Standard and reinforced PA grades overview

Diunggah oleh

abhishek_negi_41Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Standard and reinforced PA grades overview

Diunggah oleh

abhishek_negi_41Hak Cipta:

Format Tersedia

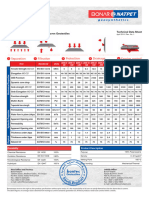

Product Range Overview

STANDARD GRADES BREATHABLE AND ANTISTATIC GRADES STABILIZATION

7233, 7033, 6333, 5533, MX 1940, 4033, MX 1205, 3533, 2533 MV 1041, MV 1074, MV 3000, MV 6100, MH 1657, INIT 1100 - SA grades: no additive for medical and food uses

- SN grades: UV stabilized

REINFORCED GRADES SOFTENING ADDITIVE FOR PA 6 - SP grades: new generation UV stabilized

RDG 314, RDG 277 MP 1878

General Characteristics

Thermoplastic Grades

CHARACTERISTICS CONDITIONS STANDARD UNITS RDG RDG 7233 7033 6333 5533 MX 4033 MX 3533 2533

314 277 1940 1205

instantaneous ISO 868/ ASTM D 2240 Shore D 75 71 69 69 64 54 55 42 46 33 27

SHORE HARDNESS Shore A - - - - - - - 90 92 82 77

after 15 seconds ISO 868/ ASTM D 2240 Shore D 71 68 61 61 58 50 48 35 41 25 22

Shore A - - - - - - - 89 90 80 74

DENSITY ISO 1183 g/cm3 1.12 1.12 1.01 1.01 1.01 1.01 1.01 1.00 1.01 1.00 1.00

MELTING POINT ISO 11357/ ASTM D 3418 C 175 174 174 172 169 159 154 160 147 143.5 133.5

VICAT SOFTENING POINT under 10 N ISO 306/ ASTM D 1525 C 173 170 164 164 157 142 127 131 111 77 58

WATER ABSORPTION AT EQUILIBRIUM at 23C and 50% RH ISO 62/ ASTM D 570 % 0.6 0.6 0.7 0.7 0.7 0.6 0.7 0.5 0.4 0.4 0.4

WATER ABSORPTION SATURATION 24h in water at 23C ISO 62/ ASTM D 570 % 0.9 1.0 0.9 0.9 1.1 1.2 1.7 1.2 1.2 1.2 1.2

MELT INDEX 235C / 1kg ISO 1133/ ASTM D 1238 g/10 mn - - 4 6 5 7 - 5 9 8 10

LINEAR COEFFICIENT - -

from - 40C to +140C ASTM D 696 10-5/C 12 16 14 17 - 19.5 20 21 20

OF THERMAL EXPANSION

SURFACE RESISTIVITY Ohm/sq - -

IEC 60093/ ASTM D 257 1012

VOLUMIC RESISTIVITY Ohm.cm - -

FILLER Glass ber - - - - - - - - -

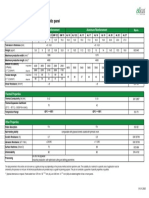

Properties (Rubber Materials Tests)

CHARACTERISTICS CONDITIONS STANDARD EQUIVALENT UNITS 7233 7033 6333 5533 4033 MX 3533 2533

1205

10% 28.7 21.6 14.2 10 5.1 5.5 1.6 1.1

TENSILE STRESS to obtain extension of 50% v = 500 mm/min ASTM D 638 MPa 25 21.8 16.6 13.2 8.9 9.1 4.6 3.2

