Bio Concrete Prevents RCC Corrosion with Bacteria

Diunggah oleh

Rakib HossainDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Bio Concrete Prevents RCC Corrosion with Bacteria

Diunggah oleh

Rakib HossainHak Cipta:

Format Tersedia

Prevention of Corrosion in Reinforced Cement Concrete (RCC) by Bacteria

Prepared By MD. Rakib Hossain and MD. Shaharul Islam

Department of Civil Engineering, Bangladesh University of Engineering and Technology.

Introduction 2Fe(OH)3 > Fe2O3.H2O+2H2O [Hydrated Ferric Oxide or Rust] Prevention of corrosion

There is a relative percentage for what corrosion of RCC is occurred

Steel gets oxidized (corrosion) in the present of oxygen and water.

is as follows:

Bio Concrete:

Even present of oxygen in the concrete pore will not cause a corro- The bacteria and Ca(OH)2 of pH 13 is added to the concrete

sion at high alkaline environment. Concrete contains microscopic

Bacteria are Bacillus Alkali-nitrulicus, Psychrophilic Bacterium,

pores which contain high concentrations of soluble calcium, sodium

Bacillus Pasteurii .

and potassium oxides, this creates alkaline condition of pH 1213.

The alkaline condition leads to a passive layer forming on the steel Survive at high pH of 9 to 13 and at the temperature range of 10 to

surface. The dense passive layer over the reinforcement prevents the 40 degree centigrade.

alkalinity. This poster involves in the prevention of corrosion by Bacteria get active with water and Ca(OH)2 with CO2

maintaining alkalinity in concrete by using bacteria. CO2 + Ca(OH)2 -> CaCO3 + H2O

Figure: Relative Volume of Iron (Fe) and its oxide from Mansfield Corrosion,1981,37

Corrosion process (5): 301-307 Diffusion of CO2:

Anhydrate Fe2O3 has a volume of about twice that of the steel. Diffusion is mass transport down a concentration gradient. Steady

When the passive layer breaks down then rust will start appearing on

the steel surface. When steel in concrete corrodes it dissolves in the When it becomes hydrated it swells even more and becomes po- state diffusion follows Ficks first law

pore water and gives up electrons: rous.

The anodic reaction is: Fe (s) > Fe

2+

(aq)+ 2e Increase volume at the steel or concrete interface is six to ten

The two electrons (2e) created in the anodic reaction must be con- times .

sumed elsewhere on the steel surface to preserve electrical neutrality. Leads to the cracking and Spalling as shown in figure below;

The cathodic reaction is: H2O +0.5O2 +2e >2OH Water cement ratio to reduce D :

The ion dissolve in the pore water. spalling of the concrete. w/c ratio =0.38

Several more stages must occur for rust to form. Using admixtures

Ferrous hydroxide becomes ferric hydroxide and then hydrated fer- 23% bound water

ric oxide or rust.

Using plasticizer for workability

Cause spalling and crack over the concrete.

Plasticizer increases the strength

up to optimum level above that

Figure: Schematic of corrosion induced spalling at corners and delamination at the it decreases the strength.

plane of the reinforcement.

Conclusion:

Carbonation: Carbonation is the result of the interaction of carbon

Even through, we had a good design, material and scheduling it is impossible to

dioxide gas in the atmosphere with the alkaline hydroxides in the attain strength and durability without good workman ship. For an example Ma-

concrete. san will add water in mortar and shovel it. For any RCC structure, corrosion is a

great threat to its durability and serviceability. To ensure proper durability for

Figure: Anode and Cathode Reaction of Corroding Bar

which it has been built, we need to ensure prevention of corrosion and using

2+

Now lets see the reaction of Fe and OH formed in anode and cath- bacteria in concrete is one of the solution to protect RCC from corrosion with-

ode combined to form ferrous hydroxide and further undergoes out affecting its strength.

chemical reaction as below: References:

1) John P. Broomfield; Corrosion of Steel in Concrete Understanding, investigation and repair, Taylor & Francis 270 Madison Ave,New York,NY 10016.

