Ocs November2016 Preseenmaterial

Diunggah oleh

Edi Kristanta PelawiHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Ocs November2016 Preseenmaterial

Diunggah oleh

Edi Kristanta PelawiHak Cipta:

Format Tersedia

Operational case study exam November 2016 pre-seen materials student copy

Marici Power

Contents: Page

Job description 2

Company background 3

What are solar panels? 4

Webpage from www.maricipower.com

5-6

How are solar panels made?

Future strategy 7

Introduction to the solar PV industry 8 - 12

Web page from www.maricipower.com

13

Extract from the glossary of terms used in the solar PV industry

Extract from Marici Power organisation chart 14

Extracts from Marici Power 2015 Financial Statements 15 - 17

Tax regime in Freeland 18

Marici Power management accounting information 19 - 20

News article reduction in solar panel subsidies 21

News article solar power storage 22

CIMA 2016. No reproduction without prior consent.

Operational case study exam November 2016 pre-seen materials student copy

Job description

You are one of three Assistant Management Accountants for Marici Power. Your main role is

to assist with the production of the annual budget, produce the monthly management

accounts and provide information to management as required.

CIMA 2016. No reproduction without prior consent.

2

Operational case study exam November 2016 pre-seen materials student copy

Company background

Marici Power is located in Freeland, a country in western Europe. Freelands currency is the

F dollar (F$).

The company offers solar power solutions to customers in Freeland and throughout the rest

of Europe. It provides a wide portfolio of products that enable private and commercial users

to generate electricity cleanly, efficiently and profitably from the power of the sun. Its

products include solar panels as well as complete solar power systems which incorporate

Marici Power panels and system components such as inverters, frames and roof-mounted

racks. In the home market, it supplies both commercial customers and installers who deal

directly with the public. The supply to the rest of Europe is through distributors and

represents 15% of the companys turnover.

All manufacturing of solar panels and solar cells, which are the key component for the solar

panels, is undertaken at Marici Powers only production facility which is located in the capital

city of Freeland. At the same location, there is a large warehouse for the storage of inventory

and office accommodation where the directors and management are based.

Over the past 20 years Marici Power has invested heavily, and has designed and developed

increasingly more sophisticated and efficient solar panels. It has developed a strong brand

and has established a reputation for producing high quality panels with high conversion

efficiency. As a result, it is now the largest manufacturer of solar panels in Freeland.

Marici Powers origins stem from the research and development division of a large oil

company, Saltenergy, also based in Freeland. Saltenergy recently decided to divest what

they considered to be peripheral businesses and concentrate on their core business of

energy from fossil fuels. As a result, in February 2016, Marici Power was sold to Wala Solar,

a major global supplier of solar products with manufacturing plants throughout Europe and

America. Marici Power now operates as a strategic business unit in the Wala Solar group

and benefits from the renewable energy market knowledge available within the group.

CIMA 2016. No reproduction without prior consent.

3

Operational case study exam November 2016 pre-seen materials student copy

What are solar panels?

Solar panels are active solar devices that use photovoltaic (PV) technology to convert

sunlight into electricity. They come in a variety of rectangular shapes and are usually

installed in combination to produce electricity.

Solar panels are fully equipped for generating electricity (direct current) from sunlight. Direct

current power can be used at the generation location itself, either immediately or stored in a

battery for later use. Inverters convert this direct current to alternating current to allow the

system to be connected to the public grid and give owners the flexibility to use both solar

energy and electricity from the public grid. Any excess power generated from the solar

system that is not required by the owners can be sold to the power company.

Sunlight

Solar Panel

Inverter

Battery

AC Loads

DC Loads

CIMA 2016. No reproduction without prior consent.

4

Operational case study exam November 2016 pre-seen materials student copy

Web page from www.maricipower.com

HOW ARE SOLAR PANELS MADE?

SILICON

Silicon is the starting point of our solar production cycle. It is extracted from quartzite

rock or sand, which is primarily made up of silicon dioxide. As the second most

common element in the earth's crust, there is a virtually endless supply of silicon.

Polysilicon is a high purity form of silicon.

SOLAR WAFERS

The next step is the production of solar wafers. These are the main component for

solar cells.

Thick Wafer

Ultra thin wafer

Silicon

To produce the polysilicon wafers used in most solar panels, the high-purity silicon

is cast into a coated mould of high-purity quartz material and melted at temperatures

over 1,400 degrees Celsius. The liquid silicon mass hardens and thousands of small

crystals combine to form a block. In the next phase of the production process, these

blocks are cut into square columns and then sliced into thin wafers.

At Marici Power, we purchase solar wafers from third party suppliers who use the

highest purity silicon.

CIMA 2016. No reproduction without prior consent.

5

Operational case study exam November 2016 pre-seen materials student copy

SOLAR CELLS

The next part of the production process involves the production of solar cells from

the wafers. These are the key components of the solar panels. These cells house all of

the technical characteristics required to generate electricity from sunlight. Light

radiation releases positive and negative charge carriers, resulting in flows of

electrical current (direct current).

At Marici Power, we manufacture solar cells using one of the most advanced solar cell

production facilities in the world. Through a series of chemical and heat treatments

we convert the wafers into productive cells i.e. cells that are capable of producing

electricity.

SOLAR PANELS

In the panel production process, solar cells are combined to form larger units

panels. Panels are enclosed in frames and weather-proofed. Solar panels are finished

solar products that are fully equipped for generating electricity (direct current) from

sunlight.

In the finishing phase, the solar panels are carefully cleaned and inspected. The

panels are then loaded on pallets for delivery to homes and businesses.

CIMA 2016. No reproduction without prior consent.

6

Operational case study exam November 2016 pre-seen materials student copy

Future strategy:

(extract from Marici Power 2015 Annual Report and Accounts)

Branding

At Marici Power, we will continue to sell our solar panels under our established brand names:

Solar Bright; Solar Glow; Solar Eclipse and Solar Halo.

