D1836 Series (Nas1836)

Diunggah oleh

blackhawkJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

D1836 Series (Nas1836)

Diunggah oleh

blackhawkHak Cipta:

Format Tersedia

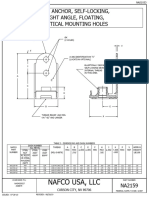

D1836 SERIES (NAS1836)

Typical Series D1836 Blind threaded insert

(NAS1836 equivalent) installed in honey comb

sandwich panel, insert is held in place by a

cured epoxy compound

See "Part Number Selection" for description of Material Codes

SIZE THREAD A B C E F H J L

SIZE HEAD DIA. BODY DIA. FLAT FLANGE DIA. MIN MIN

06 .1380-32 UNJC-3B .451 .250 .12 .260 .45 .187 .358 .218

08 .1640-32 UNJC-3B .451 .250 .12 .260 .45 .187 .358 . 218

3 .1900-32 UNJF-3B .451 .250 .12 .260 .45 .187 .358 .218

4 .2500-28 UNJF-3B .498 .300 .14 .312 .49 .250 .405 .281

HEAD STYLE

Minimum Clearance is required between bottom of insert

and inside panel skin for proper epoxy bondi ng around

bottom of insert.

PART NUMBER SELECTION

(Consult AVIAQUIP) for availability of optional finishes & sizes) PART NUMBER EXAMPLE:

Part Number

Example Selection

D1836

(Consult- 3AVIAQUIP

-5 _ for availability of optional finishes & sizes) 1. Requirements :

Optional Finish : M = Solid Film Lubricant per Mil - L - .1900-32 Thread size, Self Locking, Aluminium Screw

46010, Applied to THREADS ONLY. engagement of .50 inch, and an overall panel thickness

CRES & CARBON STEEL ONLY. of .750.

P = Cadmium Plate to QQ-A-225/6,

Type 11, Class 2 (CRES only) Part Number:

S = Silver Plate to AMS2410 (CRES

D1836 A 3 - 20

only)

insert length of .625 inch

Length of Insert in .125 inch increments

Self-Locking Thread

Thread Type (-) = Self Locking

N = Non Self Locking .1900-32 UNJF-3B Thread size

(See Table 1 )

See Size Table 1

Aluminium Alloy Material

MATERIAL (-) = Carbon Steel per ASTM -A-108 or FED STD 66. Ultimate

Tensile strength of 85 KSI MIN Cad Plate per QQ -P-416 Series

Type 11, Class 2.

A = 2024T4 or T351 Aluminium Alloy per QQ-A-225/6, Anodize

2. Requirements :

per MIL-A-8625, Type 1.

.1640-32 Thread size, Nonself -locking, Carbon Steel with

C = 303 CRES per ASTM -A-582, Passivate per QQ -P-35, Type 11 solid film lubricant, Thread engagement of .25 inch and an

overall panel thickness of .50 inch.

Series D1836 = NA S1836 Equivalent Potted in Type Panel Inserts.

INSERT LENGTH DETERMINE : See Fig 1 Above. Part Number:

The length of the insert is specifie d by a dash number which defines .125 inch increments. Insert lengths

must be a minimum of .040 inch less than depth of panel core. (SEE FIG. 1 above.)

D1836 - 08 N 12 M

Examples : - 07 = .218 inch Solid Film Lubricant

-14 = .437 inch

Insert Length of .37 inch

NOTES :

Nonself -Locking Thread

1.

1. Specified in .125 increments.

.1640-32 UNJC-3B Thread Size

2.

2. Minimum "L" values are listed in Table 1 above (See Table 1)

3. Minimum bolt engagement should not exceed "L" minus .060 inch. Carbon Steel Material

Series

Product information and part numbers shown on these pages are not guaranteed

correct by AVIAQUIP PTY. LTD and are subject to cha nge without notice.

