Posicionador Tyco Manual PDF

Diunggah oleh

cristianDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Posicionador Tyco Manual PDF

Diunggah oleh

cristianHak Cipta:

Format Tersedia

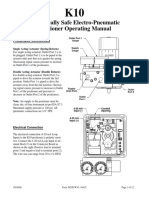

Installation & Operating Instructions

ANALOG POSITIONERS for Intrinsically Safe EaziCal IR Positioner

Mounting Instructions

Note: All AVID Products are factory equipped with Tyco direct mounting. For standard Namur

mounting see Appendix A.

FIG. 1

EaziCal IR Positioner

1. Operate the actuator to full closed position.

ModMount

* Drive Insert

2. Fasten the EaziCal IR positioner to the actu-

ator using (4) 10-32 x .50hex head screws

and (4) #10 washers while engaging its out-

put shaft into the actuators input (fig.1).

Actuator

* Drive insert must be provided with Keystone/Tyco actuators

for ModMount installations.

FIG. 2

3. Loosen the (4) captive screws which fasten

the EaziCal IR Positioner cover. Twist cover

approximately 45and lift up (fig.2). (Wiring

diagram inside EaziCal IR Positioner cover).

TWIST COVER 45,THEN LIFT STRAIGHT UP

4/28/03 Tech-321/D.W.O14722 Page 1 of 14

Pneumatic Connection

Single Acting Actuator (Spring Return):

For single acting actuators Outlet Port 2 is to be

plugged. Outlet Port 1 is to be piped to the actu-

ator inlet port that acts against the spring. Supply Outlet Port 1

(Increasing signal causes pressure to increase Gauge Gauge

in Outlet Port 1 of the positioner).

Double Acting Actuator (Double Return): Outlet

For double acting actuators Outlet Port 2 is Port 1

piped to drive the actuator towards the fail posi-

tion. Outlet Port 1 is piped to drive the actuator

away from the fail position. (Increasing signal

causes pressure to increase in Outlet Port 1 of B

the positioner and pressure to decrease in Out-

Outlet Exhaust

let Port 2 of the positioner). Supply Port 2 Port

(Inlet Port)

Thread

*Note: Air supply to the positioner must be Identification *

clean, dry, oil free instrument air per ISA-S7.3.

Maximum supply pressure is 120 psi. All pneu- *Thread Identification

matic connections are 1/4 NPT or 1/4 BSP. B = 1/4 BSP

See manifold for Identification of thread type. Without

Marking = 1/4 NPT

4-20 mA

Electrical Connection Input (-) Conduit

Opening

The electrical connection (4-20 mA Loop Input) 4-20 mA

to the EaziCal positioner is polarity sensitive. Input (+)

J2

CCW

CW

SW1

Connect the 4-20 mA Loop Input to terminal

J3

block J1 on the Connector Board as shown on

the right (Positive lead to terminal point 3 and J1

negative lead to terminal point 2). The wire size

can range from 20 to 14 AWG. J1 is removable

(plugs into a pin header soldered to the PCB) for

ease of wiring and service.

4/28/03 Tech-321/D.W.O14722 Page 2 of 14

Position Sensor Initial Angle (Setting Mode)

The Eazicals Position Sensor, which measures the absolute position of the valve, has a limited operating angle

for proper position measurement. The Position Sensor must remain within the operating angle in both the open and

fail valve positions. This is accomplished by initially setting the Position Sensor angle while the valve is in the fail

position. The Eazical has a mode of operation to accomplish the setting of this initial angle using the following steps.

1. Apply loop current to the positioner and

adjust to 12 mA.

2. Press & hold both the high and low buttons Switch

until the actuator is driven to span position. (SW1)

Release both buttons to remove air pressure Position Sensor Main Shaft

from Outlet Port 1. Gear Gear

3. If the valve fails clockwise and strokes

counter-clockwise, then set switch SW1 to CCW

SW1

CW

the CCW position. If the valve fails counter- J2

clockwise and strokes clockwise, then set J3

switch SW1 to the CW position (see figure to

right). J1

4. With no buttons pressed and the actuator in

the fail position, push the Main Shaft Gear

(larger of the two) down until it disengages

from its shaft locking position.

5. Rotate the Main Shaft Gear (both gears will

turn), until only the green LED is flashing.

Note: If the LED is already green, skip 5 and go

to 6.

6. Pull up the Main Shaft Gear allowing it to re-

engage on the shaft locking it into position.

7. Press and hold the High Calibration button

until the valve fully strokes away from the fail

position while watching the LEDs. The red or

yellow LEDs must not light as long as the

High Cal button is being held down. If the red

or yellow LED lights while the High Cal button

is being held down, then the Position Sensor

Orientation and Actuator air piping are out of

phase. Correct the phase error by changing

the position of SW1 and repeat this procedure

starting from step 2.

8. Release the High Calibration button and watch the red LED. The red LED will flash until the valve reaches the fail

position.

