Vibration Paper 1

Diunggah oleh

Anonymous J1vjrU2Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Vibration Paper 1

Diunggah oleh

Anonymous J1vjrU2Hak Cipta:

Format Tersedia

Modern Mechanical Engineering, 2011, 1, 6-11

doi:10.4236/mme.2011.11002 Published Online August 2011 (http://www.SciRP.org/journal/mme)

Design Optimization of Shell and Tube Heat

Exchanger by Vibration Analysis

Shravan H. Gawande1, Appasaheb A. Keste1, Laxman G. Navale1, Milindkumar R. Nandgaonkar1,

Vaishali J. Sonawane1, Umesh B. Ubarhande2

1

Department of Mechanical Engineering, Modern Education Societys College of Engineering, Pune, India

2

PEM Design (R&D), Alfa Laval (India) Ltd., Pune, India

E-mail: shgawande@gmail.com

Received July 23, 2011; revised August 7, 2011; accepted August 15, 2011

Abstract

In this paper a simplified approach to optimize the design of Shell Tube Heat Exchanger [STHE] by flow

induced vibration analysis [FVA] is presented. The vibration analysis of STHE helps in achieving optimiza-

tion in design by prevention of tube failure caused due to flow induced vibration. The main reason for tube

failure due to flow induced vibration is increased size of STHE. It is found that in case of increased size of

STHE, the surface area and number of tubes increases, thus the understanding and analysis of vibration be-

comes a very difficult task. Again it is found that flow induced vibration analysis is considered as an integral

part of mechanical & thermal design of STHE. The detailed design, fabrication, testing and analysis work

was carried out at Alfa Laval (India), Ltd., Pune-10.

Keywords: Heat Exchanger, Flow-Induced Vibration, TEMA, HTRI

1. Introduction changer, through the installation of sealers in the shell-

side. The gaps between the baffle plates and shell is

The principal culprit in flow induced vibration of tubes blocked by the sealers, which effectively decreases the

of STHE is the unsupported tube lengths subjected to short-circuit flow in the shell-side. The original short-

large flow rates on shell side. The increased size of circuit flow then participates in heat transfer, which in-

STHE due to large flow rates is responsible for vibration tensifies the heat transfer performance inside the heat

of tubes, which further leads to tube failure. Also the exchanger. The use of a non-traditional optimization tech-

design of STHE is made safer by modifying shell type nique; called Particle Swarm Optimization (PSO), for

and/or baffles style and baffle design. Thus, the vibration design optimization of shell-and-tube heat exchangers

analysis is of utmost importance in design of STHE. So, from economic view point is explored in [4] in which

the flow induced vibration analysis is considered as an minimization of total annual cost is considered as an ob-

integral part of thermal design. jective function. Three design variables such as shell

The characteristics of vortex shedding from tube banks internal diameter, outer tube diameter and baffle spacing

with closely mounted serrated fin was investigated in [1] are considered for optimization. Two tube layouts viz.

where the relationship between the Strouhal number de- triangle and square are also considered for optimization.

fined by the equivalent diameter as the characteristic The results of optimization using PSO technique are

length of a finned tube in the tube banks and the Strouhal compared with those obtained by using Genetic Algo-

number map for bare-tube banks was examined. Whereas rithm (GA). Also the optimization of the design of shell-

in [2] the author has presented various outlet conditions and-tube heat exchangers by minimization of the thermal

of a shell and tube heat exchanger theoretically and ex- surface of the equipment, for certain minimum excess

perimentally in which it is observed that prime parameter area and maximum pressure drops, considering discrete

geometry of outlet affects the performance, maintenance decision variables is presented in [5]. The heat transfer

and life span of a vertical shell and tube evaporator. The coefficient and pressure drop on the shell side of a

heat transfer enhancement has been achieved in [3], by shell-and-tube heat exchanger has been obtained experi-

modifying the configuration of a shell-and-tube heat ex- mentally in [6] for three different types of copper tubes.