2+

Fe (aq) +2OH > Fe(OH)2 [ Ferrous Hydroxide] 2) M.S. Shetty; concrete technology theory and practices, S.Chandra and company ltd, Ram nagar , new Delhi.

3) IS10262-2007 Recommended Guidelines for Concrete Mix Design, Bureau of Indian Standards, New Delhi, 2007.4)en.wikipedia.org/wiki/Corrosion

5)https://www.google.com/search?q=prevention-of-corrosion-in-rcc-by-bacteria.html&sourceid=chrome&ie=UTF-8 .6)http://www.engineeringcivil.com/

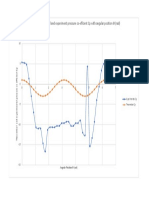

4Fe(OH)2+O2+2H2O > 4Fe(OH)3 [ Ferric Hydroxide] Figure: Reaction of Carbonation Figure: Quantity of Rust(%) Versus pH graph 7) Bjrn Lagerblad Carbon dioxide uptake during concrete life cycle State of the art, ISBN 91-976070-0-2, ISSN 0346-8240.

8) Ravindranatha, N. Kannan, Likhit M, Self-healing material bacterial concrete,IJRET: International Journal of Research in Engineering and Technology, eISSN: 2319-1163 | pISSN: 2321-

7308.

Anda mungkin juga menyukai

- Hydrogen in Steel: Effect of Hydrogen on Iron and Steel During Production, Fabrication, and UseDari EverandHydrogen in Steel: Effect of Hydrogen on Iron and Steel During Production, Fabrication, and UseBelum ada peringkat

- REINFORCEMENT CORROSION IN CONCRETE AND REMEDIAL MEASURESDokumen29 halamanREINFORCEMENT CORROSION IN CONCRETE AND REMEDIAL MEASURESSubhrangshu MondalBelum ada peringkat

- Cat2 DharDokumen6 halamanCat2 DharDhaarini SriBelum ada peringkat

- Concrete Deterioration Due to Reinforcement Corrosion(continueDokumen22 halamanConcrete Deterioration Due to Reinforcement Corrosion(continueHacking SoftwareBelum ada peringkat

- Results: Chloride Threshold Value For Corrosion of Steel in ConcreteDokumen1 halamanResults: Chloride Threshold Value For Corrosion of Steel in ConcreteOat GTBelum ada peringkat

- Embedded Metal Corrosion: National Forensic Sciences UniversityDokumen19 halamanEmbedded Metal Corrosion: National Forensic Sciences UniversityGandhi SagarBelum ada peringkat

- Design Approach For DurabilityDokumen75 halamanDesign Approach For DurabilityvicksBelum ada peringkat

- Hot DipDokumen1 halamanHot DipKartik MahajanBelum ada peringkat

- Irfan Ali Corrosion in ConcreteDokumen29 halamanIrfan Ali Corrosion in ConcreteWaqas AhmedBelum ada peringkat

- Corrosion of Steel in Concrete 2Dokumen14 halamanCorrosion of Steel in Concrete 2Irvebry Ayu WulandaryBelum ada peringkat

- Repair of Corrosion Affected Reinforced Concrete StructuresDokumen8 halamanRepair of Corrosion Affected Reinforced Concrete StructuresManjunatha GBelum ada peringkat

- Filming Corrosion Inhibitor For Oil and Gas Field PDFDokumen20 halamanFilming Corrosion Inhibitor For Oil and Gas Field PDFPabel Lema100% (1)

- Filming Corrosion Inhibitor For Oil and Gas FieldDokumen20 halamanFilming Corrosion Inhibitor For Oil and Gas FieldelsyakiebBelum ada peringkat

- Carbonation Induced CorrosionDokumen3 halamanCarbonation Induced CorrosionSiti Rohani IsdrisBelum ada peringkat

