QIP of Boiler For Erection

Diunggah oleh

Umair AwanJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

QIP of Boiler For Erection

Diunggah oleh

Umair AwanHak Cipta:

Format Tersedia

QUALITY INSPECTION PLAN

JOB NO: PROJECT NAME: CLIENT: DATE:

DRAWING No: _ DESCRIPTION: MANUFACTURER'S SERIAL NO.: QIP NO.: REV. No.: 0

H:Hold W:Witness point S:Surveillance Inspection R:Review of Record

IKAN (QC Inspector) ICI TPI/AI

Acceptance

Sr. No. Description of Inspection & Test Verifying Document Remarks

Criteria Check Check Check

Sign Sign Sign

Point Point Point

1 Documentation

1.1 Approval of Drawings ASME Section 1 Drawings R

1.2 Weld Matrix/Weld Map ASME Sec. IX, Drawings Weld Matrix/Weld Map H/R

1.3 WPS/PQR ASME Sec. IX, Drawings WPS/PQR H/R

1.4 Welder's Qualifications ASME Sec. IX WPQ/WOPQ H/R

1.5 NDE Procedure ASME Sec. V NDE Procedure H/R

List of Qualified Welders and NDE ASME SEC-V ASME NDE Procedures

1.6 H/R

Personnel SEC-IX WPQ/WOPQ

ALLIGNMENT OF DRUMS,TUBES &

2

HEADERS

2.1 Allignment of steam drum Drawings QIP / ICI/QA/QC/216/20 H

2.2 Allignment of front wall tubes Drawings QIP / ICI/QA/QC/216/20 H

2.3 Allignment of side wall tubes Drawings QIP / ICI/QA/QC/216/20 H

2.4 Allignment of back wall tubes Drawings QIP / ICI/QA/QC/216/20 H

2.5 Allignment of front wall header Drawings QIP / ICI/QA/QC/216/20 H

2.6 Allignment of side wall header Drawings QIP / ICI/QA/QC/216/20 H

ONTROLLED, ONFIDENTIAL @ IKAN Engineering Services (Pvt) Ltd.-------------------------------------------- Page 1 of 6

QUALITY INSPECTION PLAN

JOB NO: PROJECT NAME: CLIENT: DATE:

DRAWING No: _ DESCRIPTION: MANUFACTURER'S SERIAL NO.: QIP NO.: REV. No.: 0

H:Hold W:Witness point S:Surveillance Inspection R:Review of Record

IKAN (QC Inspector) ICI TPI/AI

Acceptance

Sr. No. Description of Inspection & Test Verifying Document Remarks

Criteria Check Check Check

Sign Sign Sign

Point Point Point

2.7 Allignment of Back wall header Drawings QIP / ICI/QA/QC/216/20 H

ONTROLLED, ONFIDENTIAL @ IKAN Engineering Services (Pvt) Ltd.-------------------------------------------- Page 2 of 6

QUALITY INSPECTION PLAN

JOB NO: PROJECT NAME: CLIENT: DATE:

DRAWING No: _ DESCRIPTION: MANUFACTURER'S SERIAL NO.: QIP NO.: REV. No.: 0

H:Hold W:Witness point S:Surveillance Inspection R:Review of Record

IKAN (QC Inspector) ICI TPI/AI

Acceptance

Sr. No. Description of Inspection & Test Verifying Document Remarks

Criteria Check Check Check

Sign Sign Sign

Point Point Point

2.8 Allignment of super heater header Drawings QIP / ICI/QA/QC/216/20 H

3 Fit-UP INSPECTION

3.1 Fit-up of tubes with front wall header Drawings QIP / ICI/QA/QC/216/20 H

3.2 Fit-up of tubes with side wall header Drawings QIP / ICI/QA/QC/216/20 H

3.3 Fit-up of tubes with back wall header Drawings QIP / ICI/QA/QC/216/20 H

3.4 Fit-up of tubes with super heater header Drawings QIP / ICI/QA/QC/216/20 H

3.5 Fit-up of tubes with economiser header Drawings QIP / ICI/QA/QC/216/20 H

3.5 Fit-up of downcomers header Drawings QIP / ICI/QA/QC/216/20 H

3.5 Fit-up of downcomers with steam drum Drawings QIP / ICI/QA/QC/216/20 H

3.6 Fit-up of tubes with air chamber Drawings QIP / ICI/QA/QC/216/20 H

3.7 Fit-up of connections with headers Drawings QIP / ICI/QA/QC/216/20 H

3.8 Fit-up of tubes with cooling screen headers Drawings QIP / ICI/QA/QC/216/20 H

3.9 Fitup of down-comers/risers Drawings QIP / ICI/QA/QC/216/20 H

3.10 Fitup of Cyclone Drawings H

ONTROLLED, ONFIDENTIAL @ IKAN Engineering Services (Pvt) Ltd.-------------------------------------------- Page 3 of 6