Quality

We will continue to develop our brands and our reputation as a producer of high quality panels

with high conversion efficiency. We will strive to maintain our position as the largest solar panel

manufacturer in Freeland.

Customer focus

Customer needs drive the entire business and all processes within Marici Power. Product

differentiation and comprehensive customer service will create added value for the

customer.

Innovation

Solar power systems, in which panels are combined with other components to form a complete

solution, will continue to be strategically important to us. We will continue working to improve

the electricity generation capacity of our panels. In 2017, we will offer the customer an

enhanced panel design with reduced weight and a better self-cleaning effect. These panels

will be available in various sizes and types.

Sales growth

We plan to continue to utilise the opportunities as the largest manufacturer in Freeland, to

increase shipments and gain market share. One of our ongoing goals is to grow our complete

solar power solutions business since greater differentiation from the competition is possible in

this sector.

Cost efficiency

We expect to achieve economies of scale in production in 2017, due to volume growth,

enabling the reduction of manufacturing cost per unit. We also plan to make cost reductions

in all organisational units and at all stages of the supply chain with the aim of optimising cash

flow and profit.

CIMA 2016. No reproduction without prior consent.

7

Operational case study exam November 2016 pre-seen materials student copy

Introduction to the solar PV energy industry

Renewable energy technologies are clean sources of energy that have a much lower

environmental impact than conventional energy technologies. Renewable energy will not run

out whilst other sources of energy are finite and will someday be depleted. Solar energy is one

of the main forms of renewable energy. Solar energy provides more than 1% of the worlds

electricity demand or the equivalent of 33 large coal fired power plants.

The solar energy industry is divided, based on the technology involved, into two segments,

concentrated solar thermal (CST) and photovoltaics (PV)

PV technology is where absorbed light is directly converted into electricity (photo-effect). CST

technology is where direct light is focused into one point in order to heat a liquid. The heat is

subsequently used to drive a generator as in a conventional power station.

In absolute terms, electricity generation from photovoltaics is still a relatively small market.

The worldwide installed capacity at the end of 2015 was 178 gigawatts (GW), of which 40 GW

was installed in 2015.

Cumulative PV installations 2015 (GW)

40

35

30

25

20

15

10

5

0

CIMA 2016. No reproduction without prior consent.

8

Operational case study exam November 2016 pre-seen materials student copy

PV installations 2015 (GW)

12

10

The global market for PV installations used to be dominated by Europe. In 2009, Germany

held 50% of the market share, however by 2015 the market had shifted to Asia (with over 50%

of new installations), America and Africa.

The solar panel market reached an annual capacity installed of 40 GW for the first time in

2015. This level of installations has been achieved due both to the growth of the Asian and

American markets and, to some extent, to the emergence of new markets.

After years of rapid development, the rate of market growth in Europe slowed down in 2014

and this trend continued in 2015. With around 7 GW of capacity installed in 2015, Europe as

a whole is now installing less solar power capacity than either China or Japan, but more than

the USA. However, Europe is still the predominant player with more than 88 GW cumulative

capacity installed at the end of 2015.

The size and location of installations is driven by government subsidies, tariff structures and

availability of space in each country. Consequently, countries like Romania and Spain have

concentrated on large utility-scale installations, whilst others such as Netherlands and

Portugal have virtually no utility-scale installations. In the case of solar power generation, the

expression utility-scale relates to the level at which systems are typically designed to feed

power into the public grid. In Germany, more than 60% of all solar capacity has been built on

the roofs of private homes and commercial premises.

Government subsidy schemes have varied between countries. One of the most popular

schemes in Europe is the Feed-in Tariff scheme (FITs). The Freeland government scheme

was introduced in 2010. FITs is part of a set of initiatives to encourage the deployment of

renewable energy across Freeland. The objective of the scheme, on its introduction, was to

encourage deployment of small scale, up to and including 5 megawatt (MW), low-carbon

electricity generation.

CIMA 2016. No reproduction without prior consent.

9

Operational case study exam November 2016 pre-seen materials student copy

The households or businesses generating the electricity would benefit from:

bill savings the occupier of the building would benefit from using electricity generated

onsite, and therefore have a reduced electricity bill from the public grid supplier;

an export tariff paid to the generator by the supplier, for any excess electricity exported to

the public grid; and

a generation tariff paid to the generator by the supplier, designed to incentivise the

deployment of the low-carbon technology as opposed to fossil fuel alternatives.

The subsidies paid through FITs are funded by additional charges, levied by the government,

on the energy bills of all consumers. In order to limit the impact of the charges on consumer

bills, the total amount of subsidies available is capped by the government.

Other government initiatives to encourage the further development of solar power include a

range of tax incentives. The Freeland government has set a reduced value added tax (VAT)

rate of 5% on solar panel and other solar components.

Industry history

In less than a decade, the solar energy industry has transformed from a cottage industry to a

US$100 billion business with global reach. Among the factors contributing to its growth were

government subsidies, significant capacity additions from existing and new entrants, and

continual innovation.

Between 2007 and 2011, the solar energy industry grew at approximately 70% per year driven

by government subsidies that made the installation and use of solar power units economically

attractive for many consumers. As demand rose, new entrants flocked to the industry, and the

pace of innovation accelerated. This rapid growth meant that production was hard pressed to

keep up with demand. As a result, those companies that were able to increase capacity could

gain market share.

Manufacturing capacity increased dramatically, particularly after large-scale, low-cost Chinese

manufacturers entered the market. Between 2009 and 2011, Chinese solar panel production

quadrupled to more than the entire global demand. Chinese-made panels were selling for as

much as 45% cheaper than those made in Europe and the USA. The price drop fuelled

demand but put pressure on margins. As a result of this excess supply, prices of solar cells

began to tumble as companies fought to reduce inventories and many smaller producers

simply suspended manufacturing operations.

