Project Summary

Diunggah oleh

Stacy Johnson0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

16 tayangan2 halamanLecture 4

Judul Asli

5798

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniLecture 4

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

16 tayangan2 halamanProject Summary

Diunggah oleh

Stacy JohnsonLecture 4

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 2

Project Summary

Texas Department of Transportation

0-5798: Develop Test Procedures to Characterize

Material Response Behavior, and Transfer Functions

for TxDOT M-E Design

Background

There is a national movement to develop Mechanistic-Empirical (M-E) methods for the design of flexible pavements.

M-E methods are needed to design pavements under actual loads and environmental conditions. They can evaluate

material-specific performance variations that were not evaluated by previous empirical methods. A new M-E design

method named the Mechanistic-Empirical Pavement Design Guide (MEPDG) was developed under the National

Cooperative Highway Research Program (NCHRP) project 1-37A. In a previous TxDOT research project, MEPDG

was reviewed and researchers concluded that it was important for TxDOT to initiate supplemental work in this

area since the MEPDG as currently packaged was judged not implementable in the near future. Researchers also

concluded that TxDOTs current FPS19 system, which has served well for many years, has several limitations and

needs to be updated.

This project was undertaken to provide guidance regarding the development of M-E design procedures for TxDOT.

The main objectives were to 1)identify/develop test procedures that characterize material properties needed to

predict pavement response and distresses, 2) assemble existing performance prediction models (transfer functions)

and evaluate their feasibility of being implemented in Texas, and calibrate the selected transfer functions with

available performance data.

Research Performed by:

What the Researchers Did Texas Transportation Institute (TTI),

The following items summarize work conducted in this study: The Texas A&M University System

After reviewing all existing pavement performance models, Research Supervisor:

researchers recommended the VESYS model for predicting

Tom Scullion, TTI

flexible pavement layer rutting. An overlay tester-based fatigue

cracking model was proposed that includes both crack initiation Researchers:

and propagation models. Emmanuel Fernando, TTI

A complete literature review was conducted to identify test Sheng Hu, TTI

procedures for characterizing material properties needed to predict Fujie Zhou, TTI

pavement response and distresses. In particular, test procedures

Project Completed: 8-31-09

were evaluated and revised for Tex-ME regarding: hot-mix asphalt

(HMA) dynamic modulus, fracture, and permanent deformation

properties; and resilient modulus and permanent deformation properties of base/subbase and subgrade materials.

The repeated load test was selected for characterizing materials and modeling HMA rutting. This test was

validated with field-measured rutting data from both the National Center for Asphalt Technology (NCAT) test

track and Texas highways. Use of the overlay tester for characterizing fatigue cracking was verified using

accelerated pavement tests such as ALF and HVS.

A multi-layer linear elastic system was evaluated to compute asphalt pavement response to traffic loading. Its

validity was verified through comparing measured tensile strains under accelerated pavement ALF loading with

computed ones.

All existing pavement performance models (or transfer functions) were evaluated and reasonable models for

predicting pavement distresses including rutting and fatigue cracking were recommended for Tex-ME. The

recommended pavement performance models were further developed and then calibrated using actual field

performance data. Specifically, the HMA layer rutting model was calibrated using rutting data from the NCAT

test track and the SPS 5 asphalt overlay test sections on US175 near Dallas. During the model calibration,

either lab-molded plant mix samples or field cores were characterized using HMA dynamic modulus testing and

repeated load testing to develop material properties. Calibration factors for the HMA layer rutting model were

developed through minimizing the differences between the measured field rut depths and the ones predicted from

the model. A similar approach was used to calibrate the fatigue cracking model.

For granular bases, the resilient modulus and permanent deformation tests were found to classify base materials

in the same rank as observed district performance. The moduli values (at 5 psi confining and 15 psi deviator

stress) for the different classes of base were found to be in the range of 35 to 70 ksi, which is very similar to the

values obtained from FWD testing and subsequent back-calculation.