Copyright 2011 SciRes. MME

S. H. GAWANDE ET AL. 7

The comprehensive experimental investigation on the 2.2. Fluid-Elastic Excitation

augmentation of heat transfer coefficients and pressure

drop during condensation of HFC-134a in a horizontal When fluid flows across tube bundle, due to the com-

tube at the presence of different twisted tape inserts was plexity of flow condition, some certain tube in the bank

carried out in [7]. The experiments were performed for a may take instant movement, thereby the flow field around

plain tube and four tubes with twisted tapes inserts of 6, it changes and the equilibrium of forces on adjacent

9, 12 and 15 twist ratios. Similarly, the numerical and ex- tubes is broken, which makes tubes move and begin vi-

perimental investigations to understand convective heat brating. When flow rate increases to a certain degree,

transfer from a single round pipe coiled in rectangular work of fluid elastic force on tube bundle will be larger

pattern are presented in [8] where the studied heat ex- than the work consumed by damping action of tubes, then

changers were composed with inner and outer coils so amplitude of tube will increase rapidly and cause tubes to

that the exterior flow is very similar to flow within tube- collide with each other and be destructed.

bundles. The inner and outer coils of the heat exchangers

are in turn composed of bends and straight portions. The 2.3. Turbulent Buffeting

investigation of the flow field and the heat transfer char-

Turbulence is generated when shell side fluid, flow

acteristics of a shell-and-tube heat exchanger for the

through tube bundle. In the depth of in-line and interlac-

cooling of syngas were carried out in [9] in which the

ing arrangement of tube bundle, with irregular turbulence

finite volume method based on FLUENT software and enlarging gradually, degree of turbulent pressure fluctua-

the turbulence model was adopted for modeling turbulent tion augments and has heat exchange tubes endure ran-

flow. The pressure drop, the temperature distribution and dom fluctuating acting forces. When basic frequency of

the variation of local heat transfer were studied under the turbulence pulsating is proximal or equal to natural fre-

effects of the syngas components and the operating pre- quency of tube, fierce vibration will take place.

ssure, and the effect of the arrangement of the baffles on

the heat transfer has been studied. 2.4. Fluid-Elastic Whirling

In this proposed work design, development & testing

of STHE is carried out. Along with the parameter con- This is characterized by tubes vibrating in an orbital or

sidered in [1-8], vibration analysis is performed to opti- whirling manner, once sufficient energy is available

mized unsupported span of tube by using HTRI software. for resonance to occur. This motion is produced when

Detail overview on work carried out by researchers is the shell side flows across the tubes causes both lift and

presented in Section 1, Section 2 & 3 states mechanics of drag movement of tubes at their natural frequencies. It

flow-induced vibration and the current problem defini- can lead to a runaway condition if the energy supplied

tion & objective, details of STHE is given in Section 4. to tubes cannot be absorbed by the system damping and,

Section 5 explores results of flow-induced vibration thereby, lead to failure of tubes due to flow-induced vi-

analysis, final investigations and results are presented in bration. Such a failure is likely to occur if the cross flow

Section 6 and concluding remark is given in Section 7. velocity is greater than a critical velocity.

2. Mechanics of Flow-Induced Vibration 2.5. Acoustic Resonance

Failures of heat exchangers caused by flow-induced vibra- Acoustic resonance occurs only on the condition that

tion are mainly in terms of the detriments of heat ex- shell-side fluid is gas. When gas flows across tube bun-

dle, acoustic standing waves, which is perpendicular to

changer tubes. Generally, there are several main mecha-

both tubes and flow direction, may come into being and

nisms for flow-induced vibration in heat exchangers as

be reflected repeatedly by inner wall of heat exchanger.

follows:

Meanwhile, as gas flows across tube bundle, Karmans

vortex street comes into being behind tubes. And when

2.1. Vortex Shedding frequency of vortex street accords with the frequency of

acoustic standing waves, the couple will come and all the

When shell side fluid flows across heat exchanger tubes, kinetic energy of flow media will be transmuted to acous-

alternately varying Karmans vortex streets will come tic pressure waves, thereby vibration and strong noise will

into being downstream of tubes, which generates periodic appear in heat exchanger.