The main reason solar cell prices dropped so much, in 2011, was because the price of the key

raw material, polysilicon, which makes up a very significant part of the total cost, dropped

significantly.

In 2007-2008, there was a worldwide shortage of capacity for the manufacture of polysilicon,

the raw material used to produce the solar wafers which are incorporated into solar cells. This

shortage led to an increase in the price of polysilicon to around $400 per kg. Suppliers,

attracted by the high prices, added significant additional capacity. Consequently, there was a

huge polysilicon manufacturing over capacity which eventually resulted in falling prices. At the

beginning of 2011, prices for polysilicon had fallen to around $80 per kg but by the end prices

were around $20 to $25 per kg.

CIMA 2016. No reproduction without prior consent.

10

Operational case study exam November 2016 pre-seen materials student copy

As a result of the falling prices of solar panels, due mainly to cheap imports from China and

over-capacity in the market, almost all of the companies in the solar industry were unprofitable

from 2011 to 2014.

In 2012 the US government imposed tariffs on the import of Chinese solar cells and panels on

the basis that the manufacturers benefited from unfair subsidies from their government. In

2014 the tariffs were extended to Taiwanese manufacturers.

In 2013 the European Commission decided to impose punitive import duties on solar panels

from China in a move to guard against what was seen as dumping of cheap goods in Europe.

After negotiations between the governments of the EU and China, a minimum price

undertaking was agreed for imports of solar panel and components.

Major market trends

While 2015 undoubtedly remained a challenging time for the solar industry, it did mark a

turning point in the industrys development. Sales volume grew significantly, mainly due to

government policy in China. Solar power is now broadly recognised as a cost competitive,

reliable and sustainable energy source.

The growth experienced in the industry improved the utilisation rates of manufacturing

capacities and reduced the pressure on prices, leading to a continued recovery of the industry

around the world. In 2015, manufacturers of solar cells and panels were able to significantly

improve their financial results with many reporting profits for the first time in a number of years.

This return to profitability for manufacturers and their strengthening financial position has

resulted in new investment in the industry. Several manufacturers have announced that they

have placed orders for innovative equipment to upgrade their current production lines or to put

new ones in place. At the same time, new solar panel factories are opening within, or close

to, emerging markets although some continue to close in Europe.

In Europe, the minimum price undertaking, agreed with the Chinese government, maintained

the prices of solar products from Chinese producers at higher than market levels. Other Asian

manufacturers however continued to sell to the market at cheaper prices.

Future outlook

A large part of solar power development until the end of 2015 has been driven by the regulatory

framework adopted by national governments, including tax incentives, subsidies and other ad

hoc support schemes. In the short term, market growth is strongly dependent on continued

government support. However, its sustained development will ultimately depend on its ability

to compete with conventional sources of electricity.

Demand will still be highly concentrated in a handful of countries, presenting significant risk to

those companies who do not have a strong market presence in these countries. The rapid

price declines seen by the industry has opened up solar to an enormous number of countries

around the world but the global solar market will remain driven by those countries using

supporting regulatory frameworks, e.g. in Asia and America.

The decision of some European countries to reduce or end FITs is concerning and could have

a major impact on the extent of future installations. Companies will need to convince

CIMA 2016. No reproduction without prior consent.

11

Operational case study exam November 2016 pre-seen materials student copy

customers that the reduced costs of their electricity bills, without other additional incentives, is

sufficient to justify the investment.

Historically, solar panel development has been driven by distributed installations where

electricity is produced at, or near, the point where it is used. In 2014, utility-scale solar power

grew to the extent of becoming the largest segment, in terms of GW, installed globally. In

2015, both types of installations were balanced, with around 20 GW each. The respective

development of each segment will depend on the regulatory framework adopted by the

national governments but looking at current trends the global development of utility-scale solar

power seems to be favoured, driven by its increasing cost-competitiveness.

CIMA 2016. No reproduction without prior consent.

12

Operational case study exam November 2016 pre-seen materials student copy

Web page from www.maricipower.com

Extract from the Glossary of Terms used in the solar PV

industry

G:

Grid-connected A grid-connected solar power system generates its

own electricity and feeds its excess power into the

public grid for later use. Grid-connected solar electric

systems are eligible for many incentives and rebates.

I:

The inverter electronically converts direct current (DC)

Inverter power into alternating current (AC) power and is

required for grid-connected solar power systems.

P:

Photo = light; Volt = electrical potential Literally:

electricity from light. Einstein won a Nobel Prize for

Photovoltaic (PV) technology

discovering that when light shines on certain materials

(like silicon), an electrical current is generated.

Polysilicon is a high purity form of silicon. Due to its

Polysilicon semiconductor-like properties, polysilicon is used in

most solar energy applications.

The public grid is an interconnected network of

generating stations that produce electrical power, high-

Public grid voltage transmission lines that carry power from distant

sources to demand centres, and distribution lines that

connect individual customers.

A PV array is the complete power-generating unit,

PV array

consisting of any number of solar (or PV) panels.

S:

A material that conducts current, but only partly. The

conductivity is somewhere between that of an

Semiconductor

insulator, which has almost no conductivity, and a

conductor, which has almost full conductivity.

The basic material used to make solar cells. It is the

Silicon second most abundant element in the earths crust,

after oxygen.

Semiconductor device that converts sunlight into direct

Solar Cell (or PV cell)

current (DC) electricity.

Solar panels consist of solar cells sealed in an

Solar Panel (or PV panel) environmentally protective laminate and are the

fundamental building block of solar (or PV) systems.

Energy generated by these systems is stored in

Standalone system (or off-grid batteries and then subsequently used. Also known as

system) off-grid, these systems are not connected to the

public grid.

CIMA 2016. No reproduction without prior consent.

