FL PDF

Diunggah oleh

ronaldJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

FL PDF

Diunggah oleh

ronaldHak Cipta:

Format Tersedia

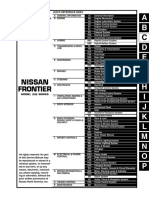

ENGINE

SECTION

FUEL SYSTEM

FL FL

E

CONTENTS

PRECAUTION ............................................... 2 FUEL TANK ....................................................... 6 F

Removal and Installation .......................................... 6

PRECAUTIONS ................................................... 2

Precaution for Supplemental Restraint System FUEL LEVEL SENSOR UNIT, FUEL FILTER G

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN- AND FUEL PUMP ASSEMBLY ........................ 10

SIONER" ................................................................... 2 Removal and Installation .........................................10

General Precaution ................................................... 2

DISASSEMBLY AND ASSEMBLY .............. 14 H

PREPARATION ............................................ 4

FUEL LEVEL SENSOR UNIT, FUEL FILTER

PREPARATION ................................................... 4 AND FUEL PUMP ASSEMBLY ........................ 14 I

Special Service Tool ................................................. 4 Disassembly and Assembly .....................................14

Commercial Service Tool .......................................... 4

SERVICE DATA AND SPECIFICATIONS

ON-VEHICLE MAINTENANCE ..................... 5 J

(SDS) ............................................................ 15

FUEL SYSTEM .................................................... 5 SERVICE DATA AND SPECIFICATIONS

Checking Fuel Line ................................................... 5 (SDS) ................................................................. 15 K

Standard and Limit ..................................................15

ON-VEHICLE REPAIR .................................. 6

L

Revision: October 2009 FL-1 2010 Frontier

PRECAUTIONS

< PRECAUTION >

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000005530135

The Supplemental Restraint System such as AIR BAG and SEAT BELT PRE-TENSIONER, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly causing

serious injury.

When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

General Precaution INFOID:0000000005275649

WARNING:

When replacing fuel line parts, be sure to observe the following.

Put a CAUTION: FLAMMABLE sign in the workshop.

Be sure to work in a well ventilated area and furnish the workshop with a CO2 fire extinguisher.

Do not smoke while servicing the fuel system. Keep open flames and sparks away from the work

area.

CAUTION:

Before removing fuel line parts, carry out the following procedures:

- Put drained fuel in an explosion-proof container and put the lid on securely. Keep the container in

safe area.

- Release fuel pressure from the fuel lines. Refer to EC-454, "Fuel Pressure Check" (QR25DE), EC-954,

"Fuel Pressure Check" (VQ40DE).

- Disconnect the battery negative terminal.

Always replace O-rings and clamps with new ones.

Do not kink or twist hoses when they are being installed.

Do not tighten hose clamps excessively to avoid damaging hoses.

Tighten high-pressure rubber hose clamp so that clamp end is 3 mm (0.12 in) from hose end.

Ensure that clamp screw does not contact adjacent parts.

Revision: October 2009 FL-2 2010 Frontier

PRECAUTIONS

< PRECAUTION >

After connecting the fuel tube quick connectors, make sure

the quick connectors are secure. A

Ensure that the connector and resin tube do not contact any

adjacent parts.

After installing tubes, make sure there is no fuel leakage at

FL

connections in the following steps.

- Apply fuel pressure to fuel lines with turning ignition switch

ON (with engine stopped). Then check for fuel leaks at con-

nections. C

- Start the engine and rev it up and check for fuel leaks at con-

nections.

Use only a Genuine NISSAN fuel filler cap as a replacement. If D

an incorrect fuel filler cap is used, the MIL may come on.

For servicing Evaporative Emission System parts, refer to

EC-459, "Removal and Installation" (QR25DE), EC-957,

"Removal and Installation" (VQ40DE). E

For servicing On Board Refueling Vapor Recovery (ORVR)

parts, refer to EC-457, "How to Detect Fuel Vapor Leakage"

(QR25DE), EC-956, "How to Detect Fuel Vapor Leakage" F

(VQ40DE).