9. Press the Low Calibration button to exit the Position Sensor Setting Mode (if no buttons are pushed then

this mode will time out automatically in about 2 minutes).

4/28/03 Tech-321/D.W.O14722 Page 3 of 14

Calibrating The EaziCal Positioner

Once the Eazical and actuator have been connected and the initial angle has been set. Low and High

Calibration can be performed on the EaziCal. Low Calibration refers to the input current value that drives

the valve into the fail position. High Calibration refers to the input current value that drives the valve into

the Span Position. Calibration adjusts parameters internal to the EaziCal that are specific to the actuator,

and input current values. The parameters that are adjusted are, the Gain of the EaziCal servo loop. the

end position (Zero/Span) of the valve travel, and Drop-Off point (input current level at which the trans-

ducer is forced to the extreme position, to insure that the valve is fully open or closed). The calibration

routine uses the input current value to set its internal adjustment, so it is important that the input current

does not change during the calibration routine.

** To Do a Low Calibration: (Zero Position)

1. Set the Input Current level to the value that drives the valve into the fail position (typically 4 mA).

2. Start the Low Calibration routine by pressing and holding the LOW CAL button on the EaziCal

until the Yellow LED flashes or by pressing the LOW button on the IR Remote (may require secu-

rity code entry).

3. Observe the flashing Yellow LED on the EaziCal which denotes the various stages of the calibra-

tion routine:

a.) Flashing 1 time indicates Zero position set routine.

b.) Flashing 2 times indicates Transducer Self Calibration routine.

c.) Flashing 3 times indicates Gain setting routine.

4. When the Green LED begins to flash the Calibration is completed. If the Red LED flashes this is

an indication that one of the Calibration routines could not be completed. The number of Red

LED flashes indicates the calibration routine that failed.

** To Do a High Calibration: (Span Position)

1. Set the Input Current level to the value that drives the valve into the span position (typically 20

mA).

2. Start the High Calibration routine by pressing and holding the HIGH CAL button on the EaziCal

until the Yellow LED flashes or by pressing the HIGH button on the IR Remote (may require

security code entry).

3. Observe the flashing Yellow LED on the EaziCal which denotes the various stages of the calibra-

tion routine:

a.) Flashing 1 time indicates Span position set routine.

b.) Flashing 2 times indicates Transducer Self Calibration routine.

c.) Flashing 3 times indicates Gain setting routine.

4. When the Green LED begins to flash the Calibration is completed. If the Red LED flashes

this is an indication that one of the Calibration routines could not be completed. The num-

ber of Red LED flashes indicates the calibration routine that failed.

Calibration Complete:

** Note: For split range enter desired input values during low & high calibration.

4/28/03 Tech-321/D.W.O14722 Page 4 of 14

Advanced Functions

The Eazical has the ability to change the calibration settings (Gain, Zero, Span, and Drop-Off) man-

ually. This function was intended to make minor changes in the calibration values after doing the Low

and High calibration. Some examples where this might be used are decreasing the Gain if the valve still

shows some overshoot on rapid position changes, or increasing the High Drop-Off point so it will not be

in effect at 20mA. Exercise caution if using the manual calibration, mis-adjustment of these set-

tings on the Eazical positioner can result in erratic behavior or failure of operation, and may

require resetting the EEPROM before auto-calibration can be performed again.

To Do a Manual Calibration Adjustment:

1. Apply Input Current to the Eazical (typically 12 mA).

2. Start the Manual Calibration routine by pressing and holding the Function (center) button on the

Eazical until the Green and Yellow LED flashes.

3. Observe the flashing Green and Yellow LED on the Eazical which denotes the various stages of

the manual calibration routine, pressing the Function (center) button again advances to the next

stage:

a.) Flashing 2 time indicates Manual Gain adjustment.

b.) Flashing 3 times indicates Zero position adjustment.

c.) Flashing 4 times indicates Low Drop-Off adjustment.

d.) Flashing 5 times indicates Span position adjustment.

e.) Flashing 6 times indicates High Drop-Off adjustment.

4. To alter any characteristics of the positioner follow the following steps:

a.) Manual gain Increase the positioner gain by pressing the High Cal button. Decrease the

Positioner gain by pressing the Low Cal button. Continue to increase or

decrease the gain by repeatedly pressing the buttons. The maximum adjust-

ment has been achieved when the red LED lights.

b.) Zero position [To adjust the zero position to a point other than the hard stop of the valve the

Low calibration of the positioner must have been performed at a current

slightly lower than the zero position current. (Ex. If the zero position current is

4.0 mA the Low Calibration as described in the previous section needs to be

performed at 3.9 mA.)]