changing exciting forces, which direction is perpendicular

to fluid flow, and results in vibration of tubes. When fre- 3. Problem Definition & Objective

quency of vortex shedding is close or equal to the natural

frequency of tube, violent vibration will occur. Flow-induced vibration analysis of a shell and tube heat

Copyright 2011 SciRes. MME

8 S. H. GAWANDE ET AL.

exchanger is an integral element of its thermal design. A 5. Flow-Induced Vibration Analysis [FVA]

proper design is one that is absolutely safe against failure

of tubes due to flow induced vibration. Most sophisti- Table 2 shows the Flow-Induced Vibration Analysis

cated thermal design software packages carry out vibra- Results of STHE by using HTRI software.

tion analysis as a routine ingredient of thermal design.

This is essential since it is during thermal design that the 6. Results & Discussion

geometry of a heat exchanger is finalized and it is this

same geometry, along with flow, physical and property From Figure 2, it is observed that the bundle shell acous-

parameters, determines whether the given heat exchanger tic frequency decreases from inlet to exit, hence the na-

is safe against failure of tubes due to flow-induced vibra- ture of the plot is parabolic. Acoustic resonance is due to

tions. Flow-induced vibration is a very complex subject gas column oscillation and is excited by phased vortex

and involves the interplay of several parameters, many of shedding. The oscillation creates an acoustic vibration of

which are not very well established. Although many cases a standing wave type. The generated sound wave will not

of failure of tubes due to flow-induced vibration has been affect the tube bundle unless the acoustic resonant fre-

reported in the past several years, and an understanding of quency approaches the tube natural frequency, although

the factors responsible for these failures leave much to be the heat exchanger shell and the attached piping may

desired. The literature depicts several interesting studies vibrate, accompanied with loud noise. Then the acoustic

on specific facets of the vibration problem; however, very resonant frequency approaches the tube natural fre-

few investigations have considered the specific problems

quency, any tendency toward tube vibration will be ac-

associated with shell and tube heat exchangers.

centuated with possible tube failure.

Hence in order to provide a simple solution to above

There are several means available to correct a resonant

stated problem, in this work Flow-induced Vibration

condition, but most could have some effect on exchanger

Analysis of a STHE is performed to optimize the design

performance. The simplest method is to install dereso-

Parameter. It is found that the FVA of STHE helps in

achieving optimization in design of STHE by prevention nating baffle(s) in the exchanger bundle to break the

of tube failure caused due to flow induced vibration. wave(s) at or near the antinode (This can be done with-

out significantly affecting the shell side flow pattern. In

4. Shell and Tube Heat Exchanger shell and tube exchangers, the standing wave forms are

Specification limited to the first or the second mode. Failure to check

both modes can result in acoustic resonance, even with

The details of STHE are shown in Table 1. deresonating baffles.

Figure 1 shows the STHE under consideration during From Figure 3, it is observed that the tube natural fre-

manufacturing phase with all parts. quency almost remains constant from inlet to center and

then drastically decreases as it approaches to exit. From

Table 1. STHE Specification. analysis it is observed that the individual unsupported

Parameter Description span natural frequency is affected by tube elastic and

Size (Dia./length) 1336/10000 mm inertial properties, tube geometry, span shape, the type of

Surface area (eff.)/unit 781.4 m. sq. support at each end of the unsupported span and axial

Shells/unit 1

Heat Exchanged, (Q) 5064.9 KW loading on the tube unsupported span. Most heat ex-

LMTD (Corrected) 9.15C changers have multiple baffle supports and varied indi-

vidual unsupported spans. Calculation of the natural fre-

quency of the heat exchanger tube is an essential step in

estimating its potential for flow induced vibration failure.

