African Business Review 012017

Diunggah oleh

santoshcal31830 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

8 tayangan78 halamanbusiness review africa

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Inibusiness review africa

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

8 tayangan78 halamanAfrican Business Review 012017

Diunggah oleh

santoshcal3183business review africa

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

Anda di halaman 1dari 78

AAAAAAAAAAAAAAAA ANY AAAAAAAAAAAAAAAAAAA

> a> | Reruns aes

January 2017

SSISA

Teranga Gold

> The Mining Chamber of

*

RD :

©) Wi-Fi Day ear “x

+,

ax

Lie

movies-tv

www. TshWi-Fi.co.za TSHWAN E

ff»

HELLO AND WELCOME to our first 2017 issue. We

covered several innovative projects during 2016, and it looks

like this year’s issue is going to be no different. Take AB

Minerals Corp., for instance. In this issue we interview CEO

Frank Balestra about the firm’s disruptive tantalum plant.

The first of its kind, the plant will process the coveted mineral

where it is mined, i.e. Rwanda. Africa’s natural resources

often end up overseas, so we're pleased that AB Minerals are

keeping business on the continent. We also feature AJS, a firm

that’s also boosting the African economy. CEO Luis Silva talks

us through the Angolan logistics industry and how his firm

are driving continual transformation. Our monthly list confers

to Women in Mining, a non-profit organisation who have

compiled a 100 Global Inspirational Women in Mining report.

From this list, we drew 10 outstanding African women. Women

are underrepresented in the global mining industry, so we're

pleased to provide visibility for those doing valuable work.

Be sure to read our exclusive company profiles on Teranga

Gold, SSISA and Dundee Precious Metals also. All three

industries have exciting plans for this year, and the details can be

found in our reports.

| hope you find this issue an interesting one; get in touch with

us @AfricaBizReview to continue the debates.

Enjoy the issue!

Wedaeli Chibelushi

Editor

Wedaeli.chibelushi@bizclikmedia.com

IN MINING

Teranga

Gold

Mining

UCT)

Chamber of

BUC T 1)

A

Dundee Precious

Metals Tsumeb

AA}

AFTER 27 YEARS of unrest,

the Angolan Civil War finally ended

in 2002. The People’s Movement

for the Liberation of Angola (MPLA)

and the National Union for the Total

Independence of Angola (NUTIA)

fought, with some intervals, until

the MPLA finally achieved victory

in 2002. However, by then 500,000

6 January 2017

People had died and nearly four million

Angolans had been displaced from

their homes. Angola was wounded,

and the scars last until this day. The

struggle devastated Angola’s economic

institutions, farming practices, religious

institutions and infrastructure.

“Angola’s transportation

infrastructure is being reconstructed

AJS IS REVOLUTIONISING THE

ANGOLAN LOGISTICS INDUSTRY.

ome iA iow (cee weeny

SPEEDY RECOVERY FROM ITS CIVIL

WAR AND CONTRIBUTING TO IT

BECOMING ONE OF THE FASTEST

GROWING ECONOMIES IN THE WORLD

Written by: WEDAELI CHIBELUSHI

(since the end of the Civil War) and

modernised. The country is in the

process of rebuilding and improving

roads, bridges, ports and airports,”

Luis Silva, CEO of Antonia J Silva Lda

Transportes e Logistica (AJS) tells us.

The head of Angola’s leading

transportation and logistics company

has a personal investment in the

health of Angola’s infrastructure. Luis

Silva's father, Antonio J. Silva, founded

AJS 40 years ago, and since then

the company has been fighting to

rejuvenate Angola’s infrastructure. Silva

joined the team as a child, absorbing

the company’s purpose and his

father’s shrewd business acumen.

Silva left Angola briefly for university.

PRO

=

“| received an engineering degree

from Universidade Técnic de Lisboa in

2006, with qualifications in hydraulic

water resources and safety and

operations of dams,” Silva tells us.

After graduating, he worked as an

engineer in Portugal, focusing on

major water projects in Lisbon, Tejo

South and Ponte de Lima. On return to

Angola, Silva worked in AJS’ nascent

Transports Department where he was

responsible for the establishment

of new business operations for the

company's logistics services.

When appointed as CEO, Luis set

to continuing his father’s work. He

recruited over 200 additional

employees and added over 200

trucks to the AUS fleet. Silva explains:

“The fleet is completely modern, and

is equipped with GPS navigation

for optimised performance”.

He continues to detail AJS’ wider

transportation developments:

“The Integrated Logistics side of

AJS, in operation since 2007, has

grown into a full-service solutions

company for the transportation

industry throughout the supply chain,

providing integrated logistics services

including: receiving, inspecting, stock

control, storage, and door-to-door

8 January 2017

“WE ARE ALWAYS

LOOKING TO

IMPROVE ON OUR

PROCESSES. NO

MATTER HOW GOOD

SOMETHING IS, IT

CAN ALWAYS BE

MADE BETTER™

transportation.” AJS supports these

activities with warehouse space,

crane-equipped trucks, refrigeration

space, forklifts and scales. As part

of its logistics operations, the firm

has over 300 collaborators.

How does Silva fit into this wider

structure? He takes us through an

average day at the helm of AJS. “The

first thing | do is check in with the senior

logistics team to find out if there are

any issues that need to be resolved

that day, such as ensuring employees

are allocated as needed to projects,”

he says. “I usually have a list of

priorities, including: the status of AUS’

large projects, customer and supplier

concerns, and any employee issues.”

Silva then reviews report highlights

CONNECTING A FRACTURED NATION

from his team to ensure that AUS is

meeting its goals for cost, productivity,

accuracy, safety and timeliness.

“Next, I check on the status of our

new business or project pipeline.

Usually | want to see requests from

potential customers to help provide

them with an accurate bid and

timeline,” Silva explains. Although

Silva is CEO, he spends little time

in the office. After catching up.

with ongoing projects, he usually

visits AJS’ distribution centres.

“| go in-person to make sure

everything is running smoothly and

talk to some of the drivers every

day to find out if they are having

any specific difficulties. | spend

much of my time on the road,” says

Silva. To finish the day, Silva and his

team review and confirm tasks in

preparation for the following morning.

Silva emphasises that this

turn of events only happens on

an average day. It’s not every day

that things run so smoothly. “Supply

chain management has many

challenges,” he tells us. “These

include: customer service, cost control,

planning and risk management,

health and safety and supplier/

partner relationship management.”

AJS manages these challenges by

setting specific goals for each areas

and applying specific metrics to

measure success. Staff review these

ry 2017

metrics at least monthly, to see where

improvements need to be made.