G

PBIC1268E

Revision: October 2009 FL-3 2010 Frontier

PREPARATION

< PREPARATION >

PREPARATION

PREPARATION

Special Service Tool INFOID:0000000005275650

The actual shapes of the Kent-Moore tools may differ from those of the special tools illustrated here.

Tool number Description

(Kent-Moore No.)

Tool name

Removing and installing fuel tank lock ring

(J-45722)

130 mm lock ring tool

LBIA0398E

Commercial Service Tool INFOID:0000000005275651

Tool name Description

Power tool Loosening bolts and nuts

PBIC0190E

Revision: October 2009 FL-4 2010 Frontier

FUEL SYSTEM

< ON-VEHICLE MAINTENANCE >

ON-VEHICLE MAINTENANCE A

FUEL SYSTEM

Checking Fuel Line INFOID:0000000005275652

FL

Inspect fuel lines, fuel filler cap and fuel tank for improper attach-

ment, leaks, cracks, damage, loose connections, chafing or deterio-

ration. C

If necessary, repair or replace damaged parts.

SMA803A

Revision: October 2009 FL-5 2010 Frontier

FUEL TANK

< ON-VEHICLE REPAIR >

ON-VEHICLE REPAIR

FUEL TANK

Removal and Installation INFOID:0000000005275653

AWBIA0866GB

1. Lock ring 2. Fuel level sensor, fuel filter, and fuel 3. EVAP hose

pump assembly

4. Fuel level sensor, fuel filter, and fuel 5. Fuel tank 6. Fuel tank straps

pump assembly O-ring

7. Fuel tank shield 8. Clip 9. Fuel filler pipe shield

Revision: October 2009 FL-6 2010 Frontier

FUEL TANK

< ON-VEHICLE REPAIR >

10. Fuel filler pipe (crew cab) 11. Fuel filler hose 12. Fuel filler hose

13. Fuel filler pipe (king cab) 14. Fuel filler cap 15. Fuel filler pipe grommet A

16. Clamp 17. EVAP canister hose B. Fuel filler hose connection

A. Fuel filler hose vent connection Front

FL

REMOVAL

WARNING:

Follow the General Precautions before working on the fuel system. Refer to FL-2, "General Precau- C

tion".

1. Remove the fuel filler cap to release the pressure from inside the fuel tank.

2. Remove the LH rear wheel and tire. Refer to WT-46, "Rotation". D

3. Check the fuel level on level gauge. If the fuel gauge indicates

more than the level as shown (full or almost full), drain the fuel

from the fuel tank until the fuel gauge indicates the level as E

shown, or less.

NOTE:

Fuel will be spilled when removing the fuel level sensor, fuel fil-

F

ter, and fuel pump assembly for the fuel level is above the fuel

level sensor, fuel filter, and fuel pump assembly fuel tank open-

ing.

As a guide, the fuel level reaches the fuel gauge position as G

shown, or less, when approximately 15 (4 US gal, 3 1/4 Imp WBIA0390E

gal) of fuel are drained from the fuel tank.

If the fuel pump does not operate, use the following procedure to drain the fuel to the specified level. H

a. Insert a suitable hose of less than 15 mm (0.59 in) diameter into the fuel filler pipe through the fuel filler

opening to drain the fuel from fuel filler pipe.

b. Remove the fuel filler pipe shield. I

c. Disconnect the fuel filler hose from the fuel filler pipe.

d. Insert a suitable hose into the fuel tank through the fuel filler hose to drain the fuel from the fuel tank.

J

4. Release the fuel pressure from the fuel lines. Refer to EC-454, "Fuel Pressure Check" (QR25DE), EC-

954, "Fuel Pressure Check" (VQ40DE).

5. Disconnect the battery negative terminal. K

6. Remove the fuel tank shield.

7. Remove the fuel tank strap bolts while supporting the fuel tank

with a suitable lift jack. L

8. Lower the fuel tank using a suitable lift jack to access the top of

the fuel level sensor, fuel filter, and fuel pump assembly.

M

LBIA0413E

O

9. Disconnect the fuel level sensor, fuel filter, and fuel pump

assembly electrical connector, EVAP hose, and the fuel feed

hose.

Disconnect the fuel feed hose from the molded clip in the side P

of the fuel tank.