34

Anda mungkin juga menyukai

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDari EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsBelum ada peringkat

- (D1832 SERIES) : Table 1Dokumen1 halaman(D1832 SERIES) : Table 1blackhawkBelum ada peringkat

- D1833 SERIES (NAS1833) : Table 1Dokumen1 halamanD1833 SERIES (NAS1833) : Table 1blackhawkBelum ada peringkat

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PDari EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PBelum ada peringkat

- 8) Tss-Glycol Surge DrumDokumen1 halaman8) Tss-Glycol Surge DrumKiran KumarBelum ada peringkat

- Pocket Guide to Flanges, Fittings, and Piping DataDari EverandPocket Guide to Flanges, Fittings, and Piping DataPenilaian: 3.5 dari 5 bintang3.5/5 (22)

- API SPEC 6D cryogenic valve specificationDokumen1 halamanAPI SPEC 6D cryogenic valve specificationMaffone NumerounoBelum ada peringkat

- 7.5 Kva BomDokumen2 halaman7.5 Kva BomDinesh MBelum ada peringkat

- D1834 SERIES (NAS1834) : Table 1Dokumen1 halamanD1834 SERIES (NAS1834) : Table 1blackhawkBelum ada peringkat

- At-1 - TANQUES RESERVATÓRIOS PDFDokumen2 halamanAt-1 - TANQUES RESERVATÓRIOS PDFJoão BaffiniBelum ada peringkat

- Level Gauge Data Sheet for UOPSL Flowstation ProjectDokumen4 halamanLevel Gauge Data Sheet for UOPSL Flowstation ProjectBABILIN VBelum ada peringkat

- Low Pressure Hose Assembly Specification SheetDokumen3 halamanLow Pressure Hose Assembly Specification SheetjcBelum ada peringkat

- Bussmann Series: Red Spot Range Offset Bolted Tags Fuse LinksDokumen13 halamanBussmann Series: Red Spot Range Offset Bolted Tags Fuse Linksshital thoratBelum ada peringkat

- Codeline Drawing 40L30NDokumen2 halamanCodeline Drawing 40L30NArmando Corral BlancoBelum ada peringkat

- Miniature and Instrument Ball Bearings Quality On Time DeliveryDokumen44 halamanMiniature and Instrument Ball Bearings Quality On Time DeliveryReginaldoBelum ada peringkat

- NA2159Dokumen2 halamanNA2159Bogdan RusuBelum ada peringkat

- VSL Tech Data PDFDokumen29 halamanVSL Tech Data PDFhythamBelum ada peringkat

- Datasheet TankDokumen1 halamanDatasheet TankAnonymous lQiANQusxiBelum ada peringkat

- Standard materials for CS900 piping systemDokumen5 halamanStandard materials for CS900 piping systemCristobal Leal ArandaBelum ada peringkat

- AC10 Duo Check Wafer Valve: DN50-DN1000Dokumen2 halamanAC10 Duo Check Wafer Valve: DN50-DN1000Akshat JainBelum ada peringkat

- 7720339161Dokumen2 halaman7720339161Madan KumarBelum ada peringkat

- FZ-S 2GS9 (Dark Night)Dokumen54 halamanFZ-S 2GS9 (Dark Night)蘇靖霖100% (3)

- Wps 22Dokumen2 halamanWps 22Avishek GuptaBelum ada peringkat

- Industrial Gas Generator Illustrated Parts CatalogueDokumen5 halamanIndustrial Gas Generator Illustrated Parts CataloguejuanaBelum ada peringkat

- StrainerDokumen2 halamanStrainerRanjithBelum ada peringkat

- 4510678501-50_GADDokumen1 halaman4510678501-50_GADJamsurf DeanBelum ada peringkat

- Yamatake Azbil Ss2 Acp110 0100 11Dokumen16 halamanYamatake Azbil Ss2 Acp110 0100 11Ricky TolletBelum ada peringkat

- 3) Tss-Gas Dehydration Inlet SeperatorDokumen1 halaman3) Tss-Gas Dehydration Inlet SeperatorKiran KumarBelum ada peringkat

- Siemens MotorDokumen1 halamanSiemens MotorFarshad MahmoudiBelum ada peringkat

- MS33660DDokumen3 halamanMS33660Dawesome_600Belum ada peringkat

- WG 950 2006 04Dokumen4 halamanWG 950 2006 04'Lampa'Belum ada peringkat

- Low SupportDokumen1 halamanLow SupportMDhana SekarBelum ada peringkat

- Solenoid Valve 2/2 Way N.O. Direct Acting - Dampness-Proof IP 67Dokumen2 halamanSolenoid Valve 2/2 Way N.O. Direct Acting - Dampness-Proof IP 67Ramius HamdaniBelum ada peringkat