Several experimental test sections were constructed at Texas A&M Riverside campus, and later tested under

traffic loads to validate the LoadGage program that was developed for thin pavement design.

What They Found

The major findings from this study are:

Repeated load tests characterizing HMA rutting correlated excellently with the field rut depths measured on

Texas highways and the NCAT test track.

The overlay tester has the capability to clearly differentiate fatigue cracking resistance of different mixes with

unmodified and modified binders. Results enabled very reasonable prediction of fatigue life based on data from

the NCAT test track.

A multi-layer elastic system is valid for predicting pavement response under traffic loading when considering the

influence of pavement temperature and vehicle traveling speed.

The calibrated/validated HMA rutting and fatigue cracking models developed as part of this project are

reasonable. The predicted pavement distresses, including both rutting and fatigue cracking, matched the field

measured ones well.

The LoadGage predictions of allowable load limits were judged to be more accurate than those in the current

Texas Triaxial check system currently used with FPS19. Very reasonable maximum allowable load limits

predicted from the LoadGage were found on the experimental test sections constructed at Texas A&M Riverside

campus, when moisture correction factors were applied to the laboratory measure engineering properties.

What This Means

Project 0-5798 demonstrated that calibrated models are now available to make reasonable predictions of the

most common distresses found on Texas highways. The proposed Tex-ME system can replace the existing

simple M-E check inside of FPS19, and the LoadGage system can replace the Texas Triaxial check. Simple

performance-related tests are now available to characterize soils, base, and asphalt materials in the lab and these

properties can be incorporated into a new thickness analysis and design system.

For More Information:

0-5798-1 A Review of Performance Models and Test Procedures with Recommendations for use

in the Texas M-E Design Program

Research Engineer - German Claros, TxDOT, 512-465-7403

Project Director - Joe Leidy, TxDOT, 512-506-5848

Research Supervisor - Tom Scullion, TTI, 979-845-9913 Research and Technology

Implementation Office

P.O. Box 5080

www.txdot.gov Austin, Texas 78763-5080

keyword: research 512-465-7403

This research was performed in cooperation with the Texas Department of Transportation and the Federal Highway Administration. The contents of this report

reflect the views of the authors, who are responsible for the facts and accuracy of the data presented herein. The contents do not necessarily reflect the official

view or policies of the FHWA or TxDOT. This report does not constitute a standard, specification, or regulation, nor is it intended for construction, bidding, or

permit purposes. Trade names were used solely for information and not for product endorsement.

Anda mungkin juga menyukai

- Terramechanics and Off-Road Vehicle Engineering: Terrain Behaviour, Off-Road Vehicle Performance and DesignDari EverandTerramechanics and Off-Road Vehicle Engineering: Terrain Behaviour, Off-Road Vehicle Performance and DesignPenilaian: 5 dari 5 bintang5/5 (1)

- Title and Subtitle: Technical Report Documentation PageDokumen384 halamanTitle and Subtitle: Technical Report Documentation PageacribdingBelum ada peringkat

- Piezocone and Cone Penetration Test (CPTu and CPT) Applications in Foundation EngineeringDari EverandPiezocone and Cone Penetration Test (CPTu and CPT) Applications in Foundation EngineeringBelum ada peringkat

- Technical Report Documentation PageDokumen142 halamanTechnical Report Documentation PagecrojastBelum ada peringkat

- A Comprehensive Database of Tests on Axially Loaded Piles Driven in SandDari EverandA Comprehensive Database of Tests on Axially Loaded Piles Driven in SandBelum ada peringkat

- Technical Report Documentation PageDokumen154 halamanTechnical Report Documentation Pageaklilu ayalewBelum ada peringkat

- Handbook of Optimization in the Railway IndustryDari EverandHandbook of Optimization in the Railway IndustryRalf BorndörferBelum ada peringkat