LBIA0412E

Revision: October 2009 FL-7 2010 Frontier

FUEL TANK

< ON-VEHICLE REPAIR >

Disconnect the quick connector as follows:

Hold the sides of the connector, push in tabs and pull out the

tube.

If the connector and the tube are stuck together, push and pull

several times until they start to move. Then disconnect them

by pulling.

SFE562A

CAUTION:

The quick connector can be disconnected when the tabs

are completely depressed. Do not twist the quick connec-

tor more than necessary.

Do not use any tools to disconnect the quick connector.

Keep the resin tube away from heat. Be especially careful

when welding near the tube.

Prevent any acid liquids such as battery electrolyte, from

getting on the resin tube.

Do not bend or twist the resin tube during connection.

Do not remove the remaining retainer on the hard tube (or

the equivalent) except when the resin tube or the retainer

is replaced.

When the resin tube or hard tube, or the equivalent, is

replaced, also replace the retainer with a new one (semi-

transparent retainer).

PBIC1268E

To keep the quick connector clean and to avoid damage

and contamination from foreign materials, cover the quick

connector with plastic bags or suitable material as shown.

PBIC0163E

Revision: October 2009 FL-8 2010 Frontier

FUEL TANK

< ON-VEHICLE REPAIR >

10. Lower the fuel tank using a suitable lift jack and remove it from

the vehicle. A

FL

LBIA0413E

D

11. Remove the lock ring using Tool as shown.

Tool number : (J-45722) E

12. Disconnect the EVAP hose from the molded clip in the top of the

fuel tank.

13. Remove the fuel level sensor, fuel filter, and fuel pump assem- F

bly. Remove and discard the fuel level sensor, fuel filter, and fuel

pump assembly O-ring.

CAUTION: G

Do not bend the float arm during removal. LBIA0436E

Avoid impacts such as dropping when handling the com-

ponents.

H

INSTALLATION

Installation is in the reverse order of removal.

For installation, use a new fuel level sensor, fuel filter, and fuel pump assembly O-ring.

I

Connect the quick connector as follows:

- Check the connection for any damage or foreign materials.

- Align the connector with the pipe, then insert the connector straight into the pipe until a click is heard.

- After connecting the quick connector, make sure that the connec- J

tion is secure by checking as follows:

- Pull the tube and the connector to make sure they are securely

connected. K

- Visually inspect the connector to make sure the two retainer tabs

are securely connected.

L

PBIC1653E

M

INSPECTION AFTER INSTALLATION

1. Turn the ignition switch ON but do not start engine, then check the fuel pipes and hose connections for N

leaks while applying fuel pressure to the system.

2. Start the engine and rev it above idle speed, then check that there are no fuel leaks at any of the fuel pipe

and hose connections.

O

Revision: October 2009 FL-9 2010 Frontier

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

< ON-VEHICLE REPAIR >

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

Removal and Installation INFOID:0000000005275654

AWBIA0866GB

1. Lock ring 2. Fuel level sensor, fuel filter, and fuel 3. EVAP hose

pump assembly

4. Fuel level sensor, fuel filter, and fuel 5. Fuel tank 6. Fuel tank straps

pump assembly O-ring

7. Fuel tank shield (If equipped) 8. Clip 9. Fuel filler pipe shield

10. Fuel filler pipe (crew cab) 11. Fuel filler hose 12. Fuel filler hose

13. Fuel filler pipe (king cab) 14. Fuel filler cap 15. Fuel filler pipe grommet

Revision: October 2009 FL-10 2010 Frontier

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

< ON-VEHICLE REPAIR >

16. Clamp 17. EVAP canister hose B. Fuel filler hose connection

A. Fuel filler hose vent connection Front A

REMOVAL

WARNING: FL

Follow the General Precautions before working on the fuel system. Refer to FL-2, "General Precau-

tion".

1. Remove the fuel filler cap to release the pressure from inside the fuel tank. C

2. Remove the LH rear wheel and tire. Refer to WT-46, "Rotation".

3. Check the fuel level on level gauge. If the fuel gauge indicates

more than the level as shown (full or almost full), drain the fuel D

from the fuel tank until the fuel gauge indicates the level as

shown, or less.