Increase the zero position by pressing the Low Cal button. Decrease the zero

position by pressing the High Cal button. Continue to increase or decrease the

zero position by repeatedly pressing the buttons.

c.) Low Drop-Off Increase the mA input signal that the positioner drops output port 1 pressure

by pressing the Low Cal button. Decrease the mA input signal that the posi-

tioner drops output port 1 pressure by pressing the High Cal button. Continue

to increase or decrease the drop-off position by repeatedly pressing the but-

tons.

d.) Span Position [To adjust the span position to a point other than the hard stop of the valve the

High calibration of the positioner must have been performed at a current

slightly higher than the span position current. (Ex. If the span position current

is 20.0 mA the Highcalibration as described in the previous section needs to

be performed at 20.1mA.)] Decrease the span position by pressing the High

Cal button. Increase the span position by pressing the Low Cal button.

4/28/03 Tech-321/D.W.O14722 Page 5 of 14

Continue to increase or decrease the span position by repeatedly pressing the

buttons.

e.) High Drop-off Decrease the mA input signal that the positioner drops output port 2 pressure

by pressing the High Cal button. Increase the mA Input signal that the posi-

tioner drops output port 2 pressure by pressing the Low Cal button. Continue

to increase or decrease the drop off position by repeatedly pressing the but-

tons.

5. The Input Current can be changed during the test to observe the adjustment effects on the Eazi-

cal behavior.

6. To save the adjustments and exit the Manual Calibration Mode the Function (center) button must

be held for approximately 5 seconds (green and yellow flashing LEDs will change to flash just

green when adjustments are saved) This procedure to save and exit can be performed from any

stage during the Manual Calibration.

7. Pressing the Function (Center) button during the High Drop-Off adjustment exits the Manual Cali-

bration Mode without saving any adjustments made.

FIG. 4

Setting The HiVue Visual Indicator

1. Replace cover and secure the (4) captive

screws. Confirm that you have noted the final VALVE OPEN VALVE CLOSED

position of the valve, (full open or full closed).

HiVue

Visual Indicator

2. Make sure the HiVue visual display coincides

with the position of the valve (fig.4).

FIG. 5 Truss Head Screw

3. The inner HiVue indicator should show either

Open or Closed. If the position indicated is

the opposite of the actuator position, remove HiVue Visual Indicator

the (4) truss head screws that secure the Cover

HiVue indicator cover and rotate the indicator

cover 90so the proper symbol for the position

of the valve is displayed. (fig 5).

HiVue Visual Indicator

4. Secure the visual indicator cover to the housing Housing Cover

cover using the (4) truss head screws.

Important: Do not exceed 10 in-lb of torque for each screw.

4/28/03 Tech-321/D.W.O14722 Page 6 of 14

The (IR) Remote Control With The Positioner

The positioner has the ability to be operated (calibrated) via an Infrared (IR) Remote Control. The posi-

tioner can be calibrated by using the buttons on the positioner module, however this requires the

removal of the top cover. With the (IR) Remote Control the positioner can be calibrated without the

removal of the top cover. If the 4-20 mA input current connected to the positioner is not available or the

Position Sensor Initial Angle must be set then the removal of the top cover is required. Although the posi-

tioner is configured for use with the remote, the (IR) Remote Control is not provided with the positioner.

The (IR) Remote Control is an option and must be purchased separately.

THE IR REMOTE CONTROL BUTTONS

Programing The IR Remote Control PROGRAMING BUTTON

USED FOR THE INITIAL SETUP OF THE IR REMOTE

BACKLIGHT BUTTON

TURNS THE IR REMOTE BACKLIGHT ON AND OFF

The IR Remote Control is programmed at the RED LED

LIGHTS WHEN IR SIGNAL IS BEING SENT

factory and should not need to be programed

D MODE BUTTONS

again, unless the batteries are removed for an ENABLES ONE OF THE TWO MODES, WHICH

REMAINS IN EFFECT UNTIL ANOTHER ONE OF THESE

P1 P2

extended period of time (greater than 10 min- BUTTONS IS PRESSED. P2 MODE IS THE ONE USED

FOR THE POSITIONER.

utes). To program the IR Remote press the P1 + HIGH

HIGH CALIBRATE BUTTON

button then press and hold the P button until USED TO BEGIN THE HIGH CALIBRATE ROUTINE

the red LED blinks twice, then press 0, 0, 8, GAIN

1 after which the red LED on the IR Remote - DROP-OFF LOW LOW CALIBRATE BUTTON

USED TO BEGIN THE LOW CALIBRATE ROUTINE

blinks twice to confirm the entry. Press the P2

button then press and hold the P button until NUMERIC BUTTONS

USED TO SELECT THE 3 DIGIT CODE FOR THE

the red LED blinks twice, then press 0, 0, 5, POSITIONER SECURITY ADDRESS

4 after which the red LED blinks twice to con-

MANUAL

firm the entry. ENTER BUTTON

USED TO ENTER THE 3 DIGIT CODE FOR THE

B A C POSITIONER SECURITY ADDRESS

EXIT UNDO

Using The IR Remote Control

The positioner has two operating modes when using the IR Remote.

