ASCO 40 Pressure Sensor

Diunggah oleh

tanvir04169Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

ASCO 40 Pressure Sensor

Diunggah oleh

tanvir04169Hak Cipta:

Format Tersedia

4 Sensors

ASCO, the leader in the design and manufacture of

solenoid valves, now offers a complete line of Pressure

Sensors. With pressure ratings up to 10,000 psig and the Sensing Element

ability to handle difficult applications like steam and Sensor elements are bonded with inorganic

refrigeration, ASCO Pressure Sensors will meet your material to provide low drift repeatable signal.

most demanding needs. The ASCO Pressure Sensor technology provides high sensitivity

permitting thicker cavities.

Sensor line is ideal for accurately measuring

MEM's technology.

many process fluids in the most demanding,

Wide operating temperature range.

pulsating, and vibrating environments.

Ranges up to 10,000 psig.

The one piece pressure cavity is machined from Rugged construction for harsh environments.

17.4 PH stainless steel, which offers no source for

contamination of the process fluid or the sensor.

This design provides the stability, accuracy, flexi-

No Leak Path Design

Pressure cavity is one piece

bility, and EMI resistance that your process

(17.4 PH Stainless Steel) construction.

needs. This single, machined, pressure cavity

Pressure sensing surface is integral

will also allow you to handle a wide variety of to body no separate diaphragm.

applications, thus standardizing on fewer Excellent Isolation, over-pressure,

sensors, as well as reducing your inventory. and burst characteristics.

No fill fluids utilized.

ASCO Pressure Sensors demonstrate

ASCO's commitment to the most reliable

flow control solutions.

INDEX PAGE

Series 40 Isolated Pressure Sensor 1

Series 42 Panel Mount Isolated Pressure Sensor 3

Series 43 Hazardous Locations Isolated Pressure Sensor 5

Series 44 Intrinsically Safe Isolated Pressure Sensor 7

Series 45 Tank Level Sensor 9

Series 46 Explosionproof Pressure Sensor 11

Series 47 High Accuracy Pressure Sensor 13

Series 48 Combination Pressure/Temperature Sensor 15

Series 50 Wet/Wet Differential Pressure Sensor 17

Series

40

Series 40

4

Stainless Steel Media Isolated Pressure Sensor

Features

High strength stainless steel construction.

No silicone oil, no internal o-rings, no welds.

Wide operating temperature range.

Ranges up to 10,000 psig.

Rugged design survives harsh environments.

Compatible with wide range of gases and liquids.

Suitable for high shock and vibration applications.

Specifications

Performance @ 25C (77F)

Accuracy1 <0.5% BFSL

Stability (1 year) 0.25% FS, typ. Electrical Data

10-28VDC, 10-28VDC,

Excitation 5VDC 5VDC

Proof Pressure 2X Rated Pressure typ. typ.

Voltage (.25-5V, 0-50mV,

Burst Pressure 5X or 20,000 psig, whichever is less Output 4-20mA 0-50mV

1-5V, 1-6V) 0-100mV

Output <100 Ohms, 1100, Ohms, <100 Ohms,

Pressure Cycles > 100 Million Impedance

-

nom. nom. nom.

1 Current

Accuracy includes: Non-linearity, Hysteresis, and Non-repeatability 25mA max. <10mA <5mA <100mA

Consumption

Bandwith DC to 5kHz,

DC to 250 Hz DC to 1kHz DC to 1kHz

Physical Description (-3dB) min.

Zero Offset <1.0% of FS <1.0% of FS <2.0% of FS <1.0% of FS

17.4PH stainless steel NACE compatible

Wetted Material Span

(for other materials, consult factory) Tolerance

<2.0% of FS <1.5% of FS <2.0% of FS <1.0% of FS

Cable, DIN, or 1/2" conduit pipe Output Noise - <2mV RMS N/A <2mV RMS

Electrical Connection

(for other lengths, consult factory) See Load

10k Ohms, 10k Ohms,

Output Load Line Curve >1M Ohms

min. min.

