Advanced Solutions For Polymers and Plastics Poster (011213D - 01)

Diunggah oleh

Mikael SalamancaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Advanced Solutions For Polymers and Plastics Poster (011213D - 01)

Diunggah oleh

Mikael SalamancaHak Cipta:

Format Tersedia

BETTER INSIGHTS

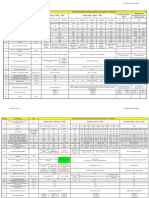

ADVANCED SOLUTIONS FOR POLYMERS AND PLASTICS FOR BETTER POLYMERS

UNDER ONE ROOF

The Polymer Market consists of a huge diversity of manufacturers of industrial products running many different processes Solutions for Polymers focused on providing more insight into product performance and

yet still facing similar challenges. There is more and more pressure to achieve high product quality and reduce costs in order to process optimization

stay one step ahead of the competition.

Material Science is becoming increasingly important, new technologies and applications make it easier to meet your daily

With our instruments and expertise, we can help you:

challenges and regulations in a more cost efficient way. Our comprehensive portfolio of thermal analysis, molecular spectroscopy,

chromatography and hyphenated techniques is the ideal choice for ensuring the quality and reliability of polymers.

Save money and ensure effective quality control

Streamline your processes for outstanding operational efficiency Glass transition & Differential Scanning Calorimetry Modulus, stiffness, Mechanical Analysis

melting temperatures; damping,

Implement cost effective solutions by reverse engineering crystallinity, heat of crystalline,

fusion, reaction rates, alpha and beta

Polymer Processes specific heat and heat

capacity, curing, safety

transitions, glass

transition & melting

and stability studies temperatures

Resin Resin Compound Compound Product

Recycling

Development Manufacture Development Manufacture Forming

DSC 4000/6000 DSC 8000/8500 DMA 8000 TMA 4000

Optimization Ensuring resins ID of chemical ID of raw materials QC of raw Classification

Thermogravimetry Hyphenated Techniques

of materials to meet agreed composition and and QC of finished materials and of materials for Wt % Additive & Identify and

bi-product losses, quantitate evolved

ensure robust specifications interactions of product to ensure finished products; recycling and Wt % Fillers & Ash, gases in resins and

downstream additives correct mix and troubleshooting disposal Decarboxylation, compounds

QC of in-process Pyrolization,

applications distribution of product defects Decomposition and

and final products; Accelerated

additives Stability studies

Optimization of determination of life testing and Optimization of

reaction times, crystal orientation biodegradability Reverse extrusion/molding

end points and studies Engineering to minimize energy STA 6000/8000 TGA 4000 TGA 8000 TL-9000 TG-IR- GC/MS

curing processes consumptions,

Study effects

to reduce costs reduce scrap and Identify and Molecular Spectroscopy FTIR & FT-NIR / Chemical Imaging Identify and Liquid Chromatography/Mass Spectrometry

of chemical or Quantitate organic quantitate additives

Presence of environmental ensure safety molecules and

compounds

residual monomers degradation Understand chemical

& physical composition

Optimization to of laminates &

improve flow, adhesives

Troubleshoot chemical

strength and origin

stiffness of occlusions

Identify orientation Spectrum Two Frontier Spotlight 400 FT-IR Altus HPLC QSight LC/MS/MS

Poly-dispersion of molecules

analysis

Volatile compounds in Gas Chromatography/Mass Spectrometry Reflectance, Molecular Spectroscopy UV/Vis & UV/Vis/NIR

packaging material transmission

and absorption

measurements

a p p l i c at i o n n o t e

for color, HAZE,

Thermal Analysis turbidity, aging,

coatings, glass and

solar cells

Authors

Tiffany Kang

PerkinElmer, Inc.

Kaohsiung, Taiwan R.O.C.

TurboMatrix Headspace & Thermal Desorber Clarus GC, Clarus SQ 8 GC/MS LAMBDA 650/750/850/950/1050

Peng Ye

Solutions for... PerkinElmer, Inc.