In the first mode, the positioner will immediately act upon commands from the IR Remote (this can be

used when the positioner being calibrated is the only one that will be within range of the IR Remote sig-

nal, such as one positioner in a closed room). This mode is enabled by setting the positioner DIP switch

position 2 (the one closest to the Low Cal Button) to the ON position (away from the LEDs).

In the second mode, the positioner will not act upon commands from the IR Remote until a 3 digit secu-

rity code is entered (this can be used when there are multiple positioners within range of the IR Remote

signal). This mode is enabled by setting the positioner DIP switch position 2 (the one closest to the Low

Cal button) to the OFF position (toward the LEDs). Once the correct code is entered (3 digits followed

by the ENTER button) the positioner is enabled to act upon IR Remote commands for 5 minutes. The IR

Command Enable time counts down to zero, or is set to zero (positioner no longer acts upon commands)

when the positioner gets an ENTER from the IR Remote, that was not preceded by the correct 3 digit

security code.

4/28/03 Tech-321/D.W.O14722 Page 7 of 14

Dip Switches

Dip Switch

#1

CCW

SW1

CW

J2

J3

J1

Dip Switch

Dip Switches shown #2

in factory set positions

Dip switch #1

Off Position (Factory Setting) = Normal Acting (4 mA represents zero/Fail position and 20 mA repre-

sents Span position).

On Position = Reverse Acting (20 mA represents zero/Fail position and 4 mA represents Span posi-

tion).

Dip switch #2

Off Position = Enables the security code requirement fo IR Remote operation.

On Position (Factory Setting) = Disables the security code requirement (Infrared remote can be used

without security code)

4/28/03 Tech-321/D.W.O14722 Page 8 of 14

Setting The Positioner Security Code

The security code is initially set by entering a 3 digit code, while the positioner is in the Position Sensor

Initial Angle setup mode. To set a security code enter Position Sensor Initial Angle setup mode, by

pressing and holding the High and Low Calibration buttons on the positioner until the Yellow and Green

LEDs flash. Press the 3 digits for the security code on the IR Remote then press the ENTER button on

the IR Remote (entering the code too quickly may prevent the positioner from reading it correctly, pause

at least 1/2 second between each button pressed and hold each button down for at least 1/2 second on

the IR Remote). When the Low Calibration button on the positioner is pressed to exit the Position Sen-

sor Initial Angle setup mode the 3 digit security code is stored in the EEPROM and will remain there

even if power is removed. Make sure that the security code you assign is different for each of the posi-

tioners in the area.

Resetting the EEPROM Back to Factory

Default Values

The positioner has an internal Electrically Erasable Programmable Read Only Memory (EEPROM) that

is used to store the calibration values and the IR Remote security code. These values remain in the

EEPROM memory even if power is removed from the positioner. During normal operation of the posi-

tioner the EEPROM will not have to be reset. The memory may become corrupted if power to the posi-

tioner is lost while the positioner is writing to the EEPROM. which only happens at the very end of the

calibration cycle or at the end of the Position Sensor Initial Angle setup. This memory can be reset back

to factory default values by holding down the HIgh Cal button while the positioner is being powered up.

After the EEPROM is reset, the positioner will have to be calibrated again and the IR Remote security

code will have to be set again.

Reversing the 4mA and 20mA Positions (Reverse Acting)

Normally 4mA of input current represents the closed valve position and 20mA represents the open valve

position. The positioner has the option to switch this so 20mA represents the closed valve position and

4mA represents the open valve position. The normal mode is chosen by setting the positioner DIP

Switch position 1 (the one closest to the LEDs) to the OFF position (toward the LEDs). The reverse

acting mode is chosen by setting the positioner DIP switch position 1 to the ONposition (away from the

LEDs). The positioner should be calibrated again any time the switch position is changed.

4/28/03 Tech-321/D.W.O14722 Page 9 of 14

Setting the Switches

1. Operate the actuator to one extreme. Choose the switch you would like to signal this position (upper

or lower switch). Disengage the appropriate switch cam from the spline by pushing or pulling against

the spring (push down for the upper switch, lift up for the lower switch).

2. Turn the cam until the switch is activated. Activation of the switch can be monitored using a continu-

ity tester or equivalent means.