13

Operational case study exam November 2016 pre-seen materials student copy

Extract from Marici Power

Organisation Chart

Jorgen Phillipson

Chief Executive Officer

Dr Samuel Liffe

Volker Stein Christian Thoele

Research and Maria Coleman Andreas Loewe

Production Director Development Director Support Services

Finance Director Commercial Director

Director

Nicole Reckitt Alex Hilliard

Senior Financial Senior Managment

Accountant Acountant

Claude Foeber

Assistant Managment

Account

YOU

Assistant Managment

Accountant

Isabellla Loebig

Assistant Managment

Accountant

CIMA 2016. No reproduction without prior consent.

14

Operational case study exam November 2016 pre-seen materials student copy

Extracts from Marici Power 2015 Financial Statements

Marici Power

Statement of Profit or Loss 2015 2014

for the year ended 31 December F$000 F$000

Revenue 69,993 60,895

Cost of materials (37,705) (33,258)

Personnel expenses (14,111) (12,692)

Amortisation and depreciation (2,412) (2,263)

Other operating expenses (13,530) (12,872)

Operating profit 2,235 (190)

Finance costs (1,978) (2,156)

Profit before tax 257 (2,346)

Taxation (106) (65)

Profit / (loss) for the year 151 (2,411)

CIMA 2016. No reproduction without prior consent.

15

Operational case study exam November 2016 pre-seen materials student copy

Marici Power

Statement of Financial Position 2015 2014

as at 31 December F$000 F$000

Non-current assets

Intangible assets 18,430 17,800

Property, plant and equipment 17,409 17,474

35,839 35,274

Current assets

Inventories 21,299 20,767

Trade receivables 10,604 10,788

Cash and cash equivalents 206 75

32,109 31,630

Total Assets 67,948 66,904

Equity and Liabilities

Share capital 1,490 1,490

Retained earnings 34,946 34,795

Total equity 36,436 36,285

Non-current liabilities

Borrowings 21,322 22,664

Current liabilities

Trade payables 8,396 6,729

Borrowings 1,688 1,161

Current tax liabilities 106 65

10,190 7,955

Total Equity and Liabilities 67,948 66,904

CIMA 2016. No reproduction without prior consent.

16

Operational case study exam November 2016 pre-seen materials student copy

Marici Power

Statement of Cash Flows 2015 2014

for the year ended 31 December 2015 F$000 F$000

Cash flows from operating activities

Profit/(loss) before tax 257 (2,346)

Depreciation and amortisation 2,412 2,263

Net finance costs 1,978 2,156

(Increase)/decrease in inventory (532) (425)

(Increase)/decrease in trade and other receivables 184 224

Increase/(decrease) in trade and other payables 1,667 567

Cash generated from operations 5,966 2,439

Interest paid (1,978) (2,156)

Tax paid (65) (125)

Net cash generated from operating activities 3,923 158

Cash flows from investing activities

Purchase of property, plant and equipment (2,347) (1,594)

Increase in intangibles (630) (245)

Net cash used in investing activities (2,977) (1,839)

Cash flows from financing activities

Increase in short-term borrowings 527 1,200

Repayment of long-term borrowings (1,342) (605)

Net cash from/(used in) financing activities (815) 595

Net increase/(decrease) in cash and cash equivalents 131 (1,086)

Cash and cash equivalents at beginning of the year 75 1,161

Cash and cash equivalents at the end of the year 206 75

CIMA 2016. No reproduction without prior consent.

17

Operational case study exam November 2016 pre-seen materials student copy

TAX REGIME IN FREELAND

Corporate profits:

The corporate tax rate applicable to taxable profits is 20%.

Unless otherwise stated below, accounting rules on recognition and measurement

are followed for tax purposes.

The following expenses are not allowable for tax purposes:

o accounting depreciation;

o amortisation;

o entertaining expenditure;

o donations to political parties; and

o taxes paid to other public bodies.

Tax depreciation allowances are available on items of plant and machinery (including

vehicles used for business purposes) at a rate of 25% per year on a reducing

balance basis.

Tax losses can be carried forward to offset against future taxable profits from the

same business.

CIMA 2016. No reproduction without prior consent.

18

Operational case study exam November 2016 pre-seen materials student copy

Marici Power

Management accounting information

The company produces an annual budget with all managers participating in its

production.

The company operates a standard absorption costing system and produces a

monthly variance analysis report reconciling actual profit to budgeted profit.

KPIs are reported on a monthly basis.

A detailed daily sales report is available to managers to enable close monitoring of

sales units and selling prices.

CIMA 2016. No reproduction without prior consent.

19

Operational case study exam November 2016 pre-seen materials student copy

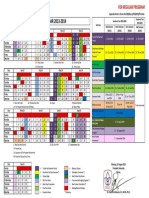

BUDGET INFORMATION 2017

Solar Panel Sales Budget 2017

Solar Solar Solar Solar

Bright Glow Halo Eclipse Total

Selling price per unit F$275 F$300 F$350 F$450

Number of units 55,000 58,000 62,000 60,000 235,000

Sales mix (units) 23.4% 24.7% 26.4% 25.5%

Total sales (F$000) 15,125 17,400 21,700 27,000 81,225

Sales mix (sales value) 18.6% 21.4% 26.7% 33.3%

Budgeted standard gross profit per unit

Solar Solar Glow Solar Solar

Bright Halo Eclipse

F$ F$ F$ F$

Selling price 275 300 350 450

Material cost 140 150 190 245

Labour cost 40 45 50 65

Variable production

2.2 2.5 2.8 3

overheads

Fixed production overheads 22 25 28 30

Standard gross profit 70.8 77.5 79.2 107

CIMA 2016. No reproduction without prior consent.

