Hazmat Management Plan

Diunggah oleh

Edy WahyudiHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Hazmat Management Plan

Diunggah oleh

Edy WahyudiHak Cipta:

Format Tersedia

Hazardous Materials and Waste Management Plan

EC 01.01.01 EP 5; EC 02.02.01; EC 04.01.01

I PURPOSE

MCG Health, Inc. (MCGHI) is a leader in health care for the state of Georgia and

provides a full spectrum of medical and health care to meet the needs of the citizens of

Georgia. The hospital and clinics are dedicated to (1) the development of professional

and technical knowledge and skills through the provision of an environment in which

students and practitioners gain exemplary clinical experience, and (2) the support of

organized programs of teaching medicine, nursing, dentistry and the allied health

professions.

MCGHI Hazardous Materials and Waste Management Plan describes the process and

mechanisms by which MCGHIs manages hazardous materials and waste in a manner

that protects the health, safety, and environment of patients, staff, and the community.

II SCOPE

The Hazardous Materials and Waste Management process involves the Management of

Chemical, Biological, and Radiological Hazardous Waste.

New employee and annual refresher training is provided to ensure that all employees

receive training in the management of hazardous materials and waste.

The procurement, use, storage, and disposal of hazardous materials and waste is

managed by assigning responsibilities, maintaining inventories, providing access to

hazardous chemical information, and performing regular audits of areas were hazardous

materials and waste are used or generated.

Hazardous gases and vapors are managed according to MCGHI policy and regulatory

requirements.

Emergency procedures for incidents involving hazardous materials and waste have been

established and published in applicable emergency procedures and emergency

response guidelines.

III FUNDAMENTALS

A. The Hazardous Materials and Waste Management Plan at MCGHI is designed to

safely control hazardous chemicals, radioactive materials, biological hazards,

hazardous waste to include radioactive waste, and biomedical waste. The structure

of the program incorporates general organizational policies and procedures further

2010 HazMat Management Plan 1 of 14 Updated January 2010

refined by department specific management policies and procedures.

B. The MCGHI Safety Department is responsible for developing, implementing,

managing and monitoring this plan. The MCG, Radiation Safety Office is responsible

for the radiation safety components of the plan. The plan is based on monitoring and

evaluation of organizational experience, applicable law and regulation, and accepted

practice. The management process involves a continuous cycle of assessment

utilizing a design, teach, implement, measure/evaluate, and improvement that

encompasses the identification, analysis, resolution, and monitoring and evaluation

of hazardous material and waste management related issues within the environment

of care.

C. Protection from hazards requires all staff who use or are exposed to hazardous

materials and wastes, to understand the nature of the hazards and to use equipment

provided for safe handling, use storage, transport, and disposal when working with or

around hazardous materials and wastes.

D. Monitoring of chemical purchasing activities is an effective means for ensuring that

employees are made aware of hazards associated with chemicals and to ensure that

appropriate protective measures are known for handling, transporting, using, storing,

and disposing of the chemical prior to being received.

E. Proper chemical storage is strictly observed to minimize or prevent unnecessary

exposure and accidents.

F. Rapid effective response is required if a spill, release or exposure to a hazardous

material and waste occurs.

G. Segregation of hazardous wastes at the point of generation is an effective means of

controlling potential for exposures or spills during collection, transport, storage and

disposal.

H. Special monitoring processes or systems are often required to manage certain

gases, vapors, or radiation, as they are often undetectable by humans.

IV GOAL

To provide guidance in hazardous materials management, engineering controls, and

work practices that will ensure a safe and healthful environment for MCGHIs patients,

staff and visitors and to protect the environment. The program will ensure that no one is

exposed above safety and healthful limits prescribed by law.

V ORGANIZATION AND RESPONSIBILITY

A. The Board of Directors receives regular reports on the activities of the Hazardous

Materials and Waste Management Program from the Safety Committee via the

Performance Improvement Council. The Board of Directors reviews reports and, as

appropriate, communicates concerns about identified issues and regulatory

2010 HazMat Management Plan 2 of 14 Updated January 2010

compliance. The Board of Directors provides support to facilitate the ongoing

activities of the Hazardous Materials and Waste Program.

B. The Vice President of Facilities receives regular reports of the current status of the

Hazardous Materials and Waste Management Program through the Safety

Committee. The Vice President of Facilities reviews the report and, as necessary,

communicates concerns about key issues and regulatory compliance to the Chair of

the Safety Committee.

C. The Safety Committee is responsible for monitoring all aspects of the Hazardous

Materials and Waste Management Program.

D. Department Directors and Managers are responsible for implementing the

Hazardous Materials and Waste Management Plan in their area of responsibility.

E. All employees are responsible for learning and following job and task specific

procedures for hazardous materials and waste management.

VI PROCESSES OF THE HAZARDOUS MATERIALS AND WASTE MANAGEMENT PLAN

The intent of this plan is to design and implement a management process that

includes all materials and waste that require special handling in order to address

identified occupational and environmental hazards.

A. Orientation and Education (HR 01.02.01, HR 01.04.01, HR 01.05.03)

The Organizational Development and Professional Learning Center has overall

responsibility for coordinating the orientation and education program for each of the

seven functions associated with Management of the Environment of Care.

General orientation is conducted by the Human Resources Department twice

monthly. Each staff member must complete the general orientation during the first

thirty days of employment. The Organizational Development and Professional

Learning Center tracks attendance to ensure compliance. Human Resources

maintains permanent records of participation and performance during orientation.

Each new staff member also participates in a department and job specific orientation.

Department managers are responsible for providing new personnel with a

department specific orientation to the Hazardous Materials and Waste Management

Plan. The goal of the department specific orientation is to provide new personnel

with current information on hazardous materials and waste found at the specific

worksite. New staff is expected to complete departmental orientation within two

weeks of employment.

