Astm

Diunggah oleh

Galih PrianggodoHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Astm

Diunggah oleh

Galih PrianggodoHak Cipta:

Format Tersedia

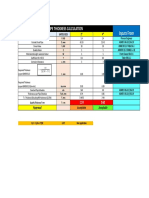

PROYEK PEMBANGUNAN PABRIK FERONIKEL HALMAHERA TIMUR (P3FH)

PIPING WALL THICKNESS CALCULATION

CALCULATION

Document Number : P3FH-PP-9000-CAL-0001

WALL THICKNESS CALCULATION SHEET

PIPING CLASS : A1

Rating : ANSI#150 Service Line : Cooling Water (Softened), Cooling Water (Non-Softened), Return

Water (Softened), Return Water (Non-Softened), River Water

Max Design Pressure : 10 bar 145 psi

Design Temperature : 60.0 C 140.0 F

Design Code : ASME B31.3 Material Basis : Carbon Steel & Carbon Steel with Concrete Lining

Mill Tolerance : -12.50% Corrosion All'n : 1.50 mm

Mechanical All'n : 1.162 mm for PT 15A, per JIS B0203

Formula : t = P.D / 2 (S.E.W + P.Y) , inch equation (3a), para 304.1.2 (a), ASME B31.3 1.162 mm for PT 20A, per JIS B0203

tm = t + C, inch equation (2), para 304 (a), ASME B31.3 1.479 mm for PT 25A, per JIS B0203

1.479 mm for PT 40A, per JIS B0203

Where : t : Pressure design wall thickness, inch.

tm : Minimum required thickness, inch

P : Internal design pressure, psi.

D : Outside diameter of pipe, inch, per ASME B36.10M Table 1.

S : Allowable stress for pipe material, psi, per ASME B31.3 Appendix-A.

E : Longitudinal weld joint factor, per ASME B31.3 Appendix-A

W : Weld joint strength reduction factor, per ASME B31.3 Table 302.3.5.

Y : Temperature factor, per ASME B31.3 table 304.1.1 .

C : The sum of mechanical allowances (groove depth and threading) plus allowances for corrosion and errosion, inch

Selected Thickness

Material Selection D S E Y W Calc. Thk, t C Required Thk, tm Status

DN Under mill tolerance Commercial

*Note 1 (inch) (mm) (psi) - - - (inch) (mm) (inch) (mm) (inch) (mm) (inch) (mm) (inch) (mm) Sch *Note 2 Ratio

15A ASTM A106 Grade B, Seamless 0.8 21.3 20000 1 0.4 1 0.003 0.08 0.105 2.66 0.108 2.74 0.128 3.26 0.147 3.73 80 PASS 84%

20A ASTM A106 Grade B, Seamless 1.1 26.7 20000 1 0.4 1 0.004 0.10 0.105 2.66 0.109 2.76 0.135 3.42 0.154 3.91 80 PASS 81%

25A ASTM A106 Grade B, Seamless 1.3 33.4 20000 1 0.4 1 0.005 0.12 0.117 2.98 0.122 3.10 0.157 3.99 0.180 4.56 80 PASS 78%

40A ASTM A106 Grade B, Seamless 1.9 48.3 20000 1 0.4 1 0.007 0.17 0.117 2.98 0.124 3.15 0.175 4.45 0.200 5.08 80 PASS 71%

50A ASTM A106 Grade B, Seamless 2.4 60.3 20000 1 0.4 1 0.009 0.22 0.059 1.50 0.068 1.72 0.135 3.42 0.154 3.91 STD PASS 50%

65A ASTM A106 Grade B, Seamless 2.9 73.0 20000 1 0.4 1 0.010 0.26 0.059 1.50 0.069 1.76 0.178 4.52 0.203 5.16 STD PASS 39%

80A ASTM A106 Grade B, Seamless 3.5 88.9 20000 1 0.4 1 0.013 0.32 0.059 1.50 0.072 1.82 0.189 4.80 0.216 5.49 STD PASS 38%

100A ASTM A106 Grade B, Seamless 4.5 114.3 20000 1 0.4 1 0.016 0.41 0.059 1.50 0.075 1.91 0.207 5.27 0.237 6.02 STD PASS 36%