20

Operational case study exam November 2016 pre-seen materials student copy

Solar Power News

16 September 2016 No. 78 $4.70

Government cuts

to solar panel

subsidies a

hammer blow to

the industry

My priority is to keep energy bills for

Damien Valence, Business Correspondent

householders and businesses as low as

possible whilst ensuring there is a sensible

level of support for low carbon

The Freeland government has decided to cut

technologies. We have to get the balance

subsidies to householders installing rooftop

right and I believe that subsidies should be

solar panels by 60%, despite admitting that the

temporary, not part of a permanent

move could result in the loss of up to 18,000

business model. The reduced cost of solar

jobs.

technologies should be followed by a

reduction in consumer-funded support.

A second subsidy scheme for large commercial

projects has also been cut. The solar industry

The shadow energy secretary, Lisanne

and environmentalist groups have described the

Furwell, said the cuts were misguided.

moves as reckless and short-sighted.

These short-sighted cuts will place great

The government argues it needs to protect wider

pressure on our solar industry and lead to

energy bills from the rising impact of renewable

thousands of job losses. At a time when

energy subsidies.

energy bills are a concern for everyone, it

makes no sense to limit one of the cheapest

The new figures from James Claville, the energy

forms of clean energy.

secretary, are less than the original government

proposal to slash subsidies by a whopping 87%,

which was met by a storm of criticism.

CIMA 2016. No reproduction without prior consent.

21

Operational case study exam November 2016 pre-seen materials student copy

Solar Technology

15 September 2016 No. 23 $5.25

Keeping the sun

shining the

future is bright

Johan Steiff, Business Correspondent

Energy from renewable sources is a really hot

topic but whilst capacity is increasing and prices

are going down, there remains one major enough to fulfil daytime electricity

constraint to solar power developing into a demands and enough to fill up batteries for

major, cost-competitive alternative to fossil the night.

fuels storage.

The problem is that cheap battery packs

For renewable sources of electricity to be viable have longevity or reliability issues. While

they must be able to provide a continuous quality battery packs are prohibitively

supply of energy and meet peaks and troughs in expensive to produce.

demand. Unfortunately, we cannot guarantee

that the sun will always be shining. Then there The renewable energy industry is working

is the matter of night-time. on this problem but has so far been unable

to bring the expensive technology down to

In order for there to be electricity during the a realistic cost. However, developments in

night, solar energy must be captured and stored the electric vehicle industry have meant

during the day while the sun is out. But as that lithium ion storage the most

people are using electricity during the day, solar promising technology for solar is

panels need to capture as much sun as possible, becoming a more viable proposition.

CIMA 2016. No reproduction without prior consent.

22

Anda mungkin juga menyukai

- Solar Bankers White PaperDokumen40 halamanSolar Bankers White PaperCarlo MaraglianoBelum ada peringkat

- Solar Panel Improvement: 1950–2016: For Solar, by Solar, to SolarDari EverandSolar Panel Improvement: 1950–2016: For Solar, by Solar, to SolarBelum ada peringkat

- High Efficiency Solar Cells - Sale Prices of Very High Efficiency Silicon, Multijunction Solar Cells - Green World InvestorDokumen3 halamanHigh Efficiency Solar Cells - Sale Prices of Very High Efficiency Silicon, Multijunction Solar Cells - Green World InvestoralkanonimBelum ada peringkat

- Wastewater Treatment Technology: Auo Sunpower SDN BHD Visit ReportDokumen8 halamanWastewater Treatment Technology: Auo Sunpower SDN BHD Visit Reportfatin naziraBelum ada peringkat

- Bluesun Solar Panel CatalogueDokumen15 halamanBluesun Solar Panel CatalogueLéonce AgamemnonBelum ada peringkat

- Corporate Social Responsibility of SunPowerDokumen27 halamanCorporate Social Responsibility of SunPowerMaricar Ondo LopezBelum ada peringkat

- Canadian Solar Situation AnalysisDokumen25 halamanCanadian Solar Situation Analysisdasniel3Belum ada peringkat

- Pahal Solar PVTDokumen21 halamanPahal Solar PVTPurab PatelBelum ada peringkat

- 1MWp Solar Power Plant Technical ProposalDokumen26 halaman1MWp Solar Power Plant Technical Proposalashuluck2007100% (3)

- Solar PV Project ReportDokumen19 halamanSolar PV Project Reportpriyanka chaudhary65% (17)

- Chapter 4 - Solar PanelDokumen6 halamanChapter 4 - Solar PanelavocadocolorBelum ada peringkat

- Price ListDokumen24 halamanPrice ListMark O'NeillBelum ada peringkat

- How Are Solar Panels Made - What Are They Made of - Solar ChoiceDokumen7 halamanHow Are Solar Panels Made - What Are They Made of - Solar ChoiceLouis gaoBelum ada peringkat

- SeminarDokumen30 halamanSeminarDevender ChahalBelum ada peringkat

- The Power of Solar Panels UpdatedDokumen21 halamanThe Power of Solar Panels UpdatedHannah Michaella Dela CruzBelum ada peringkat

- Kabita Business PlanDokumen37 halamanKabita Business PlanAk MunnaBelum ada peringkat

- Solar Cell Mobile ChargerDokumen20 halamanSolar Cell Mobile ChargerrebbalavivekBelum ada peringkat

- Thin Film Solar Record: 19.9% Efficiency: Looking Back at Recent PV InnovationsDokumen10 halamanThin Film Solar Record: 19.9% Efficiency: Looking Back at Recent PV InnovationsJim André TagannaBelum ada peringkat

- Solar Cell Mobile Charger PDFDokumen19 halamanSolar Cell Mobile Charger PDFGülşah ÜnalBelum ada peringkat

- Kabi's Business PlanDokumen19 halamanKabi's Business PlanAk MunnaBelum ada peringkat

- Mansi ReportDokumen20 halamanMansi Reportsanket goreBelum ada peringkat

- Must-Have Consumer Guide To Solar Power Generation SystemsDokumen36 halamanMust-Have Consumer Guide To Solar Power Generation SystemspavanuBelum ada peringkat

