2004-03-01 Actual vs. Effective Involute Tooth Size PDF

Diunggah oleh

srbhagat88Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

2004-03-01 Actual vs. Effective Involute Tooth Size PDF

Diunggah oleh

srbhagat88Hak Cipta:

Format Tersedia

by Brian Slone

W

While splines have been manufactured for decades, they

still seem to perplex the manufacturing engineer who is try-

ing to insure the proper assembly of two mating compo-

nents. The case frequently arises in which the dimension

First, the Basics

Spline (noun): an equally spaced, multi-toothed connector

used to transmit positive rotary motion. The primary func-

tion of a spline is to transfer torque from one shaft to

over pins is within limits, but the parts wont assemble. another shaft, or to other rotary components such as gears,

Understanding why this happensand learning how to avoid pulleys, or hubs. The spline connection can have a loose,

the associated confusion and resulting downtimeis the sliding, or pressed-fit condition.

focus of this article. Specifically, well take a look at the dif- This article will address splines with an involute tooth

ferences between actual and effective tooth/space form, since they are so widely used in the industry. An invo-

thickness, and examine the elemental errors that can keep lute spline is one that has a tooth profile form defined by

two components from assembling after manufacture. an involute curve, often referred to as the involute profile.

34 GEAR SOLUTIONS MARCH 2004 gearsolutionsonline.com

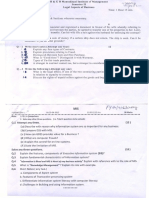

Figure 1

Splines are designed and made with an involute form, due to the ease of

manufacture and its self-centering attribute.

The Effective Fit Concept

The effective fit concept is based on the fact that a manufacturer simply

cant produce a perfect spline. There will always be some variation in the

index (the spacing of the teeth around the spline), the lead (the

straightness of the teeth), and the profile (the form of the involute pro-

file) attributes of a spline. No matter how accurately you control the actu-

al tooth size, you must account for the variation caused by index, lead,

and profile deviations when considering the assembly of two parts.

The effective fit concept can be confusing to someone who has just Figure 2

been introduced to the world of splines. The terminology alone can be a

challenge, but adding the fact that there are two different tooth-thickness

values called for in the same part tends to magnify the confusion.

This issuethe difference between actual and effective tooth size

seems to be the most commonly misunderstood concept that engineers

have to face on the shop floor when manufacturing splines. Other chal-

lenges are mostly related to the terminology used. The fundamental ques-

tion that needs to be answered in the shop, however, is will my two mat-

ing components have a proper fit at assembly?

To answer this question, we must first understand what prevents two

parts from being assembled. Every tooth on an external spline must fit

into every corresponding space of the mating internal spline. For this to

happen, the following conditions must be met:

Each tooth size on the external part must be less than that of the

corresponding space size of the internal mating part. The possible

interference issues are tooth thickness and circular space width.

Each tooth must not have a form error that would cause any portion

of the tooth surface to be increased over the space size. The possi-

ble interference issues are: lead/helix and involute profile error.

Each tooth/space must be in the correct angular position. The possi-

ble interference issue involves the index.

The two splines must be coaxial. The possible interference issues

are concentricity and runout.

Figure 3

We need to understand these potential interference issues by first looking at the EFFECTIVE TOOTH THICKNESS

proper terminology for describing them, and then look at how these errors are applied

to the fit condition between two parts.

Understanding the Terminology

According to the ANSI B92.1 standard:

Actual Tooth Thickness is the circular thickness on the pitch circle of any single

tooth, considering an infinitely thin increment of axial spline length.

Effective Tooth Thickness of an external spline is equal to the circular space

width on the pitch circle of an imaginary perfect internal spline, which would fit

the external spline without looseness or interference, considering engagement of

the entire axial length of the spline (i.e. the smallest space width that would con-

tain the entire full length of the given tooth).