The current state-of-the-art flow induced vibration cor-

relations are not sophisticated enough to warrant treating

the multi-span tube vibration problem (or mode shapes

other than the fundamental) in one comprehensive analy-

sis. Therefore, the potential for vibration is evaluated for

each individual unsupported span, with the velocity and

natural frequency considered being that of the unsup-

ported span under examination.

One of the most important and least predictable pa-

rameters of flow induced vibration is fluid velocity. To

calculate the local fluid velocity at a particular point in

Figure 1. Shell and Tube Heat Exchanger. the heat exchanger is a difficult task. Various amounts of

Copyright 2011 SciRes. MME

S. H. GAWANDE ET AL. 9

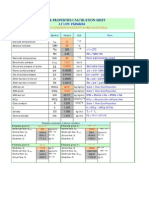

Table 2. Flow-induced vibration analysis of STHE.

HTRI Vibration Analysis Page 1

Released to the following HTRI Member Company:

Alfa Laval

Alfa Laval

Xist Ver. 6.00 3/31/2011 13:34 SN: 1500214335 MKH Units

RatingHorizontal Multipass Flow TEMA BEM Shell with NTIW-Segmental Baffles

Shellside condition Sens. Gas (Level 2.3)

Axial stress loading (kg/mm2 ) 0.000 Added mass factor 1.394

Beta 2.717

Position in the Bundle Inlet Center Outlet

Length for natural frequency (mm) 500. 390. 624.

Length/TEMA maximum span (--) 0.328 0.256 0.409

Number of spans (--) 13 13 13

Tube natural frequency (Hz) 289.5 289.0 197.4 +

Shell acoustic frequency (Hz) 339.9 310.4 300.4 +

Flow Velocities Inlet Center Outlet

Window parallel velocity (m/s) 4.19 3.50 3.28

Bundle crossflow velocity (m/s) 2.33 2.53 1.46

Bundle/shell velocity (m/s) 1.85 2.00 1.16

Fluidelastic instability Check Inlet Center Outlet

Log decrement HTRI 0.029 0.032 0.026

Critical velocity (m/s) 23.46 37.53 12.66

Baffle tip cross velocity ratio (--) 0.1061 0.0719 0.1234

Average crossflow velocity ratio (--) 0.994 0.0673 0.1155

Acoustic Vibration Check Inlet Center Outlet

Vortex shedding ratio (--) 0.164 0.178 0.103

Chen number (--) 8851 12941 8335

Turbulent buffeting ratio (--) 0.108 0.117 0.068

Tube Vibration Check Inlet Center Outlet

Vortex shedding ratio (--) 2.219 0.238 0.138

Parallel flow amplitude (mm) 0.000 0.001 0.000

Crossflow amplitude (mm) 0.002 0.001 0.002

Tube gap (mm) 6.350 6.350 6.350

Crossflow RHO-V-SQ (kg/m-s2) 208.80 293.72 105.02

Bundle Entrance/Exit

(analysis at first tube row) Entrance Exit

Fluidelastic instability ratio (--) 0.154 0.143

Vortex shedding ratio (--) 0.339 0.170

Crossflow amplitude (mm) 0.00544 0.00386

Crossflow velocity (m/s) 3.61 1.81

Tubesheet to inlet/outlet support (mm) None None

fluid bypass the clearances between baffles and shell, or direction, clearance between the bundle and the shell,

tube and baffle tube holes. Until methods are developed tube-to-baffle hole annular clearances, etc. reduce the net

to accurately calculate local fluid velocities, the designer flow rate of the shell side fluid in cross flow. This should

may use average cross flow velocities based on available be considered in computing the reference cross flow ve-

empirical methods. locity.