- Dot 18305 DS1Dokumen78 halamanDot 18305 DS1WandersonBelum ada peringkat

- Design of High-Speed Railway Turnouts: Theory and ApplicationsDari EverandDesign of High-Speed Railway Turnouts: Theory and ApplicationsPenilaian: 4.5 dari 5 bintang4.5/5 (4)

- Data Collection Experience For Preliminary Calibration of The AASHTO Pavement Design Guide For Exible Pavements in South CarolinaDokumen13 halamanData Collection Experience For Preliminary Calibration of The AASHTO Pavement Design Guide For Exible Pavements in South CarolinaDaniloWaldoDionisioSalisBelum ada peringkat

- Aashto LRFD Vs AashtoDokumen281 halamanAashto LRFD Vs AashtoLuis Miguel Gutierrez KlinskyBelum ada peringkat

- Flexible Pavement Design SummaryDokumen7 halamanFlexible Pavement Design SummarysafeccivilBelum ada peringkat

- Evaluation of Bearing Capacity of Piles From ConeDokumen116 halamanEvaluation of Bearing Capacity of Piles From ConeHuemac ContrerasBelum ada peringkat

- 2.0 Literature Review: 2.1 The Need To Predict DeteriorationDokumen10 halaman2.0 Literature Review: 2.1 The Need To Predict DeteriorationYudheesh IshanBelum ada peringkat

- Modeling Permanent Deformation of Flexible Pavements Due To Overload With Finite Element MethodDokumen52 halamanModeling Permanent Deformation of Flexible Pavements Due To Overload With Finite Element MethodMovieBelum ada peringkat

- Capsule 09-5cDokumen2 halamanCapsule 09-5cwalaywanBelum ada peringkat

- Magnitude Compared To The Basic Type C Mixture Possibly Due To An Increased Polymer Modified BinderDokumen312 halamanMagnitude Compared To The Basic Type C Mixture Possibly Due To An Increased Polymer Modified BinderKiplgat ChelelgoBelum ada peringkat

- LTRC Capsule 11-3B Testing and Analysis of LWT and SCB Properties of Asphaltic Concrete MixturesDokumen2 halamanLTRC Capsule 11-3B Testing and Analysis of LWT and SCB Properties of Asphaltic Concrete MixtureswalaywanBelum ada peringkat

- 0-6037-1 Subbase and Subgrade Performance Investigation For Concrete Pavement PDFDokumen112 halaman0-6037-1 Subbase and Subgrade Performance Investigation For Concrete Pavement PDFTim LinBelum ada peringkat

- 0 6729 1Dokumen192 halaman0 6729 1lamkinpark3373Belum ada peringkat

- AASHTO LRFD Vs AASHTO PDFDokumen281 halamanAASHTO LRFD Vs AASHTO PDFMauricio MendizabalBelum ada peringkat

- Technical Report Documentation PageDokumen40 halamanTechnical Report Documentation Pagesohail irfanBelum ada peringkat

- Evaluation of Asphalt Binder Performance With Laboratory and Field Test SectionsDokumen102 halamanEvaluation of Asphalt Binder Performance With Laboratory and Field Test SectionsLokesh KBelum ada peringkat

- 0 207 1 PDFDokumen118 halaman0 207 1 PDFmasood ahmed100% (1)

- Concrete Pavement Overlays Over Existing Asphalt Pavement Structures PDFDokumen121 halamanConcrete Pavement Overlays Over Existing Asphalt Pavement Structures PDFprmrao100% (1)

- Structural Design MethodDokumen3 halamanStructural Design MethodAmir ShaikBelum ada peringkat

- 0 6386 3 PDFDokumen302 halaman0 6386 3 PDFMD Meftahul AlamBelum ada peringkat

- Form DOT F 1700.7 (8-72) Reproduction of Completed Page AuthorizedDokumen134 halamanForm DOT F 1700.7 (8-72) Reproduction of Completed Page AuthorizedRk RegbeBelum ada peringkat

