Standards For Repair Material C 928 PDF

Diunggah oleh

Andrew PiJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Standards For Repair Material C 928 PDF

Diunggah oleh

Andrew PiHak Cipta:

Format Tersedia

Designation: C 928/C 928M 08

Standard Specification for

Packaged, Dry, Rapid-Hardening Cementitious Materials for

Concrete Repairs1

This standard is issued under the fixed designation C 928/C 928M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon () indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

1.1 This specification covers packaged, dry, cementitious 2.1 ASTM Standards:2

mortar or concrete materials for rapid repairs to hardened C 39/C 39M Test Method for Compressive Strength of Cy-

hydraulic-cement concrete pavements and structures. Materials lindrical Concrete Specimens

that contain organic compounds, such as bitumens, epoxy C 78 Test Method for Flexural Strength of Concrete (Using

resins, and polymers, as the principal binder are not included. Simple Beam with Third-Point Loading)

1.1.1 Packaged, dry, concrete material contains aggregate of C 109/C 109M Test Method for Compressive Strength of

which at least 5 % by mass of the total mixture is retained on Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube

a 9.5-mm [38-in.] sieve. Specimens)

1.1.2 Packaged, dry, mortar material contains aggregate of C 143/C 143M Test Method for Slump of Hydraulic-

which less than 5 % by mass of the total mixture is retained on Cement Concrete

a 9.5-mm [38-in.] sieve. C 157/C 157M Test Method for Length Change of Hard-

1.2 Aqueous solutions, aqueous emulsions or dispersions ened Hydraulic-Cement Mortar and Concrete

may be included as components of the packaged materials. The C 192/C 192M Practice for Making and Curing Concrete

manufacturer may specify that these liquids are to replace some Test Specimens in the Laboratory

or all of the mixing water. C 403/C 403M Test Method for Time of Setting of Concrete

1.3 Aggregates must be included as a component of the Mixtures by Penetration Resistance

packaged materials. The manufacturer may recommend job C 494/C 494M Specification for Chemical Admixtures for

site addition of specific amounts and types of additional Concrete

aggregates to his product for some uses. However, such C 666/C 666M Test Method for Resistance of Concrete to

reformulated products are not within the scope of this specifi- Rapid Freezing and Thawing

cation. C 672/C 672M Test Method for Scaling Resistance of Con-

1.4 The values stated in either SI units or inch-pound units crete Surfaces Exposed to Deicing Chemicals

are to be regarded separately as standard. The values stated in C 702 Practice for Reducing Samples of Aggregate to

each system may not be exact equivalents; therefore, each Testing Size

--`,```,`,,`,``,,,,,,`,,```,`,,`-`-`,,`,,`,`,,`---

system shall be used independently of the other. Combining C 882 Test Method for Bond Strength of Epoxy-Resin

values from the two systems may result in non-conformance Systems Used With Concrete By Slant Shear

with the standard. C 1012 Test Method for Length Change of Hydraulic-

1.5 The following safety hazards caveat pertains to the test Cement Mortars Exposed to a Sulfate Solution

methods portion of this specification: This standard does not E 96/E 96M Test Methods for Water Vapor Transmission of

purport to address all of the safety concerns, if any, associated Materials

with its use. It is the responsibility of the user of this standard

to establish appropriate safety and health practices and 3. Materials and Manufacture

determine the applicability of regulatory limitations prior to 3.1 Three types of packaged, dry, rapid-hardening concrete

use. and three types of packaged, dry, rapid-hardening mortar are

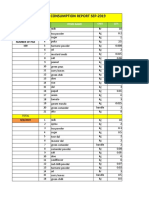

identified in Table 1.

1

This specification is under the jurisdiction of ASTM Committee C09 on

2

Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee For referenced ASTM standards, visit the ASTM website, www.astm.org, or

C09.43 on Packaged Dry Combined Materials. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Oct. 1, 2008. Published October 2008. Originally Standards volume information, refer to the standards Document Summary page on

approved in 1980. Last previous edition approved in 2005 as C 928 05. the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International 1

Provided by IHS under license with ASTM Licensee=Purdue University/5923082001

No reproduction or networking permitted without license from IHS Not for Resale, 06/23/2009 12:24:44 MDT

C 928/C 928M 08

TABLE 1 Performance RequirementsA for use in prestressed concrete. Guidance for such users is

3h 1 day 7 days 28 days outside the scope of this specification.

