Title Demonstrate Knowledge of Wheel Tractor Steering Systems, and Diagnose and Rectify Faults in Them Level 4 Credits 4

Diunggah oleh

Hassan HamdyDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Title Demonstrate Knowledge of Wheel Tractor Steering Systems, and Diagnose and Rectify Faults in Them Level 4 Credits 4

Diunggah oleh

Hassan HamdyHak Cipta:

Format Tersedia

NZQA Expiring unit standard 5443 version 5

Page 1 of 4

Title Demonstrate knowledge of wheel tractor steering systems, and

diagnose and rectify faults in them

Level 4 Credits 4

Purpose This unit standard is for people in the automotive repair

industry. People credited with this unit standard are able to:

demonstrate knowledge of wheel tractor steering systems;

diagnose faults in tractor steering systems; and rectify faults in

tractor steering systems.

Classification Motor Industry > Vehicle Steering and Suspension

Available grade Achieved

Explanatory notes

1 The following legislation and amendments are to be consulted and followed where

applicable:

Health and Safety in Employment Act, 1992.

2 Reference to suitable tools and equipment means industry approved tools and

equipment that are recognised within the industry as being the most suited to

complete the task to a professional and competent manner with due regard to safe

working practices.

3 Because of the particular nature of this unit standard, it is essential that the practical

assessment evidence is obtained from commercial jobs in the workplace under

normal workplace conditions.

Outcomes and evidence requirements

Outcome 1

Demonstrate knowledge of wheel tractor steering systems.

Evidence requirements

1.1 Types and construction of manual steering systems are described according to

tractor manufacturer's workshop manual descriptions.

Range steering column, steering boxes, drop arms, drag links, tie rods.

NZ Motor Industry Training Organisation New Zealand Qualifications Authority 2017

(Incorporated)

SSB Code 101542

NZQA Expiring unit standard 5443 version 5

Page 2 of 4

1.2 Types and construction of pivot steering systems are described according to

tractor manufacturer's workshop manual descriptions.

Range pivot points and king pins, hydraulic systems and circuits, double

acting hydraulic actuator rams.

1.3 Types and construction of power assisted steering systems are described

according to manufacturer's workshop manual descriptions.

Range integral power assisted steering, external power assisted steering.

1.4 Operation of tractor steering systems is described according to tractor

manufacturer's workshop manual descriptions.

Range manual steering boxes, pivot steering, integral power assisted

steering system, external power assisted steering box, hydraulic

circuits, hydraulic pumps, hydraulic valves, oil filters.

1.5 Hydraulic steering fault diagnostic and testing procedures are described as

specified by manufacturer's workshop manuals.

1.6 Steering geometry as applicable to agricultural tractors is described according

to tractor manufacturer's workshop manual descriptions.

Range caster, camber, toe in, toe out on turns;

turning radius for two and four wheel drive machines.

Outcome 2

Diagnose faults in tractor steering systems.

Evidence requirements

2.1 Safe working practices are observed throughout the task.

Range personal safety, safety of others, tractor and equipment safety.

2.2 Manual steering system condition is determined according to tractor

manufacturer's workshop manual instructions.

Range visual inspection of components for damage and wear, field testing

for operation.

2.3 Faults in power assisted steering systems are identified.

Range hydraulic pressure tests; hydraulic flow test; visual inspection for

damage, leakage and wear; field testing for operation.

NZ Motor Industry Training Organisation New Zealand Qualifications Authority 2017

(Incorporated)

SSB Code 101542

NZQA Expiring unit standard 5443 version 5

Page 3 of 4

Outcome 3

Rectify faults in tractor steering systems.

Evidence requirements

3.1 Safe working practices are observed throughout the task.

Range personal safety, safety of others, tractor and equipment safety.

3.2 Suitable tools and equipment are selected and used that enable faults to be

rectified according to manufacturers specifications.

3.3 Minor faults are rectified and the system adjusted according to manufacturer's

specifications.

Range minor faults are defined as those which do not require extensive

dismantling and repair.

3.4 Manual steering system faults that require dismantling and repair are rectified

according to manufacturer's workshop manual instructions.

Range safety work area established; tractor steering box area cleaned,

steering box removed, worn parts identified and replaced, steering

box reassembled and adjusted, steering box refitted to tractor and

lubricated, steering movement adjusted, assembly checked for

operation; tractor field tested.

3.5 Power assisted steering system faults that require dismantling and repair are

rectified according to manufacturer's workshop manual instructions.