- Design AptDokumen9 halamanDesign Aptsidhyanath pandaBelum ada peringkat

- Mary Beth D. Hueste, John B. Mander, and Anagha S. Parkar: Technical Report Documentation PageDokumen176 halamanMary Beth D. Hueste, John B. Mander, and Anagha S. Parkar: Technical Report Documentation PageAntonio HenryBelum ada peringkat

- Stochastic Analysis of Thermal Cracking Distress of Asphalt Pavements Using The MEPDG Thermal Cracking ModelDokumen9 halamanStochastic Analysis of Thermal Cracking Distress of Asphalt Pavements Using The MEPDG Thermal Cracking ModelAyu Intan NBelum ada peringkat

- Imprimacion 0 5635 1Dokumen150 halamanImprimacion 0 5635 1Jorge RomeroBelum ada peringkat

- Comprehensive Truck Size and Weight Limits Study: Tom Kearney, FHWA Ben Ritchey, CDM SmithDokumen28 halamanComprehensive Truck Size and Weight Limits Study: Tom Kearney, FHWA Ben Ritchey, CDM SmithgiovasBelum ada peringkat

- 00 05flexibleoverlay FDokumen72 halaman00 05flexibleoverlay FDaniel PatiñoBelum ada peringkat

- International Journal of Transportation Science and TechnologyDokumen12 halamanInternational Journal of Transportation Science and TechnologyAbd Almonem AlkabeerBelum ada peringkat

- Barreras TexasDokumen88 halamanBarreras TexasPaola Valdivia RamirezBelum ada peringkat

- Technical Report Documentation PageDokumen149 halamanTechnical Report Documentation PageABelum ada peringkat

- Literature Review: David Timm, Bjorn Birgisson, David Newcomb First Published January 1, 1998 ResearchDokumen2 halamanLiterature Review: David Timm, Bjorn Birgisson, David Newcomb First Published January 1, 1998 Researchchaudhari prajaktaBelum ada peringkat

- Design Detail Standard Sheets For Concrete Pavement Transition AreaDokumen34 halamanDesign Detail Standard Sheets For Concrete Pavement Transition AreaTim LinBelum ada peringkat

- 0 5598 1Dokumen134 halaman0 5598 1Chers1Belum ada peringkat

- Guidance and Tools Support Wider Use of Composite Paving System ConstructionDokumen2 halamanGuidance and Tools Support Wider Use of Composite Paving System ConstructionAnonymous vA7MJfmBelum ada peringkat

- Evaluating The Structural Strength of Flexible PavDokumen29 halamanEvaluating The Structural Strength of Flexible PavKenneth DacasinBelum ada peringkat

- Guide For Mechanistic-Empirical Design: Appendix QQDokumen93 halamanGuide For Mechanistic-Empirical Design: Appendix QQBridger WangBelum ada peringkat

- 0 4751 1 V1 PDFDokumen390 halaman0 4751 1 V1 PDFjorgebelvisBelum ada peringkat

- Pavement Design ReserchDokumen5 halamanPavement Design Reserchkhrizel lee tuazonBelum ada peringkat

- Ec 068Dokumen113 halamanEc 068Gezim GezimBelum ada peringkat

- Sensitivity Analysis of Rigid Pavement Systems Using MEPDGDokumen11 halamanSensitivity Analysis of Rigid Pavement Systems Using MEPDGSyria MostakBelum ada peringkat

- Foundation Design From Dynamic Penetration TestDokumen42 halamanFoundation Design From Dynamic Penetration Testmlakkiss100% (1)

- Dynamic Pile TestingDokumen6 halamanDynamic Pile TestingShahul Ikram AdnanBelum ada peringkat

- Building Block ApproachDokumen19 halamanBuilding Block ApproachSteve VagliettiBelum ada peringkat

- 0 6716 1 PDFDokumen356 halaman0 6716 1 PDFDavid DonosoBelum ada peringkat

- High Load Pavements (NHI)Dokumen176 halamanHigh Load Pavements (NHI)dbaniciBelum ada peringkat