304 stainless steel Below

Case

(for other materials, consult factory.) Reverse

Polarity Yes Yes N/A Yes

Protection

Environmental Data Pressure Ranges*+

Temperature Gage Proof Burst Pressure

psig psig psig Range Code

Operating -40 to 85C (-40 to 185 F)

0-25 50 250 00025

Storage -40 to 125C (-40 to 250 F)

0-50 100 250 00050

Thermal Limits

0-100 200 500 00100

Compensated Range 0 to 55C (30 to 130 F)

0-200 400 1,000 00200

TC Zero <1.5% of FS (<3.0% for 0-25 psig)

TC Span <1.5% of FS 0-500 1,000 2,500 00500

Other 0-1,000 2,000 5,000 01000

Shock 100G, 11msec, 1/2 sine 0-2,500 5,000 12,500 02500

Vibration 20G Peak, 20 to 2400 Hz 0-5,000 10,000 20,000 05000

Rating IP-66 0-7,500 15,000 20,000 07500

EMI/RFI Protection Yes 0-10,000 20,000 20,000 10000

* Typical Ranges. All ranges between 0-25 psig and 0-10,000 psig

are available. Please consult factory.

+

Vacuum calibration available. Please consult factory.

Specifications are subject to change without notice.

1

Series

40

4

Ordering Information

Construct a product code using the chart below. (Consult factory for other options)

40-A-00500-B-3-E-0-000

Series Process Pressure Pressure Outputs Electrical Wetted Options

Type Connection Range Unit Interface Material

40 X= Special XXXXX= X= Special X= Special X= Special X= Special XXX= Special

Standard A= 1/4" MNPT Special B= BAR A= 0-50mV A= 2ft. cable 0= 17.4 PH 000= No options

B= 1/8" MNPT K= kg/cm

2

B= 20mV/V B= 4ft. cable 1= 316 L A10= 0.10 accuracy

Insert pressure 2= Inconel

C= 1/4" BSPP Male P= psig G= 1-10V/DC C= 6ft. cable A25= 0.25 accuracy

range code

D= 1/8" BSPP Male W= Inches T= 3mV/V D= 10ft. cable C01 Calibration 1-9

from pressure

E= 1/2" MNPT of H2O 1= 10mV/V E= Mini DIN 43650 C10 Calibration 10-49

range chart.

F= 7/16" -20 UNF column 2= 0.5-4.5V F= Packard Metripack 150 C50 Calibration 50-up

Male Vacuum = V0000 ratiometric 3 pin connector C0S Cleaned for O2

H= 1/8" FNPT -14.7psig/-1.01bar 3= 1-5V/DC G= 4 pin Molex connector service

J= 1/4" FNPT 4= 4-20mA H= Flex strip 3"

For vacuum replace

N= 9/16" MNPT 5= 5mV/V J= 15ft. cable

first zero with (V) in

w/o-ring boss 6= 1-6V K= 8ft. cable

pressure code.

S= 1/2" FNPT M= Bendix military conn.

(Ex. V0500 =

V= Pollished VCR R= 6 pin Bendix

Vacuum to 500 psig)

T= 25ft. cable

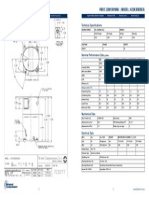

Dimensional Information

Table 1

Output Pin 3 Pin 2 Pin 1

1-5V +V Supply -V Supply Output

4-20mA +V Supply -V Supply N/C

Anda mungkin juga menyukai

- 168 Research Report - TIN PLATEDokumen8 halaman168 Research Report - TIN PLATEPriyank PatelBelum ada peringkat

- Qa16 Qa01 Qa05 Qa06Dokumen2 halamanQa16 Qa01 Qa05 Qa06Jhimnel BuhayanBelum ada peringkat

- Air Torque Pneumatic Actuator ManualDokumen1 halamanAir Torque Pneumatic Actuator ManualAmit AGRAWALBelum ada peringkat

- NCP1203D (203D6) - Ba9741f Ipboard TPV Pwpc1942aua11p (715G1492-1)Dokumen2 halamanNCP1203D (203D6) - Ba9741f Ipboard TPV Pwpc1942aua11p (715G1492-1)Maria Perez100% (1)