Figure 4 shows that the bundle cross flow velocity in- From Figure 5 it is seen that the cross flow velocity

creases from inlet to center and then drastically decreases constantly increases from inlet to center and then con-

as it approaches to exit. It is seen that the cross flow ve- stantly decreases as it approaches to exit.

locity in the bundle varies from span to span, from row From Figure 6 it is seen the log decrement constantly

to row within a span, and from tube to tube within a row. increases from inlet to centre and then constantly de-

The reference cross flow velocity is calculated for each creases as it approaches to exit.

region of interest and is based on the average velocity Figure 7 indicate that the vortex shedding ratio con-

across a representative tube row in that region. The stantly increases from inlet to center and then gradually

presence of pass partition lanes aligned in the cross flow decreases as it approaches to exit.

Copyright 2011 SciRes. MME

10 S. H. GAWANDE ET AL.

Figure 6. Tube length v/s Log decrement.

Figure 2. Tube length v/s Shell acoustic frequency.

Figure 7. Tube length v/s Vortex shedding ratio.

7. Conclusions

Figure 3. Tube length v/s Tube natural frequency

From the vibration analysis of STHE it is found that the

tube length has major impact on shell acoustic frequency,

the tube natural frequency, bundle cross flow, critical

velocity, vortex shedding ratio. From Table 2 and Fig-

ure 3 to Figure 7, it can be concluded that up to mid

span of the tube (i.e. 500 cm) the tube natural frequency,

bundle cross flow, critical velocity, and vortex shedding

ratio are gradually increasing & then decreases up to the

end of tube length. Also, the mechanisms of flow-in-

duced vibration are studied and the several main mecha-

nisms are introduced. We finally come to the conclusion

that the main parameter which largely affects the vibra-

tions caused due to flow are dependent on unsupported

Figure 4. Tube length v/s Bundle cross flow velocity.

tube length and varies at various locations across the tube

length as unsupported tube length varies. The various

other parameters which affect the flow induced vibration

are critical velocity, natural frequency of tubes, cross-

flow velocity and acoustic frequency.

8. References

[1] H. Hiromitsu, M. Kouichi, N. Eiichi and F. Tohru, Vor-

tex Shedding from Tube Banks with Closely Mounted

Serrated Fin, Journal of Environmentand Engineering,

Vol. 6, No. 1, 2011, pp. 69-80. doi:10.1299/jee.6.69

[2] C. W. M. van der Geld and J. M. W. M. Schoonen, De-

Figure 5. Tube length v/s Critical velocity. sign Improvement of Shell and Tube Heat Exchanger

Copyright 2011 SciRes. MME

S. H. GAWANDE ET AL. 11

based on Practical Experience and Numerical Analysis, and-Tube Heat Exchanger with Three Different Tube

Design Report, Eindhoven University of Technology, Bundles, Applied Thermal Engineering, Vol. 27, No. 5-6,

Netherlands, 1991, pp. 74-87. 2007, pp. 1001-1008.

[3] S. Wang, J. Wen and Y. Li, An Experimental Investiga- doi:10.1016/j.applthermaleng.2006.07.023

tion of Heat Transfer Enhancement for a Shell-and-Tube [7] V. Hejazi, M. A. Akhavan-Behabadi and A. Afshari,

Heat Exchanger, Applied Thermal Engineering, Vol. 29 Experimental Investigation of Twisted Tape Inserts Per-

No. 11-12, 2009, pp. 2433-2438. formance on Condensation Heat Transfer Enhancement

doi:10.1016/j.applthermaleng.2008.12.008 and Pressure Drop, International Communications in

[4] V. K. Patel and R.V. Rao, Design Optimization of Shell- Heat and Mass Transfer, Vol. 37, No. 9, 2010, pp. 1376-

and-Tube Heat Exchanger Using Particle Swarm Opti- 1387. doi:10.1016/j.icheatmasstransfer.2010.07.021

mization Technique, Applied Thermal Engineering, Vol. [8] I. Cont and X. F. Peng, Numerical and Experimental

30, No. 11-12, 2001, pp. 1417-1425. Investigations of Heat Transfer Performance of Rectan-

doi:10.1016/j.applthermaleng.2010.03.001 gular Coil Heat Exchangers, Applied Thermal Engi-

