Machtoolingtech

Diunggah oleh

api-3801058920 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

14 tayangan2 halamanJudul Asli

machtoolingtech

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

14 tayangan2 halamanMachtoolingtech

Diunggah oleh

api-380105892Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 2

Machine Tooling Technics

32-420-5 Technical Diploma (two-year) Financial Aid Eligible

Program Overview Campus:

New Richmond

The Machine Tooling Technics program emphasizes mold and toolmaking for the

plastic injection molding industry including using computerized machining equipment.

Basic machining skills are covered along with math and print reading. The student will

gain skills in precision measurement, metallurgical processes, in-depth programming,

operation of CNC milling machines and lathes, shop and theory courses in toolmaking,

and CAD/CAM operation.

Admission Requirements Employability essentials and indicators Curriculum

will also be addressed to develop Number Course Title Credits

Students in this program must: personal awareness, career effectiveness,

Occupational Specific Courses

Complete application form and submit and professionalism. See page 5 of the 32420306 Machine Shop Theory 1 2

with fee (fee waiver may apply if college catalog for a list of employability 32420307 Machine Shop Theory 2 2

previously submitted) essentials and indicators. 32420308 Applied Machine Tooling 1 4

Complete Accuplacer entrance 32420309 Applied Machine Tooling 2 4

assessment to determine placement Career Outlook 32420311 Materials for Machine Tooling Technics 1

(waiver may apply with acceptable Typical careers available after graduation 32420321 Print Reading for Machine Trades 1

alternative test scores and/or include: 32420334 CAD/CAM Demo 2

postsecondary degree completion)

Review and sign the Functional Ability Tool and Die Mold Maker 32420336 Applied Machine Tooling 3 4

Machinist Apprentice 32420337 Applied Machine Tooling 4 4

32420338 CAD Basics 1

Statement of Understanding

Complete admissions meeting with a Machine Operator 32420339 Mastercam 2

CNC Machinist 32420357 Advanced Machining Concepts 1

WITC counselor (above requirements

Setup Person 32420370 Machine Tooling Technics 1 4

should be completed prior to meeting)

Programmer 32420371 Machine Tooling Technics 2 4

Program Outcomes Maintenance Machinist 32420372 Machine Tooling Technics 3 (WBL) 5

32420391 Toolmaking Theory 2

Employers will expect the Machine

43

Tooling Technics graduate to be able to: Occupational Supportive/

Apply basic safety practices in the General Studies Courses w

machine shop 32801361 Applied Communications 1 2

Interpret industrial/engineering 32801363 Applied Communications 2 2

drawings 32804355 Math 355 3

Apply precision measuring methods to 32804365 Math 365 3

32809371 Applied Human Relations 2

part inspection

Perform basic machine tool equipment 32890305 Applied Information Resources

2

14

set up and operation

Perform programming, set up, and PROGRAM REQUIREMENTS 57

operation of CNC machine tools

Perform advanced tool, die, and mold

Requires a prerequisite and/or corequisite that must

operations be completed with a grade point of 2.0 or better.

w

See pages 41-43 for course descriptions.

Career Pathway Options

Career Pathways connect progressive levels of coursework to allow students to build upon their

education. Each step in the pathway connects with employment options and provides the op-

portunity for advancement to higher levels. The Machine Tooling Technics program includes the

following pathway options:

31-420-6 Entry Level Machining Technical Diploma (Page 100)

30-420-3 Multi Axis CNC Milling Technical Diploma

Technical Diploma (two-year)

Career Pathways

Technical Diploma (one-year) Machine Tooling Technics

Technical Diploma (less than one-year) Entry Level Machining

Multi-Axis CNC Milling

142 800.243.9482 witc.edu 2017-2018

Course Descriptions

Programs and Course Descriptions

(See pages 41-43 for General Studies course descriptions)

32420306 32420334 32420357

Machine Shop Theory 1 - Credits: 2 CAD/CAM Demo - Credits: 2 Advanced Machining Concepts - Credits: 1

This course provides the student with knowledge in the areas of This course builds on CAD Basics and Mastercam with additional In this course students will learn about advanced CNC

safety, speed and feed calculations, layout equipment, cutting CAD drawing concepts and CAM projects. Learners will utilize programming and setup techniques, electrical discharge

tools, and machine tool equipment. Also introduces and studies Solidworks and Mastercam applications to complete their machining, and advanced inspection techniques.