AJS also tackles challenges by

implementing continuous improvement

strategies. “We are always looking to

improve on our processes. No matter

how good something is, it can always

be made better,” Silva asserts. The firm

encourages development ideas from

all employees, not just executives. Silva

adds: “Even incremental improvements

can translate into significant savings

over time and lay the foundation for

further improvements in the future.”

Improvements, fresh ideas

and forward thinking are key AUS

tenets. Thus, it is no surprise that

AJS invests heavily in corporate

social responsibility. Last year, the

annual Congress of the South African

ION

NECTING A FRACTURED NAT

Association of Freight Forwarders

noted that women are heavily

underrepresented in Africa’s logistics

industry. AJS has responded to this

inequality by addressing gender

inequality in its employment structure.

“One important thing we do that

distinguishes us from the competition is

that AUS hires women in non-traditional

jobs such as welding,” Silva says.

Pra

Evay

Janu

rs

CONNECTING A F

AJS also makes sure to operate an

ethical, sustainable supply chain. Silva

explains: “As an importer of paper for

the Angolan market, we are acutely

aware of the necessity to maintain

an ethical and sustainable supply

chain. Protecting against an unethical

supply chain comes down to one

thing: transparency.” AJS expects its

partners to share information regarding

their labour and environmental

practices. Its supplier selection also

takes these factors into account. “We

work to reward ethical suppliers by

ensuring that they get our business,”

Silva adds. “In our own operation,

we emphasise to all employees to

reduce waste, and we use largely

recycled paper. We take the used oil

to companies that need oil to burn,

largely for the production of bricks and

ceramics.” According to Silva, AJS

recycles 3,000 litres of oil per month.

Over the last five years, AUS

has expanded into a number of

Angolan provinces and principal

cities including Benguela, Huila,

Zaire, Cuando and Cubango. It has

also diversified into a number of other

sectors. AJS has invested $9 million

in a factory that will build trailers and

flatbeds. The company also conducted

RACTURED NATION

abroad market study which revealed

a deficit of paper producers coupled

with great demand in importing paper

products to Angola. Additionally, the

firm has expanded into oil exploration

and renewables; it is participating

ina study for oil exploration in the

Congo Basin and is involved in the

construction of a mini hydro.

With these projects underway, Silva

plans to revolutionise the way AUS

serves the Angolan people, and thus

continue his father’s work. Angola’s

infrastructure may still be hurting from

the effects of the war, but AJS sees

no reason why the Angolan people

should suffer too. With Silva at the

helm, AJS provides a service that helps

to decrease, rather than increase,

the distance between Angolans.

13

home

the tantalum

African countries hold the majority of the world’s

ST NA MRL OOM LRM) ARON Merit)

carey sm Um elie Celle Lae ele] B

Unfortunately, most of Africa’s tantalum is processed

abroad in countries such as China and Europe, meaning

the African countries producing the minerals reap only

a tiny reward. AB Minerals plans to bring tantalum’s

CoM Lele a com aT oD EMAL TMT MAEM) MAX

The firm has developed a new technology to create

Peele siete eee a Kem mee) oy ETT

hydroxide from industrial scale processing plants to be

installed in many African countries. We speak to Frank

Balestra, CEO, AB Minerals Corp. to find out more:

How did this project come to be? rare earth minerals. | had a couple of

My first trip to Africa was to DR labs do some work along a different

Congo. | ended up taking a trip to path than the existing processes of

Kinshasa and spent some time trying today. We had some early success

to put a project together. It did not and achieved complete separation

go well. | was subsequently invited of tantalum-niobium from the

to look at Rwanda. | quickly fell in concentrate. We then needed to

love with Rwanda. That is where | expand on this success to get toa

started to learn the coltan business. commercial scale using parameters

In Canada, there has been a lot of that would work in African countries

work in metallurgy with complex given certain limitations. Over

the last several years we’ve been

developing the commercial process

and now get nearly 100 percent

recovery of tantalum and niobium

from our concentrate. We have

developed a very nice process that

is a low-cost, low-power solution

that will work exceptionally well in

any African country with enough

tantalite bearing ores to operate a

plant. In addition, the plant has been

i ——

designed to be easily scalable to the

size of the ore production available.

Sounds fascinating, but

complex. Can you talk about

the challenges that arose and

how you overcame them?

There are issues like power

limitations, brownouts, and electrical

storms that happen often. For many

processing plants, if the power

TECHNOLOG

goes off for some reason and

you cannot maintain your furnace

temperature, you would lose the load

you are processing. Our process,

being a low power solution, will

work on either electricity or diesel.

Inconsistent power does not stop us

from operating. After looking at the

opportunity, | realised “There has

to be a better way to do this. This

technology hasn’t changed in 60-70

years”. It is seldom that you can

find an industry that the technology

has not been considerably

upgraded in that time period.

The process today uses

hydrofluoric acid, a very dangerous

chemical. The process is very power

intensive and the capital cost to

build a plant is significant. We use

acompletely different process, one

that doesn’t use hydrofluoric acid. A

process that is more environmentally

friendly as we capture everything,

waste, gases, etc., so it’s a very

clean system. These were extremely

important aspects of how we

wanted the process designed.

How does your project

divert from this?

Instead of using hydrofluoric acid, we

48 January 2017

use a compound that is inexpensive,

plentiful, and easy to transport.

The first step in the process was

the hardest to achieve, separating

the tantalum and niobium from the

rest of the rock in the concentrate.

Once we did that, we were then able

to upgrade to a higher-level end

product, giving us the highest value

possible from the minerals. It’s a

significant upgrade in value-addition,

which significantly changes the value

proposition for the miners, the local

communities and tax revenues for the

countries that we will be operating in.

How does an up-and-

coming project translate

on a global scale?

Most of the world’s supply of

Tantalum currently originates from

Africa. With so many African countries

that have tantalum mineralisation

and no processing facilities on

the continent, AB Minerals has a

significant opportunity to implement

plants in each of those countries.

We were on a call yesterday

when the person said, “people

don’t understand that tantalum is

one of the world’s most important

minerals”. The world is going to

“We bring high value jobs

to each African country

where we install a plant”

ARDERDAASARLARABAL) MY

Socioeconomic benefits of

new coltan processing plant

BAUR Ure eRe Wire ems LE

Br OVUM RU eS Rel Re tt]

RUE CULE RUE Lee LU

- With a focus to develop SME’s (Small & Medium.

ETP Cs ee em ELL}

to reducing the economic disparity between rural

areas and the major cities in a country.

SUR Ue CROC CRC me eam Ue

by selling directly to a local smelter rather than to agents.

- Creation of many high quality jobs.

- ATantalite smelter will play an important role in assisting

the mining sector in the country where it is located.

