RT of Fuel Pump Motor-Impeller B 747

Diunggah oleh

Alfian Subhan0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

64 tayangan5 halamanMotor-Impeller B 747

Hak Cipta

© © All Rights Reserved

Format Tersedia

DOC, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniMotor-Impeller B 747

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOC, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

64 tayangan5 halamanRT of Fuel Pump Motor-Impeller B 747

Diunggah oleh

Alfian SubhanMotor-Impeller B 747

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOC, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 5

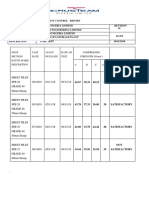

NDT INSTRUCTION

SAMPLE CRACK DRAG SPLICE FITTING P/N :

B747

See scope

1. NDT INSTRUCTION NO.: TCY / NI - RT- B737 / 2016

2. REFERENCE :

a. NDT Procedures Doc. Number : DQ-006 PART 2

3. SCOPE

To detect Crack on drag splice fitting

4. EQUIPMENT

a. Instrument : x-ray generator Any side emission, end port, X-Ray

generator capable of penetrating the equivalent of 1.5 inches of

Prepared by Approved by Saenal

Date : PAGE 1 OF 5

Ari sugito A.R

Sign : Sign : 01/05/06 REV. 0

CONTROLLED COPY DO NOT DUPLICATE

NDT INSTRUCTION

SAMPLE CRACK DRAG SPLICE FITTING P/N :

B747

See scope

aluminum may be used. The procedure was developed using Sperey

160 kv Unit.

b. Film Any medium speed, fine grain, high contrast X-ray film may be

used.

The procedure was developed using Kodak AA or Agfa D7.

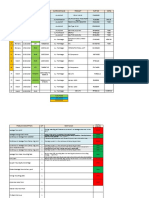

5. PREPARATION

a. Observe standard radiation safety procedures.

b. Check pressure indicator in the X-ray tube as recommended by

manufacturer. The pressure of X-ray tube indicator min 45 psi and

max 54 psi.

c. Make sure ! Pump water is running and hose not folded.

6. INSPECTION PROCEDURE

KV/mA Time Film SFD Filter

160 / 5 2,5 Menit D7 or AA 900 mm 0.010 Lead Screen

160 / 5 2,5 Menit D7 or AA 900 mm 0.010 Lead Screen

Prepared by Approved by Saenal

Date : PAGE 2 OF 5

Ari sugito A.R

Sign : Sign : 01/05/06 REV. 0

CONTROLLED COPY DO NOT DUPLICATE

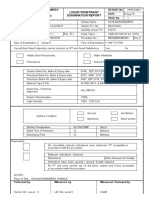

NDT INSTRUCTION

SAMPLE CRACK DRAG SPLICE FITTING P/N :

B747

See scope

Prepared by Approved by Saenal

Date : PAGE 3 OF 5

Ari sugito A.R

Sign : Sign : 01/05/06 REV. 0

CONTROLLED COPY DO NOT DUPLICATE

NDT INSTRUCTION

SAMPLE CRACK DRAG SPLICE FITTING P/N :

B747

See scope

Prepared by Approved by Saenal

Date : PAGE 4 OF 5

Ari sugito A.R

Sign : Sign : 01/05/06 REV. 0

CONTROLLED COPY DO NOT DUPLICATE

NDT INSTRUCTION

SAMPLE CRACK DRAG SPLICE FITTING P/N :

B747

See scope

Prepared by Approved by Saenal

Date : PAGE 5 OF 5

Ari sugito A.R

Sign : Sign : 01/05/06 REV. 0

CONTROLLED COPY DO NOT DUPLICATE

Anda mungkin juga menyukai

- Bush (Cover Inner) DESIGN FEASIBILITYDokumen2 halamanBush (Cover Inner) DESIGN FEASIBILITYPrakash kumarTripathiBelum ada peringkat

- Scan 27 Apr 2020Dokumen1 halamanScan 27 Apr 2020Ostian MBelum ada peringkat

- PPS WVFDokumen1 halamanPPS WVFmohammadBelum ada peringkat

- Pour Section/ Batch Mark/ Description Cast Date 28 DAY Due Date Date of Test Compressive Strength (N/MM) Remarks A B C AvgDokumen2 halamanPour Section/ Batch Mark/ Description Cast Date 28 DAY Due Date Date of Test Compressive Strength (N/MM) Remarks A B C Avgorode franklynBelum ada peringkat