- Estimation of Key PCC, Base, Subbase, and Pavement Engineering Properties From Routine Tests and Physical CharacteristicsDokumen6 halamanEstimation of Key PCC, Base, Subbase, and Pavement Engineering Properties From Routine Tests and Physical CharacteristicsDavid SupoBelum ada peringkat

- Bianchini 2012Dokumen12 halamanBianchini 2012Vanesaa Mamani KentaBelum ada peringkat

- Txdot Primary Researchers: Rigid Pavement Design and AnalysisDokumen4 halamanTxdot Primary Researchers: Rigid Pavement Design and AnalysisDarshan KashiBelum ada peringkat

- 1 s2.0 S2352146516303179 MainDokumen10 halaman1 s2.0 S2352146516303179 MainsaidBelum ada peringkat

- Development of An Expert System For Pavement Rehabilitation Decision MakingDokumen8 halamanDevelopment of An Expert System For Pavement Rehabilitation Decision MakingKreziaBelum ada peringkat

- Improved Guidance For Users of The 1993 AASHTO Flexible Pavement Design ProceduresDokumen3 halamanImproved Guidance For Users of The 1993 AASHTO Flexible Pavement Design ProceduresSony ZebuaBelum ada peringkat

- 17-CE-7 Assignment 01Dokumen7 halaman17-CE-7 Assignment 01Saad IlyasBelum ada peringkat

- Westergaard Solutions PDFDokumen11 halamanWestergaard Solutions PDFStacy JohnsonBelum ada peringkat

- 1989 1949 OdemarkDokumen40 halaman1989 1949 OdemarkStacy JohnsonBelum ada peringkat

- Biology Study Suggests FatherDokumen6 halamanBiology Study Suggests FatherStacy JohnsonBelum ada peringkat

- F Selected ProblemsDokumen21 halamanF Selected ProblemsStacy JohnsonBelum ada peringkat

- 3 Major Design Philosophies - Working Stress, Ultimate Load and Limit State - CivilDigitalDokumen6 halaman3 Major Design Philosophies - Working Stress, Ultimate Load and Limit State - CivilDigitalStacy JohnsonBelum ada peringkat

- How Is Working Stress Method (ASD) Different From Limit State Method (LRFD or LFD) - Assumptions, Advantages and Comparisons - CivilDigitalDokumen4 halamanHow Is Working Stress Method (ASD) Different From Limit State Method (LRFD or LFD) - Assumptions, Advantages and Comparisons - CivilDigitalStacy JohnsonBelum ada peringkat

- How Is Working Stress Method (ASD) Different From Limit State Method (LRFD or LFD) - Assumptions, Advantages and Comparisons - CivilDigitalDokumen4 halamanHow Is Working Stress Method (ASD) Different From Limit State Method (LRFD or LFD) - Assumptions, Advantages and Comparisons - CivilDigitalStacy JohnsonBelum ada peringkat

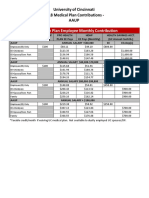

- 2018 Benefit Cost Aaup All FinalDokumen2 halaman2018 Benefit Cost Aaup All FinalStacy JohnsonBelum ada peringkat

- Partial Differentiation With Non-Independent VariablesDokumen6 halamanPartial Differentiation With Non-Independent VariablesStacy JohnsonBelum ada peringkat

- Data - Measures-of-Central-Tendency - PDF: The Following Three Problems Were Adapted FromDokumen3 halamanData - Measures-of-Central-Tendency - PDF: The Following Three Problems Were Adapted FromStacy JohnsonBelum ada peringkat

- Fdot bd543 14 RPTDokumen228 halamanFdot bd543 14 RPTStacy JohnsonBelum ada peringkat

- Cal Thomas - Roy Moore, God and The Choice Evangelicals Must Make - Fox NewsDokumen2 halamanCal Thomas - Roy Moore, God and The Choice Evangelicals Must Make - Fox NewsStacy JohnsonBelum ada peringkat

