Wps Is 2062 GR B Butt-Ok

Diunggah oleh

Anand KesarkarJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Wps Is 2062 GR B Butt-Ok

Diunggah oleh

Anand KesarkarHak Cipta:

Format Tersedia

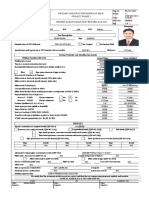

QW-482 WELDING PROCEDURE SPECIFICATIONS (WPS)

(QW-200.1 SEC.IX, ASME BOILER AND PRESSURE VESSEL CODE)

Company Name : SAMARTH ENGINEERS. By: Mr.Sachin Chechare

WPS NO. : SE/WPS/16-17/002 Rev.0 Dtd. 01/06/2016

Welding Process : GTAW(QW-256) Types: Manual.

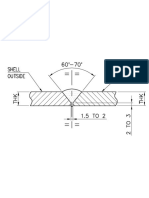

JOINTS (QW-402)

Joint Design : Single VGroove

Root Spacing :0.0 - 1.6mm

Backing : NA

Metal : Aluminium Grade 6061

BASE METALS (QW-403)

Specification Type & Grade : Aluminium Grade 6061, P.NO.: 23 Group No. NA

To,

Specification type & Grade : Aluminium Grade 6061, P.NO.: 23 Group No. NA

Thickness Range

Base Metal : 1.5 mm to 12 mm Fillet: ALL

Max.Pass Thickness (2T) : 12 mm

Other : Butt Welding, Sample Size: 300 x 300 x 6 mm thk

FILLER METALS (QW-404)

Spec. No. (SFA) : SFA 5.10/5.10M

AWS NO. (Class) : ER4043

F.No. : 23

A.No. : NA

Size of filler metals : 2 mm, 3.2 mm

Filler Metal Product Form :

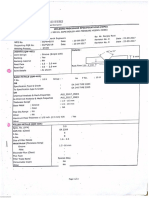

WPS NO. : SE/WPS/16-17/002 Rev.0 Dtd. 01/06/2016

POSITIONS (QW-405) POST WELD HEAT TREATMENT (QW-407)

Position of Groove : 1G Temperature Range: NA

Welding Progression : FORWARD Time Range : NA

Positions of Fillet : NA

PREHEAT (QW-406) GAS (QW-408)

Preheat Temp.Min. : Room Temp. Percent Composition:

Interpass Temp.Max. : 150-200 Degree Gas Mixture Flow Rate

Preheat Maintenance : NA Shielding Argon UHP 99.999% 20-25 LPM

Other : Trailing -------- --------- ---------

Backing -------- --------- ---------

ELECTRICAL CHARACTERISTICS (QW-409)

Current : DC Polarity : Straight/ DCEP

Amps : 170-200 amps.

Tungsten Electrode Size & Type: 3.18 Dia. 2% Thoriated

Mode of Metal Transfer for GTAW: NA

Electrode wire feed speed range : NA.

TECHNIQUE (QW-410)

Stringe or Weave Bead : Stringe/Weave for GTAW

Orifice, Nozzle or Gas Cup Size:15.8 (5/8)

Initial or Inter-pass Cleaning: Wire Brushing

Method of Back Gouging : NA

Oscillation : NA

Contact Tip to Work distance: 2.0 to 5.0mm

Multiple or single pass : Single

Multiple or Single Electrode : Single.

Travel Speed (Range) : Approx.60-140 mm /min. (Manual)

Peening : NA

Other : Both the pieces held in position with tack welds.