- NDT Report - Old.Turbine BearingsDokumen3 halamanNDT Report - Old.Turbine BearingsOm Ar TanBelum ada peringkat

- nITP For Suspenion Hanger Pin Alt 2Dokumen4 halamannITP For Suspenion Hanger Pin Alt 2ABHISHEK KUMARBelum ada peringkat

- SJV-EP-IA-011-VP-003 - DATA SHEET - 190117 - 최종Dokumen15 halamanSJV-EP-IA-011-VP-003 - DATA SHEET - 190117 - 최종Jahangir AlamBelum ada peringkat

- RT Technique Sheet + Report Rev 4Dokumen2 halamanRT Technique Sheet + Report Rev 4g_sancheti100% (3)

- QC-19 REV. 0 - Tube Bundle Skeleton Inspection ReportDokumen3 halamanQC-19 REV. 0 - Tube Bundle Skeleton Inspection ReportSales Creative EngineeringBelum ada peringkat

- Mpi Lube Tank 6000l 05Dokumen3 halamanMpi Lube Tank 6000l 05Peter StanleyBelum ada peringkat

- Sand Screen Hangoff Draft Well ProgramDokumen3 halamanSand Screen Hangoff Draft Well Programgben11Belum ada peringkat

- Data Sheet Item 2Dokumen3 halamanData Sheet Item 2Bagus SigitBelum ada peringkat

- Key To Abbreviations: Ac - Acceptable Qu - Questionable Un - Unacceptable Rs - ResampleDokumen2 halamanKey To Abbreviations: Ac - Acceptable Qu - Questionable Un - Unacceptable Rs - ResampleChristianBelum ada peringkat

- Aramco Accumulator Vessel Data SheetDokumen3 halamanAramco Accumulator Vessel Data SheetAhmed MusallamBelum ada peringkat

- Test Results of Safety Devices " Aux. Boiler " Alarms and Shut Down TestsDokumen1 halamanTest Results of Safety Devices " Aux. Boiler " Alarms and Shut Down TestsPranay SomaniBelum ada peringkat

- BHA AD 68 NOT# 200000708382 RepDokumen13 halamanBHA AD 68 NOT# 200000708382 RepArun SidharthBelum ada peringkat

- Zppg-Aico-Sas-Rt-0604 - 01-07-2018 (Pew)Dokumen1 halamanZppg-Aico-Sas-Rt-0604 - 01-07-2018 (Pew)Ahmed ThaerBelum ada peringkat

- Patrol Inspection Report Check List UpdatedDokumen2 halamanPatrol Inspection Report Check List Updatedanbusaravanan4Belum ada peringkat

- Wellhead Desander Vessel Data Sheet for Khuft-Hawiyah Area ProjectDokumen5 halamanWellhead Desander Vessel Data Sheet for Khuft-Hawiyah Area ProjectAhmed MusallamBelum ada peringkat

- Radiography Examination Report SummaryDokumen1 halamanRadiography Examination Report SummaryAhmed ThaerBelum ada peringkat

- Layout Inspection Report: M/s Pricol LTDDokumen35 halamanLayout Inspection Report: M/s Pricol LTDPrakash kumarTripathiBelum ada peringkat

- SAIC-RT-2005 Mat Insp-Fils Nad DevelopingDokumen3 halamanSAIC-RT-2005 Mat Insp-Fils Nad DevelopingKirubhakarPooranamBelum ada peringkat

- Zppg-Aico-Sas-Rt-0611 - 02-07-2018 (Pew)Dokumen1 halamanZppg-Aico-Sas-Rt-0611 - 02-07-2018 (Pew)Ahmed ThaerBelum ada peringkat

- 007 SOP For UT in StructureDokumen7 halaman007 SOP For UT in StructureAbdul Gafoor ShaikhBelum ada peringkat

- Customer Complaint Log 2019Dokumen13 halamanCustomer Complaint Log 2019Vikas KunduBelum ada peringkat

- A.P.C.System & Products Pvt. LTDDokumen1 halamanA.P.C.System & Products Pvt. LTDSudipto MajumderBelum ada peringkat

- Unloading Arm Datasheet: Crude Oil Unloading and Pumping ProjectDokumen2 halamanUnloading Arm Datasheet: Crude Oil Unloading and Pumping Projectbecpavan0% (1)