- What Determines Solar Panel Efficiency11Dokumen7 halamanWhat Determines Solar Panel Efficiency11SYED AFJAL HUSSEN FAHADBelum ada peringkat

- Target Grid Parity: Solar PV CellsDokumen5 halamanTarget Grid Parity: Solar PV CellsRahul MaliwalBelum ada peringkat

- SolarPro 7.2Dokumen80 halamanSolarPro 7.2Antonio GomesBelum ada peringkat

- Solar Car Research PaperDokumen8 halamanSolar Car Research Paperjsxmwytlg100% (1)

- SMA Catalogo 2010 - 11 - en PDFDokumen222 halamanSMA Catalogo 2010 - 11 - en PDFluca2527Belum ada peringkat

- Perovskites Material Suppliers in IndiaDokumen4 halamanPerovskites Material Suppliers in IndiaSandeep MBelum ada peringkat

- G5 Project NewFinal - TeamDokumen21 halamanG5 Project NewFinal - Teamrahul shuklaBelum ada peringkat

- Record 19 Percent Efficiency Achieved With Low-Cost Solar CellsDokumen2 halamanRecord 19 Percent Efficiency Achieved With Low-Cost Solar CellsAbubakr ShahdadBelum ada peringkat

- UsmaanDokumen5 halamanUsmaanAAKIB QURESHIBelum ada peringkat

- The Solar Industry (Market Segmentation)Dokumen3 halamanThe Solar Industry (Market Segmentation)Hira Khan0% (1)

- Significance of Solar InvertersDokumen10 halamanSignificance of Solar Invertershedonist81Belum ada peringkat

- Photo Voltaic Cell BackupDokumen8 halamanPhoto Voltaic Cell BackupShafaq NigarBelum ada peringkat

- Canadian Solar 401 Individual ProjectDokumen7 halamanCanadian Solar 401 Individual ProjecthaneenBelum ada peringkat

- Record 19 Percent Efficiency Achieved With Low-Cost Solar CellsDokumen1 halamanRecord 19 Percent Efficiency Achieved With Low-Cost Solar CellsAbubakr ShahdadBelum ada peringkat

- Solar Panel Research Paper PDFDokumen6 halamanSolar Panel Research Paper PDFrpmvtcrif100% (1)

- JTPsolar Batangas ProposalDokumen4 halamanJTPsolar Batangas ProposalMaria Imee Dela TorreBelum ada peringkat

- Thin Film Solar CellsDokumen6 halamanThin Film Solar Cellsapi-1053323867% (3)

- Jinko Solar ReferencesDokumen16 halamanJinko Solar ReferencesShayne RebelloBelum ada peringkat

- Solar Photovoltaic EnergyDokumen10 halamanSolar Photovoltaic Energyfamg67Belum ada peringkat

- Kioko Mutinda Business PlanDokumen62 halamanKioko Mutinda Business PlanJohn KiokoBelum ada peringkat

- Plagiarism Scan Report: Unique PlagiarisedDokumen2 halamanPlagiarism Scan Report: Unique PlagiarisedSushil shresthaBelum ada peringkat

- Business Plan: Kudakwashe Solomon Mavuru Paul Henri Hie Nathan KuchenaDokumen24 halamanBusiness Plan: Kudakwashe Solomon Mavuru Paul Henri Hie Nathan Kuchenakudakwashe4mavuruBelum ada peringkat

- CPV Systems in USDokumen14 halamanCPV Systems in USgayaseshaBelum ada peringkat

- QU-2024-156 - MR Nafras 3kW Single Phase On GridDokumen20 halamanQU-2024-156 - MR Nafras 3kW Single Phase On GridNafras MohammedBelum ada peringkat

- M.manishankar Reddy ReportDokumen20 halamanM.manishankar Reddy ReportHari SankarBelum ada peringkat

- Solar Power For Beginners - The DIY Guide To Easily Install A Solar Power System in Your HomeDokumen87 halamanSolar Power For Beginners - The DIY Guide To Easily Install A Solar Power System in Your HomeEdith LGBelum ada peringkat

- Ret PDFDokumen14 halamanRet PDFomkar pubg GamingBelum ada peringkat

- Module-4 in Module 4 We Have Done: - : Challenges Faced During Start-UpsDokumen7 halamanModule-4 in Module 4 We Have Done: - : Challenges Faced During Start-UpsArpit DhimanBelum ada peringkat

- Solar Power StationsDokumen20 halamanSolar Power StationsAhmad Al-ThunebatBelum ada peringkat

- Global Market Outlook 2018 2022Dokumen81 halamanGlobal Market Outlook 2018 2022Ben Fyson-SmithBelum ada peringkat

- ENCE320 Final ProjectDokumen20 halamanENCE320 Final ProjectAlec DBelum ada peringkat

- Making Big Impacts With Small Acts: SolarMyPlace Launches This Black FridayDokumen3 halamanMaking Big Impacts With Small Acts: SolarMyPlace Launches This Black FridayPR.comBelum ada peringkat

- Nanomaterials For Solar Energy Conversion and ApplicationsDokumen10 halamanNanomaterials For Solar Energy Conversion and Applicationsup4all100% (1)

- CBGuide June2022Dokumen26 halamanCBGuide June2022Yip DavidBelum ada peringkat

- 10mw Solar PowerplantDokumen14 halaman10mw Solar PowerplantMark Tristan Vallesteros0% (1)

- MbprojectDokumen46 halamanMbprojectajitsinghgrewalBelum ada peringkat

- Micro InverterDokumen28 halamanMicro InverterAatish KoulBelum ada peringkat

- Accounting HandbookDokumen14 halamanAccounting HandbookEdi Kristanta PelawiBelum ada peringkat

- Ar Ar: Er-Softw Er-SoftwDokumen1 halamanAr Ar: Er-Softw Er-SoftwEdi Kristanta PelawiBelum ada peringkat