- Corrosion Inhibitor For Reinforced Concrete - 3Dokumen5 halamanCorrosion Inhibitor For Reinforced Concrete - 3Meta ChemBelum ada peringkat

- CME Session 30 July 2022Dokumen125 halamanCME Session 30 July 2022Amol D PawarBelum ada peringkat

- Corrosion of Steel ReinforcementDokumen5 halamanCorrosion of Steel ReinforcementSiti Rohani IsdrisBelum ada peringkat

- DurabilityDokumen17 halamanDurabilitycivil departmentBelum ada peringkat

- Mechanism of Corrosion in Reinforced Cement ConcreteDokumen18 halamanMechanism of Corrosion in Reinforced Cement ConcretejoshjethBelum ada peringkat

- Session 6 CORROSIONDokumen123 halamanSession 6 CORROSIONAmol D PawarBelum ada peringkat

- ch02 PDFDokumen4 halamanch02 PDFManimaran SellamuthuBelum ada peringkat

- Corrosion of Embedded MetalsDokumen6 halamanCorrosion of Embedded MetalsBose CatBelum ada peringkat

- Sika FerroGard-903 PlusDokumen8 halamanSika FerroGard-903 PlusrogirosBelum ada peringkat

- Deterioration of Reinforced Cement Concrete: Lecture-3-4Dokumen26 halamanDeterioration of Reinforced Cement Concrete: Lecture-3-4Pratyush MishraBelum ada peringkat

- BS-88R 2018 Literature On Corrosion Protection in Concrete StructuresDokumen48 halamanBS-88R 2018 Literature On Corrosion Protection in Concrete StructuresM PMBelum ada peringkat

- Mhairul, (8) 737-2467-1-RV (Sallehuddin) - PublishDokumen8 halamanMhairul, (8) 737-2467-1-RV (Sallehuddin) - PublishNUR ADDILAH BINTI ABDUL RAHMANBelum ada peringkat

- Corrosion Inhibitor For BeginnerDokumen98 halamanCorrosion Inhibitor For BeginnerYogalingam ArumugamBelum ada peringkat

- Concrete - Technology (CH 7)Dokumen10 halamanConcrete - Technology (CH 7)Technical Tik-Tok VideoBelum ada peringkat

- Causes of Concrete Reinforcement Corrosion and Their RepairDokumen124 halamanCauses of Concrete Reinforcement Corrosion and Their RepairPritha DasBelum ada peringkat

- Corrosion CAUSES and MECHANISM Arumugam Anna University, Chennai, IndiaDokumen76 halamanCorrosion CAUSES and MECHANISM Arumugam Anna University, Chennai, Indiadeviprasadh.a100% (3)

- Corrosion Protection Methods for Steel Reinforced ConcreteDokumen23 halamanCorrosion Protection Methods for Steel Reinforced ConcreteMohammad AL HaririBelum ada peringkat

- Chloride Attack of Reinforced ConcreteDokumen8 halamanChloride Attack of Reinforced ConcreteBraydon GoyetteBelum ada peringkat

- Penthouse Fall 1996Dokumen2 halamanPenthouse Fall 1996John M. CavoteBelum ada peringkat

- Keep Your Ship in Top Shape with Transocean CoatingsDokumen30 halamanKeep Your Ship in Top Shape with Transocean CoatingsJoanna BaileyBelum ada peringkat

- K2 0-Corrosion PDFDokumen49 halamanK2 0-Corrosion PDFsyahmi azharBelum ada peringkat

- Properties of MaterialsDokumen8 halamanProperties of MaterialsajayBelum ada peringkat

- Corrosion of Steel Reinforcement in ConcreteDokumen18 halamanCorrosion of Steel Reinforcement in ConcreteSabitha RaaviBelum ada peringkat