3. Release the cam allowing it to re-engage with the spline.

4. Operate the actuator to the opposite extreme and repeat steps 1 through 3 for the other switch.

TOP CAM

TOP CAM

PUSH DOWN

PUSH DOWN

TURN &

TURN & RELEASE

RELEASE

BOTTOM CAM

LIFT UP

TURN & RELEASE

Wiring Schematic

BROWN

SWITCH NC PURPLE

1

#1 2

C YELLOW

UPPER NO 3

ORANGE

SWITCH NC 4

BLUE

#2 5

LOWER NO C RED

6

GND

4/28/03 Tech-321/D.W.O14722 Page 10 of 14

Parts List

EaziCal Parts Description

8

7 Item # Qty Description

1 1 Housing Assembly

J1

1 2 1 Shaft Assembly

J3

J2

3 1 Cover Assembly

CW

CCW

4 1 ModMount

5 1 Manifold Assembly

SLEW

CAL/

NORMAL

FAULT

CAL

HIGH

CAL

LOW

6 1 Electronic Assembly

10 2 6 7 1 Connector Board Assembly

8 1 Motor Assembly

3

9 1 Mechanical Switch Assembly

10 1 Output Transmitter

5

* 9

Optional

Mechanical Switch

Assembly

4

Product Matrix Bracket

EZ 0 0

Manifold

Air Port Size

N = 1/4 NPT

0 = N/A

Bracket Type

D = ModMount

Switch Option 0 = Without Switches

1 = (2) SPDT - V3 Mechanical Switches

*

Conduit Size

4 = 3/4 NPT

* (2) SPDT switch option is classified for general purpose

application only. The EaziCal does not hold any agency

approval when populated with switches.

0 = N/A

Example:

Product EZ040D0N = EaziCal w/3/4 NPT Conduit, No Switches, Direct Mount Bracket,

Code 1/4 NPT Manifold Air Port Size

4/28/03 Tech-321/D.W.O14722 Page 11 of 14

Technical Data

Operating Specifications

Input Current 4 to 20 mA (Analog)

Voltage Drop 9 volts

Supply Air Pressure (low) 15 to 45 psi

(high) ?40 to 120 psi

Resolution 0.5% of span

Linearity 1% of span

Hysteresis 0.4% of span

Repeatability 0.4% of span

Thermal Coefficient 3%/100C

Output Flow Rates 8.0 scfm @ 25 psi

16.2 scfm @ 90 psi

Air Consumption .30 scfm @ 25 psi

.71 scfm @ 90 psi

Operating Temp. Range -40C to 85C (-40F to 185F)

Gain Electrically Adjustable

Air Connection Ports 1/4 NPT

Materials of Construction Area Classification & Approvals

Housing Engineered Resin (Nylon)

Cover Clear Engineered Resin (Nylon) * Non-Incendive

FM Class I, Div 2 Grps A,B,C,D

Shaft Stainless Steel Class II, Div 2 Grps F,G

* APPROVED

Class III, Div 2

Fasteners Stainless Steel

HiVue Copolyester

Manifold Anodized Aluminum

ModMount Engineered Resin (Nylon)

Enclosure

Conduit

V3 Mechanical Switches Entries 1 x 3/4 NPT

Electrical Version SPDT form C

Electrical Rating 15 Amps @ 125/250 VAC

10 Amps @ 24 VDC

0.5 Amps @ 125 VDC

* Void FM approval as Non-Incendive when ordered with

2-SPDT switch option (see product matrix page 11).

EaziCal product with optional switches is for use in

0.25 Amps @ 250 VDC general purpose applications only.

4/28/03 Tech-321/D.W.O14722 Page 12 of 14

Dimensions

EaziCal IR Positioner

W/Tyco Direct Mounting

7.48

2.32

DIA (190) 3/4NPT

(59)

2.13

(54)

5.25

(133)

5.95

3.66 (151) 3.89

(93) 2.64

(98.8)

(67)

ModMount

(Namur Pattern)

5.12

Actuator 4.25 (130)

.750 .44

(108) (11)

.44 (19)

(11) 3.50

Side View Top View (8.9)

1.73

1.30 .375

(44) DIA

(9.5) .157

(33)

(4)

+.000

.157 -.001

FLAT

( 3.98+.00

-.02 )

Inches

(mm) Standard Namur

Output Shaft

ZR Plus Position Monitor

W/Tyco Direct Mounting

Appendix A

Instructions for EaziCal IR Positioner Mounting Using Standard Namur Output:

1. Remove TYCO direct mounting bracket assembly from the EaziCal IR Positioner.

Note: The EaziCal IR Positioner are equipped with a standard namur output shaft.

2. Replace bracket assembly with a standard namur mounting bracket.

Note: Standard Namur mounting bracket is not included.

4/28/03 Tech-321/D.W.O14722 Page 13 of 14

Appendix B

Electro-Pneumatic Positioner

Transmitter Calibration Procedure

1. Calibrate the Positioner per the operating manual provided with the product.

2. Stroke the valve to the fully clockwise extreme.

3. Depress the main shaft gear disengaging it from its locking position, take extreme care Not to Turn the main shaft

gear, as this will take the positioner out of calibration.

4. With the main shaft gear depressed turn the transmitter gear to the fully counter clockwise position, and note the

reading (mA) of the transmitter. Next, turn the transmitter gear clockwise until the transmitter changes no more then

0.5 mA from previous reading.

5. Turn the clockwise mA adjustment screw to adjust the transmitter reading to the desired output for this valve posi-

tion (typically this is 4 mA or 20 mA).