- Problem Solving-Practice Test A PDFDokumen23 halamanProblem Solving-Practice Test A PDFPphamBelum ada peringkat

- 97 Kunci Jawaban PDFDokumen3 halaman97 Kunci Jawaban PDFEdi Kristanta PelawiBelum ada peringkat

- Academic Calender 2013 2014Dokumen1 halamanAcademic Calender 2013 2014Edi Kristanta PelawiBelum ada peringkat

- Action - Accounting Internal Competition 2014 Registration FormDokumen1 halamanAction - Accounting Internal Competition 2014 Registration FormEdi Kristanta PelawiBelum ada peringkat

- Diversification On Astra InternationalDokumen3 halamanDiversification On Astra InternationalEdi Kristanta PelawiBelum ada peringkat

- Fraud Diamond Four ElementsDokumen5 halamanFraud Diamond Four ElementsEdi Kristanta Pelawi100% (1)

- President University Student Enrollment: Name: Academic Year: ID Number: Semester: Advisor: Study ProgramDokumen1 halamanPresident University Student Enrollment: Name: Academic Year: ID Number: Semester: Advisor: Study ProgramEdi Kristanta PelawiBelum ada peringkat

- CS RN Ah CCPDokumen7 halamanCS RN Ah CCPEdi Kristanta PelawiBelum ada peringkat

- Article of TopCima ExamsDokumen8 halamanArticle of TopCima ExamsEdi Kristanta PelawiBelum ada peringkat

- Management Information System Final Project: Enterprise Resource Planning (Erp) Software For Medium EnterpriseDokumen11 halamanManagement Information System Final Project: Enterprise Resource Planning (Erp) Software For Medium EnterpriseEdi Kristanta PelawiBelum ada peringkat

- KrsDokumen1 halamanKrsEdi Kristanta PelawiBelum ada peringkat

- Chap 001Dokumen45 halamanChap 001Edi Kristanta PelawiBelum ada peringkat

- Activity Based CostingDokumen10 halamanActivity Based CostingEdi Kristanta PelawiBelum ada peringkat

- Pet Stores in The US Industry ReportDokumen32 halamanPet Stores in The US Industry ReportEdi Kristanta PelawiBelum ada peringkat

- Pet Stores in The US Industry ReportDokumen32 halamanPet Stores in The US Industry ReportEdi Kristanta PelawiBelum ada peringkat

- Overhead AllocationDokumen3 halamanOverhead AllocationEdi Kristanta PelawiBelum ada peringkat

- SPPC-W4 - Part II - General Technical SpecificationsDokumen65 halamanSPPC-W4 - Part II - General Technical SpecificationsrekzziBelum ada peringkat

- AC Versus DC Microgrid PlanningDokumen9 halamanAC Versus DC Microgrid PlanningMuhammad AtiqBelum ada peringkat

- Design of Solar Panels For A 3.5kva Photovoltaic Power SystemDokumen24 halamanDesign of Solar Panels For A 3.5kva Photovoltaic Power SystemEmmanuel Ovie TimothyBelum ada peringkat

- Clean Energy ReviewDokumen108 halamanClean Energy ReviewRathnakrajaBelum ada peringkat

- Energy Conversion ProcessesDokumen15 halamanEnergy Conversion Processesimamsakroni048Belum ada peringkat

- DH PFM377 D2440 DatasheetDokumen3 halamanDH PFM377 D2440 DatasheetJULIEN GEORGES NGUELE BALLABelum ada peringkat

- Takeoff Edu Group Electrical Title ListDokumen11 halamanTakeoff Edu Group Electrical Title ListKollanur gunadeepBelum ada peringkat

- Feb 540: Engineering Project Proposal 2015/2016 ACADEMIC YEARDokumen74 halamanFeb 540: Engineering Project Proposal 2015/2016 ACADEMIC YEARkakagoBelum ada peringkat

- Roof Top Solar Panels - HBLDokumen12 halamanRoof Top Solar Panels - HBLRaj ABelum ada peringkat

- Design of Solar Panel - Battery Bank - Invertor CalculationDokumen18 halamanDesign of Solar Panel - Battery Bank - Invertor CalculationRezaNadianBelum ada peringkat

- Solarcarfinal 131002025032 Phpapp01 611572425309455Dokumen17 halamanSolarcarfinal 131002025032 Phpapp01 611572425309455jijo thomasBelum ada peringkat

- Soligent Product Catalog 2013 LowResDokumen240 halamanSoligent Product Catalog 2013 LowReslgv2Belum ada peringkat

- Factors Affecting The Attractiveness of Net Metered Solar Photovoltaic Technology To Member Consumers of Batangas II Electric Cooperative Inc. by J. AriasDokumen29 halamanFactors Affecting The Attractiveness of Net Metered Solar Photovoltaic Technology To Member Consumers of Batangas II Electric Cooperative Inc. by J. AriasJoan AriasBelum ada peringkat

- Modeling & Simulation Based Approach of PV System in Simulink ModelDokumen8 halamanModeling & Simulation Based Approach of PV System in Simulink ModelsirishaBelum ada peringkat

- SRM-PPT-EEE SRIDHAR VecDokumen66 halamanSRM-PPT-EEE SRIDHAR VecnikcsitBelum ada peringkat

- Report ProjectDokumen17 halamanReport ProjectMAGUDESWARAN PBelum ada peringkat

- Initial Report December 17th, 2007: Analyst: Lisa Springer, CFADokumen20 halamanInitial Report December 17th, 2007: Analyst: Lisa Springer, CFAbeacon-docs100% (1)

- Related Studies and Literature About REDokumen3 halamanRelated Studies and Literature About REDeyjeynBelum ada peringkat