[5] A. L. H. Costa and E. M. Queiroz, Design Optimization neering, Vol. 29, No. 8-9, 2009, pp. 1799-1808.

doi:10.1016/j.applthermaleng.2008.08.013

of Shell and Tube Heat Exchangers, Applied Thermal

Engineering, Vol. 28, No. 14-15, 2008, pp. 1798-1805. [9] Y. Li, X. Jiang, X. Huang, J. Jia and J. Tong, Optimiza-

doi:10.1016/j.applthermaleng.2007.11.009 tion of High-Pressure Shell-and-Tube Heat Exchanger for

Syngas Cooling in an IGCC, International Journal of

[6] R. Hosseini, A. Hosseini-Ghaffar and M. Soltani, Ex-

Heat and Mass Transfer, Vol. 53, No. 21-22, 2010, pp.

perimental Determination of Shell Side Heat Transfer

4543-4551. doi:10.1016/j.ijheatmasstransfer.2010.04.038

Coefficient and Pressure Drop for an Oil Cooler Shell-

Copyright 2011 SciRes. MME

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Heavy Hex Nuts Dimensions Weight Imperial - MetricDokumen2 halamanHeavy Hex Nuts Dimensions Weight Imperial - MetricAkshay PoddarBelum ada peringkat

- CFX-Intro 14.0 WS08 Vortex-SheddingDokumen22 halamanCFX-Intro 14.0 WS08 Vortex-SheddingRenan Ventura100% (1)

- Dynamic Analysis of Self Supported Steel Chimney As Per Indian StandardDokumen81 halamanDynamic Analysis of Self Supported Steel Chimney As Per Indian StandardrodrigoperezsimoneBelum ada peringkat

- Dynamic Analysis of Self Supported Steel Chimney As Per Indian StandardDokumen81 halamanDynamic Analysis of Self Supported Steel Chimney As Per Indian Standardmoganna73Belum ada peringkat

- Design and Development of Vortex Blade Less Wind TurbineDokumen3 halamanDesign and Development of Vortex Blade Less Wind TurbineEditor IJTSRD100% (1)

- Ribe V D P Y I: Ibration Ampers Rotect Our NvestmentDokumen8 halamanRibe V D P Y I: Ibration Ampers Rotect Our Nvestmentpisang123456100% (1)

- Stockbridge DamperDokumen17 halamanStockbridge Damperjobpei2Belum ada peringkat

- Vortex FlowmeterDokumen16 halamanVortex FlowmeterBiswajit DebnathBelum ada peringkat

- Comparision of Piping CodeDokumen14 halamanComparision of Piping CodeAnonymous J1vjrU2Belum ada peringkat

- Vortex Induced VibrationsDokumen7 halamanVortex Induced VibrationsKevin Paredes GutierrezBelum ada peringkat

- Filter Vessel Calculations Per As Me Viii 1Dokumen40 halamanFilter Vessel Calculations Per As Me Viii 1Anonymous J1vjrU2Belum ada peringkat

- Difference Between MAWP and Design PressureDokumen3 halamanDifference Between MAWP and Design PressureAnonymous J1vjrU2Belum ada peringkat

- Wet Air Properties Calculation Sheet: at Low PressureDokumen2 halamanWet Air Properties Calculation Sheet: at Low PressureAnonymous J1vjrU20% (1)

- Filtros BolsaDokumen53 halamanFiltros BolsaAnonymous J1vjrU2Belum ada peringkat

- PSE' Series: 2930 Hwy 152 West - P.O. Box 1640 Pampa, TX 79065 Phone 806-665-8446 Fax 806-665-9736Dokumen2 halamanPSE' Series: 2930 Hwy 152 West - P.O. Box 1640 Pampa, TX 79065 Phone 806-665-8446 Fax 806-665-9736Anonymous J1vjrU2Belum ada peringkat

- TANK Module: Sample PrintoutDokumen17 halamanTANK Module: Sample PrintoutAnonymous J1vjrU2Belum ada peringkat