QUALITY INSPECTION PLAN

JOB NO: PROJECT NAME: CLIENT: DATE:

DRAWING No: _ DESCRIPTION: MANUFACTURER'S SERIAL NO.: QIP NO.: REV. No.: 0

H:Hold W:Witness point S:Surveillance Inspection R:Review of Record

IKAN (QC Inspector) ICI TPI/AI

Acceptance

Sr. No. Description of Inspection & Test Verifying Document Remarks

Criteria Check Check Check

Sign Sign Sign

Point Point Point

3.11 Fit-up of tubes with tubes Drawings QIP / ICI/QA/QC/216/20 H

4 WELDING INSPECTION

Welding of tubes inside the steam drum

4.1 ASME Sec 1/IX QIP / ICI/QA/QC/216/20 H

after expansion

Welding of tubes inside the water drum

4.2 ASME Sec 1/IX QIP / ICI/QA/QC/216/20 H

after expansion

4.3 welding of tubes with front wall header ASME Sec 1/IX QIP / ICI/QA/QC/216/20 H

4.4 welding of tubes with side wall header ASME Sec 1/IX QIP / ICI/QA/QC/216/20 H

4.5 welding of tubes with back wall header ASME Sec 1/IX QIP / ICI/QA/QC/216/20 H

ONTROLLED, ONFIDENTIAL @ IKAN Engineering Services (Pvt) Ltd.-------------------------------------------- Page 4 of 6

QUALITY INSPECTION PLAN

JOB NO: PROJECT NAME: CLIENT: DATE:

DRAWING No: _ DESCRIPTION: MANUFACTURER'S SERIAL NO.: QIP NO.: REV. No.: 0

H:Hold W:Witness point S:Surveillance Inspection R:Review of Record

IKAN (QC Inspector) ICI TPI/AI

Acceptance

Sr. No. Description of Inspection & Test Verifying Document Remarks

Criteria Check Check Check

Sign Sign Sign

Point Point Point

4.6 welding of tubes with super heater header ASME Sec 1/IX QIP / ICI/QA/QC/216/20 H

4.7 Welding of down-comers/risers ASME Sec 1/IX QIP / ICI/QA/QC/216/20 H

4.8 Welding of Cyclone ASME Sec 1/IX QIP / ICI/QA/QC/216/20 H

4.9 Welding of tubes with tubes ASME Sec 1/IX QIP / ICI/QA/QC/216/20 H

QIP / Inspection

ASME SEC-V , ASME Request /

5 NDE SEC-I Dimensional

Inspection Report,

ASME SEC-V , ASME

5.1 100% VT of all attachments SEC-1

QIP / ICI/QA/QC/216/20 H

ASME SEC-V , ASME

5.2 100% RT of all Butt joints SEC-1

QIP / ICI/QA/QC/216/20 H

ASME SEC-V , ASME

5.3 Random DPT SEC-1

QIP / ICI/QA/QC/216/20 H

6 PWHT ASME SEC-1 PWHT Report H

PWHT of super heater coil & header (if

6.1 ASME SEC-1 PWHT Report H/R

required)

7 Final Inspection H

Dimensional inspection as per last revision

7.1 Drawings Dimensional Report H/R

of drawing

ONTROLLED, ONFIDENTIAL @ IKAN Engineering Services (Pvt) Ltd.-------------------------------------------- Page 5 of 6

QUALITY INSPECTION PLAN

JOB NO: PROJECT NAME: CLIENT: DATE:

DRAWING No: _ DESCRIPTION: MANUFACTURER'S SERIAL NO.: QIP NO.: REV. No.: 0

H:Hold W:Witness point S:Surveillance Inspection R:Review of Record

IKAN (QC Inspector) ICI TPI/AI

Acceptance

Sr. No. Description of Inspection & Test Verifying Document Remarks

Criteria Check Check Check

Sign Sign Sign

Point Point Point

7.2 Hydrostatic test ASME SEC 1 Hydro test Report H

Note: After the final hydrostatic test Boiler shall

7.3 be dried and cleaned completely.