The staff of MCGHI is required to participate in an annual mandatory training

program. The annual training includes material addressing hazardous material and

waste management. Completing a self-study packet or attending a regularly

scheduled continuing education program can meet the requirement for annual

2010 HazMat Management Plan 3 of 14 Updated January 2010

education. The Organizational Development and Professional Learning Center

tracks participation.

The members of the Safety Committee collaborate with the Organizational

Development and Professional Learning Center and individual department managers

to develop content and materials for general and departmental orientation and for the

annual mandatory program. The educational materials are reviewed at least

annually and are updated as needed.

The MCG EH & S Radiation Safety Office is responsible for the administration of all

training related to radioactive substances as outlined in their Radiation Safety Guide

on Training Requirements.

B. Procurement, Use, Storage, and Disposal of Hazardous Materials and Waste (EC

02.02.01)

Each Department Manager or Supervisor who uses hazardous materials is

responsible for the product from the time it enters the department until the product is

disposed of as waste.

The Radiation Safety Office reviews the procurement, use, storage, and disposal of

radioactive materials and provides approval in accordance with the MCGHI

Radioactive Material License.

Hazardous Chemical Information is available to all employees in either hardcopy at

each worksite, via the MCGHI intranet

Laboratory life safety audits are done monthly. EOC Rounds are conducted annually.

Based on surveys, managers, supervisors and employees are provided with

recommendations for laboratory safety and Personal Protective Equipment (PPE) as

required. Active chemical fume hoods are inspected and certified on an annual

basis, and re-evaluated when moved or structural modifications are done.

C. Inventory (EC 02.02.01, EP 1)

The EH&S Radiation Safety Office maintains an inventory of all radioactive materials

used or stored at MCG and MCGHI. A computerized database system is used for a

cradle to grave tracking of all radioactive materials and waste. This is reviewed by

the MCGHI Radiation Safety Committee on a quarterly basis.

MCGHI Safety Department maintains a computerized Electronic Chemical Tracking

System. Quantity and name of chemical waste is recorded from attached Waste

Tags on receipt.

D. Waste Handling (EC 02.02.01, EP 5- EP 10)

Each department manager or supervisor who generates waste is responsible for

ensuring that the waste is properly disposed of as general, hazardous, biomedical, or

radioactive waste. Departmental managers and supervisors review Material Safety

Data Sheets, the MCGHI chemical information database, and/or confer with the

MCGHI Safety Department to determine proper segregation and disposal methods

2010 HazMat Management Plan 4 of 14 Updated January 2010

for all hazardous materials and waste. Disposal methods must be in compliance with

all federal, state, and local regulations.

Pharmacy Department manages drug waste, which includes chemotherapeutic drug

waste. Drugs classified as hazardous waste are collected by MCGHI Safety

Department for disposal as hazardous waste. Controlled drugs are disposed of in

accordance with applicable laws and regulations.

Facilities Planning manages asbestos containing material. This department

samples, tests and contracts the abatement process overseeing each project.

Included is the coordination of final air testing, material disposal and tracking.

Contractors remove asbestos waste material for proper disposal.

E. Hazardous Gases and Volatile Materials (EP 02.02.01 EP 10)

Areas identified for potential exposure to hazardous gases or volatile materials are

monitored according to MCGHI policy and regulatory requirements. Policies for

hazardous gases and volatile materials are set by the Department of Anesthesiology

to control anesthetic gases in the facility. Physical management of these gases,

including oxygen and Nitrous Oxide, are handled under contract through the

Anesthesiology Department and Supply Administration. Ethylene oxide, in the

Central Supply Area, is monitored by a built in system.

F. Space Management (EP 02.02.01, EP 5-9)

MCGHI Facilities Services is responsible for appropriating space for handling and

storage of hazardous materials and waste for the hospital and clinic areas.

Space appropriations are evaluated by each departmental manager on an as

needed basis. Findings of an evaluation are communicated to the proper managing

facility.

The space appropriations for handling and storage of hazardous materials and waste

is also evaluated as part of the hazard surveillance program. The intent of

evaluating these issues during hazard surveillance is to determine if current

conditions and practices support safe handling and storage of hazardous materials

and waste. A variety of data collection documents are utilized to record observations

and other information related to space appropriations during hazard surveillance

surveys.

Departmental Managers and Supervisors are responsible for initiating action on

findings related to the space appropriations that are applicable to their scope of

responsibility.

G. Incident Reporting (EC 01.01.01 EP 1, EP 8)

The Hazardous Materials and Waste Management Program utilizes the Employees

Report of Accident/Injury Form for reporting and documentation of different types of

accidents or injury. In the even of an exposure and/or injury, the employees

supervisor is to be notified immediately. The employees immediate supervisor must

2010 HazMat Management Plan 5 of 14 Updated January 2010

fill out and Employees Report of Accident/Injury Report Form. If immediate

treatment is required, the employee may seek treatment and complete the form later.

The employee may seek non-emergency treatment at the MCGHI Emergency Room,

or through MCGHIs Employee Health Department. Copies of these reports are

distributed to Personnel Services Division, Public Safety Division, and Employee

Health to support employee health and treatment needs and for tracking purposes.

The employees supervisor must also fill out the Supervisors Follow Up Form within

72 hours.

H. Emergency Procedures (EC 02.02.01 EP 3; EC 04.01.01 EP 8)

The MCGHI Safety Department is responsible for coordinating activities related to

establishing emergency response procedures for Hazardous Materials and Waste

Management operations. Each departmental manager or laboratory supervisor is

responsible for developing area specific emergency procedures, which incorporate

institutional procedures, in conjunction wit the needs of their patients and other

departmental managers.