Compressive Strength, 4.2 If the material contains metallic iron in excess of 1 % by

min, MPa [psi]

B

weight, the package markings shall contain the following

R1 concrete or mortar 3.5 [500] 14 [2000] 28 [4000]

R2 concrete or mortar 7.0 [1000] 21 [3000] 28 [4000] B statement in letter size no smaller than the directions for use:

B

R3 concrete or mortar 21 [3000] 35 [5000] 35 [5000] If small or scattered spots of iron-staining are considered objec-

Bond strength, min, MPa [psi] tionable, do not use this material where it will be exposed.

R1, R2 and R3 concrete or 7 [1000] 10 [1500]

mortar

Length change, based on

5. Performance Requirements

length at 3 h, max, % 5.1 The materials shall comply with the performance re-

R1, R2, and R3 concrete allowable increase after 28 days +0.15

or mortar in water quirements in Table 1 for the applicable type.

allowable decrease after 28 days 0.15

in air 6. Sampling

Consistency of concrete concrete Flow of

or mortarC slump, mortar, min, % 6.1 A lot is the quantity of packaged repair material nor-

min, mm

[in.]

mally placed on a pallet. In general, this quantity will weigh

R1 consistency after 15 min 75 [3] 100 from 900 to 1800 kg [2000 to 4000 lb].

after addition of mixing 6.2 A unit sample is a single package of material randomly

liquid

R2 and R3 consistency at 5 75 [3] 100 selected from the lot.

min after addition of mixing

liquid 7. Specimen Preparation

Scaling resistance to deicing

chemicals after 25 cycles of 7.1 ConcreteMechanically mix the packaged dry concrete

freezing and thawing

Concrete, max visual rating 2.5

material with mixing liquid. Determine the properties of the

Mortar, max scaled materialD 5 kg/m2 [1 lb/ft2] unhardened mixture, and mold and cure the specimens in

A

It is recognized that other characteristics of rapid-hardening concrete repair accordance with Practice C 192/C 192M or modifications as

materials might need consideration. Such characteristics might be necessary in outlined herein.

some environments and applications; however, to impose specification limits on all

products is considered beyond the scope of this specification. Optional consider-

7.1.1 The sample of packaged dry material shall be any

ations with suggested methods of test may include tests for the following: combination of whole packages yielding not less than 20 L [23

Time of setting Test Method C 403/C 403M ft3] of hardened material.

Flexural strength Test Method C 78

Freeze thaw Test Method C 666/C 666M, Procedure A

7.1.2 Base the quantity of water, other liquid component, or

Sulfate expansion Test Method C 1012 both added to the sample on the quantity per bag stated in the

B

The strength at 28 days shall be not less than the strength at 7 days. directions for use.

C

Slump or flow requirements are waived for materials intended for vertical or

overhead applications. 7.1.3 Place the sample in the mixing machine and add the

D

A 250-mm [10-in.] square spalled to an average depth of 3 mm [18 in.] for required amount of liquid. Start mixing immediately. Continue

100 % of its surface would have about 10 kg/m2 [2.0 lb/ft2] of scaled material. mixing for the length of time indicated in the directions for use.

7.1.4 When making the slump test in accordance with Test

4. Chemical Composition Method C 143/C 143M, schedule work so the test will be

4.1 If the material contains soluble chlorides or other completed in 5 6 12 min after the mixing liquid is added to the

ingredients in sufficient quantity to cause corrosion to steel R2 or R3 materials or 15 6 12 min after mixing the liquid with

reinforcement, the package markings shall contain the follow- the R1 materials.

ing statement in letter size no smaller than the directions for 7.1.5 Mold the required number of specimens using addi-

use: tional samples as may be necessary, mixed in accordance with

7.1.1-7.1.4. Do not use the mixtures for molding test specimens

--`,```,`,,`,``,,,,,,`,,```,`,,`-`-`,,`,,`,`,,`---

This material is not recommended for use in a moist environment in contact

with steel reinforcement. when the slump is less than that specified in Table 1.

4.1.1 Consider a total chloride ion content (Berman, NOTE 1Where the nominal maximum particle size is not greater than

1972)3,4 in the packaged repair material greater than 600 25 mm [1 in.], the use of cylindrical molds 100 mm [4 in.] in diameter by

g/m3 [1 lb/yd3] of the hardened repair material indicative that 200 mm [8 in.] in length is suggested.

the packaged material contains sufficient chlorides to cause 7.2 MortarMechanically mix packaged dry mortar mate-

corrosion to steel reinforcement when the concrete is exposed rial with mixing liquid. Determine the properties of the

to weather, is on the ground, or is in an otherwise moist unhardened mixture, and mold and cure the specimens in

environment. A much lower chloride ion content is suggested accordance with Test Method C 109/C 109M or modifications

as outlined herein.