Actual Circular Space Width is the circular thickness on the pitch circle of any

single space, considering an infinitely thin increment of axial spline length.

gearsolutionsonline.com MARCH 2004 GEAR SOLUTIONS 35

Figure 4

INDUSTRIAL

EFFECTIVE TOOTH THICKNESS

CLUTCHES

Model HC Clutch

The Model HC is an oil-immersed clutch designed for

end-shaft, or through shaft mounting configuration.

The compact size of the HC makes these units ideal for

incorporation within a gear housing. Multiple speed

transmissions use a variety of these units to affect SURFACE IRREGULARITY

fixed mesh speed changes. The Model HC may be used

as a stand-alone device for disconnects service, ACTUAL TOOTH THICKNESS

or conveyor/mill soft starts.

FEATURES INCLUDE:

Pneumatic or hydraulic actuation

Figure 5

Clutch torque capacities range from

55,000 to 1,275,000 pound-inches DIMENSION ACTUAL, m EFFECTIVE,

NO-GO SECTOR

SPACE WIDTH MAX PLUG

OF INTERNAL SPLINE

m

MIN MAX

2800 Fisher Road Wichita Falls, TX 76302 515 Frederick St. Waukesha, WI 53187 GO PLUG

1-800-964-3262 866-547-3357 MIN

(COMPOSITE)

www.wichitaclutch.com www.indclutch.com TOOTH THICKNESS

MAX

NOMINAL

GO RING

wichita.info@wichitaclutch.com info@indclutch.com OF EXTERNAL SPLINE

1 (COMPOSITE)

MAX MIN

m

MIN

NO-GO SECTOR

RING

Figure 6

Figure 8

INFINITELY THIN AXIAL

SPLINE LENGTH

ACTUAL CIRCULAR

TOOTH THICKNESS

36 GEAR SOLUTIONS MARCH 2004 gearsolutionsonline.com

Figure 7

Effective Circular Space Width of an

internal spline is equal to the circu-

lar tooth thickness on the pitch cir-

cle of an imaginary perfect external

spline which would fit the internal

spline without looseness or interfer-

ence, considering engagement of

the entire axial length of the spline

(i.e. the largest tooth thickness that

would fit into the entire full length of

the given space).

Total Index Variation is the greatest

difference in any two teeth, adjacent

or otherwise, between the actual

and the perfect spacing of the tooth

profiles.

Profile Variation is any variation from

the specified tooth profile normal to

the flank. NEW MODEL

0-3 CAPACITY SHOP HARDENED LOWEST COST IN THE INDUSTRY

Lead Variation is the variation of the

direction of the spline tooth from its

intended direction parallel to the ref-

erence axis, also including paral-

Call to use gage

lelism and alignment variations. for your next

machine run off.

Determining Fit 90 days at no charge.

The key values that determine

whether two parts are going to fit

together at assembly are the mini-

mum effective circular space width

on the internal spline and the maxi-

Unite-A-Matic

GEAR INSPECTION

mum effective circular tooth thick-

ness on the external spline.

The effective size can be considered

the size seen by the mating component

and is used to determine if the parts will

fit together at assembly (not the actual

size or dimension between pins value).

The effective size includes the actu- United Tool Supply

8 5 1 O H I O P I K E C I N C I N N A T I , O H 4 5 2 4 5

al size plus any errors due to index,

lead, or involute profile variations (see TOLL FREE: (800) 755-0516 FAX: (513) 752-5599 EMAIL: unitedtool1@aol.com

Figures 4 & 8). TRUE DIMENSION GEAR INSPECTION

gearsolutionsonline.com MARCH 2004 GEAR SOLUTIONS 37

When using the effective fit concept, for machining tol-

erances (m), a manufacturer is provided with a plus and Illustration of Actual & Effective Size

minus actual tooth thickness limit for an external part, or an The diagram (Figure 6) on page 36 shows the difference

actual space width limit for an internal part. Adjusting the between actual and effective size.

depth of cut in the manufacturing process controls these

actual size limits.