- 05 Tyco TJRDokumen6 halaman05 Tyco TJRsamBelum ada peringkat

- S3L2 61SD 3 ZylinderDokumen135 halamanS3L2 61SD 3 ZylinderFranck MonnierBelum ada peringkat

- Drawing 80AQ15-60 Non CodedDokumen2 halamanDrawing 80AQ15-60 Non Codeddaus nasBelum ada peringkat

- GRINNEL Figure 577 Acoplamiento Rig RanDokumen4 halamanGRINNEL Figure 577 Acoplamiento Rig RanFIRE RL SYSTEMSBelum ada peringkat

- VB 537 Ag BR: FiguraDokumen1 halamanVB 537 Ag BR: FiguraMaffone NumerounoBelum ada peringkat

- Catalogo Asca Valvula RetencaoDokumen2 halamanCatalogo Asca Valvula RetencaoMaurício Duarte de AndradeBelum ada peringkat

- Amphenol Militar Connectors MS3106Dokumen4 halamanAmphenol Militar Connectors MS3106Stefan OlianoBelum ada peringkat

- Notes:: FV-01A FV-01BDokumen1 halamanNotes:: FV-01A FV-01BomarBelum ada peringkat

- PIPES AND FITTINGS CATALOGUEDokumen44 halamanPIPES AND FITTINGS CATALOGUEANV100% (1)

- 2GS8Dokumen58 halaman2GS8Akshat KumarBelum ada peringkat

- 25 7731564081 PDFDokumen2 halaman25 7731564081 PDFbsnegi111Belum ada peringkat

- Page 1 of 1Dokumen2 halamanPage 1 of 1Suthan M RBelum ada peringkat

- Red Spot Offset Bolted Tags Fuse Links: SeriesDokumen12 halamanRed Spot Offset Bolted Tags Fuse Links: SeriesStephen HustingsBelum ada peringkat

- Forging CatalogueDokumen27 halamanForging CatalogueTháiSơnTrầnBelum ada peringkat

- Data Sheet Amine Contactor (V-1040)Dokumen2 halamanData Sheet Amine Contactor (V-1040)Elias EliasBelum ada peringkat

- MSA Ball Valves enDokumen20 halamanMSA Ball Valves enBiswajit DeyBelum ada peringkat

- MSA Ball Valves PDFDokumen20 halamanMSA Ball Valves PDFAli FardidBelum ada peringkat

- 33kv - Twin Feeder CRPDokumen46 halaman33kv - Twin Feeder CRPRK KBelum ada peringkat

- 1100 MSDokumen1 halaman1100 MSAhmed RamzyBelum ada peringkat

- 002 - Gen5700 - 000 - PD2 - 01 2Dokumen1 halaman002 - Gen5700 - 000 - PD2 - 01 2HermanBelum ada peringkat

- Peppers - CABLE GLANDDokumen1 halamanPeppers - CABLE GLANDcahyo SBelum ada peringkat

- Alpha New Bp12Dokumen54 halamanAlpha New Bp12AUTO HUBBelum ada peringkat

- Draft: Edition: P5 Date: Dec.2007 Study: StageDokumen17 halamanDraft: Edition: P5 Date: Dec.2007 Study: StagenamenameBelum ada peringkat

- Long-lasting tubular gel SMG batteriesDokumen4 halamanLong-lasting tubular gel SMG batteriessyBelum ada peringkat

- IOCL-EKC-STATIONARY CASCADE-DIA 559 X 06 CYLINDER X 3000 LTR-SHEET 1 OF 5-REV.01Dokumen1 halamanIOCL-EKC-STATIONARY CASCADE-DIA 559 X 06 CYLINDER X 3000 LTR-SHEET 1 OF 5-REV.01subudhiprasannaBelum ada peringkat

- 1100 MRDokumen1 halaman1100 MRAhmed RamzyBelum ada peringkat

- TB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)Dokumen30 halamanTB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)blackhawkBelum ada peringkat