Weld Layer Process Filler Metal Current Travel Speed

Class Dia. Type Amp Volt mm/min

mm Polarity

Root run GTAW ER70S2 2.0 DC/EP 170-200 19-22 110-140

I Layer- GTAW ER70S2 2.5 DC/EP

170-200 19-22 70-110

(Hot Pass)

II Layer- GTAW ER70S2 2.0 DC/EP

170-200 19-22 60-80

(Capping)

Prepared By- Approved By-

Mr. Vikram Wakole Mr.Sanjay Raut

Dept-QA/QC-

Samarth Engineers MD-Samarth Engineers

Anda mungkin juga menyukai

- Fcaw 16 THKDokumen5 halamanFcaw 16 THKparesh2387Belum ada peringkat

- WPS, PQR, WPQ PoojaDokumen10 halamanWPS, PQR, WPQ PoojaRajmahesh Dakhore100% (1)

- Page No: 01: SA 240 GR 304 SA 240 GR 304Dokumen5 halamanPage No: 01: SA 240 GR 304 SA 240 GR 304jobertBelum ada peringkat

- Welding Procedure SpecificationDokumen3 halamanWelding Procedure SpecificationAhmed saber100% (1)

- WPS E6013+e7018Dokumen2 halamanWPS E6013+e7018Anvesh Vaddi100% (1)

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDokumen5 halamanWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Dokumen2 halaman(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDokumen3 halamanWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaBelum ada peringkat

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Dokumen5 halamanWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- PQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpDokumen1 halamanPQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpSatish KeskarBelum ada peringkat

- WPS 2014-002 006 - 6G PipeDokumen3 halamanWPS 2014-002 006 - 6G PipejeswinBelum ada peringkat

- WPS PQR PDFDokumen23 halamanWPS PQR PDFAhmad Daniel100% (1)

- WPQR Welding Procedure Qualification RecordsDokumen3 halamanWPQR Welding Procedure Qualification Recordsramesh rajaBelum ada peringkat

- Welding Procedure Specification for Vertical Storage TanksDokumen6 halamanWelding Procedure Specification for Vertical Storage TanksYASH BARDHAN SinghBelum ada peringkat

- Wps p91 - BhelDokumen2 halamanWps p91 - BhelAshish Gupta100% (4)

- QW-484A (WPQ) GTAW 4MM FilletDokumen2 halamanQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- For Fillet Weld Joint Project:Production ManifoldDokumen1 halamanFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- According To ASME IX: Welding Procedure Specification (W.P.S)Dokumen4 halamanAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehBelum ada peringkat

- Aws 001Dokumen1 halamanAws 001akshay sarfareBelum ada peringkat

- 19403955-WPS M.S. Is 2062Dokumen10 halaman19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- WPS PQR ProcedureDokumen31 halamanWPS PQR Proceduresudeesh kumarBelum ada peringkat

- Proposed WPSDokumen2 halamanProposed WPSChisom Ikengwu100% (2)

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Dokumen2 halamanWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajBelum ada peringkat

- WPQR Welding Procedure QualificationDokumen3 halamanWPQR Welding Procedure QualificationThanasis KyrgiazoglouBelum ada peringkat

- Welding Procedure Qualification Certificate EN ISO 15614-1: 2017Dokumen3 halamanWelding Procedure Qualification Certificate EN ISO 15614-1: 2017dcsamaraweera100% (1)

- SURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPSDokumen2 halamanSURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPSsuria qaqcBelum ada peringkat

- WQT Record for Pipeline Welder QualificationDokumen99 halamanWQT Record for Pipeline Welder QualificationVivek Jadhav100% (1)

- WPQ Sample PrintoutDokumen1 halamanWPQ Sample PrintoutKannan VelBelum ada peringkat

- WQT - WPS 01Dokumen71 halamanWQT - WPS 01Gururaj P Kundapur100% (1)

- Welder Id SampleDokumen1 halamanWelder Id Sampledevendrasingh202157% (7)

- Welder Qualification Test Certificate for Mohan ReddyDokumen2 halamanWelder Qualification Test Certificate for Mohan Reddyvijay100% (1)

- WPS - 024Dokumen4 halamanWPS - 024MAT-LIONBelum ada peringkat

- WPS - EngineerDokumen20 halamanWPS - Engineerhunghoanglong100% (1)

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDokumen3 halamanWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanBelum ada peringkat

- WELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELDokumen4 halamanWELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELAldeline SungahidBelum ada peringkat