The Safety Committee has final responsibility for reviewing emergency procedures

related to the operation of processes involving hazardous materials. An Emergency

Response flip chart has been produced and distributed to all departments. Included

in this chart are emergency telephone numbers, instructions on how to activate the

emergency response systems, and instructions on how to respond in the event of a

Medical Emergency, Fire, Radiation Spill, Chemical Spill, Biological Spill, Personal

Injury, and Indoor Environmental Quality problems. Each Manager or supervisor is

responsible for maintaining copies of emergency procedures in a location where their

personnel have ready access and can refer to the procedure during an emergency.

This can be accomplished by displaying the Emergency Response flip chart in all

work areas and near all main line phones. Managers are responsible for providing

their departmental personnel with an orientation to emergency procedures that relate

to their job responsibilities.

Radiation Safety Procedures are available and widely disseminated in a published

MCGHI Radiation Safety Guide. Equipment and kits for significant spills are readily

available, pre-packaged, and located on vehicles ready to be taken to a point of

need. All individuals that work with radioactive materials are trained in spill

procedures before they begin work.

Hazardous material spill procedures are given in the MCGHI Emergency Response

Flipchart. In the event that MCGHI resources are exceeded, the Augusta Fire

Department HAZMAT Team will be contacted. Mercury spills are the responsibility of

the specifically trained technicians in the MCGHI Safety Department. Mercury spills

on patients or patients beds will be cleaned up by trained personnel.

Trained personnel following written procedures in the MCGHI Nursing Manual will

clean all spills of chemotherapeutic drugs on the hospital wards. Trained Pharmacy

staff will clean up spills in the Pharmacy areas following written procedures. All other

areas will be directed to Environmental Services to either clean or provide vendor

resource to clean.

2010 HazMat Management Plan 6 of 14 Updated January 2010

All spills of body fluids, blood, urine excretions, and vomits are cleaned by trained

MCGHI Environmental Services personnel following written procedures.

I. Performance Standard (EC 04.01.01 EP 15; EC 04.01.03 EP 3)

The subcommittee chairs have overall responsibility for coordinating the performance

improvement standard process for each of the seven functions associated with the

Safety Committee.

The Safety committee report summarizes performance compared to the performance

improvement standard. If deficiencies are identified, a plan of action is developed to

address the deficiency. The Safety Committee is responsible for evaluating the

relevance of performance improvement standards.

The performance improvement measurement process is one part of the evaluation of

the effectiveness of the Hazardous Materials and Waste Management Program. A

performance improvement standard has been established to measure one important

aspect of the Hazardous Materials and Waste Management Program. Compliance

with this standard is considered essential to meeting the overall objective of

providing quality support of patient care. The current performance improvement

standard for the Hazardous Materials and Waste Management Program is to

decrease the quantity in pounds of Biomedical Waste generated by MCGHI.

J. Annual Evaluation (EC 04.01.01. EP 15)

The Safety Committee has overall responsibility for coordinating the annual

evaluation process with each of the seven functions associated with Management of

the Environment of Care.

The annual evaluation uses a variety of information sources including the reports

from internal policy and procedure review, incident report summaries, meeting

minutes, Safety Committee reports, and other summaries of activities. In addition,

findings by outside agencies such as accrediting or licensing bodies, community

agencies, or qualified consultants are used. The annual review examines the

objectives, scope, performance, and effectiveness of the Hazardous Materials and

Waste Management Program. The findings of the annual review are presented in a

narrative report supported by relevant data. The report provides a summary of the

Hazardous Materials and Waste Management Program over the preceding 12

months. Strengths are noted and deficiencies are evaluated to set goals for the next

year or longer term future.

The annual review is presented to the Safety Committee by the end of the first

quarter of each year. The Committee reviews and approves the report. The

deliberations and actions and recommendations of the Committee are documented

in the minutes. The annual evaluation is also distributed to the Board of Directors,

the Chief Executive Officer, the Chief Operating Officer, the Quality Assurance and

Improvement Committee, and other department managers as appropriate. Once the

review is final, the Chair, Hazardous Materials and Waste Management

Subcommittee are responsible for implementing the recommendations in the report

as part of the performance improvement process.

2010 HazMat Management Plan 7 of 14 Updated January 2010

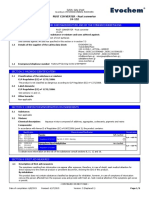

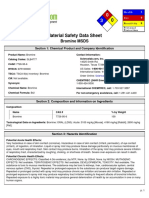

Chemicals: Chemical materials are identified and ordered by department

leadership. Appropriate storage space is maintained by each department, and

reviewed as part of environmental tours in that area. Chemical materials are

maintained in labeled containers, and staff is trained in understanding MSDS, and in

the appropriate and safe handling of the chemicals they use.

Chemical waste is held in the generating department, until weekly pickup by the

MCGHI Safety Department. The waste is stored in the MCGHI Hazardous Waste

Storage Area until the arrival of the licensed waste contractor. The contractor lab

packs the chemicals, completes the manifests, and removes the packaged waste. A

disposal copy of the manifest is returned to verify legal disposal of the waste.

Chemotherapeutic materials: Chemotherapeutic (antineoplastic) medications

and the materials used to prepare, administer, and control these materials are

controlled and the waste materials collected for special disposal. Staff using

these materials is trained in the handling, and emergency response to spills or

leaks.

Chemotherapeutic residual waste is handled as part of the Regulated Medical

Waste stream, with additional labeling to assure appropriate incineration as final

destruction. Larger than residual volumes of chemotherapeutic waste (liquids)

are handled as chemical waste, if not recyclable.

Radioactive materials: These are handled subject to the Georgia State

Radioactive Materials License, and their safety is managed by the Radiation

Safety Officer. Materials are handled in accordance with the requirements of the

facility license.