the more technical shop operations of threading, tapping, boring, learning objectives. Students will gain competency in file

carbide tooling, and principles of metal cutting. Principles of management by saving, converting, and working with different 32420370

metal cutting include the machinability of metals and how it file types. Learners will create geometry in each application and Machine Tooling Technics 1 - Credits: 4

relates to chip formation. Students will study the makeup of convert files between CAD and CAM. Students will apply various In this course learners will learn to set up, program, and run

carbide tooling, how carbide is affected by operating conditions, tool paths to the designs they have created. Surface creation and CNC mills, lathes, and EDM equipment. Learners will continue to

and various carbide characteristics, sizes, shapes, grades, and machining exercises will be demonstrated by each individual. build competencies in surface grinding, tool and cutter grinding,

applications as identified by the American Standards Association. Each learner will design and detail a plastic part including and manual milling. PREREQUISITE: 32420337 Applied Machine

The content supports activities in Applied Machine Tooling 1 a plotted final drawing to the correct scale. PREREQUISITES: Tooling 4.

and 2. 32420321 Print Reading for Machine Trades and 32420339 32420371

Mastercam. Machine Tooling Technics 2 - Credits: 4

32420307

Machine Shop Theory 2 - Credits: 2 32420336 In this course learners will build upon their machining skills

This course is a continuation of Machine Shop Theory 1. Applied Machine Tooling 3 - Credits: 4 using CNC mills, lathes, and EDM equipment. Learners will

This lecture-based course will use lecture, group work, and Students will further build their skills in machining and develop continue to build competencies in surface grinding, tool and

individual projects to introduce you to surface grinding, CNC confidence in their ability to produce good workpieces. Students cutter grinding, and manual milling. Learners will create,

theory, application, programming, and inspection procedures. will continue to use the tools and procedures introduced in program, and run CNC programs with helical interpolation,

PREREQUISITE: 32420306 Machine Shop Theory 1. Machine Shop Theory 1. Students will also be introduced to subroutines, cutter compensation, and multiple fixture offsets.

surface grinding, coordinate measuring machine inspection, Learners will practice final grinding and fitting operations.

32420308 optical comparator, and CNC programming, setup, and COREQUISITE: 32420370 Machine Tooling Technics 1.

Applied Machine Tooling 1 - Credits: 4 machining. PREREQUISITES: 32420306 Machine Shop Theory 1

This lab-based course will provide instruction in shop safety, 32420372

and 32420309 Applied Machine Tooling 2. Machine Tooling Technics 3 (WBL) - Credits: 5

measuring, print reading, and basic setup and operation of saws,

mills, and lathes. 32420337 In this course, the learner will build and polish one plastic

Applied Machine Tooling 4 - Credits: 4 injection mold. Learners will do several projects to gain

32420309 This lab-based course further develops students skills in CNC competency, which will include electrical discharge machining,

Applied Machine Tooling 2 - Credits: 4 vertical mill and CNC lathe setup, operation, and programming. tool and cutter grinding, and a project that requires problem

This lab-based course will introduce the student to threading, Students will set up increasingly complex projects on both solving set-up problems. A work-based learning component

boring, precision and taper turning, and inspection procedures the CNC lathe and CNC vertical mill. Students will learn how will be completed by each individual; you will contact a

using optical comparators and coordinate measuring machines. to troubleshoot CNC setups, programs, and tooling variations. manufacturer to get a job that you will bring back to the campus

COREQUISITES: 32420308 Applied Machine Tooling 1 and Students will also troubleshoot and run their own programs lab and complete the work as directed by the manufacturer

32420321 Print Reading for Machine Trades. created in Machine Shop Theory 2 and Mastercam. Finally, and your instructor. Learners will gain additional skills in the

students will complete surface grinding projects. COREQUISITES: operation of basic and advanced machine tools in the areas

32420311 of milling, drilling, boring, reaming, grinding, CNC milling, and

Materials for Machine Tooling Technics - Credits: 1 32420307 Machine Shop Theory 2 and 32420336 Applied

Machine Tooling 3. EDMing operations. PREREQUISITES: 32420321 Print Reading

During this course students will learn the basic principles for Machine Trades, 32420371 Machine Tooling Technics 2, and

of metallurgy related to mechanical, physical, and chemical 32420338 COREQUISITE: 32420391 Toolmaking Theory.

properties of materials used for Machine Tooling Technics. CAD Basics - Credits: 1

