 halaman04 Installation Manualamit64007Belum ada peringkat

- Ornamental Fisheries-Converted - pdf573Dokumen34 halamanOrnamental Fisheries-Converted - pdf573vaibhav pambharBelum ada peringkat

- Chemistry of S P Block ElementsDokumen119 halamanChemistry of S P Block ElementsSurender DilipBelum ada peringkat

- HOB-AM16 IomDokumen140 halamanHOB-AM16 IomLuis RamirezBelum ada peringkat

- JBL 7 Steps For AquariumDokumen17 halamanJBL 7 Steps For AquariumVlatka TomićBelum ada peringkat