Radioactive waste is held in a secured and posted room until decayed to

background, then handled as the underlying hazard of the materials for disposal.

The Radiation Safety Officer manages the waste and determines when it is no

longer considered a radioactive hazard.

Infectious and regulated medical wastes, including sharps: These materials

are found throughout the facility. The program is designed to identify, separate,

collect, and control potentially biohazardous materials, and to collect them for

licensed disposal. Staff is trained about handling materials in the regulated

medical wastes program. Labeled and specialized containers are used to collect

and transport these wastes, and all waste removal is manifested.

Regulated Medical Waste, including sharps are picked up by Environmental

Services in patient care areas. The waste is packaged for disposal, and held for

a licensed waste contractor pickup. The contractor assists in completing the

manifests, and removes the waste, returning the disposal copy of the manifest

after final disposal.

Management of Hazardous Materials and Waste Storage Space (EC.02.02.01)

The Safety Manager or delegate assesses the appropriateness of space for handling

2010 HazMat Management Plan 8 of 14 Updated January 2010

and storage of hazardous materials and waste as part of the environmental tour

program. The intent of evaluating these issues during environmental tours is to

determine if current conditions and practices support safe handling and storage of

hazardous materials and waste, and separation of the hazardous waste from clean

and sterile goods and foodstuffs.

Department Heads are responsible for initiating corrective actions on findings related

to the appropriate use of handling and storage spaces in their areas of responsibility.

The Safety Manager provides the Safety Committee with reports of findings and

follow-up action related to appropriate use of space as determined through the

environmental tours program.

Gas and Vapor Monitoring (EC 02.02.01 EP 9-10)

Department Heads are responsible for managing the program for monitoring gases

and vapors. Air contaminants found in during normal use include formaldehyde,

xylene, and gluteraldehyde (i. e., Cidex), ethylene oxide (ETO), and waste anesthetic

gases. Results of current monitoring indicate that exposure levels are below the

regulatory action level. If a monitor result were above the action level, corrective

action and additional testing should be done to demonstrate a safe working

environment.

Emergency Procedures (EC 02.02.01 EP 3)

The Safety Manager develops and maintains emergency procedures for the

Hazardous Materials and Waste program.

MCGHI has organized a spill procedure that evaluates spills to determine if outside

assistance is necessary. A minor (incidental) spill that can be cleaned up by the staff

involved, with their training and personal equipment does not require additional

response. A spill that requires use of spill kits kept in the department is documented,

to assure replacement of the kit contents.

A spill that exceeds the capability of the immediate staff to neutralize and clean up

requires a response from outside the facility. In these cases, the area is evacuated,

ventilation controlled, and a vendor or the Fire Department HAZMAT Team is called.

The Fire Department takes control of the site and cleanup, or arrange for it to be

cleaned up. Once determined safe, hospital staff finish the cleanup and recovery.

Staff, including housekeeping staff, is trained to recognize the potential for a spill that

is not safe to handle, and to contact their manager, and/or the Safety Manager.

During off-shifts, the Administrator on Duty will make the determination. Staff is

cautioned to err on the side of safety, and not to handle chemical spills that exceed

their training, or the personal protection they have available.

Incidents involving spill kits, or a response from any outside agency are documented

on Incident Report Forms, for documentation of the incident.

Documentation of Permits, Licenses, and Manifests (EC 02.02.01 EP 11)

2010 HazMat Management Plan 9 of 14 Updated January 2010

MCGHI has obtained, and maintains permits and licenses for handling and disposal

of hazardous wastes, including chemical wastes, radioactive materials, and

biohazardous (potentially infectious medical wastes) from the appropriate federal,

state, and municipal agencies.

Manifests (EC 02.02.01 EP 11)

The Safety Office is responsible for record keeping. Each load of hazardous waste

removed from the facility is documented by a manifest, as mandated by federal or

state agencies. The manifests have multiple copies, and one is left at the time the

hazardous wastes are removed. Another copy travels with the waste, and is

returned to the hospital once the wastes have been legally disposed of, to document

the completion of the activity. These copies are matched, to assure that no load has

been lost or misplaced, and kept for the record. If a completed copy of the manifest

is not returned within the deadline established by law and regulation, the appropriate

governmental agency is notified, and the information is also shared with the Safety

Committee.

Waste Labeling (EC 02.02.01 EP 12)

All hazardous wastes are labeled from generation to removal. Some wastes, such

as biohazardous wastes (Potentially Infectious Medical Waste-PIMW) are labeled by

placement in a red bag; other wastes are labeled with specific signs or with text

labels.

Biohazardous Waste: These are placed in red bags, and then placed into

cardboard boxes, or plastic bins with external labeling as biohazardous wastes, or in

a labeled rollaway container provided by the vendor, also labeled with the OSHA

Biohazardous labeling and DOC required placarding. The red bags are deemed to

be labeled, as these bags are not used for any other purpose, and any material in a

red bag is treated as biohazardous.

Chemotherapeutic Waste: Chemo wastes are placed into labeled containers

(labeled with the OSHA and international symbol for carcinogenic wastes). These

wastes are handled along with the red bag wastes. Bulk quantities are handled as

chemical waste.

Chemical Materials and Waste: Chemical materials are labeled throughout their

use and handling in the facility. The label is on the container prior to receipt, or is

placed on containers filled or mixed within the hospital. Labeling is evaluated during

environmental tours, to assure the labels are maintained and legible.

Chemical wastes are labeled on the containers. In many cases the waste is labeled

by the original chemical name, in other cases, where collection cans or containers

are used, the container is labeled. These labels are required by the vendors of

chemical disposal services to maintain the identity of the materials, and if the identity

is lost, the materials are tested and analyzed to identify them for proper handling and

disposal.