150A ASTM A106 Grade B, Seamless 6.6 168.3 20000 1 0.4 1 0.024 0.61 0.059 1.50 0.083 2.11 0.245 6.22 0.280 7.11 STD PASS 34%

200A ASTM A106 Grade B, Seamless 8.6 219.1 20000 1 0.4 1 0.031 0.79 0.059 1.50 0.090 2.29 0.282 7.16 0.322 8.18 STD PASS 32%

250A ASTM A53 Grade B, ERW 10.7 273.0 20000 0.85 0.4 1 0.046 1.16 0.059 1.50 0.105 2.66 0.319 8.11 0.365 9.27 STD PASS 33%

300A ASTM A53 Grade B, ERW 12.7 323.8 20000 0.85 0.4 1 0.054 1.38 0.059 1.50 0.113 2.88 0.328 8.34 0.375 9.53 STD PASS 34%

350A ASTM A53 Grade B, ERW 14.0 355.6 20000 0.85 0.4 1 0.060 1.51 0.059 1.50 0.119 3.01 0.328 8.34 0.375 9.53 STD PASS 36%

400A ASTM A53 Grade B, ERW 16.0 406.4 20000 0.85 0.4 1 0.068 1.73 0.059 1.50 0.127 3.23 0.328 8.34 0.375 9.53 STD PASS 39%

450A ASTM A53 Grade B, ERW 18.0 457.0 20000 0.85 0.4 1 0.076 1.94 0.059 1.50 0.136 3.44 0.328 8.34 0.375 9.53 STD PASS 41%

500A ASTM A53 Grade B, ERW 20.0 508.0 20000 0.85 0.4 1 0.085 2.16 0.059 1.50 0.144 3.66 0.328 8.34 0.375 9.53 STD PASS 44%

600A ASTM A53 Grade B, ERW 24.0 610.0 20000 0.85 0.4 1 0.102 2.59 0.059 1.50 0.161 4.09 0.328 8.34 0.375 9.53 STD PASS 49%

650A API 5L Grade B, SAW 26.0 660.0 20000 0.95 0.4 1 0.099 2.51 0.059 1.50 0.158 4.01 0.328 8.34 0.375 9.53 STD PASS 48%

Note 1. Material selection list and available size as per document number :P3FH-PP-9000-SPE-0001 "Specification for Piping Material Class" for each individual line class.

2. If required thickness same or less than selected thickness under mill tolerance, status shall be "PASS".

If required thickness more than selected thickness under mill tolerance, status shall be "FAIL" and must be changed with higher commercial wall thickness.

Anda mungkin juga menyukai

- Pipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)Dokumen1 halamanPipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)farhadBelum ada peringkat

- Pipe Thickness Calculation AS Per ASME 31.3Dokumen11 halamanPipe Thickness Calculation AS Per ASME 31.3Anonymous Iev5ggSRBelum ada peringkat

- HC525x175 Section Weight ChartDokumen31 halamanHC525x175 Section Weight ChartMuhammad Arief RamadhanBelum ada peringkat

- Shree Satyanarayan Industrial Suppliers Pvt. LTD.: Carbon Steel Pipe Hydrostatic Test Calculation SheetDokumen1 halamanShree Satyanarayan Industrial Suppliers Pvt. LTD.: Carbon Steel Pipe Hydrostatic Test Calculation SheetSalman KhanBelum ada peringkat

- Pipe Reinforcement Calculation (ASME-B31.3)Dokumen3 halamanPipe Reinforcement Calculation (ASME-B31.3)jenshid100% (2)

- Design Sheet As Per ASME 31.8 2012 For 12inch TeeDokumen3 halamanDesign Sheet As Per ASME 31.8 2012 For 12inch TeechethanBelum ada peringkat

- uPVC Pipes According to DIN StandardsDokumen7 halamanuPVC Pipes According to DIN Standardsしんちゃん ナカリンBelum ada peringkat

- Anodes in Cooling Water Exchangers PDFDokumen12 halamanAnodes in Cooling Water Exchangers PDFcbrittaivBelum ada peringkat