- Void Detection With The Falling Weight Deflectometer: Research Investigation 99-044 June 2004 Research Report 04-004Dokumen2 halamanVoid Detection With The Falling Weight Deflectometer: Research Investigation 99-044 June 2004 Research Report 04-004Stacy JohnsonBelum ada peringkat

- Pavement Deterioration Prediction Model and Project Selection For Kentucky HighwaysDokumen13 halamanPavement Deterioration Prediction Model and Project Selection For Kentucky HighwaysStacy JohnsonBelum ada peringkat

- Manual Chapter Title View: A B C DDokumen3 halamanManual Chapter Title View: A B C DStacy JohnsonBelum ada peringkat

- FEAFAA4 2 2009 Readme PDFDokumen2 halamanFEAFAA4 2 2009 Readme PDFStacy JohnsonBelum ada peringkat

- Sifat E. Ahmed, Xian-Xun Yuan, Warren Lee, Ningyuan LiDokumen14 halamanSifat E. Ahmed, Xian-Xun Yuan, Warren Lee, Ningyuan LiStacy JohnsonBelum ada peringkat

- Pushin Fitting PDFDokumen4 halamanPushin Fitting PDFvishal.nithamBelum ada peringkat

- Shear Wave Velocity: Comparison Between Centrifuge and Triaxial Based MeasurementsDokumen6 halamanShear Wave Velocity: Comparison Between Centrifuge and Triaxial Based MeasurementsLuciano JuniorBelum ada peringkat

- Solutions Manual To Introduction To Continuum Mechanics: Second EditionDokumen247 halamanSolutions Manual To Introduction To Continuum Mechanics: Second EditionRaj Pratyush80% (5)

- Flux Cored Arc Welding I (Gas Shielded)Dokumen38 halamanFlux Cored Arc Welding I (Gas Shielded)greatsteelBelum ada peringkat

- Failure Analysis by Means of MicrosDokumen31 halamanFailure Analysis by Means of Micros28192175100% (1)

- MAG8000 Manual PDFDokumen137 halamanMAG8000 Manual PDFHanks EpphBelum ada peringkat

- Rotary CompressorDokumen24 halamanRotary Compressorvijayns_250355172Belum ada peringkat

- Digital Signal Processing: Instructor: Jen-Hui Chuang Instructor: Jen-Hui ChuangDokumen31 halamanDigital Signal Processing: Instructor: Jen-Hui Chuang Instructor: Jen-Hui ChuangRakesh InaniBelum ada peringkat

- Basic Analysis 1Dokumen312 halamanBasic Analysis 1MahaBelum ada peringkat

- Gulfmaster Manual PDFDokumen15 halamanGulfmaster Manual PDFJoan RosanwoBelum ada peringkat

- Unit 2 Electrical InstrumentDokumen45 halamanUnit 2 Electrical InstrumentBoopathy C P100% (1)

- WP Correct Weight-Handling enDokumen4 halamanWP Correct Weight-Handling enbertan dağıstanlıBelum ada peringkat

- PLL - 1323 - Low Speed, High Torque Motors EatonDokumen294 halamanPLL - 1323 - Low Speed, High Torque Motors EatonWilmer Huaman PasaperaBelum ada peringkat

- CALC SHEET ZOLA - CompressedDokumen33 halamanCALC SHEET ZOLA - CompressedSami Abdelgadir MohammedBelum ada peringkat

- Cancela - Analise de TensãoDokumen35 halamanCancela - Analise de TensãoMarco JustinoBelum ada peringkat

- Lesson 13 Algebraic CurvesDokumen21 halamanLesson 13 Algebraic CurvesNiño Jhim AndrewBelum ada peringkat

- The Great Art or The Rules of AlgebraDokumen6 halamanThe Great Art or The Rules of AlgebraAlae sayBelum ada peringkat

- Elementary Linear Algebra: Howard Anton Chris RorresDokumen78 halamanElementary Linear Algebra: Howard Anton Chris Rorresdeandra isabelleBelum ada peringkat