SU Ae CUCM Rea

SO RUC CeCe nig: (te ce

the Internet of Everything, which is

interacting cars to houses, everything

to everything, and they're all using

capacitors. Without tantalum, these

capacitors don’t work. Industry has

tried different materials, and they

just don’t do what tantalum does, it’s

an irreplaceable metal. The value of

tantalum remains relatively strong,

and it’s going to keep going. The

majority of easily attainable tantalum

that remains on this earth is in Africa.

How will the project contribute

to the surrounding community?

These plants are going to be very

significant, in terms of the volume

of business they will generate,

as well as the number of people

they are going to employ.

We bring high value jobs to

each African country where we

install a plant. Individuals that have

chemistry education, metallurgy,

or lab experience for example, are

all types of people that we will be

looking to employ. There are many

people with good skills but there

aren't industry jobs available for

them in their respective fields.

Additionally, for the government,

instead of having products exported

BRINGING HOME THE TANTALUM

at minimum values, products will

be exported for multiple times their

initial value, creating a substantially

larger tax benefit for the country.

This increased tax revenue can then

in turn be reinvested into country.

For the communities, mining

revenues have declined due to

adrop in commodities prices.

Because of that, everyone is

looking for ways to add value.

For most of Africa, the problem

with their resources is that few

foreigners are willing to transfer the

necessary technology to give host

countries the ability to upgrade their

resources directly in-country. Change

that and you will see increased

value remaining in the country.

Export your raw materials and

you're left with the lowest value.

Miners are paid the lowest value

for the hardest work of getting the

minerals out of the ground. Foreign

agents pay the miners cash for their

work and consolidate the minerals

for export. They add a significant

mark up at their end, which doesn’t

go back to the miners. Then the

smelters, whether they be mainly

Chinese, or a few European, create

further added value on their end,

21

TECHNOLOG

reaping most of the benefit of

mining that was done in Africa.

By bringing AB Minerals’

processing directly to the country

of original, we believe we will

see a great change in the value

proposition for not only the miners,

but for the country as a whole.

How will you ensure that there

are no ethical violations in

the mines you source from?

This is an area that we feel very

strongly about. Firstly, we plan to deal

with mines that are iTSCI approved.

In addition, the Better Sourcing

Program (BSP) has also been

developed to achieve traceability

through the entire supply chain. The

company’s Advisory Board Member,

Bill Millman has been involved in

the development of BSP program.

We will implement a system to

continuously check on mine sites and

ensure that our suppliers (sources)

remain in compliance with acceptable

standards of operation. Being the

only smelter in any region will mean

that there will be continuous flow of

minerals coming to the facility from

many different mines. It’s important

to utilise the best available programs

22 January 2017

to ensure supply assurance and

that appropriate international

standards are continuing to be met.

Finally, where do you see the

project in 10 years’ time?

We expect our processing method

will be implemented in all countries

throughout the world that have

adequate tantalite supplies. AB

Minerals will be the first to bring this

processing to Africa. Eventually, this

will force competition to find their

own solutions to enter this market

in Africa and compete with us.

Our process is going to bring

change to the market and create

value for the countries that have

the ore supplies. If the processing

costs can be reduced significantly,

it will have an overall effect on the

pricing of the end products.

This, over time, will undoubtedly

lead to many additional applications

being developed for the tantalum

industry. Once we produce tantalum

powder in Africa, tantalum end

product producers will follow to

get direct access to the powders

and develop end products

in-country. AB Minerals Corp.

expects to start this revolution. m

MOETLO MARIA

Tre ea

Hehe ei wa

ty: South ree)

EET

fe grade 10

Py LAL)

(Aa) TRON

PU En ites i aA Pa ie BLEU TE

OE enrolled for mi MT

and/am sti Taam]

Has ase

Fal

ESTEE es ion

[

10

DAPHNE

MASHILE Np Cero}

Company: Kalagadi Manganese aya

Sie scraa Chairperson

Nationality: TU tec

Sens mining industry eels sector requires Freee PRs

Pee Uw POL transformation. | Pech Preece eee

Pa acc ee ete rola in the sector, across retouelag

chain, and! Peel au emer) Purse which fron Fou

nhc interrogated,

09

PX SNELL ism ia

Pees ee ck the state.”

AFRICAN WOMEN IN MINING

mela)

AFRICAN

rem)

MINING

CHERYL A.

CAROLUS

en Gold Fields Ltd

Bice ere er

RENCE ene ees

Ue elena

Sg rene

Pena ecm pace critical

ee Pm Pra a0 Peeled om euslaia

Tense countries.”

Prete sa

DALE) Pe lca

ease ey

FOE ead

growth

one rola

Dasa

ela tcmeua focal

Prem kee

or

(ern

rT

an Fed que

a eee ality: Chitin

a 70

USS DUE ae eR a aT

Uy ies the. Wea Cee

aa ae eT Woke

Cal cil

ETTE

Cte ee

aN 44a PND ve

Ld

MAC sical

a rote IVICA OL

Rete acucua

O02

MUON ace CON Lone

Joined the industry, most women

in technical roles were Western.

Today, there are more Ghanaian

women mining and geotechnical

eat eee TNA

etc. Women constitute 51 percent

Meee Se UO MUL MmOn 1/23

cannot isolate them from a vibrant

sector like mining! Still, a lot needs

to change. I'd like to see more.

Oem ame cle OE

TRUE le man

ADIK

AYITIVIE

Company: Newmont ei

mpany: EITC TRC

US rocg ste EI)

TUM erty ay

NE Ghanaian

SUS ONL m Marne MCLE)

and Africa should be inspired and

AOU ele em Ons Vee MU lm eek a

FSi 0) ea ANOLON D AS

OCA a Om UAL tee

up and coming African women who

Velie aa Le em mec ON OLILeR

and shows them they can make it

to the top with hard work, courage

VOR Me eNO YO 0 oa

~

= ss =

CHAMBRE DES MINES a

a

THE MINING CHAMBER

OF SENEGAL

THE MINING CHAMBER OF SENEGAL

reated on the 5th of June

2013, the Mining Chamber of

Senegal (MCOS) is a non-profit

organization currently comprising

more than 30 local and international

companies operating in the fields

of exploration and mining.

The main role of the Chamber is

to encourage, promote and protect

mining investments in Senegal,

developing and maintaining a

professional business ethic. Its

mission is to foster the emergence

of a dynamic mining sector and

to create attractive conditions

for a sustainable growth of the

sector and the national economy.

It also has a mandate to defend

the common interests of its

members as a representative,

agent and spokesman in front of

the public administrative bodies.

To carry out its mission, the

Chamber has established three

committees, namely the Tax and

Legal Committee, the Safety,

Security and Training Committee,

and the Communication Committee.

After many exchanges between

34 January 2016

the governments and all of the

stakeholders, a new mining code

has been decided upon. It does.

not include a total restructuring of

Senegal’s mining administration,

nor does it establish any review of

existing mining titles or contract.