- ANSI B 16.48 Flange Dimensions for Class 150, 300 and 600Dokumen3 halamanANSI B 16.48 Flange Dimensions for Class 150, 300 and 600l kishoreBelum ada peringkat

- Hydrostatic Test Pressure CalculationDokumen1 halamanHydrostatic Test Pressure Calculationmohd as shahiddin jafriBelum ada peringkat

- AS4041 ASME B31 - 3 Pipe Wall ThicknessDokumen8 halamanAS4041 ASME B31 - 3 Pipe Wall Thicknesscutefrenzy100% (1)

- Thickness Tolerance of API 5L ASTM A53 EN10219 StandardDokumen2 halamanThickness Tolerance of API 5L ASTM A53 EN10219 StandardhungBelum ada peringkat

- Hyundai Pipe CatalogueDokumen36 halamanHyundai Pipe Cataloguefelram100% (2)

- Hydro-Test CalculationDokumen5 halamanHydro-Test CalculationRitu SinghBelum ada peringkat

- Pipe cap thickness and coupling rating calculationsDokumen2 halamanPipe cap thickness and coupling rating calculationsmasaminathanBelum ada peringkat

- Piping Thickness by ScheduleDokumen4 halamanPiping Thickness by SchedulekkabbaraBelum ada peringkat

- IB 2019 HDPE Pipe DeflectionDokumen2 halamanIB 2019 HDPE Pipe DeflectionkavoshyarpajouhanBelum ada peringkat

- Is New Ammedment - 2023123Dokumen26 halamanIs New Ammedment - 2023123mba213Belum ada peringkat

- Hi - Temp 900Dokumen5 halamanHi - Temp 900bhavesh solankiBelum ada peringkat

- Pressure & Temperature ClassificationDokumen1 halamanPressure & Temperature Classificationkeo85100% (1)

- Compressive Strength of Carbon and Graphite: Standard Test Method ForDokumen3 halamanCompressive Strength of Carbon and Graphite: Standard Test Method ForJGD123Belum ada peringkat

- Sa 420Dokumen10 halamanSa 420Widya widyaBelum ada peringkat

- ASTM Testing ProcedureDokumen7 halamanASTM Testing Procedurederecka100% (1)

- As4041 Pressure Piping - Allowable Design PressureDokumen1 halamanAs4041 Pressure Piping - Allowable Design Pressurealvinchuan100% (1)

- Hydrostatic Test Pressure Calculation: Pipe DataDokumen2 halamanHydrostatic Test Pressure Calculation: Pipe DataAkram AlhaddadBelum ada peringkat

- Upvc Pressure Pipe Standard PDFDokumen4 halamanUpvc Pressure Pipe Standard PDFchairul anwarBelum ada peringkat

- HDPE Plastic PipingDokumen7 halamanHDPE Plastic PipingSenghy MaoBelum ada peringkat

- Calc Hoop StressDokumen11 halamanCalc Hoop StressApril TrevinoBelum ada peringkat

- Astm B423 PDFDokumen1 halamanAstm B423 PDFgaminBelum ada peringkat

- Asme b31 3 03 PDFDokumen3 halamanAsme b31 3 03 PDFAtallah BoufatahBelum ada peringkat

- Minimum Fillet Weld Size Per AWS D1.1 TableDokumen2 halamanMinimum Fillet Weld Size Per AWS D1.1 Tableperdhana2000Belum ada peringkat

- Test Bench VC25-SRVDokumen6 halamanTest Bench VC25-SRVYacine Köning100% (1)

- EN 10025 S275 Steel (S275JR, S275J0 & S275J2)Dokumen3 halamanEN 10025 S275 Steel (S275JR, S275J0 & S275J2)MohamedBelum ada peringkat

- Severin FinalDokumen26 halamanSeverin Finalcristasocum_trans1758Belum ada peringkat

- Figure: Pipe Design Concept: S S SS SDokumen2 halamanFigure: Pipe Design Concept: S S SS SNobitaKunBelum ada peringkat

- ASTM A106 GR.B Steel TubeDokumen2 halamanASTM A106 GR.B Steel TubeSpicyBelum ada peringkat