- Case Studies in Construction MaterialsDokumen10 halamanCase Studies in Construction MaterialsKarri SrinivasBelum ada peringkat

- CarbonCure Whitepaper Impact of CO2 Utilization in Fresh Concrete On Corrosion of Steel ReinforcementDokumen6 halamanCarbonCure Whitepaper Impact of CO2 Utilization in Fresh Concrete On Corrosion of Steel ReinforcementSakineBelum ada peringkat

- Mechanism of Corrosion in Reinforced Cement ConcreteDokumen14 halamanMechanism of Corrosion in Reinforced Cement ConcretejoshjethBelum ada peringkat

- Durability of ConcreteDokumen38 halamanDurability of ConcreteMatsobane LekalaksBelum ada peringkat

- Corrosion and Protection of Steel Reinforced ConcreteDokumen51 halamanCorrosion and Protection of Steel Reinforced Concreteprojectcching8372Belum ada peringkat

- Concrete CorrosionDokumen4 halamanConcrete CorrosionAhmadYossryMuham'madBelum ada peringkat

- Types of Corrosion: Dr. Hamdy A. KandilDokumen53 halamanTypes of Corrosion: Dr. Hamdy A. KandilAmyBelum ada peringkat

- Surface & Coatings Technology: G.G. Wang, L.Q. Zhu, H.C. Liu, W.P. LiDokumen5 halamanSurface & Coatings Technology: G.G. Wang, L.Q. Zhu, H.C. Liu, W.P. LiSiti MusabikhaBelum ada peringkat

- Hydrogen EmbittlementDokumen8 halamanHydrogen EmbittlementManoj SahuBelum ada peringkat

- 5 - Durability and Concrete Cover - 2020 PDFDokumen46 halaman5 - Durability and Concrete Cover - 2020 PDFIrma MedomBelum ada peringkat

- Durability of Concrete StructuresDokumen17 halamanDurability of Concrete StructuresAparna SwaminathanBelum ada peringkat

- TIHE20111802 - R04 - Type of Corrosion by The Boiler Water and The Protecting MethodDokumen8 halamanTIHE20111802 - R04 - Type of Corrosion by The Boiler Water and The Protecting Methodajshsu5682Belum ada peringkat

- 1-Corrosion and Protection of Steel Reinforced ConcreteDokumen51 halaman1-Corrosion and Protection of Steel Reinforced ConcreteEmad Behdad100% (1)

- Durability 1Dokumen17 halamanDurability 1Dhaarini SriBelum ada peringkat

- Corrosión Catodica en TuberíasDokumen4 halamanCorrosión Catodica en TuberíasAndres rodriguezBelum ada peringkat

- Corro StelDokumen2 halamanCorro StelAnurag BagadeBelum ada peringkat

- Corrosion Science: Chong Cao, Moe M.S. Cheung, Ben Y.B. ChanDokumen13 halamanCorrosion Science: Chong Cao, Moe M.S. Cheung, Ben Y.B. ChanEjazulhaq RahimiBelum ada peringkat

- Chemical AttackDokumen35 halamanChemical AttackArjun V CivilBelum ada peringkat

- Lecture 5-1 Corrosion Carbonation-1Dokumen5 halamanLecture 5-1 Corrosion Carbonation-1Zaid HabibuBelum ada peringkat

- 260-276 ConstructionDokumen17 halaman260-276 ConstructionRama KrishnaBelum ada peringkat

- Final Project ReportDokumen40 halamanFinal Project Reportmariam100% (1)

- Fusion-Bonded Epoxy Coatings, A Technology For Rebar Corrosion PreventionDokumen13 halamanFusion-Bonded Epoxy Coatings, A Technology For Rebar Corrosion PreventionMuhamad Hafid ABelum ada peringkat