Added to the machining tolerance is an allowance for pro- Analyzing Errors

cessing errors such as total index, lead, and involute pro- When evaluating the size and accuracy of a spline, the actu-

file. This allowance is called the variation allowance (l). al size can be determined by measuring over or between

These variation errors, when added to the actual tooth or pins and calculating an actual tooth thickness or actual

space size, will make the tooth size effectively larger than space width. The actual size can also be directly measured

the actual tooth size, or in the case of an internal compo- on some analytical gear measurement systems, such as the

nent, an effectively smaller space width. This effective ND430 Next Dimension Gear Measurement System.

size is what determines whether or not parts will assemble. To implement the effective fit concept, however, analytical

Thus, if your actual tooth size is within limits, but you have gear measurement equipment must be used to determine

excessive error in your index, lead, or profile, you may not be total index error, lead error, and involute profile error. Once

able to assemble the part to its mate. these variations are determined, they can be compared

Positive errorsi.e. excess material on the flanks of back to the allowances given in a standard such as the

teeth and flanks of the spaceswill cause par ts not to ANSI B92.1. These variations, if large, can prevent the suc-

assemble due to the reduced clearances. Negative errors, cessful assembly of components. If any one of these identi-

or material removed from the flanks, do not affect the abil- fied elemental allowances is exceeded, then the manufac-

ity to assemble par ts, but they do reduce sur face contact, turing engineer can begin to focus on determining the cause

thus raising localized sur face stresses. If the actual tooth of the excessive variation thats causing interference.

thickness is undersized, or actual space width is over- Still, the bottom line is, will my two components fit at

sized, then excessive looseness may occur. This should be assembly?

detected with a dimension between pins measurement, or The best method for insuring assembly is to use an analyti-

with no/go sector gages. cal measuring system to quantify the effective variation, and

FINISHED PRODUCTS THAT MEET THE MOST DEMANDING SPECIFICATIONS

Focused on Quality and a commitment to 100% customer satisfaction, C-B Gear & Machine, Inc. has designed a Quality

System within the guidelines of ISO 9000. Our complete machining and gear cutting capabilities provide for effective

processing and quality control, as well as reduced lead times. Our capabilities include (but are not limited to):

MACHINING/TURNING/CRANE HOBBING (SPUR, SINGLE & DOUBLE HELICAL) HERRINGBONE WORMS & WORM GEARS

INTERNAL GEARS STRAIGHT BEVEL GEARS INTERNAL & EXTERNAL SPLINES SPROCKETS (ROLLER & SILENT CHAIN)

C-B Gear & Machine, Inc.

4232 MOONEY ROAD HOUSTON, TX 77093

1-800-428-6028 281-449-0777 FAX 281-590-9127

EMAIL US AT SALES@CBGEAR.COM

OR VISIT OUR WEBSITE AT WWW.CBGEAR.COM

38 GEAR SOLUTIONS MARCH 2004 gearsolutionsonline.com

to use functional gaging on the shop floor to monitor your

Special Online Extra

spline manufacturing process (i.e. go/no-go rings and plugs).

What many manufacturing engineers may have already

experienced is that, just because the dimension over/

under pins measurement on a component is within limits,

it doesnt mean that it will fit at assembly. The reason?

The effective errors of total index, lead, and profile are

Frenco

usually over their allowance. Without quantifying the magni- For the most effective splines, its all in the fit, so

tude of these errors, it is ver y difficult to know where to tight manufacturing tolerances must be maintained

make the process adjustments in order to minimize the

for the ultimate outcome. Visit our Web site

effective variation. With a proper understanding of spline

terminology, and the right tools for determining variation, [www.gearsolutionsonline.com] to read an article

spline issues can be systematically addressed in a shor t on the subject by Rudolf Och, founder and president

amount of time.

of Frenco GmbH, Norbert Weiss, a technician in the

sales department, and Jerry Kowalsky, president of

About the author: Euro-Tech, Frencos U.S. representative.

Brian Slone is business unit manager of the Metrology

gowww.

to:

Systems Division of Process Equipment Company. He can

be reached at (937) 667-7105, or via e-mail at

bslone@processeq.com. Slone has worked in the

gear/spline metrology field for more than 16 years, and for

the past decade has focused on spline gaging applications.