Materials covered will be steel, cast iron, aluminum, copper, and This course offers instruction on individual computer 32420391

plastics. Lab activities will include hardening, tempering, and workstations in a computer lab. This computer-aided drafting Toolmaking Theory - Credits: 2

hardness testing. This course will give the student the ability (CAD) instruction uses SolidWorks software that is capable of This course provides the classroom instruction that supports

to make material selections and perform problem solving for creating 3D drawings. In this course you will spend a majority shop activities in semester four of the Machine Tooling Technics

specific applications that they will encounter in industry. of the time creating 3D models and exploring the concepts of program. It is a lecture course that addresses the technology of

working in 3D space. Students will create complete and fully various types of plastic injection mold dies. Major emphasis will

32420321 be placed on the theory, design, and building of plastic injection

Print Reading for Machine Trades - Credits: 1 dimensioned 3-view part prints ready to be transferred to paper.

COREQUISITE: 32420321 Print Reading for Machine Trades. molds. Small group activities will be utilized to enhance student

This course will cover the basic principles of print reading. The learning.

emphasis is on interpreting standard lines and symbols in 32420339

single- and multiple-view working drawings. Topics include print Mastercam - Credits: 2

reading procedures, drawing changes, machining specifications, This introductory course prepares students for using Computer-

and the reading of prints in specialized areas including ANSI and Aided Machining (CAM) software to create CNC machining

ISO standards. Strongly recommend a basic understanding of programs. This CAM instruction utilizes Mastercam software

mathematics concepts. that is capable of creating 2D and 3D wire drawings, from

which toolpaths to machine part features can be generated.

Students will complete a variety of exercises before working

on 2D machining projects. Students will create complete CNC

process projects including drawings, toolpaths, CNC code, and all

setup sheets and diagrams. These projects will be shop ready for

machining. PREREQUISITE: 32420338 CAD Basics.

Gainful employment information is available at this link: http://www.witc.edu/pgmpages/machtooltech/gainful-employment/Gedt.html. This informa-

tion is provided as a federal requirement in an effort to help students make informed decisions related to the costs and potential employment in a chosen field.

Graduate Employment Information

(WITC Graduate Survey Responses 2014-2015; for most recent data, go to witc.edu) career vision

Number of graduates 11 Number employed 7 % employed in WITC district 57%

Number of responses 9 Percent employed 100% Range of yearly salary $29,118-$46,880

Number available for employment 7 Employed in related field 7 Average yearly salary $40,927

800.243.9482 witc.edu 2017-2018 143

Anda mungkin juga menyukai

- MachtooltechDokumen2 halamanMachtooltechapi-384624460Belum ada peringkat

- Entry Level MachiningDokumen2 halamanEntry Level Machiningapi-366312053Belum ada peringkat

- AutopackDokumen2 halamanAutopackapi-372725811Belum ada peringkat

- MachtoolingtechDokumen2 halamanMachtoolingtechapi-302627927Belum ada peringkat

- AgpowerDokumen2 halamanAgpowerapi-383693802Belum ada peringkat

- VA - SRT FitterDokumen6 halamanVA - SRT FitterjimharoldpaliganBelum ada peringkat

- Cad Cam SyllabusDokumen4 halamanCad Cam SyllabuskrishrathoreBelum ada peringkat

- MechatronicsDokumen67 halamanMechatronicsDanuth Yashantha IllukkumburaBelum ada peringkat

- TRUMPF Catalog DitzingenDokumen49 halamanTRUMPF Catalog Ditzingennenad_lekBelum ada peringkat

- Chhattisgarh Swami Vivekanand Technical University, Bhilai (C.G.)Dokumen16 halamanChhattisgarh Swami Vivekanand Technical University, Bhilai (C.G.)Ashok Kumar ShuklaBelum ada peringkat

- Syllabus M.Tech Design and Manufacturing - 2Dokumen23 halamanSyllabus M.Tech Design and Manufacturing - 2Sudeep Kumar SinghBelum ada peringkat

- Training Details UpdatedDokumen14 halamanTraining Details UpdatedPrasannaBelum ada peringkat

- Manufacturing Engineering-II Course Code: 4341904: Page 1 of 11Dokumen11 halamanManufacturing Engineering-II Course Code: 4341904: Page 1 of 11Gest Account 08Belum ada peringkat

- Iare - Cam Lab ManualDokumen34 halamanIare - Cam Lab Manualಪವರ್ ಆನಂದ್Belum ada peringkat