In retaining the investor-friendly

incentives presented under the

current code, one of the key goals of

the new mining code is to increase

incomes to the government from

the mining sector. This means

that investors can expect to pay

expanded fees, royalties and taxes

under the new mining code.

Note that mining companies that,

as of now, hold a mining title in

Senegal will be bound by the mining

code in force at the time their title

was awarded and, if applicable,

at the time their mining contract

was signed with the government.

CHAMBRE DES MINES

CHAMBRE DES MINES

Www.cmdsenegal.com 35

AZIZ SY,

MODOU DIOP GUENE,

OUMAR TOGUYENI,

BAUNDDELANOUE,

36 January

KHADIDIATOU FALL,

DAVID MBAYE, MEMBRE CONSEIL ADMINISTRATION

MOUHAMADOU SOW,

DORO DIAGNE, — _MEMBRE CONSEIL DADHNISTRATION

STRIKING GOLD

IN SENEGAL

Written by Dale Benton

Produced by Richard Deane

TERANGA

Sabodala Gold Operations S.A.

HOW IMPORTANT IS IT TO BE A SOCIALLY

RESPONSIBLE MINING OPERATION?

TERANGA GOLD, THE FIRST AND ONLY

OPERATING GOLD MINE IN SENEGAL,

FIRMLY PLACES SOCIAL RESPONSIBILITY

AT THE HEART OF THE MATTER

he key to success

as acorporate citizen in

Senegal, Teranga Gold

Corporation believes, is earning

the right to operate in any region

the company conducts business.

For any mining company, the

importance of corporate social

responsibility (CSR) and the duty

to be a good corporate citizen are

things that simply cannot be ignored.

The very success of a mining

operation is often only achieved

through a commitment to CSR and

creating a lasting legacy for the

community in which they operate.

For Teranga, CSR is inherent to

the very core of the Company's

mission statement and is embodied

40

in its name. The word “Teranga”

translates into hospitality and

friendliness in Wolof, the local

language of Senegal, West Africa.

The Canadian-based gold mining

company owns and operates

Sabodala, the only commercial

gold mine and mill in Senegal.

Sabodala is a +200,000-ounce

gold operation with a 13.5-year mine

life and a reserve base of 2.6 million

ounces. The Company’s long term

goal is to expand its operations

in not only Senegal but in other

countries in French West Africa and

become a mid-tier gold producer.

Setting the CSR benchmark

Owning and operating the only large-

Metifex wl

Proud project development partner

of Teranga Gold Corporation

MILL OPTIMISATION CRUSHER PROJECT

e Zero LIls

Delivered under budget

Delivered ahead of schedule

All quality standards exceeded

Project objectives fully achieved

100% SENEGALESE BUILT

We work together to develop your mineral Ai ,

ee into a mining asset. Contact us for more metre,

information. www.metifex.com.au bal prec at

scale gold mine in the country, the

Chief Executive Officer of Teranga,

Richard Young, knows all too well

the responsibility resting on the

Company’s shoulders when it

comes to setting a solid example of

corporate citizenship.

Stated Mr. Young: “When you're first

in the country, it is your responsibility

to provide opportunities to the local

and regional communities and to

provide proper training. Not only are

we training people to run our own

operation, we are training Senegalese

people to develop skill sets that could

help power the country’s economy

well after the mine is gone.”

Teranga is setting the CSR

bar at a high level, hoping that it

will set the benchmark for other

mining companies that establish

operations in Senegal.

“First and foremost, we strive

to mitigate our impact on the

environment and the communities,

ensuring that our activities do not

create any loss,” stated Mr. Young.

“Our next priority is to share the

benefits of mining to create long

term sustainable growth where

we operate. On top of this we

are focused on adhering to good

governance practices and promoting

our employees and their culture.”

TERANGA GOLD

Health and safety for instance is a

prime example. The Company has

achieved almost three years without

alost time incident at Sabodala

“We provide our workforce with

quality jobs and extensive training in

an environment that promotes and

awards health and safety,” said Mr.

Young. “Currently, our employees

have worked more than 11

million hours without a lost

time incident. There are few

companies in the global mining

sector that can make this claim.”

At Sabodala, the Company

employs more than 1,200 people.

Approximately 90 percent are

Senegalese with more than half

coming from the local communities

surrounding the mine. Its strong

workforce is a commitment to

employee development.

Teranga’s ultimate goal is to

nationalise its workforce and

reduce the number of expats over

time by moving its Senegalese

employees into senior roles.

This development of employees.

not only better serves the Company,

but Senegal as a whole.

RS ER

SSS Nee

FTE DRILLING IS ONE OF THE MOST SPECIALIZED

‘COMPANIES IN THE DRILLING INSOUSTRY.

WE OFFER SERVICES COVERING DIFFERENT

‘TYPES OF DRILLING PARTICULARLY IN CANADA]

[AFRICA AND SOUTH AMERICA.

VIKING

INDUSTRIAL and MARINE SERVICES LTD

Diesel / Gas Engine Specialists

ee RRO Et eRe Rc nls

quality of service and reliability.

Saeco Rea MUI Ue EUR eRe Re Oe RUC es

eocpactuesth

OT ee Rae eeu etn ee

‘Wartsila and Caterpillar MAK

* UK Machine shop and Specialist Cast Iron and Aluminium repair service

See RU eae nee BLL

For more information call

Tel +44 (0)1522 705025

Email info@vimservice.com « Re i ale ey

- = a 7

co ee ec Cerro ks Tee)

Ear) Ee eee

oe Sta mur ke Pee een cae}

ee cheer ral

fee sere t Rar eter lord

i

esr as Kcr) Facility.

knee Sin}

a

ae

g

&

Award winning CSR program

Teranga prides itself on its

commitment to the local community

through initiatives that came out of its

2014 Regional Development Strategy,

which was created after 18 months

of consultations with all stakeholders.

The strategy sets the vision for the

Company’s long term development of

the near-mine region and defines the

priorities of its CSR programs.

The Company has received several

awards in recognition of its CSR

efforts, including most recently the

United Nations Global Compact

Network Canada Sustainability Award

and the Prospectors & Developers

Association of Canada Environmental

& Social Responsibility Award.

“Doing well by all of our stakeholders

has been our mantra since day

one and the initiatives undertaken

ensure that the local and regional

communities in the country are

truly benefiting from Teranga’s CSR

program,” stated Mr. Young.

Some of these initiatives include

the creation of community market

gardens, livestock health programs,

and the improvement of agricultural

farming techniques in support

of agriculture and food security,

school support through bursary

programs, donations of supplies

www.terangagold.com 47

TERANGA GOLD

and the construction of school

infrastructures in support of youth

education and training, as well

as programs that empower local

procurement and help develop small

and medium businesses in support

of sustainable economic growth.