- Global TolerancesDokumen24 halamanGlobal TolerancesSimbu Arasan100% (1)

- Torque-Tension Relationship For ASTM A193 B7 Bolts and StudsDokumen1 halamanTorque-Tension Relationship For ASTM A193 B7 Bolts and StudsSiva Krishna ChaudharyBelum ada peringkat

- SOLENOID VALVE ASCO LowPower - Gseries - R8 PDFDokumen14 halamanSOLENOID VALVE ASCO LowPower - Gseries - R8 PDFNUR AFIFAHBelum ada peringkat

- ASME 2017 SA 312 Sublimentry RequirementsDokumen2 halamanASME 2017 SA 312 Sublimentry RequirementsKathir VelBelum ada peringkat

- B31 3 (Mygaz) - 1Dokumen1 halamanB31 3 (Mygaz) - 1Nasrul AdliBelum ada peringkat

- 8.8 Bolt SpecificationDokumen1 halaman8.8 Bolt SpecificationStephanie FlemingBelum ada peringkat

- Pipe Wall Thickness (ASME B31.3)Dokumen12 halamanPipe Wall Thickness (ASME B31.3)Rachmad HidayatBelum ada peringkat

- ASME VIII Calc - Shell - HeadsDokumen4 halamanASME VIII Calc - Shell - HeadsMuh Safaat100% (1)

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Dokumen15 halamanFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaBelum ada peringkat

- Astm F2620-13 PDFDokumen25 halamanAstm F2620-13 PDFJORGEBelum ada peringkat

- Catalogue - RussiaDokumen21 halamanCatalogue - RussiakarimBelum ada peringkat

- Sno Product Indian British German American Japanese RussianDokumen6 halamanSno Product Indian British German American Japanese Russianyoge1130Belum ada peringkat

- A106 Pipe Spec SheetDokumen7 halamanA106 Pipe Spec SheetyanurarzaqaBelum ada peringkat

- Astm D3282 93 - 260421Dokumen6 halamanAstm D3282 93 - 260421Mark D VillanuevaBelum ada peringkat

- PIPING WALL THICKNESS CALCULATION ASME B31.3Dokumen3 halamanPIPING WALL THICKNESS CALCULATION ASME B31.3Nguyễn DuyBelum ada peringkat

- Pipe Wall Thickness CalculationDokumen1 halamanPipe Wall Thickness Calculationmahesh070Belum ada peringkat

- PIPE THICKNESS CALCULATION FORMULA AND PARAMETERSDokumen2 halamanPIPE THICKNESS CALCULATION FORMULA AND PARAMETERSgherd barkBelum ada peringkat

- Cong Thuc Tinh Toan Piping ThicknessDokumen108 halamanCong Thuc Tinh Toan Piping ThicknessTruong Ngoc SonBelum ada peringkat

- ASME B31 8 Riser CalcDokumen12 halamanASME B31 8 Riser CalcEmmanuel LawrenceBelum ada peringkat

- ASME B31.3.4.8 Wall Thickness CalculatorDokumen26 halamanASME B31.3.4.8 Wall Thickness Calculatoreko123Belum ada peringkat

- WT Calculation - Pipelines With CRA CladDokumen6 halamanWT Calculation - Pipelines With CRA CladShankar VadivelBelum ada peringkat

- ASME B31.8 Wall Thickness CalculationDokumen23 halamanASME B31.8 Wall Thickness Calculationisrar khan100% (2)

- ASME B31.8 Riser CalcDokumen12 halamanASME B31.8 Riser CalcSalz EngineeringBelum ada peringkat

- Pipe Thickness Calculation: Inputs FromDokumen1 halamanPipe Thickness Calculation: Inputs FromBankaiBelum ada peringkat

- Ladders DesignDokumen5 halamanLadders DesignGalih PrianggodoBelum ada peringkat

- Pipe ShoeDokumen1 halamanPipe ShoeGalih PrianggodoBelum ada peringkat

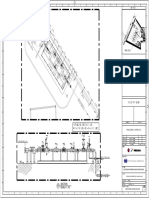

- Piping Plan Bks AllDokumen12 halamanPiping Plan Bks AllGalih Prianggodo100% (1)