- Report on Welding Procedure Specifications for Single V-Groove JointsDokumen15 halamanReport on Welding Procedure Specifications for Single V-Groove JointsAvishek Gupta100% (1)

- Welder Visual Inspection ReportsDokumen24 halamanWelder Visual Inspection ReportsKyBelum ada peringkat

- FCAW Overlay WPSDokumen2 halamanFCAW Overlay WPSAsad Bin Ala Qatari100% (1)

- Qualified Welder List Valid Until - 03-12-2019Dokumen2 halamanQualified Welder List Valid Until - 03-12-2019csolanki6586100% (1)

- DPT Report - FormatDokumen1 halamanDPT Report - Formatskc0% (1)

- 004 Gtaw P5aDokumen16 halaman004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- WPSDokumen3 halamanWPSKhurram Burjees100% (1)

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDokumen6 halamanWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberBelum ada peringkat

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Dokumen1 halamanWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- WPS Pipe 08'' SHD 40 SMAW REV02Dokumen2 halamanWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejBelum ada peringkat

- Toshiba Brazing Procedure SpecificationDokumen3 halamanToshiba Brazing Procedure Specificationsheikmoin100% (1)

- 1035 03Dokumen2 halaman1035 03Anuj ShahiBelum ada peringkat

- Welding Procedure Specification: ST NDDokumen1 halamanWelding Procedure Specification: ST NDMaung SleeperBelum ada peringkat

- Sabari Engineering PQRDokumen3 halamanSabari Engineering PQRAdvanced Quality Centre AQC100% (1)

- Welding Procedure Specification For Storage Tank & Piping SystemDokumen3 halamanWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadBelum ada peringkat

- ASME IX-Welder Performance Qualification (WPQ) : Welding and NDT Purposed FormatDokumen1 halamanASME IX-Welder Performance Qualification (WPQ) : Welding and NDT Purposed FormatArshadAliBelum ada peringkat

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDokumen2 halamanASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaBelum ada peringkat

- WPSDokumen6 halamanWPSNur Wijianto100% (1)

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Dokumen20 halamanWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- WpsDokumen3 halamanWpsPankaj KumarBelum ada peringkat

- 2G & 5GDokumen2 halaman2G & 5GRahul MoottolikandyBelum ada peringkat

- PQR 01 PDFDokumen2 halamanPQR 01 PDFVijay BhaleraoBelum ada peringkat

- Mechanical Engineering M.Abdul GhoziDokumen4 halamanMechanical Engineering M.Abdul GhoziRizaldy PhoenksBelum ada peringkat

- WPS & PQR - LTM - QW - PipeDokumen7 halamanWPS & PQR - LTM - QW - PipeKAMALBelum ada peringkat

- WPS SUMMARYDokumen10 halamanWPS SUMMARYbhavin178Belum ada peringkat

- The Truth About Fibonacci TradingDokumen34 halamanThe Truth About Fibonacci TradingAnand KesarkarBelum ada peringkat

- Breakout Trading Strategies Quick GuideDokumen10 halamanBreakout Trading Strategies Quick GuideAnand Kesarkar100% (1)

- ANUGRAHA TEJAS Automatic power loom for Coir Geo TextilesDokumen16 halamanANUGRAHA TEJAS Automatic power loom for Coir Geo TextilesAnand KesarkarBelum ada peringkat

- The Complete Guide To Trading PDFDokumen116 halamanThe Complete Guide To Trading PDFvkverma352Belum ada peringkat

- Astm A70Dokumen1 halamanAstm A70Anand KesarkarBelum ada peringkat

- Dynamic Print Solution: D P E PDokumen8 halamanDynamic Print Solution: D P E PAnand KesarkarBelum ada peringkat

- Corona Kavach Policy-Oriental Insurance - Rate ChartDokumen3 halamanCorona Kavach Policy-Oriental Insurance - Rate ChartAnand KesarkarBelum ada peringkat