Through its commitment to CSR,

the Company is working to leave a

positive and lasting legacy for Senegal.

Growing in an Ex-Growth Sector

As agold producer, commodity cycles

and the challenges they present are a

way of life. Across the entire industry,

despite major exploration investment

over the last decade, discoveries have

been minimal. The vast majority of

deposits discovered are less than

4 million ounces or less. Globally,

this has resulted in declining grades

which in turn results in lower global

gold production. Lower grades mean

a lower threshold of error. This has

led to a shift in focus in the industry

towards continuous improvement,

capital discipline and maintaining

and lowering production costs.

“We do not control the price of

gold so we focus on the things

within our purview, such as

achieving productivity and efficiency

DRILLING COMPANY

[a ICClnI Ag da 43) |) el)

Pmt Omar MeL

OPERATING PERFORMANCE

4 DEEPLY INVOLVED

TERANGA GOLD

a “WHEN YOU’RE FIRST IN THE COUNTRY, ~T

IT IS YOUR RESPONSIBILITY TO PROVIDE

OPPORTUNITIES TO THE LOCAL AND REGIONAL

COMMUNITIES AND TO PROVIDE PROPER

TRAINING. NOT ONLY ARE WE TRAINING PEOPLE

TO RUN OUR OWN OPERATION, WE ARE TRAINING

SENEGALESE PEOPLE TO DEVELOP SKILL SETS

THAT COULD HELP POWER THE COUNTRY’S

Zi ECONOMY WELL AFTER THE MINE IS GONE” | 5

Partner of

TERANGA

ie . ve =

“Who can provide you with a complete solution? ~~

i a

MINES PROJECT MANAGEMENT FINANCE LOGISTIC & INSTALLATION

ada A Meee Nea) ee) eee)

menier REBUILD OF ENGINES & COMPONENTS SAFETY

@

a BIAGROUP.COM

Ten Gears Rid

improvements,” said Mr. Young.

“We are very conscientious of how

we spend each and every dollar.”

While the global gold sector paints

a picture of ex-growth, there are a

handful of growing regions, including

West Africa, that many believe are just

beginning to make their mark on the

industry. Mr. Young views West Africa

as a literal gold mine of opportunity.

Most gold regions in the world are

witnessing falling production. However,

gold production in Africa continues to

grow. In 2015, the continent of Africa

was the second largest producer

of gold and half of this production

was derived from West Africa.

Expanding Beyond Senegal into

Greater West Africa

With its continuing success in

Senegal, Teranga has set its sights

on expanding and becoming a mid-

tier gold producer with operations

across greater West Africa. In

October, the Company acquired

Gryphon Minerals, which included

the Banfora gold project and two

prospective exploration properties

in Burkina Faso, West Africa.

Mr. Young believes that Teranga

can leverage its strong core team in

www.terangagold.com 51

TERANGA GOLD

Teranga Gold operates a gold mine in the Senegal. Like

most mining activities, the concession is established in a

remote area far from available laboratory services which are

Classified as non-core but essential

By outsourcing laboratory services, the mine is assured of a

continous and dependable services, which in tum helps them

‘o focus on their resources on the core activities of mining,

TERANGA GOLD

IS BASED ‘IN

SENEGAL,

AFRICA

Senegal and take the lessons learned

from Sabodala to develop another

world-class gold operation at

Banfora.

“Maintaining our strong social

licence is essential for growth and

success in Senegal and as we expand

our footprint into other jurisdictions in

greater West Africa,” stated Mr. Young.

With considerable drilling completed

at Banfora in the second half of 2016,

a feasibility study for the project is

currently underway and is expected

to be completed mid-2017.

Beyond Banfora

“We continue to explore in and

around our current mine sites and

large prospective land packages in

Senegal and Burkina Faso. As well,

in Cote d'ivoire, we hold four joint

venture exploration permits. We

have a lot on our plate as we pursue

our goal of becoming a mid-tier

gold producer,” said Mr. Young.

Promoting Partnership

Following many years of working

together at Barrick Gold and then

SOOO OOO OOOOOOOoooooooooooo

TERANGA GOLD

Gabriel Resources, Mr. Young

and Chairman Alan R. Hill wanted

to pursue their shared vision of

developing a gold company that could

bring significant value to shareholders.

Both Mr. Young and Hill have seen

incredible successes with Teranga

Gold and Sabodala. Mr. Young

admits that, as with many business

ventures, it is a process made possible

through the power of partnerships.

“There is no question that we

have a number of partners who have

contributed to our success,” said Mr.

Young. “It is not something we can

do on our own. Without the help of

federal, local and regional partners,

the Company simply wouldn’t be

as successful as it has been.”

In fact, 80 percent of goods and

services purchased by Teranga are

done so through local channels.

This includes fuel supplies and

anumber of consumables and

stretches as far as technical issues

such as maintenance and repair.

Most recently, the Company

has completed a mill optimisation

project at Sabodala using all

Senegalese suppliers. The project

was commissioned a quarter ahead

of schedule and well under budget.

In everything Teranga does,

promoting and growing the

Senegalese economy and

being a responsible miner sits

right at the heart of it all.

Mr. Young concluded, “Enriching

lives and growing communities

and economies will continue to

be a driving force for Teranga. As

alarge and crucial contributor

to local, regional and national

economies, the mining industry is

doing incredible CSR work.” m

TERANGA

GOLD CORPORATION

Din

54 January 2017

“IT IS NOT SOMETHING WE CAN

DO ON OUR OWN. WITHOUT

THE HELP OF FEDERAL, LOCAL

AND REGIONAL PARTNERS, THE

COMPANY SIMPLY WOULDN’T BE

AS SUCCESSFUL AS IT HAS BEEN”

ZO)

NiO sm

INSTITUTEOF

Rar ets TON

Embracing the future

of South African sport

Written by Dale Benton

Produced by Matthew Pepper

wo decades after its formation,

the Sports Science Institute

of South Africa (SSISA)

continues to create national unity and

pride through sports opportunities,

science and education. Founded

in 1995 by former South African

Rugby player Morné du Plessis and

Professor Tim Noakes , their vision

was to establish a facility that would

fund research in exercise science

applied in the areas of athletic

performance and health promotion.

“Fast forward 21 years and this

remains our core purpose. The

challenge now is adapting to an

ever-changing environment so that

our offering and research remain

meaningful, translatable and

impactful,” says Dr. Phathokuhle

(Cele) Zondi, CEO SSISA.

“We focus on both wellness and

performance, translating science

The Sports Science Institute of South Africa has been

providing opportunities for increased res

and education in sports and physical activity in South Africa

for over two decades. As the company looks to the future,

CEO Dr. Phathokuhle (Cele) Zondi embraces the past

earch, participation

through numerous Clinical services,

programmes and a growing

education platform,” she says.