QIP H

8 SURFACE PREPARATION H

8.1 Cleaning / Burushing SA 2 &1/2 QIP / ICI/QA/QC/216/20 H

8.2 Painting Manufacturer data sheet QIP / ICI/QA/QC/216/20 H

9 Review of Inspection Data Manual. H

10 NON CONFORMANCE (IF ANY) ASME SEC 1 H

NAME: NAME:

DATE: DATE:

SIGNATURE: SIGNATURE:

ONTROLLED, ONFIDENTIAL @ IKAN Engineering Services (Pvt) Ltd.-------------------------------------------- Page 6 of 6

Anda mungkin juga menyukai

- Checklist For Fabrication & Erection of Structural Steel WorkDokumen1 halamanChecklist For Fabrication & Erection of Structural Steel Workbetelehem hailuBelum ada peringkat

- MS For Fabrication of Above-Ground Storage TankDokumen8 halamanMS For Fabrication of Above-Ground Storage Tankdadz mingiBelum ada peringkat

- Burckhardt Compression (India) PVT - LTD.: 1.0 MaterialsDokumen2 halamanBurckhardt Compression (India) PVT - LTD.: 1.0 MaterialsYOGESHBelum ada peringkat

- Chemical Resistance (LLDPE) PDFDokumen24 halamanChemical Resistance (LLDPE) PDFrubyshreeBelum ada peringkat

- QAP For Conical StrainerDokumen2 halamanQAP For Conical StrainersatishchidrewarBelum ada peringkat

- Steam BoilerDokumen3 halamanSteam BoilerMohammad AzlanBelum ada peringkat

- Anand Engineering Products Private Limited: Before Welding Inspection Check ListDokumen1 halamanAnand Engineering Products Private Limited: Before Welding Inspection Check ListAnilkumarGopinathanNairBelum ada peringkat

- Is 2062 - E250 Vs Is-1367 ComparisonDokumen2 halamanIs 2062 - E250 Vs Is-1367 ComparisonDevang JaniBelum ada peringkat

- BS 1414-1975 PDFDokumen27 halamanBS 1414-1975 PDF윤규섭Belum ada peringkat

- Boiler 3.1Dokumen112 halamanBoiler 3.1Aldy Bagus PratamaBelum ada peringkat

- Structural Steel and Pipe Work ProcedureDokumen5 halamanStructural Steel and Pipe Work ProcedureMohamed100% (2)

- Painting ReportDokumen29 halamanPainting ReportDimas Afiefan AmirBelum ada peringkat

- Tech SpecDokumen16 halamanTech SpecKingston RivingtonBelum ada peringkat

- 3 Steel Structure Installation CLDokumen2 halaman3 Steel Structure Installation CLwhah11Belum ada peringkat

- Construction Baseline Book Development Time FrameDokumen4 halamanConstruction Baseline Book Development Time Framesohail2006Belum ada peringkat

- Inspection and Test Plan For Silos and HoppersDokumen15 halamanInspection and Test Plan For Silos and HoppersHOMAYOUN KHADIVIBelum ada peringkat

- Saudi Aramco Inspection Checklist: Inspection of Structural Alignment During Erection SAIC-M-2007 30-Apr-13 MechDokumen15 halamanSaudi Aramco Inspection Checklist: Inspection of Structural Alignment During Erection SAIC-M-2007 30-Apr-13 Mechpookkoya thangalBelum ada peringkat

- Approved Weld Procedure SpecificationsDokumen38 halamanApproved Weld Procedure SpecificationsJohan0001Belum ada peringkat

- Hydrotest Welding and NDTDokumen11 halamanHydrotest Welding and NDTALFA ENGINEERINGBelum ada peringkat

- Incoming Material Inspection Report: Date of ReceiptDokumen1 halamanIncoming Material Inspection Report: Date of ReceiptRaj MBelum ada peringkat

- Skid Mounted Unit InstallationDokumen2 halamanSkid Mounted Unit Installationric leonisoBelum ada peringkat

- Job Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptDokumen13 halamanJob Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaBelum ada peringkat

- AKP Storage TanksDokumen51 halamanAKP Storage Tankscris_2010Belum ada peringkat

- Pressure Gauge Technical InformationsDokumen4 halamanPressure Gauge Technical Informationssahayaraaj100% (1)

- Disclosure To Promote The Right To InformationDokumen96 halamanDisclosure To Promote The Right To InformationgovimanoBelum ada peringkat