- Manual Mfm383a SelecDokumen4 halamanManual Mfm383a SelecPhương NguyênBelum ada peringkat

- TT Schematics Snrs 0126-0300Dokumen4 halamanTT Schematics Snrs 0126-0300Michael Bottes100% (1)

- AV30 (Scheme Ver3.0)Dokumen1 halamanAV30 (Scheme Ver3.0)joe100% (2)

- TCN PDFDokumen66 halamanTCN PDFJahangir AlamBelum ada peringkat

- LEC1Dokumen17 halamanLEC1christophermrequintoBelum ada peringkat

- So Do On AP LiOa (Nen)Dokumen1 halamanSo Do On AP LiOa (Nen)Anhtu Pham100% (1)

- York Yoea36fs36adhDokumen20 halamanYork Yoea36fs36adhjean_carlos_abreu_rBelum ada peringkat

- FA-10-005 - Single Line Diagram-10-003Dokumen1 halamanFA-10-005 - Single Line Diagram-10-003avj278631Belum ada peringkat

- Differential Pressure Switches DPS Series: For Air Conditioning / Ventilation, User-AdjustableDokumen4 halamanDifferential Pressure Switches DPS Series: For Air Conditioning / Ventilation, User-AdjustableMangesh MohiteBelum ada peringkat

- 93 Deg Chrome Finish,: 1/2" NPT Quick ResponseDokumen20 halaman93 Deg Chrome Finish,: 1/2" NPT Quick ResponserajaBelum ada peringkat

- Abb PID-4Dokumen1 halamanAbb PID-4Mate PolegubićBelum ada peringkat

- 6ra4 200a TSKDokumen15 halaman6ra4 200a TSKAlvaro DiazBelum ada peringkat

- Catalogues Au MyDokumen28 halamanCatalogues Au MyChu Hữu LạcBelum ada peringkat

- DCV 94Dokumen11 halamanDCV 94albertoBelum ada peringkat

- Pic152a ViDokumen2 halamanPic152a Viiyappan5016100% (1)

- Controlado QuemadorDokumen19 halamanControlado QuemadorDaniel SrkBelum ada peringkat

- FHP Pressure FiltersDokumen10 halamanFHP Pressure Filtersfrancis_15in100% (1)

- 102-1-上自仪电动头说明书manual de Actuador EléctricoDokumen14 halaman102-1-上自仪电动头说明书manual de Actuador EléctricoLuis Miguel Fernandez Bejarano100% (1)

- DO8P Datasheet PDFDokumen10 halamanDO8P Datasheet PDFRio YuwandiBelum ada peringkat

- Mfm383a User ManualDokumen4 halamanMfm383a User ManualNhân Hồ ChíBelum ada peringkat

- Newlec Catalogue Circuit PDFDokumen12 halamanNewlec Catalogue Circuit PDFanon_376648380Belum ada peringkat

- KITZ Bronze Brass Valves E-101-11 PDFDokumen51 halamanKITZ Bronze Brass Valves E-101-11 PDFwhyme_bBelum ada peringkat

- H23A383DBEADokumen1 halamanH23A383DBEABruno Monteiro0% (1)

- WestWeld YK Series Plasma Torch Catalog 2023Dokumen24 halamanWestWeld YK Series Plasma Torch Catalog 2023bhaaBelum ada peringkat

- BAC - VXC-S - Technical Data SheetsDokumen12 halamanBAC - VXC-S - Technical Data SheetsMahmoud AliBelum ada peringkat

- BCH Electric Ltd-Limit Switch-CatalogueDokumen6 halamanBCH Electric Ltd-Limit Switch-CataloguesachmayaBelum ada peringkat

- Purchase OrderDokumen6 halamanPurchase OrderCristian DiblaruBelum ada peringkat

- Manual Call Points: GeneralDokumen2 halamanManual Call Points: GeneralAnugerahmaulidinBelum ada peringkat