- Tdi 50000 Tpy, GNFCDokumen6 halamanTdi 50000 Tpy, GNFCkrunal panchalBelum ada peringkat

- Gpti Qicl 032Dokumen2 halamanGpti Qicl 032uselessinstaid52Belum ada peringkat

- Sidhi Alcast: Product AuditDokumen4 halamanSidhi Alcast: Product AuditRohit BiriwalBelum ada peringkat

- Customer Complaint Log 2019Dokumen18 halamanCustomer Complaint Log 2019Vikas KunduBelum ada peringkat

- In Amenas Gas Project Algeria: P03 20 Jan 04 Issued For Purchase J Neely J Pile J Pile R WalkerDokumen3 halamanIn Amenas Gas Project Algeria: P03 20 Jan 04 Issued For Purchase J Neely J Pile J Pile R WalkerDaoued HaouesBelum ada peringkat

- Test Guide Distance Nari Pcs-902Dokumen8 halamanTest Guide Distance Nari Pcs-902JBelum ada peringkat

- RWNS 7Dokumen2 halamanRWNS 7Rohan SharmaBelum ada peringkat

- 004-Inspection Form-ETI-IKPT-HSE-Grinder-DrillerDokumen1 halaman004-Inspection Form-ETI-IKPT-HSE-Grinder-Drilleradhidharma50Belum ada peringkat

- Instruction For RBP250-3 and RBP300-3: Anti-Heeling PumpDokumen13 halamanInstruction For RBP250-3 and RBP300-3: Anti-Heeling PumpJan MaarschalkerweerdBelum ada peringkat

- 31 PX 401 Electric Chiller PDFDokumen37 halaman31 PX 401 Electric Chiller PDFAxel Halim PangestuBelum ada peringkat

- Global Wind Power Ltd. Preventive Maintenance Plan Cum Check ListDokumen3 halamanGlobal Wind Power Ltd. Preventive Maintenance Plan Cum Check ListMurali Krishnan SelvarajaBelum ada peringkat

- 1156-PT-038 (306) RP 1317Dokumen1 halaman1156-PT-038 (306) RP 1317el_sharkawy2011Belum ada peringkat

- SC 69503Dokumen6 halamanSC 69503sujatananasoBelum ada peringkat

- FPSO Motion Load - VerticalDokumen109 halamanFPSO Motion Load - VerticalSu Kil SungBelum ada peringkat

- L.P.T Reports.Dokumen12 halamanL.P.T Reports.Shaikh AdilBelum ada peringkat

- Overhaul Report - 2p764aDokumen12 halamanOverhaul Report - 2p764aadamnassir91Belum ada peringkat

- Especificación de Producto - Datos TécnicosDokumen7 halamanEspecificación de Producto - Datos TécnicosGustavo Alessandro Moya DelgadoBelum ada peringkat

- Sample FET To ISO 15848-1 PDFDokumen4 halamanSample FET To ISO 15848-1 PDFVivi Oktavianti100% (1)

- V-2158-103-A-851 - 4 ITP For PumpDokumen4 halamanV-2158-103-A-851 - 4 ITP For PumpMessaoud GoutasBelum ada peringkat

- Rev. Status: Customer Drawing ListDokumen9 halamanRev. Status: Customer Drawing ListDebesh ChaudharyBelum ada peringkat

- Izhar Steel Private Limited: 36km Multan Road LahoreDokumen436 halamanIzhar Steel Private Limited: 36km Multan Road LahoreAbdur RehmanBelum ada peringkat

- SPRING SpecificationsDokumen1 halamanSPRING SpecificationsASHWINI BHOSALEBelum ada peringkat

- QUALITY PLAN FOR BLOWER REPAIRDokumen4 halamanQUALITY PLAN FOR BLOWER REPAIRwandi rahmanBelum ada peringkat

- Sample Report As Motor Repair Report ACME 75HPDokumen13 halamanSample Report As Motor Repair Report ACME 75HPAnggoroBelum ada peringkat

- Pipe, Ma Pri To FR BK Hose, L 51420-67L30Dokumen6 halamanPipe, Ma Pri To FR BK Hose, L 51420-67L30majidBelum ada peringkat