- Itp TankageDokumen7 halamanItp TankageIr FankovicBelum ada peringkat

- SOW Fabrikasi C-335-01 - 19.116.1Dokumen1 halamanSOW Fabrikasi C-335-01 - 19.116.1AlfanBelum ada peringkat

- Blasting & Painting Inspection Report Format For Bottom Plate 01Dokumen7 halamanBlasting & Painting Inspection Report Format For Bottom Plate 01ABEC Trombay siteBelum ada peringkat

- WPS Sa 517Dokumen2 halamanWPS Sa 517DHANANNJAI SINGH -Belum ada peringkat

- List of Itp新 for HrsgDokumen16 halamanList of Itp新 for HrsgzhangBelum ada peringkat

- ITP For Hydraulic BarrierDokumen4 halamanITP For Hydraulic Barriermoytabura96Belum ada peringkat

- Painting Report Cd3Dokumen15 halamanPainting Report Cd3sivaBelum ada peringkat

- Welder Qualification Test - As Run Sheet: Weld Details Filler Shield Welding ParametersDokumen1 halamanWelder Qualification Test - As Run Sheet: Weld Details Filler Shield Welding ParametersGopalakrishnan GovindarajBelum ada peringkat

- Electode Equivalent China Standards (GB) Vs AWSDokumen1 halamanElectode Equivalent China Standards (GB) Vs AWSTariqBelum ada peringkat

- VN01-000-40-95-AA-11017 - Rev D1: Inspection and Testing Plan For Topside StructureDokumen8 halamanVN01-000-40-95-AA-11017 - Rev D1: Inspection and Testing Plan For Topside StructureHanLe DuyBelum ada peringkat

- WPQ Ix - C - WPW 7.0.4 Form 2007 Rev. 0Dokumen1 halamanWPQ Ix - C - WPW 7.0.4 Form 2007 Rev. 0คุณพ่อน้อง บิ๊กบอส100% (1)

- Pttep Painitng of Offshore FacilitiesDokumen66 halamanPttep Painitng of Offshore FacilitiesSufianBelum ada peringkat

- Note: This Is The Sample Document For The Related Job Only: Tank Erection ProcedureDokumen5 halamanNote: This Is The Sample Document For The Related Job Only: Tank Erection Procedurekushar_geoBelum ada peringkat

- Elding Rocedure Pecification: 7200-HDPE Butt WeldDokumen2 halamanElding Rocedure Pecification: 7200-HDPE Butt Weldsamer8saifBelum ada peringkat

- FQP 16.11.18 Vol-I - BoilerDokumen90 halamanFQP 16.11.18 Vol-I - Boilerashis chatterjeeBelum ada peringkat

- Quality Assurance and QA PlansDokumen13 halamanQuality Assurance and QA PlansAKHIL JOSEPH100% (1)

- Chimney NotesDokumen3 halamanChimney NotesmonojitdeyBelum ada peringkat

- Scope: Method Statement For Welding ControlDokumen6 halamanScope: Method Statement For Welding ControlSIBINBelum ada peringkat

- Floating Head Heat Exchanger Hydrotest ProcedureDokumen15 halamanFloating Head Heat Exchanger Hydrotest ProcedureDoğuhan DenizgezBelum ada peringkat

- Hydro Test ProcedureDokumen11 halamanHydro Test ProcedureRohit SharmaBelum ada peringkat

- Test Pack Clearance FormatDokumen2 halamanTest Pack Clearance FormatKarthikBelum ada peringkat

- FGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDDokumen10 halamanFGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDBhanu Pratap Choudhury100% (1)

- QAP TanksDokumen3 halamanQAP TanksAnonymous zejWt17100% (2)

- Lot Inspection Report For LPG New CylindersDokumen3 halamanLot Inspection Report For LPG New CylindersJagannath MajhiBelum ada peringkat

- RFI For Welding Inspection EJN00048Dokumen1 halamanRFI For Welding Inspection EJN00048nagu100% (2)

- IRN For QC 64210-1 Ansao Venturi Pin (1-800)Dokumen1 halamanIRN For QC 64210-1 Ansao Venturi Pin (1-800)Senthil KumarBelum ada peringkat

- 800D SeriesDokumen3 halaman800D Seriesvkeie0206Belum ada peringkat

- Itp - 002 - Duct Installation - IfrDokumen3 halamanItp - 002 - Duct Installation - IfrMari BelajarBelum ada peringkat