Radioactive Materials and Waste: Radioactive materials are marked with the

2010 HazMat Management Plan 10 of 14 Updated January 2010

standard magenta and yellow labels having the radiation symbol and storage areas

are appropriately posted. These materials are handled and stored in accordance with

the Georgia State Radioactive Materials regulations and license provisions. Wastes

are held to decay to background, when the labels are removed or covered, and

wastes handled as the other hazards they may reflect.

Separation of Waste Handling Areas (EC 02.02.01)

MCGHI maintains appropriate handling and storage areas for hazardous wastes that

are separated and maintained to minimize the possibility of contamination of food,

clean and sterile goods, or contact with staff, visitors or patients.

Hazardous wastes are moved in covered or closed containers, from holding areas to

the storage space designated for processing and handling those wastes. Those

spaces are inspected periodically, to assure they are adequate for there intended

use, that appropriate equipment and personal protection is available, and that they

remain clean and orderly.

Routing of materials during transport is determined to minimize contact with patients

and visitors, and to protect staff and the facility from contamination. Where food,

clean and sterile materials, and staff are moved on the same transportation vehicle

as wastes (e. g., elevators), scheduling and other practices minimize the potential for

cross contamination.

Regular inspections of the storage areas and of behaviors in transport are included

as part of environmental tours and problems are identified and documented as part

of the environmental tours program.

The organization monitors and improves conditions in the Environment of Care

(EC 04.01.01; EC 04.01.03; EC 04.01.05)

Reporting of Environment of Care Issues (EC 04.01.01 EP 8)

The Director of Safety/Security makes quarterly reports of problems, failures, and

incidents to the Safety Committee. The reports summarize findings of incident

reports, inspection activities and other information of interest.

Collection, Analysis, and Dissemination of Information (EC04.04.01)

The Safety Officer coordinates the collection and analysis of information about each

of the Environment of Care management programs. The information is used to

evaluate the effectiveness of the programs and to improve performance. The

information collected includes deficiencies in the environment, staff knowledge and

performance deficiencies, actions taken to address identified issues, and evidence of

successful improvement activities.

Performance Monitoring (EC 04.01.03 EP 1-3)

The Chairperson of the Safety Committee coordinates the performance

measurement and improvement process for each of the seven functions associated

with management of the EC. The Safety Manager manages the Hazardous

2010 HazMat Management Plan 11 of 14 Updated January 2010

Materials and Waste Program performance measurement process.

The Safety Manager is responsible for preparing quarterly reports of performance

and experience for the Safety Committee. The reports include ongoing

measurement of performance, and summary reports of incidents, including the

results of any Root Cause Analysis (RCA) of Sentinel Events.

The Safety Manager establishes performance indicators to objectively measure the

effectiveness of the Hazardous Materials and Waste Program. The Safety Manager

determines appropriate data sources, data collection methods, data collection

intervals, analysis techniques and report formats for the performance improvement

standards. Human, equipment, and management performance are evaluated to

identify opportunities to improve the Hazardous Materials and Waste Program.

The performance measurement process is one part of the evaluation of the

effectiveness of the Hazardous Materials and Waste Program. A performance

indicator has been established to measure at least one important aspect of the

Hazardous Materials and Waste Program. The FY 2009 performance indicator for

the Hazardous Materials and Waste Program is: "To reduce the total chemical

waste stream by 3% (in alignment with census trends)."

Annual Review of Management Plans (EC 04.01.01 EP 15)

The Safety Officer and managers responsible for the design and implementation of

the EC programs perform an annual review of each EC management plan. The

review evaluates the content of the plan to determine if changes in organization

structure, scope of services, or other changes create a need to update the plan.

Annual Program Evaluation (EC.04.01.01 EP 15)

The Chairperson of the Safety Committee is responsible for coordinating the annual

evaluation of the seven functions associated with Management of the Environment of

Care. The Safety Manager is responsible for performing the annual evaluation of the

Hazardous Materials and Waste Program.

Annual evaluations examine the scope, objectives, performance, and effectiveness

of the Hazardous Materials and Waste Program. The annual evaluation uses a

variety of information sources including: internal policy and procedure review,

incident report summaries, safety meeting minutes, Safety Committee reports, and

summaries of other activities. In addition, findings by outside agencies such as

accrediting or licensing bodies, or qualified consultants are used. The findings of the

annual evaluation are presented in a narrative report supported by relevant data.

The report provides a summary of the Hazardous Materials and Waste Program

performance over the preceding 12 months. Strengths are noted and deficiencies

are evaluated to set goals for the next year.

The annual evaluation is presented to the Safety Committee. The Committee

reviews and approves the report. The deliberations, actions, and recommendations

of the committee are documented in the minutes. The annual evaluation is

distributed to the Chief Executive Officer, the Performance Improvement Committee,

and other Department Heads as appropriate. Once the evaluation is finalized, the

2010 HazMat Management Plan 12 of 14 Updated January 2010

Safety Manager is responsible for implementing the recommendations in the report

as part of the performance improvement process.

Patient Safety (EC 01.01.01 EP 1-2) (EC 02.01.01 EP 1) (EC 04.01.01 EP 1)

The Safety Officer is responsible for working with the Patient Safety Officer who is

responsible for patient safety to integrate EC monitoring and response activities into the

patient safety program. The integration includes conducting risk assessments to identify

environmental threats to patient safety, conducting environmental rounds to evaluate

patient safety concerns on an ongoing basis, participating in the analysis of patient

safety incidents, participating in the development of material for general and job-related

orientation and on-going education.

The Organization analyzes identified Environment of Care issues and develops

recommendations for resolving them (EC. 04.01.03) (EC 04.01.01 EP 3-6)(EC 04.01.05)

The multidisciplinary Safety Committee considers reports of Environment of Care issues

at regularly scheduled meetings. The committee evaluates the reports and approves

actions to address identified issues.