- WS 059Dokumen4 halamanWS 059san2inBelum ada peringkat

- Drill Pipe Ad 68 Not# 200000708382Dokumen5 halamanDrill Pipe Ad 68 Not# 200000708382Arun SidharthBelum ada peringkat

- PSV Datasheet - Rev1Dokumen64 halamanPSV Datasheet - Rev1sswahyudiBelum ada peringkat

- Qa/Qc Department Welding Inspection ReportDokumen3 halamanQa/Qc Department Welding Inspection Reportabdulgafoor54Belum ada peringkat

- Q-11650, Cage Bin - 600 LTRSDokumen4 halamanQ-11650, Cage Bin - 600 LTRSanita shindeBelum ada peringkat

- Qip Ice 31 Stirling EnginesDokumen20 halamanQip Ice 31 Stirling EnginesChetanPrajapatiBelum ada peringkat

- A C M V V O: IR Onditioning and Echanical Entilation Olume NEDokumen7 halamanA C M V V O: IR Onditioning and Echanical Entilation Olume NEye htutkyawmeBelum ada peringkat

- Venturi Eductor: Nol-Tec Europe PresentsDokumen2 halamanVenturi Eductor: Nol-Tec Europe PresentsJorge Luis Apaza GutierrezBelum ada peringkat

- Periodic Table Study Guide: How To Draw Bohr DiagramsDokumen15 halamanPeriodic Table Study Guide: How To Draw Bohr Diagramsrudi_zBelum ada peringkat

- Chapter 7 Hydrometeorological HazardsDokumen9 halamanChapter 7 Hydrometeorological HazardsanneBelum ada peringkat

- Doppler Effect ExplainedDokumen6 halamanDoppler Effect ExplainedBrandonBelum ada peringkat

- Lubricant Additives - A Practical GuideDokumen17 halamanLubricant Additives - A Practical GuideNeeraj Raushan KanthBelum ada peringkat

- Gamma RaysDokumen34 halamanGamma RaysuzmaBelum ada peringkat

- Mole ConceptDokumen26 halamanMole Conceptzefrus kunBelum ada peringkat

- Course Plan: Contents: Topics Lecturer Hrs Tut. HrsDokumen1 halamanCourse Plan: Contents: Topics Lecturer Hrs Tut. HrsAhmedTahaBelum ada peringkat

- Exportar Páginas Meriam Kraige Engineering Mechanics Statics 7th TXTBKDokumen1 halamanExportar Páginas Meriam Kraige Engineering Mechanics Statics 7th TXTBKabrahamrv44Belum ada peringkat

- BiochemistryDokumen504 halamanBiochemistryeleonora josimovicBelum ada peringkat

- BNT Quartet BrochureDokumen2 halamanBNT Quartet BrochureAnonymous 0oFWTQFBelum ada peringkat

- Thermal Shock and Thermal Fatigue On Delamination of Glass Fiber Reinforced Polymeric CompositesDokumen14 halamanThermal Shock and Thermal Fatigue On Delamination of Glass Fiber Reinforced Polymeric CompositesSuresh KumarBelum ada peringkat

- Astm D156 - 15Dokumen6 halamanAstm D156 - 15mancja100% (2)

- Astm C39Dokumen5 halamanAstm C39Sergio Pascual50% (2)

- VLE Curve for Cyclohexane-Toluene MixtureDokumen6 halamanVLE Curve for Cyclohexane-Toluene MixtureAnuj SrivastavaBelum ada peringkat

- Temp RTDDokumen8 halamanTemp RTDShambhavi VarmaBelum ada peringkat

- Fluid Mechanics - BuoyancyDokumen6 halamanFluid Mechanics - BuoyancyAbduljalil AlabidiBelum ada peringkat

- ETABS Examples ManualDokumen50 halamanETABS Examples ManualnasrBelum ada peringkat

- Durham E-Theses: Novel Block Co-Polymers As Potential Photonic MaterialsDokumen118 halamanDurham E-Theses: Novel Block Co-Polymers As Potential Photonic MaterialsWassini BensBelum ada peringkat

- The Idea That A Machine Can Be Decomposed Into Simple Movable Elements Led Archimedes To Define The LeverDokumen2 halamanThe Idea That A Machine Can Be Decomposed Into Simple Movable Elements Led Archimedes To Define The LeverEndalkachew AbateBelum ada peringkat