- Daily Fit-Up/Welding Inspection ReportDokumen7 halamanDaily Fit-Up/Welding Inspection ReportRichard PeriyanayagamBelum ada peringkat

- Procedure Qualification RecordsDokumen2 halamanProcedure Qualification RecordsRM ENTERPRISESBelum ada peringkat

- Cold Forming ProcedureDokumen5 halamanCold Forming ProcedureMassimo FumarolaBelum ada peringkat

- Welder Qualification: Procedure Qualification Thickness & Dia LimitsDokumen4 halamanWelder Qualification: Procedure Qualification Thickness & Dia LimitsHoque AnamulBelum ada peringkat

- Wps Mig PDF FreeDokumen3 halamanWps Mig PDF Freehanz bermejoBelum ada peringkat

- QCP 040 QCP CrmsDokumen7 halamanQCP 040 QCP Crmsarockiyathass100% (1)

- ITP For Boiler ErectionDokumen6 halamanITP For Boiler ErectionUmair Awan100% (2)

- Part 1: Summary of The Entire Session:: Light FormsDokumen7 halamanPart 1: Summary of The Entire Session:: Light FormsUmair AwanBelum ada peringkat

- Part 1: Summary of The Entire SessionDokumen4 halamanPart 1: Summary of The Entire SessionUmair AwanBelum ada peringkat

- Solved Passed Paper FCPS Part-2 DaleepDokumen20 halamanSolved Passed Paper FCPS Part-2 DaleepUmair AwanBelum ada peringkat

- Factory Acceptance Test For PRVDokumen4 halamanFactory Acceptance Test For PRVUmair AwanBelum ada peringkat

- GEMSS-G-05 Rev 03 - Quality Control - Quality AssuranceDokumen20 halamanGEMSS-G-05 Rev 03 - Quality Control - Quality AssuranceUmair Awan100% (1)

- PART 1: Summary of The Entire Session: in EnglishDokumen4 halamanPART 1: Summary of The Entire Session: in EnglishUmair AwanBelum ada peringkat

- Taking Control of Your Career: Sandra Haase & Catherine Steele Centre For People at WorkDokumen19 halamanTaking Control of Your Career: Sandra Haase & Catherine Steele Centre For People at WorkUmair AwanBelum ada peringkat

- Supervisor Competency Guideline FinalDokumen77 halamanSupervisor Competency Guideline FinalUmair Awan100% (1)

- Factory Acceptance Test For RDDokumen3 halamanFactory Acceptance Test For RDUmair Awan100% (1)

- Machinery Alignment TechniquesDokumen79 halamanMachinery Alignment TechniquesUmair Awan100% (2)

- ITP For Boiler ErectionDokumen6 halamanITP For Boiler ErectionUmair Awan100% (2)

- Minimum Quality Requirements For Epc Contractors PDFDokumen47 halamanMinimum Quality Requirements For Epc Contractors PDFUmair Awan100% (2)

- Tanhov Industrial Co.,Ltd: ITP (Inspection and Test Plan) FOR PRVDokumen2 halamanTanhov Industrial Co.,Ltd: ITP (Inspection and Test Plan) FOR PRVUmair AwanBelum ada peringkat

- Boiler 1 Boiler 2 ESP Switchyard: DAILY QC-Mech Report Dated: Sr. Steel Structure Erected Welded Joints UT RemarksDokumen1 halamanBoiler 1 Boiler 2 ESP Switchyard: DAILY QC-Mech Report Dated: Sr. Steel Structure Erected Welded Joints UT RemarksUmair AwanBelum ada peringkat

- Punch ListDokumen1 halamanPunch ListUmair Awan100% (2)

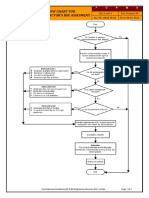

- Subcontractor HS&E Assessment FlowchartDokumen1 halamanSubcontractor HS&E Assessment FlowchartUmair Awan100% (1)

- QQQ QQQ QQQ QQQ: Final InspectionDokumen2 halamanQQQ QQQ QQQ QQQ: Final InspectionUmair Awan100% (1)

- Changes Contained in The 10th Edition of API 510Dokumen3 halamanChanges Contained in The 10th Edition of API 510Umair Awan100% (7)

- Technical Assesment For WelderDokumen1 halamanTechnical Assesment For WelderUmair AwanBelum ada peringkat

- Release For GroutingDokumen1 halamanRelease For GroutingUmair AwanBelum ada peringkat

- Positive Material Identification ReportDokumen1 halamanPositive Material Identification ReportUmair AwanBelum ada peringkat