100% 24.8 21.1 16.9 13.6 10.5 9.1 5.8 4.2

5% 0.8 0.5 0.5 0.5 0.4 0.5 0.4 0.4

10% ASTM D 412 2.4 1.9 1.5 1.5 1.2 1.2 0.7 0.5

TENSION SET under v = 500 mm/min ISO 2285 %

15% (method A) 4.2 3.8 3.3 2.9 2.1 2.3 0.9 0.8

20% 6.6 5.8 5.1 4.6 3.1 3.3 1.4 0.9

unnotched 194 177 147 135 116 115 78 66

TEAR RESISTANCE ISO 34-1 ASTM D 624 kN/m

notched 166 149 127 106 85 77 50 44

H18 / load 1kg /

TABER ABRASION RESISTANCE ISO 9352 mm 54 59 60 62 62 60 77 99

1000 rotations

ABRASION RESISTANCE 10 N / 40 m ISO 4649 DIN 53516 mm3 - - 55 47 48 40 64 130

RESILIENCE ISO 4662 DIN 53512 - - 53 57 66 58 69 70

COMPRESSION SET under deformation of 25% 70h at 23C ISO 815 % - - 47 43 32 37 22 19

ASTM D 395

COMPRESSION SET under load of 9.3MPa 22h at 70C % - - 5 10 21 - 54 62

(method A)

RESISTANCE TO CRACKING 20 C 100 000 ex - - 5 3 2 - 2 2

BY REPEATED FLEXURE ISO 133 mm

-20 C 50 000 ex - - 14 9 4.5 - 2.5 2.5

FICHE PROPRIETES-ITAL.indd 1 2/10/07 19:55:58

Properties (Plastic Materials Tests)

CHARACTERISTICS CONDITIONS STANDARD UNITS RDG RDG 7233 7033 6333 5533 MX 4033 MX 3533 2533

314 277 1940 1205

ISO 178 MPa 2200 1500 513 390 285 170 167 77 86 21 12

FLEXURAL MODULUS

ASTM D 790 MPa - - 518 379 278 164 - 81 93 20 14

ISO 527 MPa - - 522 384 280 161 - 71 81 18 10

TENSILE MODULUS

ASTM D 638 MPa 2600 2000 521 383 287 160 158 74 79 20 10

TENSILE STRESS AT YIELD MPa 62 50 26 22 18 12 12 - - - -

TENSILE STRAIN AT YIELD % 6 10 18 20 22 25 25 - - - -

v = 50 mm/min ASTM D 638 type IV

TENSILE STRESS AT BREAK MPa 56 45 56 54 53 52 51 40 42 39 32

TENSILE STRAIN AT BREAK % 10 17 300 350 350 450 550 450 550 600 750

unnotched - - 1380 p 969 p 607 p N - N N N N

IMPACT STRENGTH * (IZOD) AT + 23 C ASTM D 256 J/m

notched - - 192 c 847 p 554 p N - N N N N

unnotched - - 2460 p 2345 p 1589 p 1589 p - N N N N

IMPACT STRENGTH * (IZOD) AT - 40 C ASTM D 256 J/m

notched - - 50 c 50 c 11 c 1038 p - N N N N

unnotched - - N N N N N N N N N

IMPACT STRENGTH * (CHARPY) AT + 23 C ISO 179 kJ/m2

notched - - 15 c 120 p N N N N N N N

unnotched - - N N N N N N N N N

IMPACT STRENGTH * (CHARPY) AT - 30 C ISO 179 kJ/m2

notched 7.3 7.3 10 c 10 c 20 c N N N N N N

* N: no break

p

: partial break

c

: complete break

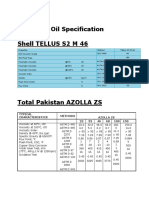

General Characteristics - Special Grades

ANTISTATIC

CHARACTERISTICS CONDITIONS STANDARD EQUIVALENT UNITS MH MV MV MP MV MV INIT

1657 1074 1041 1878 3000 6100 1100

SHORE HARDNESS instantaneous ISO 868 ASTM D 2240 Shore D 40 40 60 58 35 58 75

DENSITY ISO 1183 g/cm3 1.14 1.07 1.04 1.09 1.02 1.04 1.12

MELTING POINT ISO 11357 ASTM D 3418 C 204 158 170 195 158 170 198

VICAT SOFTENING POINT under 10 N ISO 306 ASTM D 1525 C 160 - - 169 - - -

FLEXURAL MODULUS at 23C and 50% RH ISO 178 ASTM D 790 MPa 80 80 270 180 45 210 440

TENSILE STRESS AT BREAK v = 50 mm/min ISO 527 MPa 32 30 44 60 35 48 71

TENSILE STRAIN AT BREAK v = 50 mm/min ISO 527 % 500 700 450 550 500 - 300

WATER ABSORPTION AT EQUILIBRIUM at 23C and 50% RH ISO 62 ASTM D 570 % 4.5 1.4 0.9 1.35 1 0.9 -

WATER ABSORPTION SATURATION 24h in water at 23C ISO 62 ASTM D 570 % 120 48 12 6.7 28 11 -