- Pipe Rack Loading Data - 2 PDFDokumen55 halamanPipe Rack Loading Data - 2 PDFGalih PrianggodoBelum ada peringkat

- Miyawaki Air Trap AG11 AG12 AGC1VDokumen1 halamanMiyawaki Air Trap AG11 AG12 AGC1VGalih PrianggodoBelum ada peringkat

- Fire Water and Foam Line NumberDokumen30 halamanFire Water and Foam Line NumberGalih PrianggodoBelum ada peringkat

- Tabel StressDokumen6 halamanTabel StressGalih Prianggodo100% (1)

- JIS ListDokumen78 halamanJIS ListGalih Prianggodo100% (2)

- PaintingDokumen1 halamanPaintingGalih PrianggodoBelum ada peringkat

- Piping Plan Bks AllDokumen12 halamanPiping Plan Bks AllGalih Prianggodo100% (1)

- Cryogenics-Gas Liquefaction PDFDokumen16 halamanCryogenics-Gas Liquefaction PDFGalih Prianggodo50% (2)

- CryogenicsDokumen32 halamanCryogenicsGalih PrianggodoBelum ada peringkat

- REQSteel PipeDokumen3 halamanREQSteel PipeGalih PrianggodoBelum ada peringkat

- Req4 Fitting, Flange, GasketDokumen6 halamanReq4 Fitting, Flange, GasketGalih PrianggodoBelum ada peringkat

- Piping Thermal InsulationDokumen21 halamanPiping Thermal InsulationGalih Prianggodo100% (2)

- Specification For Wrapping TapeDokumen17 halamanSpecification For Wrapping TapeGalih Prianggodo100% (2)

- Ladder and StairDokumen1 halamanLadder and StairGalih PrianggodoBelum ada peringkat

- REQSteel PipeDokumen3 halamanREQSteel PipeGalih PrianggodoBelum ada peringkat

- Koordinat Pipe Support Area 2Dokumen4 halamanKoordinat Pipe Support Area 2Galih Prianggodo100% (1)

- 1.1 CS Ball Valve (For Tie-In)Dokumen16 halaman1.1 CS Ball Valve (For Tie-In)Galih PrianggodoBelum ada peringkat

- PSFT-WK-TBEC-40-016B-A4-R.1 (Galvanized Flange) PDFDokumen7 halamanPSFT-WK-TBEC-40-016B-A4-R.1 (Galvanized Flange) PDFGalih Prianggodo100% (1)

- Of Dod 156, 1000: DistributionDokumen30 halamanOf Dod 156, 1000: DistributionSergio_Rangel_9936Belum ada peringkat

- 2 PPT Sumpal Compression ProjectDokumen5 halaman2 PPT Sumpal Compression ProjectGalih PrianggodoBelum ada peringkat

- GA DrawingDokumen4 halamanGA DrawingGalih PrianggodoBelum ada peringkat

- PSFT-WK-TBEC-40-016B-A4-R.1 (Galvanized Flange) PDFDokumen7 halamanPSFT-WK-TBEC-40-016B-A4-R.1 (Galvanized Flange) PDFGalih Prianggodo100% (1)

- Flange Management Procedure FixDokumen13 halamanFlange Management Procedure FixGalih Prianggodo100% (2)

- GA DrawingDokumen4 halamanGA DrawingGalih PrianggodoBelum ada peringkat

- Allowable Nozzle Forces Mome... P-MEP010-B02-00001 - Rev 0ADokumen3 halamanAllowable Nozzle Forces Mome... P-MEP010-B02-00001 - Rev 0AGalih PrianggodoBelum ada peringkat

- GA DrawingDokumen4 halamanGA DrawingGalih PrianggodoBelum ada peringkat

- List of UniversitasDokumen40 halamanList of UniversitasMuhamad Erlangga SaputraBelum ada peringkat

- WideFlange All PDFDokumen19 halamanWideFlange All PDFDede HerdiantoBelum ada peringkat

- Capstone - Design, Installations and Testing of Electrical Systems in BuildingDokumen10 halamanCapstone - Design, Installations and Testing of Electrical Systems in BuildingHaziq10101Belum ada peringkat