- ENGR 2343 - Fluid Mechanics Chapter 7: Dimensional Analysis & Modeling Homework #8 - Due 10/22/14 at Beginning of ClassDokumen10 halamanENGR 2343 - Fluid Mechanics Chapter 7: Dimensional Analysis & Modeling Homework #8 - Due 10/22/14 at Beginning of ClassKarthik_BondaBelum ada peringkat

- Energy Harvesting Eel: JFLS 20000355Dokumen13 halamanEnergy Harvesting Eel: JFLS 20000355hextobinaryBelum ada peringkat

- Absolute and Convective Instabilities of Two-Dimensional Bluff Body Wakes in Ground EffectDokumen13 halamanAbsolute and Convective Instabilities of Two-Dimensional Bluff Body Wakes in Ground Effectsamik4uBelum ada peringkat

- Smoke Flow Experiment ReportDokumen7 halamanSmoke Flow Experiment ReportSharan Teja ElagandulaBelum ada peringkat

- 1996 Williamson Vortex Dynamics in The Cylinder Wake Ann ReviewDokumen67 halaman1996 Williamson Vortex Dynamics in The Cylinder Wake Ann ReviewPedroRamosBelum ada peringkat

- Influence of Dimple Design On Aerodynamic Drag of Golf BallsDokumen7 halamanInfluence of Dimple Design On Aerodynamic Drag of Golf BallsCaioBelum ada peringkat

- FPC Low Re PDFDokumen25 halamanFPC Low Re PDFAndrew RobertsonBelum ada peringkat

- Wind-Induced Vibration of Structural CablesDokumen72 halamanWind-Induced Vibration of Structural CablessazradBelum ada peringkat

- Summer (2010) Two Circular Cylinders in Cross-Flow. A Review PDFDokumen57 halamanSummer (2010) Two Circular Cylinders in Cross-Flow. A Review PDFLisa PooleBelum ada peringkat

- Research Paper For Vortex BladelessDokumen7 halamanResearch Paper For Vortex BladelessasifBelum ada peringkat

- Choi Flow Control ReviewDokumen29 halamanChoi Flow Control ReviewVivek KantiBelum ada peringkat

- Adam Freeman - 071229 - Thesis PDFDokumen95 halamanAdam Freeman - 071229 - Thesis PDFrigelBelum ada peringkat

- Inclined Cable Aerodynamics of Cable-Stayed BridgesDokumen7 halamanInclined Cable Aerodynamics of Cable-Stayed Bridgesafzal taiBelum ada peringkat

- Cylinder Drag2Dokumen23 halamanCylinder Drag2Andrew SunderlandBelum ada peringkat

- Tree-Inspired Piezoelectric Energy HarvestingDokumen12 halamanTree-Inspired Piezoelectric Energy Harvestingnsrajput.eceBelum ada peringkat

- Fluid-Structure Interaction in Bluff-Body AerodynaDokumen82 halamanFluid-Structure Interaction in Bluff-Body AerodynaAngie ArenasBelum ada peringkat

- Vortex and VorticityDokumen121 halamanVortex and VorticityVictor MarchantBelum ada peringkat

- Vortex DynamicsDokumen15 halamanVortex DynamicsAditya KumarBelum ada peringkat

- Exp3-Direct Weighing MethodDokumen19 halamanExp3-Direct Weighing MethodSaurabh TripathiBelum ada peringkat

- Abaqus/CFD - Sample ProblemsDokumen42 halamanAbaqus/CFD - Sample ProblemsLava SatBelum ada peringkat

- Hot-Wire Anemometry of The Streamwise Vorticity On The Windward Surface of A Swept-Back CylinderDokumen28 halamanHot-Wire Anemometry of The Streamwise Vorticity On The Windward Surface of A Swept-Back CylinderAndyMirzaiBelum ada peringkat

- Vortex Bladeless TurbineDokumen5 halamanVortex Bladeless TurbineAswithareddy AswithareddyBelum ada peringkat