6. Stroke the valve to the fully counter clockwise extreme.

7. Turn the counter clockwise mA adjustment screw to adjust the transmitter reading to the desired output for this

valve position.

8. Stroke the valve between the full clockwise and counter-clockwise positions checking and readjusting the (mA) out-

put as necessary.

Main Shaft

Main Shaft Gear

J2

J3 mA Adjustment Screw

CW

for clockwise position

J1

FAULT

CAL/

SLEW

NORMAL

Transmitter CCW

Output { LOW

CAL

Terminals 1 & 2

(Not Polarity Dependent) HIGH

CAL

mA Adjustment

Screw for counter-

clockwise position

Transmitter Gear

4/28/03 Tech-321/D.W.O14722 Page 14 of 14

Anda mungkin juga menyukai

- SIMRAD SAL R1a Easy Tank User ManualDokumen25 halamanSIMRAD SAL R1a Easy Tank User ManualDeepak HaridasBelum ada peringkat

- Boiler Safety PurgeDokumen2 halamanBoiler Safety PurgeŞansal Dikmener100% (1)

- G1 4400 Manual 1009Dokumen25 halamanG1 4400 Manual 1009Alexandru BoboceaBelum ada peringkat

- Rabbit SR9000Dokumen2 halamanRabbit SR9000Servo2GoBelum ada peringkat

- ODMEDokumen12 halamanODMEAntonio Antonio100% (1)

- Crude Oil Tankers: K-Gauge CLS Tank Gauging SystemDokumen19 halamanCrude Oil Tankers: K-Gauge CLS Tank Gauging SystemCem BozBelum ada peringkat

- Carrier Snap ChillersDokumen32 halamanCarrier Snap ChillersTim WeigandtBelum ada peringkat

- Sound Powered TelephoneDokumen10 halamanSound Powered TelephoneJonathan MooreBelum ada peringkat

- P-42 - Tank Monitoring SystemDokumen118 halamanP-42 - Tank Monitoring SystemCengiz İyiceBelum ada peringkat

- Calibration Laboratories, Inc.: Portable Electronic Gauging Tapes For Petroleum and Chemical TanksDokumen1 halamanCalibration Laboratories, Inc.: Portable Electronic Gauging Tapes For Petroleum and Chemical TanksArmando SixtoBelum ada peringkat

- CD0166 ALCAP 5 - Monitoring SystemDokumen1 halamanCD0166 ALCAP 5 - Monitoring SystemVladBelum ada peringkat

- SFC4 AutronicaDokumen1 halamanSFC4 AutronicaFab SgnBelum ada peringkat

- Marine Growth Protection SystemDokumen21 halamanMarine Growth Protection Systemwin htikeBelum ada peringkat

- CATALOGO KrausnaimerDokumen24 halamanCATALOGO KrausnaimerCarlos OreBelum ada peringkat

- Aqua CubicDokumen7 halamanAqua CubicdanieleBelum ada peringkat

- FW 007 SMS 3-0002-0002-2dDokumen5 halamanFW 007 SMS 3-0002-0002-2dBanyar AungBelum ada peringkat

- Autro Safe Bs310 Commissioning - Handbook - Key1c6Dokumen52 halamanAutro Safe Bs310 Commissioning - Handbook - Key1c6Mohamed MeeranBelum ada peringkat

- 15PPM Bilge Alarm (Gba-155) Manual (Rev5)Dokumen16 halaman15PPM Bilge Alarm (Gba-155) Manual (Rev5)Raúl Oscar Ledesma100% (1)

- Installation, Operating & Maintenance Manual. Electronic Level Switch LIDEC 91-92Dokumen22 halamanInstallation, Operating & Maintenance Manual. Electronic Level Switch LIDEC 91-92carlos_sagitarioBelum ada peringkat

- 2 DescriptionDokumen21 halaman2 Descriptionnitin9860Belum ada peringkat

- 5 Alarms and Fault Finding Stype Separation SystemDokumen22 halaman5 Alarms and Fault Finding Stype Separation SystemjonbilbaoBelum ada peringkat

- Procedure To Discharge Clean Bilge Training - enDokumen3 halamanProcedure To Discharge Clean Bilge Training - enclaudioBelum ada peringkat

- AVID CR Position MonitorsDokumen5 halamanAVID CR Position MonitorsNanDo Wandi SaputraBelum ada peringkat

- Veiland ModulesDokumen13 halamanVeiland ModulesJavier FundoraBelum ada peringkat

- BF10 T1000 CV SysDokumen16 halamanBF10 T1000 CV SysNguyen Phuoc HoBelum ada peringkat

- 4.3251.0x.001-002 Winddisplay-LED EngDokumen38 halaman4.3251.0x.001-002 Winddisplay-LED EngJean-Guy PaulBelum ada peringkat