- Stage 2 NGV A Sembly. - Rotor.: - Engine Third Suppor1 AssemblyDokumen10 halamanStage 2 NGV A Sembly. - Rotor.: - Engine Third Suppor1 AssemblyblackhawkBelum ada peringkat

- TB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)Dokumen84 halamanTB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)blackhawkBelum ada peringkat

- TB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)Dokumen16 halamanTB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)blackhawkBelum ada peringkat

- Turbine Assembly Maintenance ManualDokumen1 halamanTurbine Assembly Maintenance ManualblackhawkBelum ada peringkat

- SMS ToolkitDokumen40 halamanSMS ToolkitSushant PradhanBelum ada peringkat

- (EMM Book1 TOC) (Chapter 72 TOC) : (Main Menu)Dokumen43 halaman(EMM Book1 TOC) (Chapter 72 TOC) : (Main Menu)blackhawkBelum ada peringkat

- 04removal InstallationDokumen28 halaman04removal InstallationblackhawkBelum ada peringkat

- (EMM Book1 TOC) (Chapter 72 TOC) : TB3 - 117 Engine Maintenance ManualDokumen65 halaman(EMM Book1 TOC) (Chapter 72 TOC) : TB3 - 117 Engine Maintenance ManualblackhawkBelum ada peringkat

- 072 90 13 ChipDetectorDokumen6 halaman072 90 13 ChipDetectorblackhawkBelum ada peringkat

- 01descrjption and OperationDokumen15 halaman01descrjption and OperationblackhawkBelum ada peringkat

- Combustion Chamber Description and Operation: L. GeneralDokumen14 halamanCombustion Chamber Description and Operation: L. GeneralblackhawkBelum ada peringkat

- (EMM Book1 TOC) (Chapter 72 TOC) : TB3 - 117 Engine Maintenance ManualDokumen25 halaman(EMM Book1 TOC) (Chapter 72 TOC) : TB3 - 117 Engine Maintenance ManualblackhawkBelum ada peringkat

- 由陆-32MTBE: AbcdefghDokumen1 halaman由陆-32MTBE: AbcdefghblackhawkBelum ada peringkat

- Engine Accessory Drives GuideDokumen12 halamanEngine Accessory Drives GuideblackhawkBelum ada peringkat

- 072 90 00 EngineAcessoryDokumen30 halaman072 90 00 EngineAcessoryblackhawkBelum ada peringkat

- Arriel 1 Training Manual L1 PDFDokumen354 halamanArriel 1 Training Manual L1 PDFblackhawk86% (7)

- 072 58 00 ExhaustSectionDokumen22 halaman072 58 00 ExhaustSectionblackhawkBelum ada peringkat

- Fuel and Control System - Schematic Diagram: From Neighboring EngineDokumen1 halamanFuel and Control System - Schematic Diagram: From Neighboring EngineblackhawkBelum ada peringkat

- 155b1 FLM EasaDokumen1.548 halaman155b1 FLM EasarobinyBelum ada peringkat

- AW119Kx ASMTCDokumen888 halamanAW119Kx ASMTCblackhawkBelum ada peringkat

- TB3-117 Maintenance Manual: (5) (2) 4) End (3) (2) End 4)Dokumen59 halamanTB3-117 Maintenance Manual: (5) (2) 4) End (3) (2) End 4)blackhawkBelum ada peringkat

- A119Dokumen1.060 halamanA119blackhawk100% (1)

- EASA Approved MMEL for Airbus EC135/635 HelicoptersDokumen114 halamanEASA Approved MMEL for Airbus EC135/635 HelicoptersblackhawkBelum ada peringkat

- TM 1 1500 328 23Dokumen99 halamanTM 1 1500 328 23blackhawk100% (1)

- NYCO ProductsCatalogue Issue-4Dokumen70 halamanNYCO ProductsCatalogue Issue-4Piyush50% (2)

- TM 1 1500 323 24 1Dokumen1.032 halamanTM 1 1500 323 24 1blackhawkBelum ada peringkat