- ASS 1-FinalDokumen8 halamanASS 1-FinalKudzai MushunjeBelum ada peringkat

- The BossDokumen1 halamanThe BossRakib HossainBelum ada peringkat

- 14 AlkalinityDokumen2 halaman14 AlkalinityRakib HossainBelum ada peringkat

- variation of theoretical and experiment pressure co-effcient Cp with angular position Ө (rad)Dokumen1 halamanvariation of theoretical and experiment pressure co-effcient Cp with angular position Ө (rad)Rakib HossainBelum ada peringkat

- M22 SlabDokumen1 halamanM22 SlabRakib HossainBelum ada peringkat

- Exchange Rate 22 December 2022Dokumen2 halamanExchange Rate 22 December 2022JsjsBelum ada peringkat

- Wind Load (+X Direction) On Different Floor of Building: Storey Level H (FT) CZ (-) PZ (+X Direction) Projected Area (SFT)Dokumen1 halamanWind Load (+X Direction) On Different Floor of Building: Storey Level H (FT) CZ (-) PZ (+X Direction) Projected Area (SFT)Rakib HossainBelum ada peringkat

- Kech 1 PsDokumen12 halamanKech 1 PsBale varun kumarBelum ada peringkat

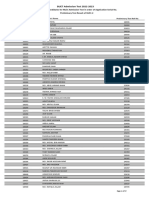

- Prel Result Shift 2Dokumen57 halamanPrel Result Shift 2Rakib HossainBelum ada peringkat

- Variation Of Cp Cosө Against Ө (Radian)Dokumen1 halamanVariation Of Cp Cosө Against Ө (Radian)Rakib HossainBelum ada peringkat

- BLK EsyDokumen1 halamanBLK EsyRakib HossainBelum ada peringkat

- Science 8 (2017)Dokumen140 halamanScience 8 (2017)Rakib HossainBelum ada peringkat

- M22 FinalDokumen1 halamanM22 FinalRakib HossainBelum ada peringkat

- Nomograph PDFDokumen7 halamanNomograph PDFDejene HailuBelum ada peringkat

- Transport MathDokumen13 halamanTransport MathRakib HossainBelum ada peringkat

- One Way Slab (RCC)Dokumen14 halamanOne Way Slab (RCC)Rakib HossainBelum ada peringkat

- Area of Rebar - 168Dokumen1 halamanArea of Rebar - 168Rakib HossainBelum ada peringkat

- SteelDokumen38 halamanSteelvidrascuBelum ada peringkat

- Nomograph PDFDokumen7 halamanNomograph PDFDejene HailuBelum ada peringkat

- SteelDokumen38 halamanSteelvidrascuBelum ada peringkat

- SteelDokumen38 halamanSteelvidrascuBelum ada peringkat

- ICDRM Paper FormatDokumen3 halamanICDRM Paper FormatRakib HossainBelum ada peringkat

- DL InterDokumen1 halamanDL InterRakib HossainBelum ada peringkat

- Trigonometry 7.1Dokumen1 halamanTrigonometry 7.1Rakib HossainBelum ada peringkat

- Final PosterDokumen1 halamanFinal PosterRakib HossainBelum ada peringkat

- Trigonometry 7.1 PDFDokumen1 halamanTrigonometry 7.1 PDFRakib HossainBelum ada peringkat

- SyllabusDokumen28 halamanSyllabusPalash Ranjan SanyalBelum ada peringkat

- Drywall Solutions: Everest Industries LimitedDokumen34 halamanDrywall Solutions: Everest Industries LimitedVengatesh HariBelum ada peringkat

- CAPE Chemistry 2017 U1 P1Dokumen14 halamanCAPE Chemistry 2017 U1 P1Ismadth2918388100% (1)

- Formulas and Concepts for SPM ChemistryDokumen14 halamanFormulas and Concepts for SPM ChemistryThanabalan MunuswamyBelum ada peringkat

- 05 Heat Treatments To Produce Ferrite and PerliteDokumen23 halaman05 Heat Treatments To Produce Ferrite and PerliteRicardo Fidel Duarte SánchezBelum ada peringkat