- SCBDDokumen4 halamanSCBDDivyanshu nagarBelum ada peringkat

- Effekta AX PDFDokumen4 halamanEffekta AX PDFAndone AnutuBelum ada peringkat

- 3 Renewable Energy Technologies in The ROW - Alternative Uses of Highway Right-Of-Way - Publications - Real Estate - FHWADokumen23 halaman3 Renewable Energy Technologies in The ROW - Alternative Uses of Highway Right-Of-Way - Publications - Real Estate - FHWAHemantha KumarBelum ada peringkat

- Paper - 062 - INTEGRATION OF SOLAR PHOTOVOLTAIC DISTRIBUTED GENERATION IN NIGERIAN POWER SYSTEM NETWORKDokumen6 halamanPaper - 062 - INTEGRATION OF SOLAR PHOTOVOLTAIC DISTRIBUTED GENERATION IN NIGERIAN POWER SYSTEM NETWORKabera alemayehuBelum ada peringkat

- TANGEDCO DT 17 02 14Dokumen22 halamanTANGEDCO DT 17 02 14SheikBelum ada peringkat

- Conventional and Renewable Energy Scenario of India: Present and FutureDokumen19 halamanConventional and Renewable Energy Scenario of India: Present and FutureWritdhama PrasadBelum ada peringkat

- ReportDokumen197 halamanReport13121977Belum ada peringkat

- 5 Cells Modules and Arrays PDFDokumen75 halaman5 Cells Modules and Arrays PDFsemuaBelum ada peringkat

- Webinar - Gerakan Inisiatif Listrik Tenaga Surya - 20210619Dokumen25 halamanWebinar - Gerakan Inisiatif Listrik Tenaga Surya - 20210619Abbi Pamungkas100% (1)

- Lab Power System OFF GRID SOLAR PVDokumen23 halamanLab Power System OFF GRID SOLAR PVمحممد ترميزي بحر الدينBelum ada peringkat

- STP50 40 BE en 12Dokumen106 halamanSTP50 40 BE en 12VarazhdinecBelum ada peringkat

- Design Guide For Rooftop Solar: 1 JUNE 2019Dokumen5 halamanDesign Guide For Rooftop Solar: 1 JUNE 2019VINH TRANBelum ada peringkat

- The End of Craving: Recovering the Lost Wisdom of Eating WellDari EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellPenilaian: 4.5 dari 5 bintang4.5/5 (80)

- Sully: The Untold Story Behind the Miracle on the HudsonDari EverandSully: The Untold Story Behind the Miracle on the HudsonPenilaian: 4 dari 5 bintang4/5 (103)

- Highest Duty: My Search for What Really MattersDari EverandHighest Duty: My Search for What Really MattersBelum ada peringkat

- Hero Found: The Greatest POW Escape of the Vietnam WarDari EverandHero Found: The Greatest POW Escape of the Vietnam WarPenilaian: 4 dari 5 bintang4/5 (19)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaDari EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaBelum ada peringkat

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindDari EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindBelum ada peringkat

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyDari EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyBelum ada peringkat

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestDari EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestPenilaian: 4 dari 5 bintang4/5 (28)

- The Fabric of Civilization: How Textiles Made the WorldDari EverandThe Fabric of Civilization: How Textiles Made the WorldPenilaian: 4.5 dari 5 bintang4.5/5 (57)

- A Place of My Own: The Architecture of DaydreamsDari EverandA Place of My Own: The Architecture of DaydreamsPenilaian: 4 dari 5 bintang4/5 (242)

- Transformed: Moving to the Product Operating ModelDari EverandTransformed: Moving to the Product Operating ModelPenilaian: 4 dari 5 bintang4/5 (1)

- Broken Money: Why Our Financial System is Failing Us and How We Can Make it BetterDari EverandBroken Money: Why Our Financial System is Failing Us and How We Can Make it BetterPenilaian: 5 dari 5 bintang5/5 (3)

- The Weather Machine: A Journey Inside the ForecastDari EverandThe Weather Machine: A Journey Inside the ForecastPenilaian: 3.5 dari 5 bintang3.5/5 (31)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationDari EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationPenilaian: 4.5 dari 5 bintang4.5/5 (46)

- System Error: Where Big Tech Went Wrong and How We Can RebootDari EverandSystem Error: Where Big Tech Went Wrong and How We Can RebootBelum ada peringkat

- Mini Farming: Self-Sufficiency on 1/4 AcreDari EverandMini Farming: Self-Sufficiency on 1/4 AcrePenilaian: 4 dari 5 bintang4/5 (76)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDari EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansBelum ada peringkat

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerDari EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerPenilaian: 4.5 dari 5 bintang4.5/5 (54)

- Pale Blue Dot: A Vision of the Human Future in SpaceDari EverandPale Blue Dot: A Vision of the Human Future in SpacePenilaian: 4.5 dari 5 bintang4.5/5 (588)

- The Future of Geography: How the Competition in Space Will Change Our WorldDari EverandThe Future of Geography: How the Competition in Space Will Change Our WorldPenilaian: 4.5 dari 5 bintang4.5/5 (5)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDari EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterBelum ada peringkat

- Packing for Mars: The Curious Science of Life in the VoidDari EverandPacking for Mars: The Curious Science of Life in the VoidPenilaian: 4 dari 5 bintang4/5 (1395)

- Reality+: Virtual Worlds and the Problems of PhilosophyDari EverandReality+: Virtual Worlds and the Problems of PhilosophyPenilaian: 4 dari 5 bintang4/5 (24)

- How to Do Nothing: Resisting the Attention EconomyDari EverandHow to Do Nothing: Resisting the Attention EconomyPenilaian: 4 dari 5 bintang4/5 (421)

- 35 Miles From Shore: The Ditching and Rescue of ALM Flight 980Dari Everand35 Miles From Shore: The Ditching and Rescue of ALM Flight 980Penilaian: 4 dari 5 bintang4/5 (21)

- Grunt: The Curious Science of Humans at WarDari EverandGrunt: The Curious Science of Humans at WarPenilaian: 4 dari 5 bintang4/5 (430)