NOTE: E

Fuel will be spilled when removing the fuel level sensor, fuel fil-

ter, and fuel pump assembly for the fuel level is above the fuel

level sensor, fuel filter, and fuel pump assembly fuel tank open-

ing. F

As a guide, the fuel level reaches the fuel gauge position as

shown, or less, when approximately 15 (4 US gal, 3 1/4 Imp WBIA0390E

gal) of fuel are drained from the fuel tank. G

If the fuel pump does not operate, use the following procedure to drain the fuel to the specified level.

a. Insert a suitable hose of less than 15 mm (0.59 in) diameter into the fuel filler pipe through the fuel filler

opening to drain the fuel from fuel filler pipe. H

b. Remove the fuel filler pipe shield.

c. Disconnect the fuel filler hose from the fuel filler pipe.

d. Insert a suitable hose into the fuel tank through the fuel filler hose to drain the fuel from the fuel tank. I

4. Release the fuel pressure from the fuel lines. Refer to EC-454, "Fuel Pressure Check" (QR25DE), EC-

954, "Fuel Pressure Check" (VQ40DE).

J

5. Disconnect the battery negative terminal.

6. Remove the fuel tank shield.

7. Remove the fuel tank strap bolts while supporting the fuel tank K

with a suitable lift jack.

8. Lower the fuel tank using a suitable lift jack to access the top of

the fuel level sensor, fuel filter, and fuel pump assembly. L

LBIA0413E N

9. Disconnect the fuel level sensor, fuel filter, and fuel pump

assembly electrical connector, EVAP hose, and the fuel feed

hose. O

Disconnect the fuel feed hose from the molded clip in the side

of the fuel tank.

P

LBIA0412E

Revision: October 2009 FL-11 2010 Frontier

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

< ON-VEHICLE REPAIR >

Disconnect the quick connector as follows:

Hold the sides of the connector, push in tabs and pull out the

tube.

If the connector and the tube are stuck together, push and pull

several times until they start to move. Then disconnect them

by pulling.

SFE562A

CAUTION:

The quick connector can be disconnected when the tabs

are completely depressed. Do not twist the quick connec-

tor more than necessary.

Do not use any tools to disconnect the quick connector.

Keep the resin tube away from heat. Be especially careful

when welding near the tube.

Prevent any acid liquids such as battery electrolyte, from

getting on the resin tube.

Do not bend or twist the resin tube during connection.

Do not remove the remaining retainer on the hard tube (or

the equivalent) except when the resin tube or the retainer

is replaced.

When the resin tube or hard tube, or the equivalent, is

replaced, also replace the retainer with a new one (semi-

transparent retainer).

PBIC1268E

To keep the quick connector clean and to avoid damage

and contamination from foreign materials, cover the quick

connector with plastic bags or suitable material as shown.

PBIC0163E

Revision: October 2009 FL-12 2010 Frontier

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

< ON-VEHICLE REPAIR >

10. Lower the fuel tank using a suitable lift jack and remove it from

the vehicle to access the fuel level sensor, fuel filter, and fuel A

pump assembly.

FL

LBIA0413E

D

11. Remove the lock ring using Tool as shown.

Tool number : (J-45722) E

12. Disconnect the EVAP hose from the molded clip in the top of the

fuel tank.

13. Remove the fuel level sensor, fuel filter, and fuel pump assem- F

bly. Remove and discard the fuel level sensor, fuel filter, and fuel

pump assembly O-ring.

CAUTION: G

Do not bend the float arm during removal. LBIA0436E

Avoid impacts such as dropping when handling the com-

ponents.

H

INSTALLATION

Installation is in the reverse order of removal.

For installation, use a new fuel level sensor, fuel filter, and fuel pump assembly O-ring.

I

Connect the quick connector as follows:

- Check the connection for any damage or foreign materials.

- Align the connector with the pipe, then insert the connector straight into the pipe until a click is heard.

- After connecting the quick connector, make sure that the connec- J

tion is secure by checking as follows:

- Pull the tube and the connector to make sure they are securely

connected. K

- Visually inspect the connector to make sure the two retainer tabs

are securely connected.