Shelton, CT USA

Packaging film manufacturers

MULTIPLE TECHNIQUES - MULTIPLE EXPERTISE FROM ONE COMPANY

Isothermal Introduction

Tire and rubber industries

The crystallization behavior of polymer

Crystallization Study resin For performing QA/QC applications

Plastic goods and components manufacturers

is important to know. For polymer

processors, it helps to optimize the

for Quality Assurance and holding time. DSC ismold

processing conditions like temperature

For studying processes in polymers

Paint and resins manufacturers

traditionally used

to study the thermophysical properties of

polymers. The isothermal crystallization

For research & development

Automotive, aviation, space and defense

experiment is very useful to determine the crystallization kinetic parameters.

In an isothermal crystallization experiment, the polymer sample is first heated

to above its melting temperature and held for some time to fully melt out any

existing crystals. Next, the sample is quench-cooled quickly to the desired

Academics and research institutions

isothermal temperature which is usually between its melting temperature and its

glass transition temperature. The sample is left crystallized under this temperature

and the heat generated during this crystallization process is recorded by the DSC

instrument. The experiment may stop when the crystallization finishes and heat

flow signal reaches the baseline. The isothermal crystallization experiment can be

conducted at a series of temperatures and the result curves can be processed by

the software to get kinetic parameters like reaction order and activation energy.

The isothermal crystallization result is very sensitive to the sample properties. It

can be influenced by many factors, including average molecular weight, molecular

weight distribution, type and concentration of nucleating agent, and its concen-

tration, presence of plasticizers or presence of regrind. Therefore, it is a sensitive

test and can be used to show the difference between various batches of material,

which may show little difference under a conventional heating experiment.

Batches with different crystallization behavior will lead to variation in the quality

of the final processed product. For polymer resin manufacture, it can be used for

quality assurance purposes, the optimization of resin formula or the evaluation

of a competitors resin.

Copyright 2013-2017, PerkinElmer, Inc. All rights reserved. PerkinElmer is a registered trademark of PerkinElmer, Inc. All other trademarks are the property of their respective owners. 011213D_01

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Reinforced Concrete Bridge Deck Design PDFDokumen6 halamanReinforced Concrete Bridge Deck Design PDFFrancisco FaggioniBelum ada peringkat

- Strength of MaterialsDokumen13 halamanStrength of MaterialsPJ Gealone50% (12)

- TGM - Petrochemical Complexes - 160910 - NK PDFDokumen240 halamanTGM - Petrochemical Complexes - 160910 - NK PDFChristina george babyBelum ada peringkat

- Atmospheric Crude Distillation UnitDokumen2 halamanAtmospheric Crude Distillation UnitFahmi Ramadhan PutraBelum ada peringkat

- Third Quarter Science 8: Content StandardDokumen19 halamanThird Quarter Science 8: Content StandardGypsie Ann Pacon100% (1)

- Soil Washing TechnologiesDokumen15 halamanSoil Washing TechnologiesMikael SalamancaBelum ada peringkat

- Lecture Notes - Chem 16 LE3Dokumen8 halamanLecture Notes - Chem 16 LE3Alexander Gordon InesBelum ada peringkat

- Project Report On Activated Carbon (Granular and Powder)Dokumen9 halamanProject Report On Activated Carbon (Granular and Powder)EIRI Board of Consultants and Publishers100% (1)

- Comparing DRI/OGC and Model 2001 thermal/optical carbon analyzersDokumen100 halamanComparing DRI/OGC and Model 2001 thermal/optical carbon analyzersMikael SalamancaBelum ada peringkat

- Analizador de Carbon BlackDokumen2 halamanAnalizador de Carbon BlackMikael SalamancaBelum ada peringkat

- Determinacion Cuantitativa de Carbon Black en El Glaciar AmpayDokumen15 halamanDeterminacion Cuantitativa de Carbon Black en El Glaciar AmpayMikael SalamancaBelum ada peringkat

- The Measurement and Impact of Light Absorbing Particles On Snow SurfacesDokumen16 halamanThe Measurement and Impact of Light Absorbing Particles On Snow SurfacesMikael SalamancaBelum ada peringkat

- 2 Sage29apr2021 Critical-Evidence SinopharmDokumen16 halaman2 Sage29apr2021 Critical-Evidence SinopharmSergio RomeroBelum ada peringkat