Process Equipment offers in-plant gear and spline training gearsolutionsonline

seminars. Learn more by visiting their Web site at

[www.processeq.com].

.com

Custom Cut Gears to AGMA Class 12

Complete Line of CNC Gear Manufacturing

Equipment

Hobbed or Shaped Gears

Shaved Gears

Straight and Spiral Bevel Gear Manufacturing

Custom and Standard Sprocket Manufacturing

Splined Shaft Manufacturing

Turning, Milling, Drilling, Honing & Broaching

Equipment

In House Grinding, Heat Treat & Welding

CNC "M & M" Gear analyzer

AGMA, JIS & DIN Capabilities

Spiral Bevel Gear Cutting Process Development

Software

Our modern manufacturing facility is equipped to

process a wide variety of medium & fine pitch gear

& sprocket products. Our reputation and our ability

to provide superior quality, cost effective pricing

& on-time delivery gives us a significant advantage

over the competition.

Let Us Quote Your Next Job!

M E M B E R O F T H E A M E R I C A N G E A R M A N U F A C T U R E R S A S S O C I AT I O N

Royal Road - P.O. Box 880 Keokuk, Iowa 52632 www.stlouisgear.com

Toll Free: 800 / 437-0514 Phone: 319 / 524-5042 Fax: 319 / 524-1959

gearsolutionsonline.com MARCH 2004 GEAR SOLUTIONS 39

Anda mungkin juga menyukai

- Technotorc Product Catalog-CompressedDokumen43 halamanTechnotorc Product Catalog-Compressedsrbhagat88Belum ada peringkat

- What To Charge HandoutDokumen6 halamanWhat To Charge Handoutsrbhagat88Belum ada peringkat

- Tips On Tensioning 2006 PDFDokumen4 halamanTips On Tensioning 2006 PDFsagar1503Belum ada peringkat

- Technotorc V4Dokumen38 halamanTechnotorc V4srbhagat88Belum ada peringkat

- PHD in Document StudyDokumen1 halamanPHD in Document Studysrbhagat88Belum ada peringkat

- Unilever-Closeup Research MethodologyDokumen24 halamanUnilever-Closeup Research Methodologysrbhagat88Belum ada peringkat

- Second Semester 2012Dokumen18 halamanSecond Semester 2012srbhagat88Belum ada peringkat

- Hydraulic Sockets PlugDokumen1 halamanHydraulic Sockets Plugsrbhagat88Belum ada peringkat

- SQC X and R ChartsDokumen7 halamanSQC X and R Chartssrbhagat88Belum ada peringkat

- Jindal Steel PracticesDokumen3 halamanJindal Steel Practicessrbhagat88Belum ada peringkat

- Project Is Related To Product Innovation in Soap Lactic AcidDokumen1 halamanProject Is Related To Product Innovation in Soap Lactic Acidsrbhagat88Belum ada peringkat

- Caes FitsDokumen1 halamanCaes Fitssrbhagat88Belum ada peringkat

- Sinch NormaDokumen1 halamanSinch Normasrbhagat88Belum ada peringkat

- Caes FitsDokumen1 halamanCaes Fitssrbhagat88Belum ada peringkat

- BHTSWGDokumen1 halamanBHTSWGsrbhagat88Belum ada peringkat

- FormulasDokumen6 halamanFormulasmwlandolsiBelum ada peringkat

- FormulasDokumen6 halamanFormulasmwlandolsiBelum ada peringkat

- BoltDokumen1 halamanBoltsrbhagat88Belum ada peringkat

- FormulasDokumen6 halamanFormulasmwlandolsiBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (120)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Torque Chart For 12.9Dokumen7 halamanTorque Chart For 12.9Amit SinghBelum ada peringkat

- Bevel GearsDokumen3 halamanBevel GearsFayez KazíBelum ada peringkat

- Minepro Field Inspection GaugesDokumen1 halamanMinepro Field Inspection GaugesedwinBelum ada peringkat