Range safety work area established; tractor steering box area cleaned,

steering box assembly removed, worn parts and seals identified

and replaced; hydraulic pump removed, worn parts identified and

replaced; control valves removed, worn parts identified and

replaced; steering assembly assembled and refitted to tractor,

adjustments made, hydraulic tests; tractor field tested.

3.6 Pivot steering system faults that require dismantling and repair are rectified

according to manufacturer's workshop manual instructions.

Range safety work area established; tractor steering system area

cleaned, steering components removed, worn parts identified and

replaced; hydraulic rams removed, worn parts identified and

replaced; steering assembly assembled and refitted to tractor,

adjustments made, hydraulic tests; tractor field tested.

3.7 Tractor steering geometry is checked and adjusted according to manufacturer's

specifications.

NZ Motor Industry Training Organisation New Zealand Qualifications Authority 2017

(Incorporated)

SSB Code 101542

NZQA Expiring unit standard 5443 version 5

Page 4 of 4

Replacement information This unit standard has been replaced by unit standard

24438 and unit standard 24439.

This unit standard is expiring. Assessment against the standard must take place by

the last date for assessment set out below.

Status information and last date for assessment for superseded versions

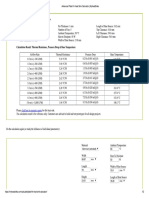

Process Version Date Last Date for Assessment

Registration 1 31 October 1995 31 December 2016

Review 2 29 March 1999 31 December 2016

Review 3 25 January 2008 31 December 2016

Rollover 4 19 November 2010 31 December 2016

Rollover 5 18 February 2016 31 December 2020

Consent and Moderation Requirements (CMR) reference 0014

This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do.

Please note

Providers must be granted consent to assess against standards (accredited) by NZQA, or

an inter-institutional body with delegated authority for quality assurance, before they can

report credits from assessment against unit standards or deliver courses of study leading

to that assessment.

Industry Training Organisations must be granted consent to assess against standards by

NZQA before they can register credits from assessment against unit standards.

Providers and Industry Training Organisations, which have been granted consent and

which are assessing against unit standards must engage with the moderation system that

applies to those standards.

Consent requirements and an outline of the moderation system that applies to this

standard are outlined in the Conesnt and Moderation Requirements (CMR). The CMR

also includes useful information about special requirements for organisations wishing to

develop education and training programmes, such as minimum qualifications for tutors and

assessors, and special resource requirements.

NZ Motor Industry Training Organisation New Zealand Qualifications Authority 2017

(Incorporated)

SSB Code 101542

Anda mungkin juga menyukai

- An Introduction to Predictive MaintenanceDari EverandAn Introduction to Predictive MaintenancePenilaian: 4 dari 5 bintang4/5 (5)

- AURTTX008 - Overhaul Manual Transmissions PDFDokumen55 halamanAURTTX008 - Overhaul Manual Transmissions PDFAakash100% (1)

- Genetic Algorithms - Principles and Perspectives - A Guide To GA TheoryDokumen327 halamanGenetic Algorithms - Principles and Perspectives - A Guide To GA Theoryluis-barrios-941150% (4)

- Uc 3 Perform Periodic Maintenance of Drive TrainDokumen70 halamanUc 3 Perform Periodic Maintenance of Drive Trainbelinda Espano100% (3)

- AURETR023 - Diagnose and Repair Spark Ignition Engine Management SystemsDokumen96 halamanAURETR023 - Diagnose and Repair Spark Ignition Engine Management SystemsAnzel Anzel100% (1)

- As Series - Installation Operation and Maintenance Manua1 - 1Dokumen35 halamanAs Series - Installation Operation and Maintenance Manua1 - 1Ramesh BhosleBelum ada peringkat

- Induction Motor Failure AnalysisDokumen8 halamanInduction Motor Failure AnalysisMunazar HussainBelum ada peringkat

- Pajero Sports Workshop-Service Manual 1999Dokumen934 halamanPajero Sports Workshop-Service Manual 1999kiran_rm200693% (15)

- Title Describe Tractor Braking Systems, and Diagnose and Rectify Faults in Wheel Tractor Braking Systems Level 4 Credits 7Dokumen6 halamanTitle Describe Tractor Braking Systems, and Diagnose and Rectify Faults in Wheel Tractor Braking Systems Level 4 Credits 7Mohamad Nadzri YahayaBelum ada peringkat