- CIV2040S L3 Problems Basic Fluid PropertiesDokumen2 halamanCIV2040S L3 Problems Basic Fluid PropertiesMosameem ARBelum ada peringkat

- TS PGECET Civil Engineering Exam Syllabus & PatternDokumen3 halamanTS PGECET Civil Engineering Exam Syllabus & PatternpavaniBelum ada peringkat

- ANSYS 10.0 Workbench Tutorial - Description of TutorialsDokumen7 halamanANSYS 10.0 Workbench Tutorial - Description of TutorialssangeethsreeniBelum ada peringkat

- Volcanic SoilsDokumen14 halamanVolcanic SoilsVictor Hugo BarbosaBelum ada peringkat

- Method Statement For Bridge Load Test: 1. PurposeDokumen10 halamanMethod Statement For Bridge Load Test: 1. PurposeAnonymous HN7WMQBmcBelum ada peringkat

- Lecture4 Static and Dynamic Fluid PDFDokumen13 halamanLecture4 Static and Dynamic Fluid PDFRudi BerlianBelum ada peringkat

- Lesson Plan Solar SystemDokumen4 halamanLesson Plan Solar SystemAnneValdezAcostaBelum ada peringkat

- Emerging Trends in Electronics NanobioelectronicsDokumen13 halamanEmerging Trends in Electronics Nanobioelectronicsapi-26871643100% (2)

- FEBio Theory Manual 1.0Dokumen43 halamanFEBio Theory Manual 1.0palmajoaquin99Belum ada peringkat

- Organic Chemistry Lab Formal Report FormatDokumen2 halamanOrganic Chemistry Lab Formal Report FormatJohn Kenneth PranadaBelum ada peringkat

- Servo Solenoid ValvesDokumen204 halamanServo Solenoid Valveschandushar1604100% (1)

- A Room-by-Room Guide For Ergonomic Lighting LevelsDokumen4 halamanA Room-by-Room Guide For Ergonomic Lighting LevelsshamsBelum ada peringkat

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDari EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansPenilaian: 4.5 dari 5 bintang4.5/5 (21)

- To Engineer Is Human: The Role of Failure in Successful DesignDari EverandTo Engineer Is Human: The Role of Failure in Successful DesignPenilaian: 4 dari 5 bintang4/5 (138)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindDari EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindBelum ada peringkat

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetDari EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetPenilaian: 4.5 dari 5 bintang4.5/5 (10)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeDari EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgePenilaian: 4.5 dari 5 bintang4.5/5 (59)

- Rocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyDari EverandRocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyPenilaian: 4.5 dari 5 bintang4.5/5 (5)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)Dari EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)Belum ada peringkat

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsDari EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsBelum ada peringkat

- Troubleshooting and Repair of Diesel EnginesDari EverandTroubleshooting and Repair of Diesel EnginesPenilaian: 1.5 dari 5 bintang1.5/5 (2)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureDari EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CulturePenilaian: 4.5 dari 5 bintang4.5/5 (2)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsDari EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsBelum ada peringkat

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Dari EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Penilaian: 4 dari 5 bintang4/5 (3)

- Skyway: The True Story of Tampa Bay's Signature Bridge and the Man Who Brought It DownDari EverandSkyway: The True Story of Tampa Bay's Signature Bridge and the Man Who Brought It DownBelum ada peringkat

- Rock Fracture and Blasting: Theory and ApplicationsDari EverandRock Fracture and Blasting: Theory and ApplicationsPenilaian: 5 dari 5 bintang5/5 (2)

- Geotechnical Engineering Calculations and Rules of ThumbDari EverandGeotechnical Engineering Calculations and Rules of ThumbPenilaian: 4 dari 5 bintang4/5 (17)

- Structural Cross Sections: Analysis and DesignDari EverandStructural Cross Sections: Analysis and DesignPenilaian: 4.5 dari 5 bintang4.5/5 (19)

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesDari EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesBelum ada peringkat