- C Clamp Design PDFDokumen10 halamanC Clamp Design PDFmadhu100% (1)

- SKF RemeniceDokumen91 halamanSKF RemeniceSeherzada Kadric-RibicBelum ada peringkat

- Catalogo RICAMBI SPARE PARTS Catalogue Catalogo de Piezas de Repuesto Catalogue de PIECES DETACHEES ErsatzteilkatalogDokumen168 halamanCatalogo RICAMBI SPARE PARTS Catalogue Catalogo de Piezas de Repuesto Catalogue de PIECES DETACHEES ErsatzteilkatalogАлексей100% (1)

- Zbook - Eaa8959c B9e9 40bb A30a f856d4 - 4d77c6Dokumen20 halamanZbook - Eaa8959c B9e9 40bb A30a f856d4 - 4d77c6gaelBelum ada peringkat

- Newlong DS9 PartslistDokumen29 halamanNewlong DS9 Partslisthector_medina_17Belum ada peringkat

- Robotics - Gears and Gear RatiosDokumen27 halamanRobotics - Gears and Gear Ratiosrajdeepchandra100% (1)

- Tajima TMFXII-C PDFDokumen63 halamanTajima TMFXII-C PDFVictorCortesBelum ada peringkat

- DTSDokumen26 halamanDTSvijayakumarBelum ada peringkat

- JK T1377 InstructionDokumen45 halamanJK T1377 InstructionJose Antonio Rojas BautistaBelum ada peringkat

- September '96: 709 CARRARO AXLES REF. 122634-122146 For "CASE" IH P100 Spare Parts ListDokumen9 halamanSeptember '96: 709 CARRARO AXLES REF. 122634-122146 For "CASE" IH P100 Spare Parts Listmarc danielBelum ada peringkat

- Ejot WN-1451Dokumen1 halamanEjot WN-1451Diogo DoiBelum ada peringkat

- PUMA 11 e ManualDokumen10 halamanPUMA 11 e ManualJarlath2010Belum ada peringkat

- Bolt Database 23Dokumen3 halamanBolt Database 23Daniel YongBelum ada peringkat

- All Drawers DrawingDokumen20 halamanAll Drawers DrawingwisamBelum ada peringkat

- Drilling Reaming & TappingDokumen17 halamanDrilling Reaming & TappingLeo HsiehBelum ada peringkat

- Gupilya Split Pins Splint: DIN 94-ISO 1234 A2-A4Dokumen108 halamanGupilya Split Pins Splint: DIN 94-ISO 1234 A2-A4Arif AkbasBelum ada peringkat

- Theory of Machines and Mechanisms 4thDokumen10 halamanTheory of Machines and Mechanisms 4thseasorn kanyasornBelum ada peringkat

- Gear TrainsDokumen11 halamanGear TrainsAttique JavaidBelum ada peringkat

- LAB REPORT of Gear Hobbing MachineDokumen6 halamanLAB REPORT of Gear Hobbing MachineAhtisham AmjadBelum ada peringkat

- Drawings & Replacemnt PartsDokumen11 halamanDrawings & Replacemnt PartsJohn Jairo Simanca CastilloBelum ada peringkat

- Gear Backlash - KHK GearsDokumen11 halamanGear Backlash - KHK Gearsmarcio_soutoBelum ada peringkat

- ChartsDokumen1 halamanChartsravikumarmgowdaBelum ada peringkat

- Maryland MetricsDokumen19 halamanMaryland MetricsKurt VaughnBelum ada peringkat

- AI Countersunk BoltDokumen66 halamanAI Countersunk BoltHugo Mario Ariza PalacioBelum ada peringkat

- SWF Sa SeriesDokumen61 halamanSWF Sa SeriesJuciêr AlcântaraBelum ada peringkat

- Double Class 1 LeverDokumen4 halamanDouble Class 1 Levernurlisa khaleedaBelum ada peringkat

- Chassis - Grille MF5709Dokumen21 halamanChassis - Grille MF5709Fariqin MuhBelum ada peringkat