- Inspect and Machine Engine Crankshafts: Level 4 Credits 25 PurposeDokumen4 halamanInspect and Machine Engine Crankshafts: Level 4 Credits 25 PurposeIqtidar GulBelum ada peringkat

- Diagnose Faults and Overhaul A Cummins PT Diesel Fuel Injection PumpDokumen4 halamanDiagnose Faults and Overhaul A Cummins PT Diesel Fuel Injection PumpOmkar ChogaleBelum ada peringkat

- Learner Guide - AURLTE002 - Diagnose and Repair Light Vehicle EnginesDokumen73 halamanLearner Guide - AURLTE002 - Diagnose and Repair Light Vehicle EnginesAakashBelum ada peringkat

- Title Describe and Operate A Bucket Wheel Excavator at An Extraction Site Level 4 Credits 15Dokumen4 halamanTitle Describe and Operate A Bucket Wheel Excavator at An Extraction Site Level 4 Credits 15Anonymous cf6mPd3Belum ada peringkat

- Title Demonstrate Knowledge of Diesel Engine Air Intake and Exhaust Systems, and Inspect and Test Them Level 3 Credits 6Dokumen5 halamanTitle Demonstrate Knowledge of Diesel Engine Air Intake and Exhaust Systems, and Inspect and Test Them Level 3 Credits 6dhanangspBelum ada peringkat

- Title Repair And/or Overhaul Aircraft Landing Gear System Components Level 4 Credits 15Dokumen4 halamanTitle Repair And/or Overhaul Aircraft Landing Gear System Components Level 4 Credits 15hasrulBelum ada peringkat

- Title Install and Commission D.C. Rotating Machines Level 4 Credits 5Dokumen4 halamanTitle Install and Commission D.C. Rotating Machines Level 4 Credits 5AauBelum ada peringkat

- Core CompetenciesDokumen56 halamanCore CompetenciesPaul Senen Didulo100% (1)

- Set and Operate A Manual Feed Edge-Trimming Machine To Trim Edged PanelsDokumen3 halamanSet and Operate A Manual Feed Edge-Trimming Machine To Trim Edged Panelsahmadafaq09Belum ada peringkat

- Title Clean The Gas Path of Aircraft Gas Turbine Engines Level 4 Credits 2Dokumen3 halamanTitle Clean The Gas Path of Aircraft Gas Turbine Engines Level 4 Credits 2misba shaikhBelum ada peringkat

- Maintenance of Electrical Motors 1.5Dokumen5 halamanMaintenance of Electrical Motors 1.5Sayed NagyBelum ada peringkat

- F2689 PDFDokumen3 halamanF2689 PDFAhmad Zubair RasulyBelum ada peringkat

- Title Maintain Control Valve Actuators and Positioners Level 3 Credits 5Dokumen4 halamanTitle Maintain Control Valve Actuators and Positioners Level 3 Credits 5Sarah Shibu ThomasBelum ada peringkat

- Tan Da RD Is IngDokumen4 halamanTan Da RD Is IngJiang ChenBelum ada peringkat

- Title Maintain Aircraft Mechanical Ice and Rain Protection Systems Level 4 Credits 6Dokumen4 halamanTitle Maintain Aircraft Mechanical Ice and Rain Protection Systems Level 4 Credits 6BurhanudinUrcBelum ada peringkat

- Trailer Axles: Applications and Specifications GuideDokumen70 halamanTrailer Axles: Applications and Specifications GuideRossman MejicanosBelum ada peringkat

- Design and Manufacture of Reciprocating Compression Ignition Engines For Light Sport AircraftDokumen4 halamanDesign and Manufacture of Reciprocating Compression Ignition Engines For Light Sport AircraftAhmad Zubair RasulyBelum ada peringkat

- De12t PDFDokumen175 halamanDe12t PDFlarasBelum ada peringkat

- Guide TRS Automotive OccupationsDokumen2 halamanGuide TRS Automotive Occupationshunegnaw shegawBelum ada peringkat

- FMRC 1046 Fire Pump Flowmeter Systems PDFDokumen18 halamanFMRC 1046 Fire Pump Flowmeter Systems PDFdyıldırım_4Belum ada peringkat

- 3990 Less or Nonflammable TransformersDokumen16 halaman3990 Less or Nonflammable TransformersmilecsaBelum ada peringkat

- Carry Out A Direct Current Voltage Gradient (DCVG) Survey in The Gas Transmission IndustryDokumen4 halamanCarry Out A Direct Current Voltage Gradient (DCVG) Survey in The Gas Transmission IndustryMuhammad Nasir SiddiqueBelum ada peringkat