MELT INDEX 235C / 1kg ISO 1133 ASTM D 1238 g/10 mn 27 14 7 8 1.7

SURFACE RESISTIVITY Ohm/sq 1 10 9 3 10 9 - - - - -

IEC 60093 ASTM D 257

VOLUMIC RESISTIVITY Ohm.cm 2 10 9 2.5 10 9 - - - - -

The statements, technical information and recommendations contained herein are believed to be accurate as of the date hereof. Since the conditions and methods of use of the product and of the information referred to herein are beyond our control, AR-

KEMA expressly disclaims any and all liability as to any results obtained or arising from any use of the product or reliance on such information; NO WARRANTY OF FITNESS FOR ANY PARTICULAR PURPOSE, WARRANTY OF MERCHANTABILITY OR ANY OTHER

WARRANTY, EXPRESS OR IMPLIED, IS MADE CONCERNING THE GOODS DESCRIBED OR THE INFORMATION PROVIDED HEREIN. The information provided herein relates only to the specic product designated and may not be applicable when such product

is used in combination with other materials or in any process. The user should thoroughly test any application before commercialization. Nothing contained herein constitutes a license to practice under any patent and it should not be construed as an

inducement to infringe any patent and the user is advised to take appropriate steps to be sure that any proposed use of the product will not result in patent infringement.

See MSDS for Health & Safety Considerations

The information contained in this document is based on trials carried out by our Research Centres and data selected from the literature, but shall in no event be held to constitute or imply any warranty, undertaking, express or implied commitment from our

part. Our formal specications dene the limit of our commitment. No liability whatsoever can be accepted by Arkema with regard to the handling, processing or use of the product or products concerned which must in all cases be employed in accordance

with all relevant laws and/or regulations in force in the country or countries concerned.

Arkema Socit anonyme au capital de 604 538 230 euros 445 074 685 RCS Nanterrre

Dircom 3965 E / 06-2007 / 50 TECH photos : Arkema. Conception Publicis Activ

420, rue dEstienne dOrves

92700 Colombes - France

Tel.: + 33 (0)1 49 00 80 80

Fax: + 33(0)1 49 00 83 96 www.pebax.com

www.arkema.com info.pebax@arkema.com

FICHE PROPRIETES-ITAL.indd 2 2/10/07 19:56:10

Anda mungkin juga menyukai

- Optigear 1100 RangeDokumen3 halamanOptigear 1100 RangeResistenciaDisidenteBelum ada peringkat

- Total Azolla ZSDokumen1 halamanTotal Azolla ZSVelibor KaranovicBelum ada peringkat

- UPVC Pipe DIN 8062 TdsDokumen3 halamanUPVC Pipe DIN 8062 TdsAdany AdenBelum ada peringkat

- Datasheet Hdpe 1-1.5-2-2.5Dokumen1 halamanDatasheet Hdpe 1-1.5-2-2.5மதன் குமார் முனியசாமிBelum ada peringkat

- Maker Tauro enDokumen2 halamanMaker Tauro enibrahim maulanaBelum ada peringkat

- Hydroflux Ep tcm14-62558Dokumen1 halamanHydroflux Ep tcm14-62558Azis GPBBelum ada peringkat

- Kaiser Aluminum 7075 Rod and BarDokumen2 halamanKaiser Aluminum 7075 Rod and BarH VBelum ada peringkat

- Rogers - Unknown - RO4400 Series BondplyDokumen4 halamanRogers - Unknown - RO4400 Series BondplyHadi SaeidiManeshBelum ada peringkat