- The Role of Zeolite Structure and Acidity in Catalytic Deoxygenation of Biomass Pyrolysis VaporsDokumen12 halamanThe Role of Zeolite Structure and Acidity in Catalytic Deoxygenation of Biomass Pyrolysis VaporsMikael SalamancaBelum ada peringkat

- WHO 2019 nCoV Vaccines SAGE Recommendation BIBP 2021.1 EngDokumen7 halamanWHO 2019 nCoV Vaccines SAGE Recommendation BIBP 2021.1 EngDiane LigmanBelum ada peringkat

- COVID-19 Strains Remote Regions of Peru: World ReportDokumen1 halamanCOVID-19 Strains Remote Regions of Peru: World Reportkayegi8666Belum ada peringkat

- The Role of Catalysis in The Valorization of Woody Biomass Fast Pyrolysis LiquidsDokumen50 halamanThe Role of Catalysis in The Valorization of Woody Biomass Fast Pyrolysis LiquidsMikael SalamancaBelum ada peringkat

- Carbon Black en Glaciares DeterminaciónDokumen11 halamanCarbon Black en Glaciares DeterminaciónMikael SalamancaBelum ada peringkat

- Thermogravimetric Study On Pyrolysis of Biomass With Cu Al2O3 CatalystsDokumen5 halamanThermogravimetric Study On Pyrolysis of Biomass With Cu Al2O3 CatalystsMikael SalamancaBelum ada peringkat

- Validation of A New Set-Up For Continuous Catalytic Fast Pyrolysis of Biomass Coupled With Vapour Phase UpgradingDokumen9 halamanValidation of A New Set-Up For Continuous Catalytic Fast Pyrolysis of Biomass Coupled With Vapour Phase UpgradingMikael SalamancaBelum ada peringkat

- Mechanisms of Biomass Pyrolysis Studied by Combining A Fixed Bed Reactor With Advanced Gas AnalysisDokumen13 halamanMechanisms of Biomass Pyrolysis Studied by Combining A Fixed Bed Reactor With Advanced Gas AnalysisMikael SalamancaBelum ada peringkat

- Screening Acidic Zeolites For Catalytic Fast Pyrolysis of Biomass and Its ComponentsDokumen15 halamanScreening Acidic Zeolites For Catalytic Fast Pyrolysis of Biomass and Its ComponentsMikael SalamancaBelum ada peringkat

- Chapter 9 PDFDokumen4 halamanChapter 9 PDFMikael SalamancaBelum ada peringkat

- Air Pollutant ConcentrationsDokumen5 halamanAir Pollutant ConcentrationsMilton Beychok100% (1)

- B016Dokumen10 halamanB016Mikael SalamancaBelum ada peringkat

- B016Dokumen10 halamanB016Mikael SalamancaBelum ada peringkat

- Air Pollutant ConcentrationsDokumen5 halamanAir Pollutant ConcentrationsMilton Beychok100% (1)

- Environmental Science For DummiesDokumen35 halamanEnvironmental Science For DummiesMikael Salamanca0% (1)

- Guidelines For Kinetic Input To Basin and Petroleum System ModelsDokumen28 halamanGuidelines For Kinetic Input To Basin and Petroleum System ModelsMikael SalamancaBelum ada peringkat

- Remediation of Contaminated Soil by A Solvent/surfactant SystemDokumen7 halamanRemediation of Contaminated Soil by A Solvent/surfactant SystemMikael SalamancaBelum ada peringkat

- B026 PDFDokumen12 halamanB026 PDFMikael SalamancaBelum ada peringkat

- Soil WashingDokumen6 halamanSoil WashingMikael SalamancaBelum ada peringkat

- B 16 Â " B 16M Â " 00 QJE2L0IXNK0 - PDFDokumen4 halamanB 16 Â " B 16M Â " 00 QJE2L0IXNK0 - PDFJoffre ValladaresBelum ada peringkat

- Thermogravimetric AnalysiDokumen11 halamanThermogravimetric AnalysiMikael SalamancaBelum ada peringkat