3

Berman, H. A., Determination of Chloride in Hardened Portland Cement Paste,

7.2.1 The sample of packaged dry material shall weigh 3000

Mortar, and Concrete, ASTM Journal of Materials, Vol. 7 , No. 3, pp. 330335, 1972 6 3 g [6.6 6 0.005 lb] and shall be representatively obtained

. from a whole package in accordance with Practice C 702.

4

Clear, K. C., and Harrigan, E. T., Sampling and Testing for Chloride Ion in

Concrete, Report No. FHWA-RD77-85, Federal Highway Administration, Wash-

7.2.2 Base the quantity of water, or other liquid component,

ington, DC, August 1977 (Available as PB 275428/AS National Technical or both added during mixing on the quantity per unit of weight

Information Services). stated in the directions for use.

Copyright ASTM International 2

Provided by IHS under license with ASTM Licensee=Purdue University/5923082001

No reproduction or networking permitted without license from IHS Not for Resale, 06/23/2009 12:24:44 MDT

C 928/C 928M 08

7.2.3 When making the flow test in accordance with the 8.5.1 Do not apply a bonding system to prepared surface

section on consistency in Test Method C 109/C 109M, sched- unless a bonding system is required by the manufacturer of the

ule work so the test will be completed in 5 6 12 min after the rapid-hardening cementitious material. Fill the top half of the

start of mixing liquid with the R2 or R3 materials or 15 6 12 cylinder with the rapid-hardening cementitious material instead

min after mixing the liquid with the R1 materials. of the portland cement mortar specified.

7.2.4 Mold the required number of specimens using addi- 8.5.2 Test three specimens in compression at 1 day and three

tional samples as necessary mixed in accordance with 7.2.1- at 7 days. Calculate the bond strength on the elliptical area and

7.2.3. Do not use the mixtures for molding test specimens report the failure type.

when the flow is less than that specified in Table 1.

7.3 In those cases where the manufacturer has indicated in 9. Report

the package markings, or elsewhere, that the packaged repair 9.1 Report the following:

material can be mixed and applied at temperatures that lie 9.1.1 Source and identification, including type, of material

beyond the range of 20 6 8 C [70 6 15 F], the product must tested,

meet the requirements of Table 1. Specimens must be made and 9.1.2 Details of any variations and options practiced by the

cured in accordance with the procedures of this section. The tester that are recommended or allowed by the manufacturer or

mixing, molding and curing temperatures during the first 3 h others,

after molding shall be within 61 C [62 F] of the extreme 9.1.3 Compressive strength of material at 3 h, 1 day, 7 days

temperature(s) stated by the manufacturer in the package and 28 days,

markings. 9.1.4 Bond strength at 1 day and 7 days,

9.1.5 Percent length change at 28 days in water and in air,

8. Test Methods 9.1.6 Percent flow in mortar at 5 or 15 min,

9.1.7 Slump in concrete at 5 or 15 min, and

8.1 Manifestly Faulty SpecimensTreat manifestly faulty

9.1.8 Scaling resistance after 25 cycles.

specimens in accordance with the corresponding section in

Specification C 494/C 494M. 10. Rejection

8.2 Compressive StrengthPrepare and test three test speci- 10.1 The purchaser has the right to reject material that fails

mens for each age of test and each level of mixing temperature. to conform to the requirements of this specification. Rejection

Test in accordance with Test Method C 39/C 39M for concrete shall be reported to the producer or supplier promptly and in

and Test Method C 109/C 109M for mortar. writing.

8.3 Length ChangePrepare and test specimens in accor-

dance with Test Method C 157/C 157M, except as modified by 11. Certification

this section and 7.3. Use 25 mm [1-in.] prism for mortar 11.1 When specified in the purchase order or contract, a

material and 75 mm [3-in.] prism for concrete material. producer, supplier, or an independent testing laboratory shall

8.3.1 Remove specimens from the molds at an age of 212 to furnish certification to the purchaser that the material has been

234 h after the addition of mixing liquid to the dry cementitious tested in accordance with this specification and found to meet

mixture during the mixing operation. the requirements. When specified in the purchase order or

8.3.2 Make the initial observation of length at 3 to 314 h contract, a report of test results on samples taken from material

after the addition of mixing liquid to the dry cementitious shipped shall be furnished.

mixture during the mixing operation. When specimens are

cured at temperatures other than 23 6 2 C [73.4 6 3 F], then 12. Product Marking

both initial and final length observations must be made with the 12.1 Mark all packages to contain the following informa-

bars conditioned to 62 C [63 F] of initial temperatures. tion:

8.3.3 Immediately store one set of specimens as for Air 12.1.1 Specification designation.

Storage and one set as for Water Storage except that the 12.1.2 R1 or R2 or R3 type.

water-stored specimens shall be stored in untreated tap water 12.1.3 Directions for use that shall include but are not

with no more than one set of specimens per container. limited to:

8.3.4 Take observations of length at age 28 days 6 20 h. 12.1.3.1 When a bonding agent is used in the test of bond

Determine the average percent change in length when stored in strength, the type and kind of adhesive recommended to bond

water, and the average change in length of specimens stored in fresh repair material to the concrete or mortar being repaired.

air. 12.1.3.2 The recommended amount of water, other liquid

8.4 Scaling ResistanceMake and cure the test specimens component, or both, to be mixed with the package contents.

in accordance with Test Method C 672/C 672M, except as 12.1.3.3 The recommended length of mixing time or se-

--`,```,`,,`,``,,,,,,`,,```,`,,`-`-`,,`,,`,`,,`---

provided herein. For specimens of mortar omit the visual rating quence of mixing and resting times in minutes.

procedure after every 5 cycles and after 25 cycles determine 12.1.4 Date the material was packaged.

the amount of scaling as the oven dry 110 6 5 C [230 6 9 F] 12.1.5 The yield in litres [cubic feet] or yield in square

mass per unit area of exposed test area. metres per centimetre [square feet per inch] thickness when

8.5 Slant Shear Bond StrengthPrepare six complete test mixed with the recommended amount of liquid.

specimens in accordance with Test Method C 882 for Type II 12.1.6 The net weight in each container. The contents of any

and V systems except as modified by this section. container shall not vary by more than 2 % from the weight

Copyright ASTM International 3

Provided by IHS under license with ASTM Licensee=Purdue University/5923082001

No reproduction or networking permitted without license from IHS Not for Resale, 06/23/2009 12:24:44 MDT

C 928/C 928M 08

stated in the markings. The average weight of filled containers lb/ft3] in 24 h as determined in accordance with Procedure B of

in a lot shall be not less than the weight stated in the markings. Test Methods E 96/E 96M.

12.1.7 If the product is formulated for use in vertical or

overhead applications, it shall be so stated on the package. 14. Keywords

13. Packaging 14.1 cementitious mortar or concrete materials for repair;

13.1 The material from which the containers are made shall concrete; packaged; mortar; packaged; packaged dry materials

have water vapor transmission not greater than 100 g/m2 [0.2 for concrete repair; rapid hardening materials; repair materials

SUMMARY OF CHANGES

Committee C09 has identified the location of selected changes to this specification since the last issue,

C 928 05, that may impact the use of this specification. (Approved October 1, 2008)

(1) Revised the standard as a combined units standard.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

--`,```,`,,`,``,,,,,,`,,```,`,,`-`-`,,`,,`,`,,`---

Copyright ASTM International 4

Provided by IHS under license with ASTM Licensee=Purdue University/5923082001

No reproduction or networking permitted without license from IHS Not for Resale, 06/23/2009 12:24:44 MDT

Anda mungkin juga menyukai

- Astm C942-15Dokumen3 halamanAstm C942-15adolfo camayoBelum ada peringkat

- Compressive Strength of Grouts For Preplaced-Aggregate Concrete in The LaboratoryDokumen3 halamanCompressive Strength of Grouts For Preplaced-Aggregate Concrete in The LaboratoryEmman Cosme Gumanit Virtudazo100% (3)

- Latex Agents For Bonding Fresh To Hardened ConcreteDokumen2 halamanLatex Agents For Bonding Fresh To Hardened ConcretemickyfelixBelum ada peringkat

- Elastomeric Cellular Preformed Gasket and Sealing Material: Standard Specification ForDokumen5 halamanElastomeric Cellular Preformed Gasket and Sealing Material: Standard Specification ForĐường Nguyễn ThừaBelum ada peringkat

- Astm C-1384Dokumen5 halamanAstm C-1384yayan febriantoBelum ada peringkat

- Flow of Freshly Mixed Hydraulic-Cement Concrete: Standard Test Method ForDokumen3 halamanFlow of Freshly Mixed Hydraulic-Cement Concrete: Standard Test Method ForEvert RiveraBelum ada peringkat

- ASTM1506, Water Retention of Mortar TestDokumen4 halamanASTM1506, Water Retention of Mortar TestTabish Islam100% (2)