- TRUMPF Course Catalog DitzingenDokumen49 halamanTRUMPF Course Catalog DitzingenBranislavVorgic100% (1)

- Mechanical Design of Process Equipment CourseDokumen2 halamanMechanical Design of Process Equipment CourseVijay SajjanshettyBelum ada peringkat

- Mini ProjectDokumen40 halamanMini ProjectSai DhanchanderBelum ada peringkat

- PDFDokumen13 halamanPDFShlok PatelBelum ada peringkat

- Technical Drafting NC Ii - Tesda Course ModuleDokumen12 halamanTechnical Drafting NC Ii - Tesda Course ModuleJASON LAROABelum ada peringkat

- MEM14061A Plan and Design Mechanical Engineering Projects: Release: 1Dokumen13 halamanMEM14061A Plan and Design Mechanical Engineering Projects: Release: 1rezaBelum ada peringkat

- Mec IV Year (2020-21) Syllabus VR17Dokumen81 halamanMec IV Year (2020-21) Syllabus VR17santoshteja_69Belum ada peringkat

- Degree Requirements MechanicalDokumen9 halamanDegree Requirements MechanicalPing LiBelum ada peringkat

- Mumbai Univ SyllabusDokumen18 halamanMumbai Univ SyllabusssaprodBelum ada peringkat

- National Skill Competitions: Category: Manufacturing & Engineering TechnologyDokumen11 halamanNational Skill Competitions: Category: Manufacturing & Engineering Technologyivan bernardBelum ada peringkat

- AutopackDokumen2 halamanAutopackapi-301107168Belum ada peringkat

- 3DPD Meeting 2Dokumen5 halaman3DPD Meeting 2Saravanan J Maths KIOTBelum ada peringkat

- CNC Milling: Technical DescriptionDokumen15 halamanCNC Milling: Technical Descriptiongia1985Belum ada peringkat

- WSMP 2022 - TD - MecadDokumen15 halamanWSMP 2022 - TD - Mecadamirul rofiqBelum ada peringkat

- Notes-MDB4213-Jan 2018 - Advance Machining Process PDFDokumen70 halamanNotes-MDB4213-Jan 2018 - Advance Machining Process PDFVeenoShiniBelum ada peringkat

- Training Brochure 2023 - Robot - Welding - ENG - Web - NeuDokumen28 halamanTraining Brochure 2023 - Robot - Welding - ENG - Web - NeuErvin ArifiBelum ada peringkat

- Jitendra ItrDokumen22 halamanJitendra Itrmeenajitendra262Belum ada peringkat

- Fact Sheet - Fitter GeneralDokumen4 halamanFact Sheet - Fitter Generalrana0% (1)

- Ernani D. Ubalde: Objective: Qualiffications and BackgroundDokumen4 halamanErnani D. Ubalde: Objective: Qualiffications and Backgroundernani ubaldeBelum ada peringkat

- Detailed Curriculum Construction Technology Level 5Dokumen18 halamanDetailed Curriculum Construction Technology Level 5SM Zuhail100% (2)

- TRUMPF Course Catalog DitzingenDokumen41 halamanTRUMPF Course Catalog DitzingenRocha Augusto MarisaBelum ada peringkat

- Training Brochure 2023 - Robot - Welding - ENG - WebDokumen28 halamanTraining Brochure 2023 - Robot - Welding - ENG - WebTalha WahabBelum ada peringkat

- Mechanical - VI. Sem Syllabus GtuDokumen115 halamanMechanical - VI. Sem Syllabus GtukishormechBelum ada peringkat

- List of Exercises: Computer Integrated Manufacturing & Technology Driven PracticesDokumen1 halamanList of Exercises: Computer Integrated Manufacturing & Technology Driven Practicesnavneetkpatil8409Belum ada peringkat

- M - Scheme: Course Code: 1021Dokumen171 halamanM - Scheme: Course Code: 1021Gunal KuttyBelum ada peringkat

- Camd 3331906 PDFDokumen7 halamanCamd 3331906 PDFjayyadavvpcBelum ada peringkat

- HCTDokumen63 halamanHCTMohsen SaidiBelum ada peringkat

- Alvita Melisa Castro Guerrero - CV2024Dokumen2 halamanAlvita Melisa Castro Guerrero - CV2024Constructora Ingenieria AlemanBelum ada peringkat

- List of Training Programmes BrochureDokumen8 halamanList of Training Programmes BrochureMechanical2022Belum ada peringkat