- PennBarry Fumex Catalog FXDokumen32 halamanPennBarry Fumex Catalog FXArmando MantillaBelum ada peringkat

- Manual AquaSnapDokumen100 halamanManual AquaSnapplastico852100% (1)

- A.C.Synchronous Transmitter Manual PDFDokumen15 halamanA.C.Synchronous Transmitter Manual PDFAbhishek RajBelum ada peringkat

- Operation and Service Manual For Hermetic Utimeter Gtex ChemDokumen78 halamanOperation and Service Manual For Hermetic Utimeter Gtex ChemMAXBelum ada peringkat

- DRAGER Relay Display Card IFU 2 PDFDokumen36 halamanDRAGER Relay Display Card IFU 2 PDFlucasBelum ada peringkat

- Gefran 800 CONTROLLER ManualDokumen21 halamanGefran 800 CONTROLLER Manualaleks100% (1)

- OdmeDokumen10 halamanOdmeHarshit Nanda100% (1)

- CCTV Hernis General BrochureDokumen10 halamanCCTV Hernis General BrochurepiolinwallsBelum ada peringkat

- 10 Boiler Operating Mistakes On Ships That Can Cost Big TimeDokumen18 halaman10 Boiler Operating Mistakes On Ships That Can Cost Big TimeThusitha DalpathaduBelum ada peringkat

- Technical Description: Type: 810.001.210Dokumen6 halamanTechnical Description: Type: 810.001.210Radu VasilacheBelum ada peringkat

- Seres Mk-II Start Stop InstructionsDokumen3 halamanSeres Mk-II Start Stop Instructionsdodoi_neelrBelum ada peringkat

- M-E-Gmc8022 Manual PDFDokumen14 halamanM-E-Gmc8022 Manual PDFArunava BasakBelum ada peringkat

- Trouble ShootingDokumen16 halamanTrouble ShootingVinay Singh100% (1)

- NA-E-USM-001-12 ShipCEMS User ManualDokumen88 halamanNA-E-USM-001-12 ShipCEMS User ManualMladen PerkovicBelum ada peringkat

- Bar Graphic Type Digital Indicator ManualDokumen10 halamanBar Graphic Type Digital Indicator Manualjamukanak pad0% (1)

- Working A X400223enDokumen723 halamanWorking A X400223enАлександр МедковBelum ada peringkat

- Instruction Operation For Packaged BoilerDokumen37 halamanInstruction Operation For Packaged BoilerHasnul Hisyam Harun0% (1)

- Hanla Vol1Dokumen40 halamanHanla Vol1jasleenchhabraBelum ada peringkat

- ACM Standard Integrated SystemDokumen2 halamanACM Standard Integrated SystemmatchutBelum ada peringkat

- ABB IS2 SwitchboardDokumen308 halamanABB IS2 SwitchboardchupzptBelum ada peringkat

- OKI ML3320-21 Maintenance ManualDokumen155 halamanOKI ML3320-21 Maintenance ManualAnthony DaskalierosBelum ada peringkat

- Valves CatalogueDokumen33 halamanValves CatalogueDheeraj ThakurBelum ada peringkat

- DetTronics GasDetector PIRECLDokumen51 halamanDetTronics GasDetector PIRECLyasfin1990Belum ada peringkat

- Lenze 8200 Vector-25Dokumen25 halamanLenze 8200 Vector-25poaguiBelum ada peringkat

- Hydraulic Simulation Using EASY5 SoftwareDokumen13 halamanHydraulic Simulation Using EASY5 Softwarechuckhsu1248Belum ada peringkat

- Damco LPU-DDokumen6 halamanDamco LPU-DgeomariolisBelum ada peringkat

- Final ICAF 12242 - 202321 - HT64-132 - V01Dokumen16 halamanFinal ICAF 12242 - 202321 - HT64-132 - V01Kunpeng ZhouBelum ada peringkat

- UT-2506 User ManualDokumen22 halamanUT-2506 User ManualBayanaka TehnikBelum ada peringkat

- Logiturn II: Installation Manual For 3-Arm, 2-Arm and Open Gate Turnstiles Und Vario Vertical TurnstilesDokumen48 halamanLogiturn II: Installation Manual For 3-Arm, 2-Arm and Open Gate Turnstiles Und Vario Vertical TurnstilesCarlos RibeiroBelum ada peringkat

- Change Address Procedure-Tyco T2000Dokumen1 halamanChange Address Procedure-Tyco T2000Tomasz KowalewskiBelum ada peringkat

- Installation and Operating Instructions For Avid Eazical Ir PositionerDokumen9 halamanInstallation and Operating Instructions For Avid Eazical Ir PositionerFlavioBelum ada peringkat

- Intrinsically Safe Electro-Pneumatic Positioner Operating ManualDokumen12 halamanIntrinsically Safe Electro-Pneumatic Positioner Operating ManualhamamBelum ada peringkat