- Tables 7-12Dokumen6 halamanTables 7-12blackhawkBelum ada peringkat

- Inspection and Repaer of Control Cables and TurnbucklesDokumen13 halamanInspection and Repaer of Control Cables and TurnbucklesblackhawkBelum ada peringkat

- BoltsDokumen6 halamanBoltsblackhawkBelum ada peringkat

- DirectoryBulk DrugsDokumen48 halamanDirectoryBulk DrugsPrashantsuthar100% (1)

- Power Plant Familiarisation and DCS AdvantagesDokumen22 halamanPower Plant Familiarisation and DCS AdvantagesSethu NaiduBelum ada peringkat

- Benetton Presentation67876876Dokumen17 halamanBenetton Presentation67876876Pramod DasadeBelum ada peringkat

- True Centrifugal CastingDokumen6 halamanTrue Centrifugal Castingmuhammadasrafazmi0% (1)

- Chemrite - 520 M NEWDokumen2 halamanChemrite - 520 M NEWghazanfarBelum ada peringkat

- ME 303 Study Set PDFDokumen44 halamanME 303 Study Set PDFFajar RumantoBelum ada peringkat

- Industrial Report (Naveena Textile)Dokumen6 halamanIndustrial Report (Naveena Textile)YES UCETianBelum ada peringkat

- Liquid NitridingDokumen7 halamanLiquid NitridingSenthil_kumar_palaniBelum ada peringkat

- Cold Storage FishDokumen5 halamanCold Storage FishChandanBelum ada peringkat

- Automotive Mission PlanDokumen4 halamanAutomotive Mission PlanRohith PBelum ada peringkat

- Life Cycle of A Ship - ShippipediaDokumen3 halamanLife Cycle of A Ship - ShippipediaarvindkaushikBelum ada peringkat

- Essay On AgricultureDokumen3 halamanEssay On AgricultureKen Khumancha100% (1)

- Project Report On Plywood ManufacturingDokumen26 halamanProject Report On Plywood ManufacturingSumit Bhardwaj50% (14)

- E 22 Mashop IDokumen11 halamanE 22 Mashop ISi Aniel TohBelum ada peringkat

- ECOM6008 12 Project GuidelineDokumen4 halamanECOM6008 12 Project GuidelinerierunaruBelum ada peringkat

- ASME IX Interpretation-Part8Dokumen37 halamanASME IX Interpretation-Part8kevin herry100% (1)

- Conversion Cycle NotesDokumen7 halamanConversion Cycle NotesJoana TrinidadBelum ada peringkat

- Betafoam Corporation Company ProfileDokumen1 halamanBetafoam Corporation Company ProfileOlive Dago-ocBelum ada peringkat

- Costing SheetDokumen2 halamanCosting SheetazadBelum ada peringkat

- Case Sudy On Quality Management System (Quality Assurance and Quality Control) in Construction Projects - ZipDokumen56 halamanCase Sudy On Quality Management System (Quality Assurance and Quality Control) in Construction Projects - ZipArif Azizan100% (2)

- 0208 DressingforsuccessDokumen4 halaman0208 DressingforsuccessNatKThBelum ada peringkat

- Condulets Galco PDFDokumen6 halamanCondulets Galco PDFCesar ArroyoBelum ada peringkat

- Wootz Crucible Steel: Mel-Siruvalur Site in South India (Sharada Srinivasan 1994)Dokumen11 halamanWootz Crucible Steel: Mel-Siruvalur Site in South India (Sharada Srinivasan 1994)Srini KalyanaramanBelum ada peringkat

- BBA 603 Production Operations ManagementDokumen2 halamanBBA 603 Production Operations ManagementKavya KhandelwalBelum ada peringkat

- 06 - 1 Cutting Tools - 2013 - LRDokumen17 halaman06 - 1 Cutting Tools - 2013 - LRBaggerkingBelum ada peringkat

- Foster90 66Dokumen2 halamanFoster90 66didapopescuBelum ada peringkat

- I Rod BrochureDokumen4 halamanI Rod BrochureHạo Nam-Born To WinBelum ada peringkat

- Chapter 2Dokumen77 halamanChapter 2hanaBelum ada peringkat

- Fabric Defects & InspectionDokumen23 halamanFabric Defects & InspectionYogesh SharmaBelum ada peringkat