For Zondii, life as CEO of SSISA

began in June 2016, a time of great

flux for SSISA. “I’m fresh out of

the starting blocks and excited

about the road ahead” she says.

As a medical doctor by profession,

Zondi has strong experience in the

sports health and fitness industry,

working in sports medicine with

federations and academics.

“I'm really passionate about

physical ability, sport and its ability

to empower. So it only felt like a

natural progression that | find myself

with SSISA today,” she says.

The company has recently

undergone a process of strategic

renewal as it strives to adapt and

stay ahead of the changes within the

industry. One of the key components.

SSISA

“It’s about the importance of looking at

ow we can differentiate our offering

d really position ourselves so that

d apart fronmvother providers”

60 January 2017

of SSISA's offering is its partnership

with the University of Cape Town,

specifically its division of Exercise

Science and Sports Medicine.

The University of Cape Town,

Zondi says, represents the

research arm and intel of SSISA.

Over the last 18 months, SSISA

through this strategic renewal process,

entered a merger between the two.

“This represents quite a change

in the history of SSISA. Through our

strategic renewal process, we ensured

that the interests of the two partners

became better aligned. We are working

together to create more products

and services that speak to the vision,

goal and intention of SSISA and The

University of Cape Town,” says Zondi.

Portfolio of empowerment

The health and fitness industry is

constantly evolving, like any other,

and SSISA must react and adapt

to ensure that it continues to offer

market leading products and services

that the industry demands.

Zondi believes that through the

strategic renewal process, SSISA

stands at a key turning point.

MINING

“We had a few key strategic shifts

that will position us well to capitalise

on our standing not only as a provider

of services, but as providers of

education in the near future” she says.

SSISA is looking to launch

an education platform that will

allow an ease of access to its

dynamic education portfolio.

“Strategically, this is very exciting

in that not only are we leveraging off

our relationship and partnership with

the university but we are importantly

addressing current needs in the

Education industry,” she says.

SSISA will launch this education

platform in 2017, providing a clear

pathway for individuals who want to

get into this field at university level.

Technically speaking

For the education platform to come

to life, SSISA has had to embrace the

ever-changing nature of technology. In

the sports, health and fitness industry,

the impact of technology is almost

two-fold — it will affect the service

providers and the way they work, but

also it shapes the role of the athlete,

from elite athletes right through to

www.ssisa.com 61

SSISA

recreational athletes. There is more

scope for data, tracking and monitoring

of performances, something that

Zondi believes represents a “shifting

mindset” across the industry.

“As service providers, we've had

to adapt quickly, as the technological

space brings about certain pressures

on the industry,” she says.

With technology - comes

competition. 21 years

ago, when the SSISA

was first established,

it stood alone as a

pioneer in terms

of constructing

asports science

institute and the

services it offered in

Africa. Fast forward to

today and there are a number

of players in the industry, something

that Zondi admits plays a key role

in the company’s new outlook.

“It’s about looking at how we can

differentiate our offering and really

position ourselves so that we stand

apart from other providers,” she says.

This technological demand and

pressure is handled through regular,

mn

125

open dialogue with clients and

members, in order to determine what

they need from technology and how

they are engaging with it. This is key

for SSISA to adapt its products and

services to better suit them. Our

clients in part, inform our offering.

“While we serve elite athletes

who access our most technically

advanced technology, we also

need to accommodate the

client or the member

who doesn’t have that

level of technology

and offer our services

and our products in

an accessible way

to them,” she says.

Honouring the past,

embracing the future

21 years ago, when the institute

was founded, it was done so on the

foundation of creating national pride

and unity through sport’s performance

using applied scientific research.

SSISA strives to ensure that in

everything it does through research,

education its fitness centre and

multiple programmes and services -

that those principles are centre fold.

Reine ce aoe

Francois Knoetze

(@iitvtuee-re

Mr. Francois Knoetze, also known as Faffa, is employed by Remgro

Limited and focuses on Remgro’s interests in the financial services /

(insurance and banking) and the sport industries. He is a qualified actuary and b

currently serves as a Non-Executive Director on a number of company boards, ;

such as Business Partners Limited, FirstRand Limited and Outsurance Holdings

Le TniCclo Pan em uel e- MeO RO MU QU CUT Solem PAUL ey

and holds a B Com (Hons) from the University of Stellenbosch. He is a former

South African Rugby player and represented the Springboks in 1989 and 1992.

One way in which SSISA delivers

on this, is through its staff and its level

of communication and engagement

with clients, members and research

subjects. According to Zondi,

SSISA's greatest asset is its staff.

The people who greet members at

the door right through to those in

the fitness centre and laboratories,

are the embodiment of SSISA and

what it stands for and represents.

“There was one particular member

who has been with us since the very

start. When we asked them what

kept them coming back, aside from

the services we provide, they said

it was the people,” says Zondi.

“There is a culture and a sense of

family here at SSISA and we take

great pride in being at our best in

order to bring out the best in others.”

Creating that culture and sense

of family goes one step further at

SSISA. The company hosts a number

of activation events with members,

where members of staff right through

to leadership level sit down with

clients and members in a unique

opportunity to discuss and better

understand more about the institute,

MINING

the direction of leadership and how

it can serve members better.

Olympian level

One recent function in particular was

unique, as it highlighted the institute’s

involvement with the 2016 Rio Olympic

and Paralympics. Our facility is home

for a number of national athletes and

we have staff that have served as

trainers and support staff for these

athletes during their Olympic journey.

“The Paralympics is something

that is very close to SSISA and

the nation’s heart and ,a pre-

Paralympics members’ function

was a very special opportunity for

clients to understand what we do

at such an elite level,” she says.

Zondi was in fact part of the medical

team at the 2016 Paralympics with

Team South Africa. Being active and

visible at such a prestigious sporting

events over two decades highlights the

growth and impact that SSISA has..

“To be seen to be active and

working at the different levels in the

sporting industry affirms that SSISA

has numerous experts who apply

their trade day by day,” says Zondi.

www.ssisa.com 65

SSISA

“It also represented a key moment

for members of staff at SSISA to

recognise that we have many experts

in-house in multiple disciplines

and we need to allow them the

space and opportunity to engage

at the highest level,” she says.

Power to the people

SSISA not only strives to create better

sport, research and health education

opportunities, it works closely within

the local community. In their new

strategic model, Corporate Social

Responsibility (CSR) sits at the very top

of everything that the company offers.

The company has two flagship

community based projects, the

Community Health Intervention

Programmes (CHIPS) and the

MACSTEEL Maestros programme,

which they manage for Macsteel.

Established in 1997, CHIPS aims to

encourage a culture of health, wellness

and an active lifestyle through regular

physical activity and health education.