The Safety Committee meets at least six times per year to address EC, risk

management, patient safety, quality, and other business as appropriate.

Managers of each EC function and the Safety Committee collaborate to analyze EC

issues. The analysis includes ongoing analysis of performance and aggregate analysis

of environmental tours, incident reports, maintenance activities, and other issues.

The analysis is used to manage the stability of current programs, assess risks related to

new programs, and to identify opportunities for improvement.

The Safety Committee publishes minutes of each meeting. The minutes summarize

materials presented, issues identified, and actions to be taken. The minutes also include

a tracking log designed to assure management of all activities until they are resolved.

Managers of each EC function are responsible for identifying important measures of

environmental or patient safety or of program management. The measures are used to

evaluate performance on an ongoing basis, to measure the success of implementation

of performance improvement activities and to develop an understanding of processes

that are no meeting expectations.

Minutes and relevant supporting materials are communicated to all EC and organization

leaders. All managers are required to read the materials and respond as appropriate.

When EC managers and the Safety Committee identify performance improvement

opportunities, a proposal for improvement is prepared and sent to leadership. The

leadership reviews all improvement proposals and determines the priority and need for

the proposed improvement.

When leadership approves a proposal for improvement, appropriate staff or a team is

appointed to address the identified issues and to design a process improvement. The

2010 HazMat Management Plan 13 of 14 Updated January 2010

staff or team appointed make regular reports to the Safety Committee and leadership.

The reports address progress toward improvement, including measurement of changes

to assure they are effective and sustainable.

The minutes of the Safety Committee are presented to the Performance

Improvement Council at its regular meetings. Issues of interest to the Performance

Improvement Council are presented for discussion and action as appropriate. The

minutes of and issues identified by the Patient Safety Committee are handled in the

same manner before the Safety Committee.

Orientation, Training, and Education (HR 01.02.01) (HR 01.04.03) (HR 01.05.03)

All staff must attend new employee orientation within 10 days of hire. New employee

orientation addresses key issues and objectives of all seven areas of the EC

including the role each area and staff play in the overall patient safety program.

Employees also receive departmental safety orientation at their respective work

areas regarding hazards and their responsibilities to patients, visitors, and co-

workers. In addition, all staff participates in periodic refresher training relative to the

EC.

CC: Safety Committee (Reviewed & Approved-)

JCC to Board (Reviewed & Approved-)

2010 HazMat Management Plan 14 of 14 Updated January 2010

Anda mungkin juga menyukai

- 13 Emergency Response: Project Employer Engineer ContractorDokumen9 halaman13 Emergency Response: Project Employer Engineer ContractorcenkunalBelum ada peringkat

- RA - Risk Assessment - Surveying and Pegging - 2021Dokumen4 halamanRA - Risk Assessment - Surveying and Pegging - 2021Asakundwi Mukhwa100% (1)

- Sop Hazmat Response PlanDokumen20 halamanSop Hazmat Response PlanChristian MakandeBelum ada peringkat

- Social Management PlanDokumen46 halamanSocial Management PlanNilamSanjeev Kumar SinghBelum ada peringkat

- Safety Health Emergency Response ProcedureDokumen2 halamanSafety Health Emergency Response Procedurearjuna rahmat100% (1)

- Environmental Compliance ChecklistDokumen5 halamanEnvironmental Compliance ChecklistNIJESH100% (1)

- Flooding Fast Facts: What Is A Flood?Dokumen5 halamanFlooding Fast Facts: What Is A Flood?George KingBelum ada peringkat

- ED2 SampleDokumen53 halamanED2 SampleadelBelum ada peringkat

- 88Dokumen60 halaman88muthuswamy77Belum ada peringkat

- ESMPDokumen21 halamanESMPdavid chisambaBelum ada peringkat

- Sample AHADokumen55 halamanSample AHAdavidbteammira100% (3)

- 10 Site RulesDokumen5 halaman10 Site Rulesابو محمد علي100% (1)

- General Risk Assessment FormDokumen8 halamanGeneral Risk Assessment FormmkmusaBelum ada peringkat

- Hazard Identification and Risk Control-TemplateDokumen2 halamanHazard Identification and Risk Control-TemplateShristika Pradhan100% (1)

- Personal Protective Equipment ProceduresDokumen3 halamanPersonal Protective Equipment ProceduresLwandziso DlaminiBelum ada peringkat

- Risk AssessmntDokumen5 halamanRisk Assessmntapi-456358200Belum ada peringkat

- Risk Assesssment-Vinyl & Tile Floor InstallationDokumen2 halamanRisk Assesssment-Vinyl & Tile Floor InstallationMunaku TafadzwaBelum ada peringkat

- Tun Razak Exchange, Retail Plot 1: Appendix 4 - Emergency Response PlanDokumen32 halamanTun Razak Exchange, Retail Plot 1: Appendix 4 - Emergency Response PlanMatthew Mohan PerumalBelum ada peringkat

- CONST-PK-HSE FRM-38 Environmental Risk Assessment and Control FormDokumen6 halamanCONST-PK-HSE FRM-38 Environmental Risk Assessment and Control FormPerwez21Belum ada peringkat

- Hazardous WasteDokumen16 halamanHazardous WasteJasonBelum ada peringkat

- Environmental Management PlanDokumen14 halamanEnvironmental Management Plansafak ışıkBelum ada peringkat

- Objectives and TargetsDokumen2 halamanObjectives and TargetsZohaib TahirBelum ada peringkat

- Home Office-Dealing With DisasterDokumen104 halamanHome Office-Dealing With DisastervilladoloresBelum ada peringkat