- Istanbul Bilgi University Associate and Undergraduate Programs' Tuition Fee StructureDokumen3 halamanIstanbul Bilgi University Associate and Undergraduate Programs' Tuition Fee StructureAISHA AHAMMEDBelum ada peringkat

- A Comprehensible Guide To J1939Dokumen1 halamanA Comprehensible Guide To J1939androBelum ada peringkat

- AcronymsDokumen65 halamanAcronymsSaid TouhamiBelum ada peringkat

- Httpbarbianatutorial.blogspot.comDokumen180 halamanHttpbarbianatutorial.blogspot.comsksarkar.barbianaBelum ada peringkat

- Mtech Environmental EngineeringDokumen12 halamanMtech Environmental EngineeringUrvish VadgamaBelum ada peringkat

- Recent Evolution of Cable-Stayed Bridges: Michel VirlogeuxDokumen19 halamanRecent Evolution of Cable-Stayed Bridges: Michel VirlogeuxprakharBelum ada peringkat

- Iii - Ii It DPPMDokumen20 halamanIii - Ii It DPPMBalajiBelum ada peringkat

- Simplified Assessment of Bending Moment Capacity For RCDokumen11 halamanSimplified Assessment of Bending Moment Capacity For RCAbhishek KumarBelum ada peringkat

- Online ShoppingDokumen54 halamanOnline ShoppingVaryam Pandey50% (6)

- Koseki-4paper Seismic Stability of Reinforced Soil Walls PDFDokumen28 halamanKoseki-4paper Seismic Stability of Reinforced Soil Walls PDFpabulumzengBelum ada peringkat

- Ebook PDF Engineering Graphics Essentials 5th Edition by Kirstie PlantenbergDokumen61 halamanEbook PDF Engineering Graphics Essentials 5th Edition by Kirstie Plantenbergdeborah.sheehan548100% (40)

- Est200 Design and Engineering, December 2021Dokumen2 halamanEst200 Design and Engineering, December 2021publicuse2716Belum ada peringkat

- Hvac Design Manual: First EditionDokumen124 halamanHvac Design Manual: First EditionNathan Tom100% (7)

- Introduction To FACTS Controllers: A Technological Literature SurveyDokumen42 halamanIntroduction To FACTS Controllers: A Technological Literature SurveySEP-PublisherBelum ada peringkat

- Numerical Methods For Engineers LectureDokumen20 halamanNumerical Methods For Engineers Lectureregassa rajiBelum ada peringkat

- Space RoboticsDokumen9 halamanSpace RoboticsRushikesh WareBelum ada peringkat

- Railway Reservation System SDLCDokumen45 halamanRailway Reservation System SDLCChetan RajuBelum ada peringkat

- Quality Control & Quality Assurance Engineer - Job DescriptionDokumen2 halamanQuality Control & Quality Assurance Engineer - Job DescriptioncvssbvBelum ada peringkat

- Comparison of HVDC and AC TransmissionDokumen2 halamanComparison of HVDC and AC Transmissionktkt24Belum ada peringkat

- Checker BoardDokumen9 halamanChecker BoardJoseph JohnBelum ada peringkat

- Top 100 Magazine - DB - FINALDokumen31 halamanTop 100 Magazine - DB - FINALCharlesBelum ada peringkat

- Voltage Profile Improvement, Transmission Line Loss Reduction in Rajasthan Power System: A Case StudyDokumen12 halamanVoltage Profile Improvement, Transmission Line Loss Reduction in Rajasthan Power System: A Case StudyAdvanced Research PublicationsBelum ada peringkat

- Software Architecture PDFDokumen14 halamanSoftware Architecture PDFFrancesHsiehBelum ada peringkat

- B.C.A. (Received On 30.05.2023)Dokumen198 halamanB.C.A. (Received On 30.05.2023)JohnsonBelum ada peringkat

- Statcom BrochureDokumen12 halamanStatcom BrochureLê Mạnh HoàBelum ada peringkat

- SGS IND Construction Material Inspection in India A4 EN 10 PDFDokumen2 halamanSGS IND Construction Material Inspection in India A4 EN 10 PDFIndra MishraBelum ada peringkat