The MACSTEEL Maestros looks

specifically at providing opportunities

and nurturing young athletes from

disadvantaged circumstances to

be reach their greatest potential.

“CSR is absolutely important,” says

Zondi. “Accessibility and equity are

very important to us and we must

ensure that our reach extends to every

level of society. We must continue to

extend our footprint into communities

which would otherwise not have

access to our offering. Any corporation

that exists in our country must play a

role in skills development, education or

creating greater job opportunities.” m

f Ping

SPORTS

SCIENCE

Earners

66 January 2017

Phathokuhle Zondi

Chief Executive Officer

’

ont SERS eens cue cm Celi cn si Ma NSE Moet t eRe le|)

SOOM UO CCM INTs esl mciteclCren me TOM c-(6 SOM DPN RUM ates clam

the South African Sports Medicine Association (NGO), and serves on the South

African Institute for Drug Free Sports (SAIDS) Appeal board. She is involved in

PSL NMCM eMC MececU UM MU KOMsetecC cu lem a ol |ect (Ona

local and international peer reviewed journals and delivers impactful corporate

ETCede Cercle et aN (eM (eee MO MMV Mesa ere UAL ee MOLT eee =] CeCe Ue me (r-

Lie el ene eC IANO MrT SCOP AV Tecate UPA (Omz-Ue- NV) em LU

2014 Commonwealth Games and 2012 London Olympic Games. Dr Zondi is

passionate about developing and mentoring young women and future leaders of

South Africa. Her qualifications include a Bachelor degree in Surgery and Medicine,

a Masters degree in Sports Medicine and a Masters in Business Administration.

bia

= 9

i

AAT S- eo

} a

Responsible

minine

How Dundee Precious Metals

ensures its Tsumeb smelting

plant serves the Namibian

community with the utmost

corporate responsibility

undee Precious Metals

Tsumeb, one of three

subsidiaries of the Canadian

company Dundee Precious Metals

Inc., is the Namibian faction of the

business. Its site in Tsumeb is located

around 430 kilometres north of

Windhoek - Namibia’s capital -— and sits

close to the nation’s greatest wildlife

sanctuary, Etosha National Park.

Dundee Precious Metals built a

smelter here in the 1960s, drawing

on the rich seams of copper found

in Tsumeb’s mines. Now, the

plant contains two Pierce Smith

Converters, a Top-Submerged

Lance Ausmelt furnace, a sulphuric

acid plant, and slag milling and

flotation plant. 700 people are

employed at the smelter — a significant

portion of its 14,000 population.

The company originally began as

70 January 2017

Tsumeb Corporation Limited, putting

the Tsumeb plant into production in

1963 using the expertise of Newport

Mining Corporation. It was soon

producing over 3,500 tons of copper

and 6,000 of lead a month (until the

lead smelter closed in the 1990s), and

the company went through a period

of uncertainty as it changed hands

several times and suffered a period

of inactivity due to labour strikes.

The smelting plant was finally sold

to Dundee Precious Metals Inc. in

2010, with the TSL Ausmett furnace

quickly converted from a lead smelting

vessel to a copper one. An oxygen

plant was then added to increase

the efficiency of the furnace, and

the sulphuric acid plant followed

soon after. The latter ensures that no

harmful sulphur dioxide enters the

atmosphere in the treatment process.

Protea

Chemicals Namibia

A member of the Omnia Group

www.omnia.co.za

It is with great pride that Protea Chemicals Namibia partners with Dundee Precious Metals Tsumeb (DPMT) to add value

to the Namibian economy and communities. Protea ensures that Sulphuric Acid produced at PMT is transported

safely to end users in Namibia, and our services to DPMT includes, amongst ather, the following:

+ SHEQ management and enforcement along the transportation route and on site

+ Emergency response persons, systems and equipment strategically located along the transportation route.

+ Community, fire department and medical centre hazardous chemicals awareness training,

Protea Chemicals Namibia (Pty) Ltd., as a member of the Omnia Group, isa signatory to the Responsible Care program”,

maintained by the Chemical Allied Industries Association. We are committed to the safe and responsible handling of,

chemicals, with the philosophy of “cradle to grave” management.

‘+ We are committed to promoting safety, health, responsible care, environmental and quality awareness.

‘+ SHEQ & Responsible Care management is applied through an Integrated Management System (ISO 9001, ISO

14001 and OHSAS 18001).

* Our dedicated internal SHEQ department focus on internal and external training programmes with a view to

continual improvement of overall SHEQ standards.

‘* Spillage management and emergency response support.

* Acomprehensive Hazmat plan for warehousing facilities

Above is allowing customers to focus on the metallurgy of their process, whilst we manage their chemical supply and/or

distribution in a safe and responsible way.

Corner of 1 Rikumbi Kandanga Road and 3rd Street, Walvis Bay 4-6 Newcastle Street, Norther industrial, Windhoek

T+264 64.221 540 F+264 64 221 541 T+264 61 214.849 F#264 61 214 846

Tsumeb's smelter is a rare one in that

itis able to treat and process complex

copper concentrate, something few

others are advanced enough for. It

produces 98.5 percent pure copper

blister, which is refined in Europe

and Asia to be turned into metal. The

other elements, arsenic trioxide and

sulphuric acid, are sold to third party

customers and Namibian uranium

and copper producers respectively.

Dundee Precious Metals, too, is

unusual in its unwavering approach

to sustainability, not something that

is always a priority in the industry.

It claims to follow the highest

possible standard of business

ethics and social behaviour,

and has implemented various

continuous improvement strategies

to ensure this. DPM’s excellent

relationships with shareholders

means that the company trusts

each of them to abide by the same

policies, cementing a positive

reputation for everybody involved.

Some of DPM’s policies, as per the company’s website, include:

* Compliance with all applicable

laws and regulatory controls.

Morse seca teeta omer at

Deb sereeeertme mcg Ca.)

ER cee ctetcae nena)

Seer ec ema ercrtn

Sere else Ne) hae testo}

Pobre meaathg

Seta tated

Eb atsrttt totes Mos moeaEaey erent

management opportunitie:

* Outstanding minerals

Rlageloeetart rae tester)

SecetnocemrteRetetresteracteTl

pervert tse Beets tng

ba HEMET Thee CRITE TOOK

Daven rar oenente notches!

ose asere to ententer tects

Come Na uCEET yearned

Sagontong oleae

Caos tere sseask ate

Os oee eC a Rom titties

Employee and contractor a

CaeteertnaGieiiert Rater

Neen s sen teiotriit

eb ieC ho tenatrerten

fion is a 100% Namibian owned and managed company.

Me eek cr teem tec Leas

en omen ee hares

“As a foreign

company, we

believe in investing

part of our

proceeds into the

community in

which we operate”

aay

DPM'’s recognition of itself as a

huge part of the economy in which

it operates, emphasising the

importance of financial stability

and corporate responsibility.