- Nyco Grease GN 22 Air4222Dokumen1 halamanNyco Grease GN 22 Air4222muhammad_andinovaBelum ada peringkat

- Geotextiles DatasheetDokumen1 halamanGeotextiles DatasheetMohammad TalalBelum ada peringkat

- Castrol Magna SW D - 150 PDFDokumen2 halamanCastrol Magna SW D - 150 PDFPabloBelum ada peringkat

- Tds Total Preslia 46 693 202003 enDokumen2 halamanTds Total Preslia 46 693 202003 enhalasanBelum ada peringkat

- Specifications For Hydraulic OilDokumen3 halamanSpecifications For Hydraulic OilAliya NaseemBelum ada peringkat

- Agip OSO: Characteristics (Typical Figures)Dokumen2 halamanAgip OSO: Characteristics (Typical Figures)Luis Carlos Lagos SalinasBelum ada peringkat

- Corys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsDokumen1 halamanCorys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsVenkadesh PeriathambiBelum ada peringkat

- Castrol Hyspin AWS RangeDokumen2 halamanCastrol Hyspin AWS RangeVusal HasanovBelum ada peringkat

- Wepp bpzs8fDokumen2 halamanWepp bpzs8fArthur Sanda LayukBelum ada peringkat

- Ficha Tecnica Castrol Hyspin AWS RangeDokumen2 halamanFicha Tecnica Castrol Hyspin AWS Rangeel pro jajaja GonzalezBelum ada peringkat

- L-CKD Heavy Duty Industrial Gear OilDokumen3 halamanL-CKD Heavy Duty Industrial Gear OilDavidBelum ada peringkat

- Technical Characteristics 2020 ENDokumen1 halamanTechnical Characteristics 2020 ENezzularabBelum ada peringkat

- Bontec Non-Woven Geotextiles - TDSDokumen11 halamanBontec Non-Woven Geotextiles - TDSAnang BagusBelum ada peringkat

- Hyspin AWS 15Dokumen2 halamanHyspin AWS 15nargueBelum ada peringkat

- Enersyn RC-S RangeDokumen2 halamanEnersyn RC-S RangecarmaBelum ada peringkat

- Castrol Aircol SR RangeDokumen2 halamanCastrol Aircol SR RangeJeremias UtreraBelum ada peringkat

- CLC 18.10LN: A Nitrogen Containing 18Cr-10Ni Austenitic Stainless Steel (304LN Grade)Dokumen4 halamanCLC 18.10LN: A Nitrogen Containing 18Cr-10Ni Austenitic Stainless Steel (304LN Grade)PeterWayBelum ada peringkat

- TDS BOPP Clear LSA47 TaghleefDokumen2 halamanTDS BOPP Clear LSA47 TaghleefEmmanuel AlvarezBelum ada peringkat

- NORYLDokumen1 halamanNORYLSenthil Kumar GanesanBelum ada peringkat

- Special Steels A320 L43: American Standards AstmDokumen1 halamanSpecial Steels A320 L43: American Standards Astmsamirfun2006Belum ada peringkat

- Azolla ZSDokumen1 halamanAzolla ZSSami KahtaniBelum ada peringkat

- Azolla ZS PDFDokumen1 halamanAzolla ZS PDFYQBelum ada peringkat

- Alphasyn GS: DescriptionDokumen2 halamanAlphasyn GS: Descriptioncool_ddBelum ada peringkat

- 5370 N Pag8Dokumen11 halaman5370 N Pag8payoseBelum ada peringkat

- Carter EpDokumen2 halamanCarter EpNguyễn Quang HưngBelum ada peringkat

- Moto Sport 4T motorcycle lubricantsDokumen1 halamanMoto Sport 4T motorcycle lubricantsSergo ZingerBelum ada peringkat