- Astm D4060 14Dokumen5 halamanAstm D4060 14hadi ebrahimfathBelum ada peringkat

- Isobond: SBR Bonding AdmixtureDokumen3 halamanIsobond: SBR Bonding AdmixtureHussain MarzooqBelum ada peringkat

- SS S 210aDokumen10 halamanSS S 210akeithc01Belum ada peringkat

- FS Ss-S-200eDokumen23 halamanFS Ss-S-200eGiorgos LympertasBelum ada peringkat

- Lime Putty For Structural PurposesDokumen2 halamanLime Putty For Structural Purposesasemamaw damtieBelum ada peringkat

- D9-12 Standard Terminology Relating To Wood and Wood-Based ProductsDokumen12 halamanD9-12 Standard Terminology Relating To Wood and Wood-Based ProductsAlabbas Fadhel100% (1)

- C780Dokumen16 halamanC780Karlita Cisneros100% (2)

- C827 PDFDokumen5 halamanC827 PDFRam Kumar JaiswalBelum ada peringkat

- ASTM-C 512 (Creep of Concrete Test)Dokumen5 halamanASTM-C 512 (Creep of Concrete Test)Evgeny PankovBelum ada peringkat

- New Ansi 118.15Dokumen2 halamanNew Ansi 118.15Tensile TestingBelum ada peringkat

- Astm F 679-03Dokumen6 halamanAstm F 679-03JORGE ARTURO TORIBIO HUERTA100% (1)

- C933 PDFDokumen2 halamanC933 PDFDIAZCORDOBABelum ada peringkat

- C61-C61M - 00 (Reapproved 2011)Dokumen3 halamanC61-C61M - 00 (Reapproved 2011)Black Goku100% (1)

- ASTM C1019 GroutingDokumen4 halamanASTM C1019 GroutingTrung Hieu NguyenBelum ada peringkat

- Lime and Limestone (As Used by The Industry) : Standard Terminology Relating ToDokumen3 halamanLime and Limestone (As Used by The Industry) : Standard Terminology Relating ToGabriel Arteaga100% (1)

- CEVA 250-Phyzite 380Dokumen1 halamanCEVA 250-Phyzite 380hernie w. vergel de dios jrBelum ada peringkat

- Astm c580 Mortar Flexural PDFDokumen6 halamanAstm c580 Mortar Flexural PDFMaha MuflehBelum ada peringkat

- Roofing and Waterproofing: Standard Terminology Relating ToDokumen9 halamanRoofing and Waterproofing: Standard Terminology Relating ToRONALD MUELLERBelum ada peringkat

- Laboratory Filter Papers: Standard Specification ForDokumen4 halamanLaboratory Filter Papers: Standard Specification ForAhmed AlzubaidiBelum ada peringkat

- D7032 1213477 1 PDFDokumen11 halamanD7032 1213477 1 PDFBodhi RudraBelum ada peringkat

- D 2939 - 98 Rdi5mzktukveDokumen9 halamanD 2939 - 98 Rdi5mzktukvedaovandongpktBelum ada peringkat

- C1032 - 06Dokumen2 halamanC1032 - 06Black GokuBelum ada peringkat

- ASTM C59-C59M - 00 (Reapproved 2011)Dokumen2 halamanASTM C59-C59M - 00 (Reapproved 2011)Black GokuBelum ada peringkat

- Blindside WaterproofingDokumen4 halamanBlindside WaterproofingPramod V PatilBelum ada peringkat

- Astm C868-02 PDFDokumen4 halamanAstm C868-02 PDFIan HsuBelum ada peringkat

- Aci 221R-96Dokumen3 halamanAci 221R-96farhadamBelum ada peringkat

- Astm F3010 - 13Dokumen4 halamanAstm F3010 - 13kinich acevedo100% (1)

- ASTM C-845 Expansive Hydraulic Cement1Dokumen3 halamanASTM C-845 Expansive Hydraulic Cement1Hsaam HsaamBelum ada peringkat

- D41D41M-11 (2016) Aashto M116 PDFDokumen2 halamanD41D41M-11 (2016) Aashto M116 PDFRonnyBelum ada peringkat

- C 1063 - 03 QzewnjmDokumen9 halamanC 1063 - 03 QzewnjmGarcia ManuelBelum ada peringkat

- Fiberglass Reinforced Styrene-Butadiene-Styrene (SBS) Modified Bituminous Sheets With A Factory Applied Metal SurfaceDokumen3 halamanFiberglass Reinforced Styrene-Butadiene-Styrene (SBS) Modified Bituminous Sheets With A Factory Applied Metal SurfaceKevin Josue100% (1)