- Model 42 RotofeederDokumen85 halamanModel 42 RotofeederhauBelum ada peringkat

- Flow-Switch-RapidropDokumen4 halamanFlow-Switch-RapidropNOMANBelum ada peringkat

- TC544 TC244 TC344 PDFDokumen3 halamanTC544 TC244 TC344 PDFGaurav AgrawalBelum ada peringkat

- Spare Parts List Arcweld 200i-SDokumen2 halamanSpare Parts List Arcweld 200i-SEmanuel ZalazarBelum ada peringkat

- Amtronic Profiles DP1300Dokumen32 halamanAmtronic Profiles DP1300Handriono OnoBelum ada peringkat

- Golink Temperature Controller Fy SeriesDokumen2 halamanGolink Temperature Controller Fy SeriesJulio OchoaBelum ada peringkat

- Ducati Energia-Capacitors PDFDokumen68 halamanDucati Energia-Capacitors PDFVikaas JainBelum ada peringkat

- Sinorix™: A6V10867394 - en - c2 Building Technologies 2017-06-06 Control Products and SystemsDokumen4 halamanSinorix™: A6V10867394 - en - c2 Building Technologies 2017-06-06 Control Products and SystemsEngineering TFIBelum ada peringkat

- Mizar 6 PDFDokumen5 halamanMizar 6 PDFEric RangelBelum ada peringkat

- MC 35E / MC 45 / MC 65 / MC 90: InnovensDokumen12 halamanMC 35E / MC 45 / MC 65 / MC 90: Innovenskoscoloi365Belum ada peringkat

- Siemens Landis QRA2 Detector Llama UltravioletaDokumen14 halamanSiemens Landis QRA2 Detector Llama UltravioletaPabloAlvBelum ada peringkat

- Outseal PLC Shield UNODokumen1 halamanOutseal PLC Shield UNODadang Ibnu SetyawanBelum ada peringkat

- Cgi Bindownload2.Cgidk 6irqr3rar86jw0xdtmym89mpo0w84778mdngz1g5na7n69qm&fid 13649&file Haier Hsu 18c0Dokumen60 halamanCgi Bindownload2.Cgidk 6irqr3rar86jw0xdtmym89mpo0w84778mdngz1g5na7n69qm&fid 13649&file Haier Hsu 18c0Gayduk ValeriyBelum ada peringkat

- Pressure Regulators For 200/300 Bar Inert Gas SystemsDokumen4 halamanPressure Regulators For 200/300 Bar Inert Gas SystemsDiego Martinez ConteiroBelum ada peringkat

- Evak Multistage PumpsDokumen14 halamanEvak Multistage PumpsRahid Bhatti100% (1)

- CRC HBP 50 60Hz - MS0117A 0415 - NpyDokumen16 halamanCRC HBP 50 60Hz - MS0117A 0415 - NpyMARCOSBelum ada peringkat

- Rotaclip PlanosDokumen121 halamanRotaclip PlanosEnrique Martinez RojasBelum ada peringkat

- Motorized Butterfly Valve: Actuated Wafer Type Butterfly ValvesDokumen6 halamanMotorized Butterfly Valve: Actuated Wafer Type Butterfly ValvesMOSTAFA HabibBelum ada peringkat

- 42pd5000 DatasheetDokumen4 halaman42pd5000 DatasheetImraan RamdjanBelum ada peringkat

- TC5 User ManualDokumen5 halamanTC5 User Manualnightlight2014Belum ada peringkat

- Catalogo Tecnico Split Ducto Baja SiluetaDokumen120 halamanCatalogo Tecnico Split Ducto Baja SiluetaPavlo Rodriguex100% (2)

- TV On DVD-mst720-113Dokumen3 halamanTV On DVD-mst720-113dann222Belum ada peringkat

- LG - LBUM7280BL Exploded ViewDokumen55 halamanLG - LBUM7280BL Exploded ViewGuillermo HernandezBelum ada peringkat

- LG Eay62851201 Eax64908101, LGP4755-13PDokumen72 halamanLG Eay62851201 Eax64908101, LGP4755-13PArgenis BriceñoBelum ada peringkat