- High Purity Boehmite: Hiq - 40 Alumina Offers Due TheDokumen2 halamanHigh Purity Boehmite: Hiq - 40 Alumina Offers Due TheJC Jane BarnesBelum ada peringkat

- History of EnamelDokumen5 halamanHistory of Enamellamdan20040% (1)

- Broad Form DeedDokumen3 halamanBroad Form DeedWesley KuemmelBelum ada peringkat

- Stainless Steels at High TemperaturesDokumen40 halamanStainless Steels at High TemperaturesMACKAY9999Belum ada peringkat

- Periodic TableDokumen1 halamanPeriodic TableDhanya GoswamiBelum ada peringkat

- Lubetrend GuideDokumen100 halamanLubetrend GuideKashif AhmedBelum ada peringkat

- Product Brochure Zincalume1 PDFDokumen2 halamanProduct Brochure Zincalume1 PDFRamius HamdaniBelum ada peringkat

- Redox Reactions Class 11 Chemistry NotesDokumen2 halamanRedox Reactions Class 11 Chemistry NotesNitesh GuptaBelum ada peringkat

- Chapter 2 - TTA - TTT - DiagramsDokumen13 halamanChapter 2 - TTA - TTT - DiagramsPrasad Mhatre100% (1)

- D3682-Standard Test Method For Major and Minor Elements in Combustion Residues From Coal Utilization ProcessesDokumen7 halamanD3682-Standard Test Method For Major and Minor Elements in Combustion Residues From Coal Utilization ProcessesAyaBelum ada peringkat

- Metal Composition of 1 Rs CoinDokumen15 halamanMetal Composition of 1 Rs Coinrupali parmarBelum ada peringkat

- ASTM - D6386-99 (Reapproved 2005)Dokumen4 halamanASTM - D6386-99 (Reapproved 2005)tkBelum ada peringkat

- Metallurgy: Smelting, A Basic Step in Obtaining Usable Quantities of Most MetalsDokumen8 halamanMetallurgy: Smelting, A Basic Step in Obtaining Usable Quantities of Most MetalssiswoutBelum ada peringkat

- Indian Granite IndustryDokumen4 halamanIndian Granite IndustrySanthosh Kumar MurugesanBelum ada peringkat

- Building Materials and Construction Multiple Choice QuestionsDokumen14 halamanBuilding Materials and Construction Multiple Choice QuestionsleGionBelum ada peringkat

- Sobre o Alu6061Dokumen2 halamanSobre o Alu6061Lais RanieleBelum ada peringkat

- Excavator SelectionDokumen10 halamanExcavator SelectionMario HezkeeaBelum ada peringkat

- Answers Chapter 8Dokumen3 halamanAnswers Chapter 8Zoe SiewBelum ada peringkat

- Unit 2 WeldingDokumen95 halamanUnit 2 Weldingsayan halderBelum ada peringkat

- Conservation GuideDokumen12 halamanConservation Guidemp190Belum ada peringkat

- External Corrosion of Buried Metal PipesDokumen5 halamanExternal Corrosion of Buried Metal PipesVinh Do ThanhBelum ada peringkat

- Reviewing A Typical EIA For A Mining Project: 3.1 Evaluating The Executive SummaryDokumen60 halamanReviewing A Typical EIA For A Mining Project: 3.1 Evaluating The Executive SummaryBlacksacerdoteBelum ada peringkat

- Inzenjerstvo PovrsinaDokumen23 halamanInzenjerstvo PovrsinamasinacmasinacBelum ada peringkat

- Electrical Installation GuideDokumen15 halamanElectrical Installation GuideVanna Rebekah IbatuanBelum ada peringkat

- Epa 6020aDokumen23 halamanEpa 6020acandyBelum ada peringkat

- Chemistry Form 4 Chapter 2Dokumen6 halamanChemistry Form 4 Chapter 2Mur_nie91% (22)