- D1199Dokumen2 halamanD1199Ненад КнежевићBelum ada peringkat

- ISO 13007-1 E - Adhesives DDokumen11 halamanISO 13007-1 E - Adhesives DGIAPBelum ada peringkat

- Curing In-Place ConcreteDokumen2 halamanCuring In-Place ConcreteaaBelum ada peringkat

- C952Dokumen8 halamanC952Lew IceBelum ada peringkat

- ASTM Designation: C 1305 - 08Dokumen3 halamanASTM Designation: C 1305 - 08Lupita RamirezBelum ada peringkat

- Plastic (Stucco) Cement: Standard Specification ForDokumen4 halamanPlastic (Stucco) Cement: Standard Specification ForAlejandroBelum ada peringkat

- C836C836M 15.PDF (EngPedia - Ir)Dokumen3 halamanC836C836M 15.PDF (EngPedia - Ir)Baba Mountain Gem ServicesBelum ada peringkat

- Recent Trend: Use of Metakaolin As Admixture: A ReviewDokumen7 halamanRecent Trend: Use of Metakaolin As Admixture: A ReviewAJER JOURNALBelum ada peringkat

- C32 13Dokumen2 halamanC32 13diego rodriguezBelum ada peringkat

- MS 14 - Internal Waterproofing PDFDokumen3 halamanMS 14 - Internal Waterproofing PDFsullamsBelum ada peringkat

- Sika Fibre 2011 - PDSDokumen4 halamanSika Fibre 2011 - PDSIbnu SenaBelum ada peringkat

- Bulk Density ("Unit Weight") and Voids in Aggregate: Standard Test Method ForDokumen5 halamanBulk Density ("Unit Weight") and Voids in Aggregate: Standard Test Method ForNibaldo BernardoBelum ada peringkat

- Cement Content of Hardened Soil-Cement Mixtures: Standard Test Method ForDokumen4 halamanCement Content of Hardened Soil-Cement Mixtures: Standard Test Method ForAmwaleed AlghbBelum ada peringkat

- Hydraulic Hydrated Lime For Structural PurposesDokumen3 halamanHydraulic Hydrated Lime For Structural PurposesAlejandroBelum ada peringkat

- C827C827M 16Dokumen5 halamanC827C827M 16Jamman Shahid ShiblyBelum ada peringkat

- Aci 211.2 - 1998 PDFDokumen18 halamanAci 211.2 - 1998 PDFBhavanishankar ShettyBelum ada peringkat

- Agencies Engaged in The Testing And/or Inspection of Materials Used in ConstructionDokumen9 halamanAgencies Engaged in The Testing And/or Inspection of Materials Used in ConstructionFredyBelum ada peringkat

- Determining The Potential Alkali-Silica Reactivity of Combinations of Cementitious Materials and Aggregate (Accelerated Mortar-Bar Method)Dokumen6 halamanDetermining The Potential Alkali-Silica Reactivity of Combinations of Cementitious Materials and Aggregate (Accelerated Mortar-Bar Method)Satya kaliprasad vangaraBelum ada peringkat

- Astm D 1073Dokumen2 halamanAstm D 1073Konul SeyidovaBelum ada peringkat

- D227 PDFDokumen2 halamanD227 PDFArnold RojasBelum ada peringkat

- Packaged, Dry, Rapid-Hardening Cementitious Materials For Concrete RepairsDokumen5 halamanPackaged, Dry, Rapid-Hardening Cementitious Materials For Concrete RepairsFatah FatahBelum ada peringkat

- 1 s2.0 S0360132323004596 MainDokumen14 halaman1 s2.0 S0360132323004596 MainAndrew PiBelum ada peringkat

- National Waste Report 2018Dokumen126 halamanNational Waste Report 2018Andrew PiBelum ada peringkat

- 1 s2.0 S1110016823006087 MainDokumen11 halaman1 s2.0 S1110016823006087 MainAndrew PiBelum ada peringkat

- 1 s2.0 S1110016823006087 MainDokumen11 halaman1 s2.0 S1110016823006087 MainAndrew PiBelum ada peringkat

- Construction and Building MaterialsDokumen11 halamanConstruction and Building MaterialsAndrew PiBelum ada peringkat

- Impacts of Cement Industry On Environment - An Overview: February 2018Dokumen7 halamanImpacts of Cement Industry On Environment - An Overview: February 2018Glen Carlo VillanuevaBelum ada peringkat

- CIVE 443-Syllabus - Fa2019Dokumen7 halamanCIVE 443-Syllabus - Fa2019Andrew PiBelum ada peringkat