- Bpxe B6ctalDokumen2 halamanBpxe B6ctalVusal HasanovBelum ada peringkat

- Cepsa Engranajes HPDokumen1 halamanCepsa Engranajes HPRamonBelum ada peringkat

- Mobil DTE 10 Excel SeriesDokumen3 halamanMobil DTE 10 Excel SeriesSuprastowo Bin SarinoBelum ada peringkat

- Tot Preslia 06-18 TDSDokumen1 halamanTot Preslia 06-18 TDSphucdc095041Belum ada peringkat

- TenCate Polyfelt TS Nonwoven GeotextilesDokumen6 halamanTenCate Polyfelt TS Nonwoven GeotextilesChee Soon LeeBelum ada peringkat

- CYCLON HYDRAULIC - EN - Vja21Dokumen1 halamanCYCLON HYDRAULIC - EN - Vja21Jolie AbarcaBelum ada peringkat

- Wepp bxdm63Dokumen2 halamanWepp bxdm63Arthur Sanda LayukBelum ada peringkat

- TDS Co-3-X 27 03 2018 (003) - 1687274055Dokumen2 halamanTDS Co-3-X 27 03 2018 (003) - 1687274055KSXBelum ada peringkat

- ADVAFELT_TDSDokumen1 halamanADVAFELT_TDSMohammed AbugharbiehBelum ada peringkat

- Cofran Mecanep 220 enDokumen2 halamanCofran Mecanep 220 enMATHEW JOSEBelum ada peringkat

- TDS Total Rubia-Sx-40 G6e 202011 en CanDokumen2 halamanTDS Total Rubia-Sx-40 G6e 202011 en CanRobert Isac0% (1)

- RO4400 PrepregDokumen2 halamanRO4400 Prepreggcohen03Belum ada peringkat

- RO3000 Series BondplyData Sheet Processing GuidelinesDokumen4 halamanRO3000 Series BondplyData Sheet Processing GuidelinesEricson NavasBelum ada peringkat

- ROHACELL HERO 2022 April EN 243522Dokumen2 halamanROHACELL HERO 2022 April EN 243522c.breckonsBelum ada peringkat

- AHS 187 - Air Handling Systems Product Selector GuideDokumen8 halamanAHS 187 - Air Handling Systems Product Selector GuideKhang NguyenBelum ada peringkat

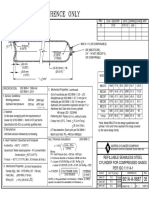

- Refillable Seamless Steel Cylinder For Compressed Gases PER ISO 11114-1Dokumen1 halamanRefillable Seamless Steel Cylinder For Compressed Gases PER ISO 11114-1bkprodhBelum ada peringkat

- T 90 Ep2 S: Motor Vehicle Transmission OilDokumen1 halamanT 90 Ep2 S: Motor Vehicle Transmission Oilrobertjob34Belum ada peringkat

- Castrol Hyspin VG Range: DescriptionDokumen2 halamanCastrol Hyspin VG Range: DescriptionBruno RussoBelum ada peringkat

- Property of Polyfelt TS Nonwoven GeotextilesDokumen1 halamanProperty of Polyfelt TS Nonwoven GeotextilesAgis Satryo Falck100% (1)

- Datasheet Sanicro 26mo For Wirelines enDokumen3 halamanDatasheet Sanicro 26mo For Wirelines enafonsomlima_1Belum ada peringkat

- 2.double Shear Conversion Table LBFDokumen1 halaman2.double Shear Conversion Table LBFaxis inspection solutionsBelum ada peringkat

- Omega Amide Nylon Pa CatalogueDokumen5 halamanOmega Amide Nylon Pa Cataloguesoni10483Belum ada peringkat

- HT Mobilgear 600 Series EngDokumen2 halamanHT Mobilgear 600 Series Engmgamal1080Belum ada peringkat

- تنزيلDokumen2 halamanتنزيلShady MohamedBelum ada peringkat

- Castrol Tribol GR 4020 220-460 PD Tds-EnDokumen3 halamanCastrol Tribol GR 4020 220-460 PD Tds-EnIulian BarbuBelum ada peringkat

- Class Notes - FMDokumen108 halamanClass Notes - FMabhishek_negi_41Belum ada peringkat