- Land Rover lt230t Transfer Box Overhaul Manual 2nd Edition LRL 0081engDokumen79 halamanLand Rover lt230t Transfer Box Overhaul Manual 2nd Edition LRL 0081engĐình TịnhBelum ada peringkat

- Operate A Steam Turbine: Level 4 Credits 14 PurposeDokumen4 halamanOperate A Steam Turbine: Level 4 Credits 14 PurposeMije SahajaBelum ada peringkat

- Title Perform Maintenance and Repairs On A Vessel's Mechanical and Electrical Systems Level 4 Credits 5Dokumen5 halamanTitle Perform Maintenance and Repairs On A Vessel's Mechanical and Electrical Systems Level 4 Credits 5kevinBelum ada peringkat

- AURTTM3006 Perform Advanced Machining and Blueprinting of Engine ComponentsDokumen10 halamanAURTTM3006 Perform Advanced Machining and Blueprinting of Engine ComponentsAshley CookBelum ada peringkat

- Land Rover 300tdi Engine Overhaul Manual LRL 0070ENGDokumen103 halamanLand Rover 300tdi Engine Overhaul Manual LRL 0070ENGJohn Hyung Cho75% (4)

- Carry Out Cathodic Protection System Troubleshooting Survey in The Gas Transmission IndustryDokumen4 halamanCarry Out Cathodic Protection System Troubleshooting Survey in The Gas Transmission IndustryImam BuchairiBelum ada peringkat

- AURLTD004 Diagnose and Repair Light Vehicle Steering Systems PDFDokumen84 halamanAURLTD004 Diagnose and Repair Light Vehicle Steering Systems PDFCHANDRASIRI K.H.M.C. (BETA16009)Belum ada peringkat

- Manual Hardinge Gx480Dokumen63 halamanManual Hardinge Gx480Welington Barrios100% (2)

- Competency Based Curriculum NC3 AutomotiveDokumen10 halamanCompetency Based Curriculum NC3 AutomotiveGilbert MendozaBelum ada peringkat

- Servicing BrakesDokumen33 halamanServicing BrakesJoe Vane Niñal AntifuestoBelum ada peringkat

- Competency Standard ChrisDokumen3 halamanCompetency Standard ChrisJohnray HabolBelum ada peringkat

- AS22 Service Manual en 20180112(归档版)Dokumen1.256 halamanAS22 Service Manual en 20180112(归档版)tallerr.360Belum ada peringkat

- 4 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDokumen1 halaman4 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightBelum ada peringkat

- Articulated Truck SOPDokumen6 halamanArticulated Truck SOPVarlee KamaraBelum ada peringkat

- Federal Mutual 7400Dokumen13 halamanFederal Mutual 7400Jorge VieyraBelum ada peringkat

- AURTTF005 - Diagnose and Repair Engine Forced-Induction SystemsDokumen68 halamanAURTTF005 - Diagnose and Repair Engine Forced-Induction SystemsAnzel AnzelBelum ada peringkat

- External Assessment SpecificationsDokumen8 halamanExternal Assessment SpecificationsElisette RahantamalalaBelum ada peringkat

- Operation Manual 4V222TIDokumen306 halamanOperation Manual 4V222TIhuynh tienBelum ada peringkat

- 1996 Pajero Sport Service ManualDokumen923 halaman1996 Pajero Sport Service ManualPedro Ipanema100% (1)

- Prepare and Implement Civil Plant, Equipment, and Vehicle Maintenance ScheduleDokumen4 halamanPrepare and Implement Civil Plant, Equipment, and Vehicle Maintenance ScheduleAkma DanielBelum ada peringkat

- Mitsubishi Pajero Montero Sport 98Dokumen858 halamanMitsubishi Pajero Montero Sport 98corollafx16100% (17)

- ASTM-D-6439 Flushing Turbine OilsDokumen16 halamanASTM-D-6439 Flushing Turbine OilsNavneet PandeyBelum ada peringkat

- 0595 vsb6 Section D Rear AxlesDokumen9 halaman0595 vsb6 Section D Rear AxlesJustin Trevor NyathiBelum ada peringkat

- Astm D-6439-2005Dokumen29 halamanAstm D-6439-2005MasBelum ada peringkat

- Testing UMTS: Assuring Conformance and Quality of UMTS User EquipmentDari EverandTesting UMTS: Assuring Conformance and Quality of UMTS User EquipmentBelum ada peringkat