- Worksheet N º 6. Sixth Grade. Unit 7.: Colegio San SebastiánDokumen3 halamanWorksheet N º 6. Sixth Grade. Unit 7.: Colegio San Sebastiángenesis llancapaniBelum ada peringkat

- Reinforced Masonry Engineering Handbook .6th - Ed.secDokumen647 halamanReinforced Masonry Engineering Handbook .6th - Ed.secEc Ef100% (2)

- Fabrication of WC Micro-Shaft by Using Electrochemical EtchingDokumen6 halamanFabrication of WC Micro-Shaft by Using Electrochemical EtchingGanesa BalamuruganBelum ada peringkat

- Extended-Design and Analysis of A Network Arch BridgeDokumen10 halamanExtended-Design and Analysis of A Network Arch BridgehansBelum ada peringkat

- MP ProblemsDokumen2 halamanMP Problemskartikesh prasadBelum ada peringkat

- 7 PDFDokumen103 halaman7 PDFmuhammad izzulBelum ada peringkat

- How smartphone camera specs affect low light performanceDokumen2 halamanHow smartphone camera specs affect low light performanceSatyendra KumarBelum ada peringkat

- FP 17 32754 06Dokumen3 halamanFP 17 32754 06Murugan RaghuBelum ada peringkat

- A Place of My Own: The Architecture of DaydreamsDari EverandA Place of My Own: The Architecture of DaydreamsPenilaian: 4 dari 5 bintang4/5 (241)

- Coating and Drying Defects: Troubleshooting Operating ProblemsDari EverandCoating and Drying Defects: Troubleshooting Operating ProblemsPenilaian: 5 dari 5 bintang5/5 (1)

- Nuclear Energy in the 21st Century: World Nuclear University PressDari EverandNuclear Energy in the 21st Century: World Nuclear University PressPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Science Goes Viral: Captivating Accounts of Science in Everyday LifeDari EverandScience Goes Viral: Captivating Accounts of Science in Everyday LifePenilaian: 5 dari 5 bintang5/5 (1)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksDari EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksPenilaian: 5 dari 5 bintang5/5 (1)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationDari EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationPenilaian: 4 dari 5 bintang4/5 (18)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeDari EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifePenilaian: 4.5 dari 5 bintang4.5/5 (3)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsDari EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsPenilaian: 4 dari 5 bintang4/5 (146)

- An Architect's Guide to Construction: Tales from the Trenches Book 1Dari EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1Belum ada peringkat

- Building Construction Technology: A Useful Guide - Part 2Dari EverandBuilding Construction Technology: A Useful Guide - Part 2Penilaian: 5 dari 5 bintang5/5 (1)

- Guidelines for Asset Integrity ManagementDari EverandGuidelines for Asset Integrity ManagementPenilaian: 5 dari 5 bintang5/5 (1)

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsDari EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsPenilaian: 4.5 dari 5 bintang4.5/5 (6)

- Civil Engineer's Handbook of Professional PracticeDari EverandCivil Engineer's Handbook of Professional PracticePenilaian: 4.5 dari 5 bintang4.5/5 (2)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionDari EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedDari EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedPenilaian: 5 dari 5 bintang5/5 (1)

- Building Construction Technology: A Useful Guide - Part 1Dari EverandBuilding Construction Technology: A Useful Guide - Part 1Penilaian: 4 dari 5 bintang4/5 (3)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDari EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialBelum ada peringkat

- Asset Integrity Management for Offshore and Onshore StructuresDari EverandAsset Integrity Management for Offshore and Onshore StructuresBelum ada peringkat

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsDari EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsPenilaian: 5 dari 5 bintang5/5 (3)

- Stuff Matters: Exploring the Marvelous Materials That Shape Our Man-Made WorldDari EverandStuff Matters: Exploring the Marvelous Materials That Shape Our Man-Made WorldPenilaian: 4 dari 5 bintang4/5 (289)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolDari EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolBelum ada peringkat

- Essential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilDari EverandEssential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilPenilaian: 5 dari 5 bintang5/5 (1)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseDari EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HousePenilaian: 5 dari 5 bintang5/5 (3)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeDari EverandChemistry for Breakfast: The Amazing Science of Everyday LifePenilaian: 4.5 dari 5 bintang4.5/5 (14)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifeDari EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifePenilaian: 4 dari 5 bintang4/5 (9)