- Autocad Catia Walk in Interview - Pune - Sunline Green Systems PVT LTD - 0 To 5 Years of Experience PDFDokumen3 halamanAutocad Catia Walk in Interview - Pune - Sunline Green Systems PVT LTD - 0 To 5 Years of Experience PDFabhishek_negi_41Belum ada peringkat

- Mechanical Design Engineer (Exp - 1-5 Years & Unemployed) - Chennai - MSQUARE ENGINEERING SERVICES PVT. LTD. - 1 To 5 Years of ExperienceDokumen3 halamanMechanical Design Engineer (Exp - 1-5 Years & Unemployed) - Chennai - MSQUARE ENGINEERING SERVICES PVT. LTD. - 1 To 5 Years of Experienceabhishek_negi_41Belum ada peringkat

- Presentations Oil Refinery ProcessesDokumen36 halamanPresentations Oil Refinery ProcessesGururaj SreepatharaoBelum ada peringkat

- Oil Refinery ProcessesDokumen2 halamanOil Refinery Processesabhishek_negi_41Belum ada peringkat

- Coking 101Dokumen26 halamanCoking 101digecaBelum ada peringkat

- Brochure Steam and Condensate ManifoldsDokumen8 halamanBrochure Steam and Condensate Manifoldsabhishek_negi_41Belum ada peringkat

- Manufacturers & Suppliers of Forged Flanges: Corporate OfficeDokumen4 halamanManufacturers & Suppliers of Forged Flanges: Corporate Officeabhishek_negi_41Belum ada peringkat

- Documents - Tips Re Reverse Engineering As Necessary Phase by Rapid Product DevelopmentDokumen6 halamanDocuments - Tips Re Reverse Engineering As Necessary Phase by Rapid Product Developmentabhishek_negi_41Belum ada peringkat

- FMSRV (DN20-50) Forbes Marshall Safety Relief ValveDokumen2 halamanFMSRV (DN20-50) Forbes Marshall Safety Relief Valveabhishek_negi_41Belum ada peringkat

- Gasification India 2016Dokumen9 halamanGasification India 2016abhishek_negi_41Belum ada peringkat

- Indian NavyDokumen1 halamanIndian Navyabhishek_negi_41Belum ada peringkat

- Fluid Propellant Thrust Chamber Design PDFDokumen33 halamanFluid Propellant Thrust Chamber Design PDFabhishek_negi_41Belum ada peringkat

- FMSRV (DN15) Forbes Marshall Safety Relief ValveDokumen2 halamanFMSRV (DN15) Forbes Marshall Safety Relief Valveabhishek_negi_41Belum ada peringkat

- Cho Joon-Yeoun Diss PDFDokumen121 halamanCho Joon-Yeoun Diss PDFabhishek_negi_41Belum ada peringkat

- ThinkingObliquely EbookDokumen278 halamanThinkingObliquely EbookDavid Otero NavarroBelum ada peringkat

- AbhishekDokumen29 halamanAbhishekabhishek_negi_41Belum ada peringkat

- Adv Gear Analysis 6Dokumen15 halamanAdv Gear Analysis 6abhishek_negi_41Belum ada peringkat

- Adv Gear Analysis 6Dokumen15 halamanAdv Gear Analysis 6abhishek_negi_41Belum ada peringkat

- 1 Automobile Intro v5 1Dokumen66 halaman1 Automobile Intro v5 1igoysinghBelum ada peringkat

- HandoutDokumen4 halamanHandoutZack CullenBelum ada peringkat

- 1989 Volvo 740 Instruments and ControlsDokumen107 halaman1989 Volvo 740 Instruments and Controlsskyliner538Belum ada peringkat

- Canberra As A Planned CityDokumen12 halamanCanberra As A Planned Citybrumbies15100% (1)

- AP Research Survival Guide - RevisedDokumen58 halamanAP Research Survival Guide - RevisedBadrEddin IsmailBelum ada peringkat