- SCXL004DN: Precision Compensated, Low Pressure SensorsDokumen3 halamanSCXL004DN: Precision Compensated, Low Pressure Sensorsloza_2912004Belum ada peringkat

- Pressure Transducer: SpecificationsDokumen9 halamanPressure Transducer: SpecificationsWILLIAM AGUDELOBelum ada peringkat

- 8314Dokumen4 halaman8314tanvir04169Belum ada peringkat

- California Air Tools 10020C-22050 Owner's Manual 3-17 PDFDokumen17 halamanCalifornia Air Tools 10020C-22050 Owner's Manual 3-17 PDFtanvir04169Belum ada peringkat

- Silent CheckDokumen3 halamanSilent Checktanvir04169Belum ada peringkat

- Cem3581 TDokumen1 halamanCem3581 Ttanvir04169Belum ada peringkat

- Apollo 32-100 Series Regular Port Threaded Bronze Ball ValveDokumen1 halamanApollo 32-100 Series Regular Port Threaded Bronze Ball Valvetanvir04169Belum ada peringkat

- Forged Brass Spring Loaded Check & Lever Operated Gate ValvesDokumen1 halamanForged Brass Spring Loaded Check & Lever Operated Gate Valvestanvir04169Belum ada peringkat

- APCO Silent Check PDFDokumen8 halamanAPCO Silent Check PDFtanvir04169Belum ada peringkat

- Bray 52 BrochureDokumen6 halamanBray 52 Brochuretanvir04169Belum ada peringkat

- 750 Gallon Vertical TankDokumen1 halaman750 Gallon Vertical Tanktanvir04169Belum ada peringkat

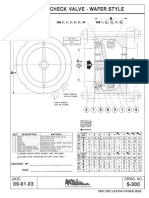

- Silent Check Silent Check Silent Check Silent Check Silent Check V V V V VAL AL AL AL Alve - VE-VE - VE - Ve - W W W W Wafer Style Afer Style Afer Style Afer Style Afer StyleDokumen2 halamanSilent Check Silent Check Silent Check Silent Check Silent Check V V V V VAL AL AL AL Alve - VE-VE - VE - Ve - W W W W Wafer Style Afer Style Afer Style Afer Style Afer Styletanvir04169Belum ada peringkat

- 73 PDFDokumen4 halaman73 PDFtanvir04169Belum ada peringkat

- PPE Sample QuestionDokumen3 halamanPPE Sample Questiontanvir04169Belum ada peringkat

- Engineers and Geoscientists ActDokumen32 halamanEngineers and Geoscientists Acttanvir04169Belum ada peringkat

- Instructions For Installing Series LF23B, LF123LP, LFN250 and LFN250BDokumen2 halamanInstructions For Installing Series LF23B, LF123LP, LFN250 and LFN250Btanvir04169Belum ada peringkat

- How To Apply For A New PassportDokumen6 halamanHow To Apply For A New Passporttanvir04169Belum ada peringkat

- APEGBC Code of EthicsDokumen1 halamanAPEGBC Code of EthicsprithvikhannaBelum ada peringkat

- Apegbc BylawsDokumen21 halamanApegbc Bylawstanvir04169Belum ada peringkat

- A Guide To Copyright - Canadian Intellectual Property OfficeDokumen13 halamanA Guide To Copyright - Canadian Intellectual Property Officetanvir04169Belum ada peringkat

- NPPE Exam - Multiple Choice Sample ExamDokumen13 halamanNPPE Exam - Multiple Choice Sample ExamM G79% (19)

- Design and Analysis of Monopole Circularly Polarised Microstrip Patch Antenna Using HFSSDokumen17 halamanDesign and Analysis of Monopole Circularly Polarised Microstrip Patch Antenna Using HFSSKashif FurkanBelum ada peringkat

- Hindu Temples Models of A Fractal Universe by Prof - Kriti TrivediDokumen7 halamanHindu Temples Models of A Fractal Universe by Prof - Kriti TrivediAr ReshmaBelum ada peringkat