- Toolbox Talks 2Dokumen100 halamanToolbox Talks 2Shafick GabungaBelum ada peringkat

- FormsDokumen134 halamanFormstaisiermed.safety100% (1)

- Flood Mitigation PlanningDokumen14 halamanFlood Mitigation PlanningJingBelum ada peringkat

- Guide Lines For NSC HSE PlanDokumen52 halamanGuide Lines For NSC HSE Planജിനാദ് അബ്ദുസ്സലാംBelum ada peringkat

- HSE Procedures Hseprof ComDokumen121 halamanHSE Procedures Hseprof ComMansoor BabbarBelum ada peringkat

- GoodHousekeepingPractices HazardousWasteManagementDokumen4 halamanGoodHousekeepingPractices HazardousWasteManagementNuragus Hariyadi100% (1)

- Emergency Contingency PlanDokumen14 halamanEmergency Contingency PlanClarence PieterszBelum ada peringkat

- CIV510 - Management of Temporary WorksDokumen14 halamanCIV510 - Management of Temporary Worksezzularab100% (1)

- HIRAC TemplateDokumen45 halamanHIRAC TemplateMadelo, Allysa Mae, M.Belum ada peringkat

- SCP109 - Risk Assessment For Glass Partition EditedDokumen4 halamanSCP109 - Risk Assessment For Glass Partition EditedamenmohdBelum ada peringkat

- Chemical Waste Disposal ProcedureDokumen5 halamanChemical Waste Disposal ProcedureHussain AhmadBelum ada peringkat

- Project Health Safety and Environmental HSE Plan With All Forms - Method Statement HQDokumen3 halamanProject Health Safety and Environmental HSE Plan With All Forms - Method Statement HQsvsrnbBelum ada peringkat

- HSE-RA-064 Control of Hazardous - Substances - Rev 0Dokumen13 halamanHSE-RA-064 Control of Hazardous - Substances - Rev 0عمروBelum ada peringkat

- Apendix 13-HSE Plan ManualDokumen50 halamanApendix 13-HSE Plan ManualShahid IqbalBelum ada peringkat

- EP06Dokumen5 halamanEP06Chrome PicassoBelum ada peringkat

- Ohs Legal - Ohsa Act 1994Dokumen1 halamanOhs Legal - Ohsa Act 1994Nurul HidayahBelum ada peringkat

- Incident Investigation ReportDokumen4 halamanIncident Investigation ReportABGM SalemBelum ada peringkat

- Activity Hazard Analysis FinalDokumen23 halamanActivity Hazard Analysis FinalPedro PereiraBelum ada peringkat

- CPWD Maintenance Manual 2019Dokumen81 halamanCPWD Maintenance Manual 2019pawan2scribdBelum ada peringkat

- Ide Guide Sep 16 Spec v4Dokumen56 halamanIde Guide Sep 16 Spec v4Manish KumarBelum ada peringkat

- Hse PlanDokumen99 halamanHse Planjayesh utekarBelum ada peringkat

- Painting, Taping, Texturing or Epoxy CoatingsDokumen1 halamanPainting, Taping, Texturing or Epoxy CoatingsHenryOdohBelum ada peringkat

- Risk Assessment - Mobile Crane Operations - 2021Dokumen3 halamanRisk Assessment - Mobile Crane Operations - 2021Asakundwi MukhwaBelum ada peringkat

- Lead Exposure Control PlanDokumen3 halamanLead Exposure Control PlanShahzeb HassanBelum ada peringkat

- AHA-004, Earth Work Site PrepDokumen6 halamanAHA-004, Earth Work Site PrepBuddhikaBelum ada peringkat

- OS 1.5 Pollution PreventionDokumen9 halamanOS 1.5 Pollution PreventionclintBelum ada peringkat

- Incident-sharing-and-Statistics-Standard-10.2018 OPALDokumen28 halamanIncident-sharing-and-Statistics-Standard-10.2018 OPALSHRISH SHUKLA100% (1)

- Worker WelfareDokumen2 halamanWorker WelfareNibu P ShajiBelum ada peringkat

- Guidelines For Personal Protective Equipment (Ppe) : JUNE 2020Dokumen40 halamanGuidelines For Personal Protective Equipment (Ppe) : JUNE 2020Tanri Andita Wicaksono100% (1)

- H S ChecklistDokumen17 halamanH S ChecklistkhajaimadBelum ada peringkat

- Contract Environmental Management Plan: Generic Shire CouncilDokumen46 halamanContract Environmental Management Plan: Generic Shire Councilmjvw100% (1)

- HSE AuditingDokumen20 halamanHSE AuditingMuhammad AbdullahBelum ada peringkat

- Hard Land Scape Risk AssessmentDokumen4 halamanHard Land Scape Risk AssessmentvivekanandhanBelum ada peringkat

- Coshh Assessment FormDokumen4 halamanCoshh Assessment FormLsri MurthyBelum ada peringkat

- Safety in the Chemical Laboratory and Industry: A Practical GuideDari EverandSafety in the Chemical Laboratory and Industry: A Practical GuideBelum ada peringkat

- Psycho TriageDokumen49 halamanPsycho TriageEdy WahyudiBelum ada peringkat

- Graduate Trainee Program: What We Offer All Over IndonesiaDokumen1 halamanGraduate Trainee Program: What We Offer All Over IndonesiaMohamadHabibiBelum ada peringkat

- Explanation Cardiac TriageDokumen2 halamanExplanation Cardiac TriageHendraDarmawanBelum ada peringkat

- Ppe FactsheetDokumen2 halamanPpe FactsheetYulianti KosasihBelum ada peringkat

- Hazardous Materials Management Plan SMDokumen26 halamanHazardous Materials Management Plan SMdarmayunitaBelum ada peringkat