- Polygon shapes solve complex mechanical problemsDokumen6 halamanPolygon shapes solve complex mechanical problemskristoffer_mosshedenBelum ada peringkat

- Chapter 5Dokumen11 halamanChapter 5XDXDXDBelum ada peringkat

- V Ships Appln FormDokumen6 halamanV Ships Appln Formkaushikbasu2010Belum ada peringkat

- TheSun 2008-11-04 Page16 Asian Stocks Rally Continues On Policy HopesDokumen1 halamanTheSun 2008-11-04 Page16 Asian Stocks Rally Continues On Policy HopesImpulsive collectorBelum ada peringkat

- Alarm Management Second Ed - Hollifield Habibi - IntroductionDokumen6 halamanAlarm Management Second Ed - Hollifield Habibi - IntroductionDavid DuranBelum ada peringkat

- IPIECA - IOGP - The Global Distribution and Assessment of Major Oil Spill Response ResourcesDokumen40 halamanIPIECA - IOGP - The Global Distribution and Assessment of Major Oil Spill Response ResourcesОлегBelum ada peringkat

- GUEST MAIL HANDLINGDokumen17 halamanGUEST MAIL HANDLINGJoelThambi0% (1)

- De Thi Thu Tuyen Sinh Lop 10 Mon Anh Ha Noi Nam 2022 So 2Dokumen6 halamanDe Thi Thu Tuyen Sinh Lop 10 Mon Anh Ha Noi Nam 2022 So 2Ngọc LinhBelum ada peringkat

- The Meaning of Solar CookerDokumen4 halamanThe Meaning of Solar CookerJaridah Mat YakobBelum ada peringkat

- Nidhi Investment Consultant: Magic Mix Illustration For Mr. AB Prafulbhai (Age 18)Dokumen2 halamanNidhi Investment Consultant: Magic Mix Illustration For Mr. AB Prafulbhai (Age 18)jdchandrapal4980Belum ada peringkat

- New Microsoft Word DocumentDokumen1 halamanNew Microsoft Word Documentshubhangiw17Belum ada peringkat

- Sine and Cosine Exam QuestionsDokumen8 halamanSine and Cosine Exam QuestionsGamer Shabs100% (1)

- Adjectives Weekly Plan1Dokumen10 halamanAdjectives Weekly Plan1RItta MariaBelum ada peringkat

- Some Technical Aspects of Open Pit Mine Dewatering: Section2Dokumen11 halamanSome Technical Aspects of Open Pit Mine Dewatering: Section2Thiago MarquesBelum ada peringkat

- Data Structures LightHall ClassDokumen43 halamanData Structures LightHall ClassIwuchukwu ChiomaBelum ada peringkat

- Express VPN Activation CodeDokumen5 halamanExpress VPN Activation CodeButler49JuulBelum ada peringkat

- Mediclaim - ChecklistDokumen4 halamanMediclaim - ChecklistKarthi KeyanBelum ada peringkat

- Bond Strength of Normal-to-Lightweight Concrete InterfacesDokumen9 halamanBond Strength of Normal-to-Lightweight Concrete InterfacesStefania RinaldiBelum ada peringkat

- New Directions Formative TestDokumen1 halamanNew Directions Formative TestAnonymous xGQcti3qK100% (1)

- Nigerian Romance ScamDokumen10 halamanNigerian Romance ScamAnonymous Pb39klJBelum ada peringkat

- Communication in Application: WhatsappDokumen18 halamanCommunication in Application: WhatsappNurul SuhanaBelum ada peringkat

- Base Is OkDokumen84 halamanBase Is OkajaydevmalikBelum ada peringkat

- #1Dokumen7 halaman#1Ramírez OmarBelum ada peringkat

- A Secret Baby by The Bratva by Lexi AsherDokumen184 halamanA Secret Baby by The Bratva by Lexi Asheralisa sanchez100% (1)

- Method Statement Pressure TestingDokumen15 halamanMethod Statement Pressure TestingAkmaldeen AhamedBelum ada peringkat

- 457 PDFDokumen8 halaman457 PDFAbbey Joy CollanoBelum ada peringkat