- Construction and Building Materials: Linglei Zhang, Yongsheng Ji, Jun Li, Furong Gao, Guodong HuangDokumen10 halamanConstruction and Building Materials: Linglei Zhang, Yongsheng Ji, Jun Li, Furong Gao, Guodong HuangAndrew PiBelum ada peringkat

- Concentration of NaOH and The Effect On The Properties of Fly Ash Based Geopolymer (Hamidi - 2016)Dokumen5 halamanConcentration of NaOH and The Effect On The Properties of Fly Ash Based Geopolymer (Hamidi - 2016)juan diazBelum ada peringkat

- Zhuang 2016Dokumen41 halamanZhuang 2016Daiana IuliaBelum ada peringkat

- E.I. Diaz, E.N. Allouche, S. Eklund: SciencedirectDokumen5 halamanE.I. Diaz, E.N. Allouche, S. Eklund: SciencedirectAdji SutamaBelum ada peringkat

- Composites Part B: F. Colangelo, R. Ciof Fi, G. Roviello, I. Capasso, D. Caputo, P. Aprea, B. Liguori, C. FeroneDokumen7 halamanComposites Part B: F. Colangelo, R. Ciof Fi, G. Roviello, I. Capasso, D. Caputo, P. Aprea, B. Liguori, C. FeroneAndrew PiBelum ada peringkat

- Recycling of Brick Aggregate Concrete As Coarse AggregateDokumen9 halamanRecycling of Brick Aggregate Concrete As Coarse AggregateAndrew PiBelum ada peringkat

- Potential For Use of Crushed Waste Calcined-Clay Brick As A Supplementary Cementitious Material in BrazilDokumen9 halamanPotential For Use of Crushed Waste Calcined-Clay Brick As A Supplementary Cementitious Material in BrazilAndrew PiBelum ada peringkat

- Geopolymer Commercial ProgressDokumen16 halamanGeopolymer Commercial ProgressGagan DeepBelum ada peringkat

- Design Example 01Dokumen171 halamanDesign Example 01jpobando100% (1)

- Construction and Building Materials: M. Adamson, A. Razmjoo, A. PoursaeeDokumen7 halamanConstruction and Building Materials: M. Adamson, A. Razmjoo, A. PoursaeeNiamul IslamBelum ada peringkat

- Construction and Building Materials: Zhi Ge, Yuanyuan Wang, Renjuan Sun, Xinsheng Wu, Yanhua GuanDokumen9 halamanConstruction and Building Materials: Zhi Ge, Yuanyuan Wang, Renjuan Sun, Xinsheng Wu, Yanhua GuanAndrew PiBelum ada peringkat

- Construction and Building Materials: F. Bektas, K. Wang, H. CeylanDokumen6 halamanConstruction and Building Materials: F. Bektas, K. Wang, H. CeylanAndrew PiBelum ada peringkat

- Construction and Building Materials: F. Bektas, K. Wang, H. CeylanDokumen6 halamanConstruction and Building Materials: F. Bektas, K. Wang, H. CeylanAndrew PiBelum ada peringkat

- Alcali Activatied Fly AshDokumen6 halamanAlcali Activatied Fly AshppipilikakiBelum ada peringkat

- Appendix A Example 1 2Dokumen113 halamanAppendix A Example 1 2Karthik Reddy ArekutiBelum ada peringkat

- Design Example 01Dokumen171 halamanDesign Example 01jpobando100% (1)

- Geopolymer Commercial ProgressDokumen16 halamanGeopolymer Commercial ProgressGagan DeepBelum ada peringkat

- ConcreteRepair ALL Brochure WEBDokumen12 halamanConcreteRepair ALL Brochure WEBAndrew PiBelum ada peringkat

- Drying Shrinkage of Slag Blended Fly Ash Geopolymer Concrete PDFDokumen7 halamanDrying Shrinkage of Slag Blended Fly Ash Geopolymer Concrete PDFankit raiBelum ada peringkat

- Hanjitsuwan 2014Dokumen6 halamanHanjitsuwan 2014Andrew PiBelum ada peringkat

- Materials 12 03312Dokumen12 halamanMaterials 12 03312hormilopezBelum ada peringkat

- Repair Mortar - An Overview - ScienceDirect Topics PDFDokumen18 halamanRepair Mortar - An Overview - ScienceDirect Topics PDFAndrew PiBelum ada peringkat

- Rakngan 2018Dokumen8 halamanRakngan 2018Andrew PiBelum ada peringkat

- Big 9 Master SoalDokumen6 halamanBig 9 Master Soallilik masrukhahBelum ada peringkat