- Name Contact No. Location DOB Age SR No. Employee CodeDokumen5 halamanName Contact No. Location DOB Age SR No. Employee CodeAnand KesarkarBelum ada peringkat

- Candlestick Patterns Every Trader Should KnowDokumen65 halamanCandlestick Patterns Every Trader Should KnowDxtr V Drn100% (1)

- Unit 8 - Week 7: Assignment 07Dokumen3 halamanUnit 8 - Week 7: Assignment 07Anand KesarkarBelum ada peringkat

- The Truth About Fibonacci TradingDokumen34 halamanThe Truth About Fibonacci TradingAnand KesarkarBelum ada peringkat

- Manufacturing Processes UNIT Test-I - Series A With SolutionsDokumen1 halamanManufacturing Processes UNIT Test-I - Series A With SolutionsAnand KesarkarBelum ada peringkat

- Symbol of Weld PDFDokumen28 halamanSymbol of Weld PDFSyarif IrwantoBelum ada peringkat

- Cap 3 Dse CutoffDokumen614 halamanCap 3 Dse CutoffAnand KesarkarBelum ada peringkat

- A270Dokumen6 halamanA270Anonymous O39pjWBelum ada peringkat

- Symbol of Weld PDFDokumen28 halamanSymbol of Weld PDFSyarif IrwantoBelum ada peringkat

- Standard Operation ProcedureDokumen3 halamanStandard Operation ProcedureAnand KesarkarBelum ada peringkat

- Let's Discuss Your Next Project.: Contact USDokumen8 halamanLet's Discuss Your Next Project.: Contact USAnand KesarkarBelum ada peringkat

- Symbol of Weld PDFDokumen28 halamanSymbol of Weld PDFSyarif IrwantoBelum ada peringkat

- Pressure Testing Safety EssentialsDokumen7 halamanPressure Testing Safety EssentialsSuleyman HaliciogluBelum ada peringkat

- Dss 2205 Wps PQR WPQDokumen8 halamanDss 2205 Wps PQR WPQAnand KesarkarBelum ada peringkat

- 1.4 BG00381946 - ADokumen1 halaman1.4 BG00381946 - AAnand KesarkarBelum ada peringkat

- Change Address Contact Details Email IdDokumen1 halamanChange Address Contact Details Email IdAnand KesarkarBelum ada peringkat

- Hydrostatic Testing Procedures for FacilitiesDokumen17 halamanHydrostatic Testing Procedures for Facilitiesprakash07343Belum ada peringkat

- Maharashtra State Road Transport Corporation Public Online Reservation System TicketDokumen1 halamanMaharashtra State Road Transport Corporation Public Online Reservation System TicketAnand KesarkarBelum ada peringkat

- WPQ Is 2062 Haresh Shah W1Dokumen1 halamanWPQ Is 2062 Haresh Shah W1Anand KesarkarBelum ada peringkat

- M CR 601r1Dokumen14 halamanM CR 601r1nazari123Belum ada peringkat

- Cr10830005 - 3 Heat Exchanger 01Dokumen1 halamanCr10830005 - 3 Heat Exchanger 01Anand KesarkarBelum ada peringkat

- Process Flow Chart - Heat ExchangerDokumen7 halamanProcess Flow Chart - Heat ExchangerAnand KesarkarBelum ada peringkat

- SNP Tanker ReportDokumen3 halamanSNP Tanker ReportfikrifadzalBelum ada peringkat

- General Purpose US FusesDokumen69 halamanGeneral Purpose US FusesEliasBelum ada peringkat

- Heui PDFDokumen56 halamanHeui PDFGerman Ramos German Ramos100% (5)

- TriScroll 300 Series Dry Scroll Vacuum Pump PDFDokumen106 halamanTriScroll 300 Series Dry Scroll Vacuum Pump PDFWilliamRiveraBelum ada peringkat

- Busduct PDFDokumen7 halamanBusduct PDFrohith87nairBelum ada peringkat

- Thyristor 3 Phase InverterDokumen31 halamanThyristor 3 Phase InverterjorgeBelum ada peringkat