- Triage ATS PDFDokumen7 halamanTriage ATS PDFkalembrowBelum ada peringkat

- A Triage Scale PDFDokumen13 halamanA Triage Scale PDFQueeiin NeeshaBelum ada peringkat

- Aust Triage ScaleDokumen3 halamanAust Triage ScalemutiaBelum ada peringkat

- Daftar PustakaDokumen5 halamanDaftar PustakaEdy WahyudiBelum ada peringkat

- Sikadur® 52 Part A: Safety Data SheetDokumen11 halamanSikadur® 52 Part A: Safety Data Sheetjoker batmanBelum ada peringkat

- Msds Whisper VDokumen11 halamanMsds Whisper VEndri SudrajatBelum ada peringkat

- Întrebările 1 - 10 Pentru: TTM - Tehnica Transportului MaritimDokumen261 halamanÎntrebările 1 - 10 Pentru: TTM - Tehnica Transportului MaritimAlex BarbanBelum ada peringkat

- Oxy-Sept333 MSDS (Peracetic Acid) Poultry Egg PDFDokumen12 halamanOxy-Sept333 MSDS (Peracetic Acid) Poultry Egg PDFvasudevBelum ada peringkat

- Cleanser 20180606Dokumen4 halamanCleanser 20180606esensialaboratBelum ada peringkat

- MS0800288 Angh enDokumen5 halamanMS0800288 Angh enSeason AkhirBelum ada peringkat

- DOE Order 460dDokumen16 halamanDOE Order 460dBryan JonesBelum ada peringkat

- Msds Tetrahydrofluran (Lem PVC)Dokumen6 halamanMsds Tetrahydrofluran (Lem PVC)ReniBelum ada peringkat

- Housekeeping Procedures: Why Should We Pay Attention To Housekeeping at Work?Dokumen4 halamanHousekeeping Procedures: Why Should We Pay Attention To Housekeeping at Work?Selva KumarBelum ada peringkat

- Turmoxygen Lco 27 MSDS enDokumen6 halamanTurmoxygen Lco 27 MSDS enJavier Fernando Marquez RamosBelum ada peringkat

- Calcium Borate CAS No 13701-64-9: Material Safety Data Sheet Sds/MsdsDokumen6 halamanCalcium Borate CAS No 13701-64-9: Material Safety Data Sheet Sds/MsdsMariaCamilaGomezBelum ada peringkat

- OHSE Subbypack Contractors ARSDokumen43 halamanOHSE Subbypack Contractors ARSrumplestilkinsBelum ada peringkat

- Dow Corning Corporation Material Safety Data SheetDokumen7 halamanDow Corning Corporation Material Safety Data SheetSalvador NegreteBelum ada peringkat

- MSDS Rust Converter 2016 enDokumen9 halamanMSDS Rust Converter 2016 enDimitrios KolovosBelum ada peringkat

- Msds BR PDFDokumen7 halamanMsds BR PDFBruno FanyBelum ada peringkat

- Loading InstructionsDokumen27 halamanLoading InstructionsGuilherme LopesBelum ada peringkat

- Emergency Response Requirements Around The WordDokumen15 halamanEmergency Response Requirements Around The WordJuan VergaraBelum ada peringkat

- Instructions On Installation, Operation and Maintenance For Kirloskar Pump Type DBDokumen27 halamanInstructions On Installation, Operation and Maintenance For Kirloskar Pump Type DBDipesh ParekhBelum ada peringkat

- MSDS DR - DR - Disinfectant Multi Enzyme Detergent1Dokumen4 halamanMSDS DR - DR - Disinfectant Multi Enzyme Detergent1ralothaimeen.mohBelum ada peringkat

- Correlation Between GHS and New Zealand HSNO Hazard Classes and CategoriesDokumen6 halamanCorrelation Between GHS and New Zealand HSNO Hazard Classes and CategoriesLaura Marcela Guarin QuinteroBelum ada peringkat

- Material Safety Data Sheet: CombitreatDokumen5 halamanMaterial Safety Data Sheet: CombitreatJezrell JaravataBelum ada peringkat

- Biostone C 20 - SDSDokumen10 halamanBiostone C 20 - SDSchoton_iiiBelum ada peringkat

- Safety Data Sheet Diffu - Therm Diffusions - Rot BDR (Aerosol) 1. Identification of SubstanceDokumen5 halamanSafety Data Sheet Diffu - Therm Diffusions - Rot BDR (Aerosol) 1. Identification of Substanceazam RazzaqBelum ada peringkat

- Your Electronic Ticket ReceiptDokumen2 halamanYour Electronic Ticket ReceiptSekretariat DaerahBelum ada peringkat

- Comfort PEN - (V5.3) - EN-SDSDokumen6 halamanComfort PEN - (V5.3) - EN-SDSMd. Monirul IslamBelum ada peringkat

- Sds FB 961 E - 20230329Dokumen6 halamanSds FB 961 E - 20230329Agus Mr MrBelum ada peringkat

- NGL 17 40 P SP STCV - MSDS - GUS - ENDokumen11 halamanNGL 17 40 P SP STCV - MSDS - GUS - ENThálitaS.PereiraBelum ada peringkat

- Design, Construction, and Evaluation of A Fuel Tank/Tool Box CombinationDokumen43 halamanDesign, Construction, and Evaluation of A Fuel Tank/Tool Box CombinationEng Ȝḿr ȜḿấdBelum ada peringkat

- 1 Actividad de Aprendizaje 6 Evidencia 5: Reading Workshop: International TransportDokumen7 halaman1 Actividad de Aprendizaje 6 Evidencia 5: Reading Workshop: International TransportDiego JimenezBelum ada peringkat

- ImistDokumen33 halamanImistprakashBelum ada peringkat