- Pozitioner Analogic AVIDDokumen14 halamanPozitioner Analogic AVIDPop-Coman Simion100% (2)

- CSC204 - Chapter 3.1Dokumen30 halamanCSC204 - Chapter 3.1Alif HaiqalBelum ada peringkat

- EBS SDK Best PracticesDokumen57 halamanEBS SDK Best Practicespurnachandra426Belum ada peringkat

- C-Zone SDN BHD: Price List Effective 10 AUG 2019Dokumen2 halamanC-Zone SDN BHD: Price List Effective 10 AUG 2019Cikgu AlBelum ada peringkat

- SUD50N024-09P: Vishay SiliconixDokumen5 halamanSUD50N024-09P: Vishay SiliconixOirã Vinícius Moreira de OliveiraBelum ada peringkat

- Characteristic of Wastewater: Chapter OverviewDokumen8 halamanCharacteristic of Wastewater: Chapter Overviewpenelopezeus39Belum ada peringkat

- Alternative Sources of EnergyDokumen6 halamanAlternative Sources of EnergykageBelum ada peringkat

- Zeal High Precision Wet Test Gas Flow Meters 2022Dokumen5 halamanZeal High Precision Wet Test Gas Flow Meters 2022Hiran ChathurangaBelum ada peringkat

- D85A-21 Parts PDFDokumen599 halamanD85A-21 Parts PDFBudi setyantoBelum ada peringkat

- GERMAN Embassy ContractDokumen79 halamanGERMAN Embassy ContractVE.03 QELBelum ada peringkat

- CPP Schematic Diagram Duplex Complete 9 Jan 2019Dokumen1 halamanCPP Schematic Diagram Duplex Complete 9 Jan 2019BdSulianoBelum ada peringkat

- Institute of Technology & Engineering, Malegaon BK.: Lesson Teaching Plan (LTP)Dokumen3 halamanInstitute of Technology & Engineering, Malegaon BK.: Lesson Teaching Plan (LTP)Pramod DhaigudeBelum ada peringkat

- Iso 8100 2 2019Dokumen15 halamanIso 8100 2 2019AchmadBelum ada peringkat

- IT Dashboard Dec2013Dokumen870 halamanIT Dashboard Dec2013Dolly SinghBelum ada peringkat

- Gujarat Technological University: A Project Report On:-Automatic Water Purification SystemDokumen11 halamanGujarat Technological University: A Project Report On:-Automatic Water Purification SystemJay KakadiyaBelum ada peringkat

- CilindarDokumen44 halamanCilindardjoko123Belum ada peringkat

- Digital Electronics Interview Questions PDFDokumen3 halamanDigital Electronics Interview Questions PDFSanjeev100% (2)

- Jovan Marjanovic Theory of Gravity MachinesDokumen10 halamanJovan Marjanovic Theory of Gravity MachinesWilhelm HartmanBelum ada peringkat

- Gogostemcells StudentpagesDokumen2 halamanGogostemcells Studentpagesapi-356824125Belum ada peringkat

- The Multiple Directions of Antiferromagnetic Spintronics Nature Physics PDFDokumen4 halamanThe Multiple Directions of Antiferromagnetic Spintronics Nature Physics PDFLog LouBelum ada peringkat

- Table (.) Wastewater Storage Tank (STO1)Dokumen4 halamanTable (.) Wastewater Storage Tank (STO1)Chelsea MartinezBelum ada peringkat

- (Task Specific Risk Assessment) : No Name Signature Position Date N Name Signature Position DateDokumen5 halaman(Task Specific Risk Assessment) : No Name Signature Position Date N Name Signature Position DateRavi Shankar TurlapatiBelum ada peringkat

- Design Report For Proposed 3storied ResidentialbuildingDokumen35 halamanDesign Report For Proposed 3storied ResidentialbuildingMohamed RinosBelum ada peringkat

- ENTEC Catálogo GeneralDokumen26 halamanENTEC Catálogo GeneralPEDRO RISCOBelum ada peringkat

- Lesson 3 - Equipment and FacilitiesDokumen15 halamanLesson 3 - Equipment and FacilitiesRishiel Dimple BalonesBelum ada peringkat

- Ch12 - Peter NolanDokumen22 halamanCh12 - Peter Nolanjohnb2bBelum ada peringkat

- Load Calculation JowharDokumen6 halamanLoad Calculation JowharKhalid Abdirashid AbubakarBelum ada peringkat

- K SedimentationDokumen13 halamanK SedimentationKitty VBelum ada peringkat

- Klauke - Bi-Metal Lugs & ConnectorsDokumen6 halamanKlauke - Bi-Metal Lugs & ConnectorsBiplab PaulBelum ada peringkat

- Python ScriptingDokumen2 halamanPython ScriptingRavikumar TumuluriBelum ada peringkat

- Building Applied Natural Language GenerationDokumen32 halamanBuilding Applied Natural Language Generationrat86Belum ada peringkat