- PV Module IonDokumen4 halamanPV Module IonrmalewarBelum ada peringkat

- Automated Process Design and Optimization in Oil and Gas DevelopmentDokumen221 halamanAutomated Process Design and Optimization in Oil and Gas DevelopmentMurali MuthuBelum ada peringkat

- Tooth Colour Restorative Materials in Ped DentDokumen27 halamanTooth Colour Restorative Materials in Ped DentNilay ShahBelum ada peringkat

- Cutting Tool Tech and Tool Life CalcDokumen25 halamanCutting Tool Tech and Tool Life CalcPrashant ChouhanBelum ada peringkat

- AIATS Practise Paper-01 AnalysisDokumen111 halamanAIATS Practise Paper-01 AnalysisC R Ramsakha100% (1)

- F&C Safety Data Sheet Catalog No.: 315407 Product Name: Ammonia Solution 25%Dokumen7 halamanF&C Safety Data Sheet Catalog No.: 315407 Product Name: Ammonia Solution 25%Rizky AriansyahBelum ada peringkat

- Lecture Notes On Mixed Signal Circuit Design by Prof Dinesh.K.sharmaDokumen565 halamanLecture Notes On Mixed Signal Circuit Design by Prof Dinesh.K.sharmaSumanth VarmaBelum ada peringkat

- ALM Refrigeration Air DryerDokumen34 halamanALM Refrigeration Air DryerJunaid AhmedBelum ada peringkat

- A 421 - A 421M - 02 Qtqyms9bndixtqDokumen4 halamanA 421 - A 421M - 02 Qtqyms9bndixtqdelta lab sangliBelum ada peringkat

- Internship Format1Dokumen44 halamanInternship Format1Prajwal ChavanBelum ada peringkat

- Aashto T265-15Dokumen4 halamanAashto T265-15Besha aliBelum ada peringkat

- Dehydration of Ethanol To EthyleneDokumen10 halamanDehydration of Ethanol To EthylenewiboonwiBelum ada peringkat

- Build Up MaterialsDokumen5 halamanBuild Up MaterialsMishell CarolinaBelum ada peringkat

- STM 124 Electronic Configuration and Quantum NumbersDokumen18 halamanSTM 124 Electronic Configuration and Quantum NumbersIvana BalanoBelum ada peringkat

- Chem 16 LE-1 AnswerKeyDokumen4 halamanChem 16 LE-1 AnswerKeyAntonette OngBelum ada peringkat

- Physico-chemical Water Treatment Processes AssignmentDokumen6 halamanPhysico-chemical Water Treatment Processes AssignmentAbir HasanBelum ada peringkat

- David Yu Zhang - Dynamic DNA Strand Displacement CircuitsDokumen290 halamanDavid Yu Zhang - Dynamic DNA Strand Displacement CircuitsCogsmsBelum ada peringkat

- Acid Base SaltMay 24, 2023Dokumen6 halamanAcid Base SaltMay 24, 2023Archi SamantaraBelum ada peringkat

- Cracking and Repair of Closing Welds in 2.25 Cr1 Mo Steel Vessels Operating in High Temperature Synthesis GasDokumen9 halamanCracking and Repair of Closing Welds in 2.25 Cr1 Mo Steel Vessels Operating in High Temperature Synthesis Gasvaratharajan g rBelum ada peringkat

- C7015 Infrarroja PDFDokumen16 halamanC7015 Infrarroja PDFAlfredo Mitzi HernandezBelum ada peringkat

- Allelopathic Potential of Tagetes Minuta Terpenes by A ChemicalDokumen9 halamanAllelopathic Potential of Tagetes Minuta Terpenes by A ChemicalbiologiaufbaBelum ada peringkat

- Accessing The Chemical Properties of Clay Deposits in Ekiti StateDokumen41 halamanAccessing The Chemical Properties of Clay Deposits in Ekiti StateJayla CroninBelum ada peringkat

- Jackman 1996Dokumen66 halamanJackman 199612545343Belum ada peringkat

- HS Analysis of AminesDokumen10 halamanHS Analysis of AminesВиталий ШариповBelum ada peringkat