- Study Notes On Isomers and Alkyl HalidesDokumen3 halamanStudy Notes On Isomers and Alkyl HalidesChristian Josef AvelinoBelum ada peringkat

- Pip-Elsmt01 P66 Midstream Projects 0 1/02/18: Document Number S & B Job Number Rev Date SheetDokumen11 halamanPip-Elsmt01 P66 Midstream Projects 0 1/02/18: Document Number S & B Job Number Rev Date SheetAjay BaggaBelum ada peringkat

- SanMilan Inigo Cycling Physiology and Physiological TestingDokumen67 halamanSanMilan Inigo Cycling Physiology and Physiological Testingjesus.clemente.90Belum ada peringkat

- NG Teng Fong Discharge DocumentsDokumen14 halamanNG Teng Fong Discharge DocumentsAnonymous yGwMIPJRawBelum ada peringkat

- Alugbati Plant Pigment Extraction As Natural Watercolor SourceDokumen6 halamanAlugbati Plant Pigment Extraction As Natural Watercolor SourceMike Arvin Serrano100% (1)

- Pigeon Disease - The Eight Most Common Health Problems in PigeonsDokumen2 halamanPigeon Disease - The Eight Most Common Health Problems in Pigeonscc_lawrence100% (1)

- CBEU Service ConditionsDokumen623 halamanCBEU Service ConditionsAtul ModiBelum ada peringkat

- Village Survey Form For Project Gaon-Setu (Village Questionnaire)Dokumen4 halamanVillage Survey Form For Project Gaon-Setu (Village Questionnaire)Yash Kotadiya100% (2)

- Chapter 2 and 3 ImmunologyDokumen16 halamanChapter 2 and 3 ImmunologyRevathyBelum ada peringkat

- Science and TechnologyDokumen21 halamanScience and TechnologyPat MillerBelum ada peringkat

- Bisleri Water Industry: Project ReportDokumen53 halamanBisleri Water Industry: Project ReportJohn CarterBelum ada peringkat

- ISO - TR - 15608 - 2017 (En) - Pipe Grouping SystemsDokumen12 halamanISO - TR - 15608 - 2017 (En) - Pipe Grouping SystemsTeodor ProdanBelum ada peringkat

- What Is A VolcanoDokumen2 halamanWhat Is A VolcanonatachaBelum ada peringkat

- Dungeon World ConversionDokumen5 halamanDungeon World ConversionJosephLouisNadeauBelum ada peringkat

- Adsorbents and Adsorption Processes For Pollution ControlDokumen30 halamanAdsorbents and Adsorption Processes For Pollution ControlJoao MinhoBelum ada peringkat

- Nutrition & You - Chapter 6Dokumen40 halamanNutrition & You - Chapter 6Bridget KathleenBelum ada peringkat

- Cargador de BateríaDokumen34 halamanCargador de BateríaBenBelum ada peringkat

- Behavior Specific Praise Statements HandoutDokumen3 halamanBehavior Specific Praise Statements HandoutDaniel BernalBelum ada peringkat

- Standards Spec Brochure ME WEBDokumen44 halamanStandards Spec Brochure ME WEBReza TambaBelum ada peringkat

- Home Composting SystemsDokumen8 halamanHome Composting Systemssumanenthiran123Belum ada peringkat

- Method Statement (RC Slab)Dokumen3 halamanMethod Statement (RC Slab)group2sd131486% (7)

- Soil Biotechnology (SBT) - Brochure of Life LinkDokumen2 halamanSoil Biotechnology (SBT) - Brochure of Life Linkiyer_lakshmananBelum ada peringkat

- Benzil PDFDokumen5 halamanBenzil PDFAijaz NawazBelum ada peringkat

- Fast FashionDokumen9 halamanFast FashionTeresa GonzalezBelum ada peringkat

- Arsenal Strength Catalog 6.2-1Dokumen41 halamanArsenal Strength Catalog 6.2-1Mohammed NavedBelum ada peringkat

- Ras Shastra PPT 6Dokumen10 halamanRas Shastra PPT 6Soham BhureBelum ada peringkat

- Daily Staff Food Consumption Reports Sep-2019Dokumen4 halamanDaily Staff Food Consumption Reports Sep-2019Manjit RawatBelum ada peringkat

- The Case - Lijjat PapadDokumen16 halamanThe Case - Lijjat Papadganesh572Belum ada peringkat

- ASOTDokumen4 halamanASOTemperors_nestBelum ada peringkat