- Lubrication and Reliability HandbookDari EverandLubrication and Reliability HandbookPenilaian: 3.5 dari 5 bintang3.5/5 (2)

- Ensuring Quality to Gain Access to Global Markets: A Reform ToolkitDari EverandEnsuring Quality to Gain Access to Global Markets: A Reform ToolkitBelum ada peringkat

- Capilares Diferentes GasesDokumen14 halamanCapilares Diferentes GasesWalter RuedaBelum ada peringkat

- Fiesta Mk6 EnglishDokumen193 halamanFiesta Mk6 EnglishStoicaAlexandru100% (2)

- HR Report ON Moser BaerDokumen77 halamanHR Report ON Moser BaerKomal DhaliwalBelum ada peringkat

- Lancaster LinksDokumen3 halamanLancaster LinksTiago FerreiraBelum ada peringkat

- SV50SP2RevB Released User DocumentsDokumen8 halamanSV50SP2RevB Released User DocumentsAhmed RamadanBelum ada peringkat

- The 'X' Chronicles Newspaper - August 2010Dokumen50 halamanThe 'X' Chronicles Newspaper - August 2010Rob McConnell100% (1)

- Antony Kungu - Final Project AssignmentDokumen11 halamanAntony Kungu - Final Project Assignmentapi-420816837Belum ada peringkat

- Em - 1110 1 1005Dokumen498 halamanEm - 1110 1 1005Sajid arBelum ada peringkat

- Lutec Katalog PDFDokumen166 halamanLutec Katalog PDFSpeedyBelum ada peringkat

- Vi35 San GuideDokumen43 halamanVi35 San Guideapi-3824328Belum ada peringkat

- Remuz TreeDokumen608 halamanRemuz TreeEdward JonesBelum ada peringkat

- Scan 0001Dokumen1 halamanScan 0001ochiroowitsBelum ada peringkat

- RFC 5227Dokumen21 halamanRFC 5227chetan666123Belum ada peringkat

- BEAFAd 01Dokumen124 halamanBEAFAd 01Vina Zavira NizarBelum ada peringkat

- Lab 01 IntroductionDokumen4 halamanLab 01 IntroductiontsikboyBelum ada peringkat

- Topic 10 - Advanced Approvals in Salesforce CPQDokumen18 halamanTopic 10 - Advanced Approvals in Salesforce CPQRamkumar Poovalai100% (1)

- Kil Exb-Exblt Series Empty Enclosures U IecexDokumen6 halamanKil Exb-Exblt Series Empty Enclosures U IecexAmir SahraBelum ada peringkat

- Is Iec 60534 2 1 1998Dokumen48 halamanIs Iec 60534 2 1 1998Sreeram PanigrahiBelum ada peringkat

- PDFDokumen7 halamanPDFJose JohnBelum ada peringkat

- Manual Instructions For Using Biometric DevicesDokumen6 halamanManual Instructions For Using Biometric DevicesramunagatiBelum ada peringkat

- Advanced Plate Fin Heat Sink Calculator - MyHeatSinksDokumen2 halamanAdvanced Plate Fin Heat Sink Calculator - MyHeatSinksHarsh BhardwajBelum ada peringkat

- Fw102 User ManuleDokumen12 halamanFw102 User ManulerobBelum ada peringkat

- Application of Pinnipedvibrissae To AeropropulsionDokumen31 halamanApplication of Pinnipedvibrissae To AeropropulsionShahzadBelum ada peringkat

- Econ Ball Valves Stainless Steel 3 Way Port: Blow-Out Proof StemDokumen1 halamanEcon Ball Valves Stainless Steel 3 Way Port: Blow-Out Proof StemChristianGuerreroBelum ada peringkat

- Workshop Manual Group 21-26 - 7745282 PDFDokumen228 halamanWorkshop Manual Group 21-26 - 7745282 PDFabdelhadi houssinBelum ada peringkat

- PS User Security SetupDokumen30 halamanPS User Security Setupabhi10augBelum ada peringkat

- Incredible IndiaDokumen13 halamanIncredible IndiaShradha DiwanBelum ada peringkat

- 1213-23-Si-Og RR GecDokumen8 halaman1213-23-Si-Og RR Gecvkj5824Belum ada peringkat

- Operating System ComponentsDokumen59 halamanOperating System ComponentsJikku VarUgheseBelum ada peringkat