- GS (2006) Vol 2 Rev20 S15 Steel ReinforcementDokumen14 halamanGS (2006) Vol 2 Rev20 S15 Steel ReinforcementLap Chun TUNGBelum ada peringkat

- TrimLite™ UT20706 HomeliteDokumen7 halamanTrimLite™ UT20706 HomeliteBKVBelum ada peringkat

- Teleprotection Over IP MPLS Network White PaperDokumen23 halamanTeleprotection Over IP MPLS Network White PaperLakshmi Kiran100% (1)

- Air Movements 06-26-2019 - Full ScoreDokumen5 halamanAir Movements 06-26-2019 - Full ScoreMichael CrawfordBelum ada peringkat

- X-Plane Mobile ManualDokumen66 halamanX-Plane Mobile ManualRafael MunizBelum ada peringkat

- Stellar Evolution SimulationDokumen2 halamanStellar Evolution Simulationncl12142Belum ada peringkat

- Question IARDokumen4 halamanQuestion IARAryan jay vermaBelum ada peringkat

- K20 Engine Control Module X3 (Lt4) Document ID# 4739106Dokumen3 halamanK20 Engine Control Module X3 (Lt4) Document ID# 4739106Data TécnicaBelum ada peringkat

- ST7201-Finite Element MethodDokumen14 halamanST7201-Finite Element MethodVishal RanganathanBelum ada peringkat

- 3x Exemplar 2017 en PDFDokumen4 halaman3x Exemplar 2017 en PDFgudzalovBelum ada peringkat

- Sympoly Toolbox IssuesDokumen7 halamanSympoly Toolbox IssuesAli FahemBelum ada peringkat

- Life Processes: Science Unit 1Dokumen19 halamanLife Processes: Science Unit 1patil pratikBelum ada peringkat

- The Joyce of Science - ConclusionDokumen2 halamanThe Joyce of Science - ConclusionAhmadBelum ada peringkat

- PHYSICSDokumen24 halamanPHYSICS21SO204 AnvithaBelum ada peringkat

- ATR4518R2Dokumen2 halamanATR4518R2estebanarca50% (4)

- 7625-300 Vitamin B12 AccuBind ELISA Rev 6Dokumen2 halaman7625-300 Vitamin B12 AccuBind ELISA Rev 6carlosalfredorivasBelum ada peringkat

- TitleDokumen142 halamanTitleAmar PašićBelum ada peringkat

- Satisfaction and Revisit Intentions at Fast Food RestaurantsDokumen12 halamanSatisfaction and Revisit Intentions at Fast Food RestaurantsKunal LodhiBelum ada peringkat

- Specializations MTech Software SystemsDokumen5 halamanSpecializations MTech Software SystemsAkanksha SinghBelum ada peringkat

- Fisher Paykel SmartLoad Dryer DEGX1, DGGX1 Service ManualDokumen70 halamanFisher Paykel SmartLoad Dryer DEGX1, DGGX1 Service Manualjandre61100% (2)

- Ergonomic DesignDokumen132 halamanErgonomic DesignErin WalkerBelum ada peringkat

- Residual Alkalinity Nomograph by John Palmer PDFDokumen1 halamanResidual Alkalinity Nomograph by John Palmer PDFcarlos pablo pableteBelum ada peringkat

- EC 201 Network TheoryDokumen2 halamanEC 201 Network TheoryJoseph JohnBelum ada peringkat

- PPF CalculatorDokumen2 halamanPPF CalculatorshashanamouliBelum ada peringkat

- Engine Performance Data at 1500 RPM: QSK 1 Cummins IncDokumen4 halamanEngine Performance Data at 1500 RPM: QSK 1 Cummins IncBalariniRetífica100% (1)

- Laboratory Manual: BTY351 Plant Biotechnology LaboratoryDokumen40 halamanLaboratory Manual: BTY351 Plant Biotechnology LaboratoryRetik KoulBelum ada peringkat

- Test ElectrolysisDokumen3 halamanTest ElectrolysisNatalia WhyteBelum ada peringkat

- Lynx LX v8Dokumen5 halamanLynx LX v8Bambang KaryantoBelum ada peringkat