The company dedicates itself to

the use of efficient energy, recycling

and waste minimisation, outsourcing

of work to local businesses where

appropriate,

ensuring

operations benefit

locals and minimise

risks to the community,

and that environmental

remediation and

economic improvement

are always a priority.

Improvements to

infrastructure, public

health, and education

regarding projectsare

to be implemented early.

All business practices will be

conducted at the highest possible

ethics and transparency standards.

In summer 2016, DPMs Vice

President and Managing Director

Zebra Kasete was interviewed

for Lela Mobile, and discussed

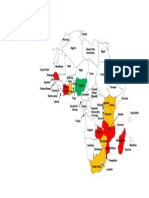

The location

OTT

cH ty

WEES

Tsumeb

MINING

with Rosalia David many of these

aspects, as well as the future of

Dundee Precious Metals Tsumeb.

“Any international company

operating in alocal community

needs to be appreciative towards

their host community,” he explained.

“Corporate social responsibility is

crucial to Dundee Precious Metals

Tsumeb. As

a foreign

company, we believe

in investing part of our

proceeds into the community

in which we operate. With

the administrative assistance

from the Namibian Chamber of

Commerce and Industry’s local

branch, the Tsumeb Community

Trust has provided grants to

over 80 small Namibian-owned

businesses that have in turn

employed and trained a significant

number of Namibians who might

otherwise be unemployed.

“Dundee has contributed

approximately N$15 million to a

public-private partnership with

the National Housing Enterprise to

build 67 houses for ownership by

www.dundeeprecious.com 75

our employees, with more in the

pipeline. This is also in line with the

Harambee Prosperity Plan theme

for mining companies to continue

providing houses to the communities.

We are happy and committed to

work together with the government

to progress this specific theme.”

DPM also awards bursaries

to local students, having spent

N$5 million on them already, and

focuses heavily on utilising local

businesses through its preferential

procurement policy. The business's

dedication to its many continuous

improvement causes is incredibly

admirable, and Kasete summed up

his feelings on the subject succinctly:

“Managing expectations on all

levels is the biggest challenge for

new leaders. | must understand the

commitment made by the company,

and manage those expectations

effectively whilst delivering on

them. Despite all of the exciting

challenges, | am happy that | am

working for a company whose

value resonates with my own.” m

Dundee

PRECIOUS

METALS

THE NAMIBIAN TEAM

Zebra Kasete

Kasete is Vice President and Managing Director, with nearly 30 years of mining and

smelting experience behind him. He is a metallurgist and has a Master’s Degree in

Business Administration, and has held various senior positions within the industry.

Barcelona Plaatjies

Plaatjies is Director of Operations and is working towards her

Honours Degree in Technology Management, with several

years of experience in mining already under her belt.

Jan Kruger

As the Director of Technical Services, Kruger has worked in the base

metal smelting sector for several years, and provides operational

support throughout the entire smelting process.

Isai Nekundi

Nekundi is in charge of liasing with senior management and collaborating to develop

effective relationships, with an Advanced Diploma in Business Administration behind him.

Thinus Loftie-Eaton

Loftie-Eaton is Director of Finance, Supply Chain, and IT, and is responsible for

strategic financial management, commercial, and supply chain management.

Arthur Scholz

EStolsfelra aM Le oe Meats acco srelacile) Rom cua nce) ere We MU Le

and an invaluable asset to the sustainability side of the business.

Nyro R eae nEy

The Director of Human Resources is responsible for the development and execution

of DPMT’s HR strategy, and has over 30 years of experience in the sector.

Tel: 012 665 0618 - 012 111 0482 | Fax: 086 522 1764

Q-Kon Building, Erfd Office Suites, 8 Pieter Street, Technopark Highveld, Centurion, Gauteng, 0157

Burgersfort Branch, 40 Aloe Street, Aloe Ridge East, Burgersfort, Limpopo, 1150

Anda mungkin juga menyukai

- Global Strategy and Leadership: Cpa Program Su Bjec T Ou TlineDokumen6 halamanGlobal Strategy and Leadership: Cpa Program Su Bjec T Ou Tlinesantoshcal3183Belum ada peringkat

- Opportunities For Export of Fruits and Vegetable Based Products (Summary)Dokumen5 halamanOpportunities For Export of Fruits and Vegetable Based Products (Summary)Akshay MehtaBelum ada peringkat

- NewsletterMSMEJuly2019 EngDokumen7 halamanNewsletterMSMEJuly2019 Engsantoshcal3183Belum ada peringkat

- IFR Magazine March 24 2018Dokumen108 halamanIFR Magazine March 24 2018santoshcal3183Belum ada peringkat

- Elabana Brochure PDFDokumen2 halamanElabana Brochure PDFsantoshcal3183Belum ada peringkat

- IFR Magazine March 31 2018Dokumen92 halamanIFR Magazine March 31 2018santoshcal3183Belum ada peringkat

- Alice Blue Financial Services Alice Blue Financial Services (P) Ltd. Nse Early Pay-In Bse Early Pay-InDokumen1 halamanAlice Blue Financial Services Alice Blue Financial Services (P) Ltd. Nse Early Pay-In Bse Early Pay-Insantoshcal3183Belum ada peringkat

- Season Chart FINAL PDFDokumen1 halamanSeason Chart FINAL PDFMithun NairBelum ada peringkat

- Allrecipes - April-May 2018Dokumen96 halamanAllrecipes - April-May 2018santoshcal3183100% (1)

- IFR Magazine March 31 2018Dokumen92 halamanIFR Magazine March 31 2018santoshcal3183Belum ada peringkat

- India Pulses en PDFDokumen7 halamanIndia Pulses en PDFsantoshcal3183Belum ada peringkat

- Guide To Global BusinessDokumen27 halamanGuide To Global Businesssantoshcal3183Belum ada peringkat

- Chapter 02Dokumen22 halamanChapter 02Noor Ahmed ChandioBelum ada peringkat

- Capital Market InstrumentsDokumen7 halamanCapital Market InstrumentsManjunathreddy SeshadriBelum ada peringkat

- African CoverageDokumen1 halamanAfrican Coveragesantoshcal3183Belum ada peringkat

- India Pulses en PDFDokumen7 halamanIndia Pulses en PDFsantoshcal3183Belum ada peringkat

- SBB Briefing 1 Mar 12Dokumen15 halamanSBB Briefing 1 Mar 12santoshcal3183Belum ada peringkat

- McKinsey BP AdviceDokumen65 halamanMcKinsey BP AdviceEvert Troch100% (7)

- SBB Briefing 2 Feb 12Dokumen21 halamanSBB Briefing 2 Feb 12santoshcal3183Belum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)