- Design and Analysis of 42-V Permanent-Magnet Generator For Automotive ApplicationsDokumen12 halamanDesign and Analysis of 42-V Permanent-Magnet Generator For Automotive ApplicationsNicholas ValdezBelum ada peringkat

- On BiomassDokumen364 halamanOn BiomassRusty MacCharlesBelum ada peringkat

- User Manual CA AllDokumen79 halamanUser Manual CA AllAnonymous LU6nvFBelum ada peringkat

- On Developments On Solar Cookers 160213040826Dokumen10 halamanOn Developments On Solar Cookers 160213040826Vishal KundalBelum ada peringkat

- Crydom ModuleDokumen36 halamanCrydom ModulenormandofloresBelum ada peringkat

- Flexible Organo-Metal Halide Perovskite Solar Cells On A Ti Metal SubstrateDokumen5 halamanFlexible Organo-Metal Halide Perovskite Solar Cells On A Ti Metal SubstrateHuckkey HuBelum ada peringkat

- Renewable Energy-DigitalDokumen33 halamanRenewable Energy-DigitalMubeen NavazBelum ada peringkat

- Akash Internship ProjectDokumen68 halamanAkash Internship Projectmohittandel100% (1)

- Popular Mechanics PDFDokumen116 halamanPopular Mechanics PDFdhani_is100% (2)

- Expression of InterestDokumen108 halamanExpression of InterestswetashahBelum ada peringkat

- Ram Sethu, SethumandirDokumen29 halamanRam Sethu, SethumandirvyasdesaiBelum ada peringkat

- "Optimal Investment Scenarios For The Power Generation Mix Development of Iraq," by Hashim Mohammed Al-Musawi and Arash FarnooshDokumen17 halaman"Optimal Investment Scenarios For The Power Generation Mix Development of Iraq," by Hashim Mohammed Al-Musawi and Arash FarnooshThe International Research Center for Energy and Economic Development (ICEED)Belum ada peringkat

- Vapor Compression RefrigerationDokumen8 halamanVapor Compression RefrigerationSepehr SaBelum ada peringkat

- Chapter 1Dokumen17 halamanChapter 1DrGopikrishna PasamBelum ada peringkat

- Biogas TechnologyDokumen35 halamanBiogas Technologyraghunath670743Belum ada peringkat

- Exciter With DiagnosticsDokumen5 halamanExciter With DiagnosticsHafizuddin RazaliBelum ada peringkat

- Rheological Characterization of Animal Fats andDokumen8 halamanRheological Characterization of Animal Fats andnatyquimica100% (2)

- Advanced Power Electronic For Wind-Power Generation Buffering (TH., Alejandro Montenegro León)Dokumen194 halamanAdvanced Power Electronic For Wind-Power Generation Buffering (TH., Alejandro Montenegro León)bubulescuBelum ada peringkat

- Acknowledgement: Mr. Ganesh BhosaleDokumen28 halamanAcknowledgement: Mr. Ganesh BhosaleganeshBelum ada peringkat

- Factors For Site SelectionDokumen4 halamanFactors For Site SelectionHiren AjwaniBelum ada peringkat

- DocumentDokumen8 halamanDocumentKURNIAWANBelum ada peringkat

- Physics 5054 Paper 2 Oct Nov 2011Dokumen16 halamanPhysics 5054 Paper 2 Oct Nov 2011samuthiram771198Belum ada peringkat

- Simple Van and RV Solar SystemsDokumen9 halamanSimple Van and RV Solar SystemsMgWaiBelum ada peringkat

- 1.1 Introduction To The ProjectDokumen26 halaman1.1 Introduction To The ProjectMayank SharmaBelum ada peringkat

- GCSE Physics SpecificationDokumen36 halamanGCSE Physics SpecificationsheelahaiBelum ada peringkat

- Bakhtar Bastan Solar Wind CompanyDokumen3 halamanBakhtar Bastan Solar Wind Companygraceenggint8799Belum ada peringkat

- Wired and Wireless Charging of EVDokumen7 halamanWired and Wireless Charging of EVShubham RajBelum ada peringkat

- Solar Photovoltaic Technology and Systems - A Manual For Technicians, Trainers and EngineersDokumen319 halamanSolar Photovoltaic Technology and Systems - A Manual For Technicians, Trainers and Engineerssanthi80% (35)

- Solar InvertersDokumen2 halamanSolar InvertersPrakhar Thamke100% (1)