L

PBIC1653E

M

INSPECTION AFTER INSTALLATION

1. Turn the ignition switch ON but do not start engine, then check the fuel pipes and hose connections for N

leaks while applying fuel pressure to the system.

2. Start the engine and rev it above idle speed, then check that there are no fuel leaks at any of the fuel pipe

and hose connections.

O

Revision: October 2009 FL-13 2010 Frontier

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

< DISASSEMBLY AND ASSEMBLY >

DISASSEMBLY AND ASSEMBLY

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

Disassembly and Assembly INFOID:0000000005275655

Fuel Level Sender Unit Assembly

WAIA0114E

1. Harness connector 2. Fuel sensor 3. Fuel level sender unit assembly

Disassembly

1. Disconnect the harness connector.

2. Remove the fuel sensor.

3. Remove the fuel level sender unit assembly.

Assembly

Assembly is the reverse order of disassembly.

Revision: October 2009 FL-14 2010 Frontier

SERVICE DATA AND SPECIFICATIONS (SDS)

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS) A

SERVICE DATA AND SPECIFICATIONS (SDS)

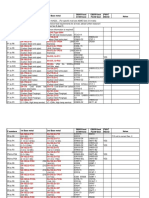

Standard and Limit INFOID:0000000005275656

FL

Fuel tank capacity 80 (21 1/8 US gal, 17 5/8 Imp gal)

C

Revision: October 2009 FL-15 2010 Frontier

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Sewing Machine MechanicDokumen66 halamanSewing Machine Mechaniczeeshan_220100% (17)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Lab 4 - PhotoelasticityDokumen10 halamanLab 4 - PhotoelasticityHaroon Rashidi67% (3)

- Acc PDFDokumen7 halamanAcc PDFronaldBelum ada peringkat

- Adp PDFDokumen165 halamanAdp PDFronaldBelum ada peringkat

- Adjustable Pedal: SectionDokumen14 halamanAdjustable Pedal: SectionmohhizbarBelum ada peringkat

- SRC PDFDokumen86 halamanSRC PDFronaldBelum ada peringkat

- ST PDFDokumen36 halamanST PDFronaldBelum ada peringkat

- TM PDFDokumen281 halamanTM PDFronaldBelum ada peringkat

- STR PDFDokumen26 halamanSTR PDFronaldBelum ada peringkat

- ST PDFDokumen36 halamanST PDFronaldBelum ada peringkat

- Fsu PDFDokumen25 halamanFsu PDFronaldBelum ada peringkat

- TM PDFDokumen281 halamanTM PDFronaldBelum ada peringkat

- SRC PDFDokumen86 halamanSRC PDFronaldBelum ada peringkat

- TM PDFDokumen281 halamanTM PDFronaldBelum ada peringkat

- STR PDFDokumen26 halamanSTR PDFronaldBelum ada peringkat

- ST PDFDokumen36 halamanST PDFronaldBelum ada peringkat

- SRC PDFDokumen86 halamanSRC PDFronaldBelum ada peringkat

- DLN PDFDokumen330 halamanDLN PDFronaldBelum ada peringkat

- STR PDFDokumen26 halamanSTR PDFronaldBelum ada peringkat

- Exl PDFDokumen150 halamanExl PDFronaldBelum ada peringkat

- Ext PDFDokumen33 halamanExt PDFronaldBelum ada peringkat

- Ex PDFDokumen7 halamanEx PDFronaldBelum ada peringkat

- FWD PDFDokumen10 halamanFWD PDFronaldBelum ada peringkat

- Em PDFDokumen252 halamanEm PDFronaldBelum ada peringkat

- Fax PDFDokumen16 halamanFax PDFronaldBelum ada peringkat

- CHG PDFDokumen23 halamanCHG PDFronaldBelum ada peringkat

- CCS PDFDokumen2 halamanCCS PDFronaldBelum ada peringkat

- Door & Lock: SectionDokumen142 halamanDoor & Lock: SectionronaldBelum ada peringkat

- Engine Cooling System: SectionDokumen57 halamanEngine Cooling System: SectionronaldBelum ada peringkat