- Machinery Lubrication Level I: Maintenance StrategiesDokumen7 halamanMachinery Lubrication Level I: Maintenance StrategiesbodiemcdBelum ada peringkat

- Calculation of Inrush Currents - Benchmarking of TDokumen9 halamanCalculation of Inrush Currents - Benchmarking of TPawan Kumar SahaBelum ada peringkat

- Concept of Net Zero Energy Buildings (NZEB) - A Literature ReviewDokumen16 halamanConcept of Net Zero Energy Buildings (NZEB) - A Literature ReviewJaime PazBelum ada peringkat

- 64L - Coffee - Table - Book (1) (1) (1) - 032Dokumen1 halaman64L - Coffee - Table - Book (1) (1) (1) - 032Nilda Ester RomeroBelum ada peringkat

- Availability Based Tariff PDFDokumen8 halamanAvailability Based Tariff PDFakshay jawaleBelum ada peringkat

- Preparation of A Feasibility Study For NPPDokumen143 halamanPreparation of A Feasibility Study For NPPIrfan YogaBelum ada peringkat

- SCBA CertDokumen2 halamanSCBA CertSup ChomBelum ada peringkat

- PAPER SIDIQ ICOS FixDokumen7 halamanPAPER SIDIQ ICOS FixAtika AssalafiyahBelum ada peringkat

- Ibrahim Dincer, Adnan Midilli, Haydar Kucuk (Eds.) - Progress in Exergy, Energy, and The Environment-Springer International Publishing (2014) PDFDokumen1.055 halamanIbrahim Dincer, Adnan Midilli, Haydar Kucuk (Eds.) - Progress in Exergy, Energy, and The Environment-Springer International Publishing (2014) PDFpheliphs100% (2)

- Worcester Danesmoor Utility Boiler ManualDokumen12 halamanWorcester Danesmoor Utility Boiler ManualdavidraeburnBelum ada peringkat

- !indice BrochureDokumen61 halaman!indice BrochureAdrianoBelum ada peringkat

- 6MW Wind Turbine Control Design AnalysisDokumen8 halaman6MW Wind Turbine Control Design Analysisoat_sohoBelum ada peringkat

- Zero BezzelDokumen2 halamanZero BezzelkhoerulmuftiBelum ada peringkat

- Scania HPI System EDCDokumen29 halamanScania HPI System EDCnoran100% (1)

- Electricity Magnetism and ElectromagnetismDokumen64 halamanElectricity Magnetism and ElectromagnetismFe DBelum ada peringkat

- Energy Recharge Calculator - Energy Recharge CalculatorDokumen12 halamanEnergy Recharge Calculator - Energy Recharge Calculatorsubit timalsinaBelum ada peringkat

- Distillation DesignDokumen30 halamanDistillation Designfdc20062340100% (2)

- GV Actuator Adv. Rev.4 (Webinar)Dokumen37 halamanGV Actuator Adv. Rev.4 (Webinar)Boriche DivitisBelum ada peringkat

- Robin Engine EH650 EH650DA JapanDokumen29 halamanRobin Engine EH650 EH650DA JapanyewlimBelum ada peringkat

- Submission Prime Coat (MC-30) Test ResultDokumen2 halamanSubmission Prime Coat (MC-30) Test ResultAdyam YonasBelum ada peringkat

- Servo Lubricants GreaseDokumen62 halamanServo Lubricants GreasenagbabuiBelum ada peringkat

- Portable welding load banks for testing AC/DC welding powerDokumen2 halamanPortable welding load banks for testing AC/DC welding powerlauguicoBelum ada peringkat

- Maximal Forklift LineUp Brochure PDFDokumen10 halamanMaximal Forklift LineUp Brochure PDFJose Luis GarciaBelum ada peringkat

- Pressure Vessel Creep Analysis: RuptureDokumen7 halamanPressure Vessel Creep Analysis: RuptureFlorin TrBelum ada peringkat