- Def PDFDokumen41 halamanDef PDFronaldBelum ada peringkat

- CL PDFDokumen25 halamanCL PDFronaldBelum ada peringkat

- Product Design SpecificationDokumen2 halamanProduct Design SpecificationCharlie100% (1)

- Unit 1Dokumen78 halamanUnit 1thusiyanthanpBelum ada peringkat

- Chapter 8 - Part A - Fully Developed Laminar Flow PDFDokumen12 halamanChapter 8 - Part A - Fully Developed Laminar Flow PDFShubham ChoudharyBelum ada peringkat

- Air Conditioning SystemsDokumen14 halamanAir Conditioning Systemsarslan KhanBelum ada peringkat

- Design Procedure of A Pyramid Shaped HopperDokumen4 halamanDesign Procedure of A Pyramid Shaped HopperOkayBelum ada peringkat

- CF PumpsDokumen133 halamanCF PumpsNilesh GohelBelum ada peringkat

- Design of Aluminum Structure 1Dokumen3 halamanDesign of Aluminum Structure 1Ray Coello100% (2)

- 1 Landfill Design ConsiderationsDokumen41 halaman1 Landfill Design ConsiderationsShanSaharBelum ada peringkat

- Hub AppletonDokumen2 halamanHub AppletonDavid JuyarBelum ada peringkat

- Welding Electrodes SelectionDokumen19 halamanWelding Electrodes SelectionjerickBelum ada peringkat

- Energies 13 00610 v2 PDFDokumen25 halamanEnergies 13 00610 v2 PDFIsmail ŞahbazBelum ada peringkat

- PSM 2Dokumen23 halamanPSM 2luisBelum ada peringkat

- Material Safety Data Sheet: Product and Company Identification 1Dokumen11 halamanMaterial Safety Data Sheet: Product and Company Identification 1Simon WijayaBelum ada peringkat

- TI-A-EDP300-TZIDC-AV Mounting Kits 9-8-15 Combo W PGDokumen21 halamanTI-A-EDP300-TZIDC-AV Mounting Kits 9-8-15 Combo W PGalicardozoBelum ada peringkat

- Caleb Catalogue DiscspringDokumen5 halamanCaleb Catalogue DiscspringsantoshBelum ada peringkat

- Boozhound Laboratories JFETPhono PreampDokumen3 halamanBoozhound Laboratories JFETPhono Preampvali29Belum ada peringkat

- Experiment No 6Dokumen4 halamanExperiment No 6LJ IDANE ARANASBelum ada peringkat

- Steel8 PDFDokumen18 halamanSteel8 PDFJon LawheadBelum ada peringkat

- 6cyl English PDFDokumen16 halaman6cyl English PDFking852Belum ada peringkat

- Knan, Knaf, Onan, OnafDokumen2 halamanKnan, Knaf, Onan, Onafponnarasu8250% (2)

- TDS MasterSeal-540Dokumen2 halamanTDS MasterSeal-540Taposh PaulBelum ada peringkat

- The Detection of Alpha Prime in Duplex Stainless SteelsDokumen10 halamanThe Detection of Alpha Prime in Duplex Stainless Steelsapply19842371Belum ada peringkat

- About Welding Process 43Dokumen1 halamanAbout Welding Process 43XerexBelum ada peringkat

- GRI 180-12-B-W1K Data SheetDokumen3 halamanGRI 180-12-B-W1K Data SheetJMAC SupplyBelum ada peringkat

- Tipiel Sa Tipiel Sa Tipiel Sa Tipiel Sa: Specification Sheets For On-Off (Swagelok) ValvesDokumen5 halamanTipiel Sa Tipiel Sa Tipiel Sa Tipiel Sa: Specification Sheets For On-Off (Swagelok) ValvesMichell TurbayBelum ada peringkat

- FA - CDS - PLB DuctDokumen26 halamanFA - CDS - PLB Ductmba213Belum ada peringkat

- Vacuum PumpDokumen126 halamanVacuum PumpJessicalba Lou100% (1)

- Auraton 2020 2020txplus en PDFDokumen29 halamanAuraton 2020 2020txplus en PDFNikoletta GólyaBelum ada peringkat