- Manufacturing Technology (As Degree S0918) : Required CoursesDokumen1 halamanManufacturing Technology (As Degree S0918) : Required CoursesMFBelum ada peringkat

- CTS Technician Mechatronics CTS NSQF-5Dokumen77 halamanCTS Technician Mechatronics CTS NSQF-5Mohammad AbdullahBelum ada peringkat

- TA202A Lecture 01 2019Dokumen27 halamanTA202A Lecture 01 2019Vedant JoshiBelum ada peringkat

- Cad-Cam-Cim Lab Manual Me804Dokumen47 halamanCad-Cam-Cim Lab Manual Me804siddharth100% (1)

- CADCAM MinDokumen91 halamanCADCAM MinBandi KumarreddyBelum ada peringkat

- Me - D&T - FT - CBCS 2015-16Dokumen50 halamanMe - D&T - FT - CBCS 2015-16RAVI GIRI GOSWAMIBelum ada peringkat

- Auto2 - 8th Sem - 2902Dokumen15 halamanAuto2 - 8th Sem - 2902dsfsfBelum ada peringkat

- Dkhissene Imad-Eddine: CAD DesignerDokumen1 halamanDkhissene Imad-Eddine: CAD DesignerImad DkBelum ada peringkat

- Plastic Processing Lab Sheet - 3D PrintingDokumen2 halamanPlastic Processing Lab Sheet - 3D PrintingAqil AzadBelum ada peringkat

- EIT Masters Engineering Mechanical MME BrochureDokumen4 halamanEIT Masters Engineering Mechanical MME BrochureMuhammad ImranBelum ada peringkat

- OS Mechanics L4Dokumen65 halamanOS Mechanics L4mulualemBelum ada peringkat

- Suvidya Institute of Technology Pvt. LTD.: Mechanical Design of Process Equipment (Full Time) Batch No. 053Dokumen2 halamanSuvidya Institute of Technology Pvt. LTD.: Mechanical Design of Process Equipment (Full Time) Batch No. 053Gaurav TripathiBelum ada peringkat

- RPTDokumen4 halamanRPTSARAN PRASANTHBelum ada peringkat

- Module Selection Guide - B.SC in Computing Major Information Technology - Minor Enterprise SystemsDokumen2 halamanModule Selection Guide - B.SC in Computing Major Information Technology - Minor Enterprise SystemsDelano BannisterBelum ada peringkat

- CADCAM Course OutlineDokumen9 halamanCADCAM Course OutlineJibril JundiBelum ada peringkat

- Engineering Applications: A Project Resource BookDari EverandEngineering Applications: A Project Resource BookPenilaian: 2.5 dari 5 bintang2.5/5 (1)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successDari EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Pan Tex Catalog PDF Cabinetry Decorative ArtsDokumen1 halamanPan Tex Catalog PDF Cabinetry Decorative ArtsCody M HilliardBelum ada peringkat

- Flange Guard and Its ImportanceDokumen6 halamanFlange Guard and Its ImportanceCelestine OzokechiBelum ada peringkat

- CatalysisDokumen22 halamanCatalysisVhyiitrii Shanqk Peñjhaqa Haatii100% (1)

- PLU06Dokumen42 halamanPLU06John Rafael SabidoBelum ada peringkat

- Galvanic CorrosionDokumen2 halamanGalvanic Corrosionspy0161Belum ada peringkat

- Masterbrace Adh 1406Dokumen3 halamanMasterbrace Adh 1406akhemraBelum ada peringkat

- Top 6 Hydrogen Cracking - Cswip 3.1 Course Questions and AnswersDokumen3 halamanTop 6 Hydrogen Cracking - Cswip 3.1 Course Questions and AnswersJlkKumarBelum ada peringkat

- Defects in Gtaw or Tig WeldingDokumen13 halamanDefects in Gtaw or Tig WeldingRamesh R80% (5)

- Bruxite Catalogue 2013 WEBDokumen32 halamanBruxite Catalogue 2013 WEBSergey SlomchinskiyBelum ada peringkat

- Wastewater Treatment ReportDokumen35 halamanWastewater Treatment ReportAditya ChopraBelum ada peringkat

- Penggantian Jembatan Air Tb. TerunjamDokumen4 halamanPenggantian Jembatan Air Tb. TerunjamjoelfriBelum ada peringkat

- HVAC Brochure Rev No 12Dokumen66 halamanHVAC Brochure Rev No 12steve@air-innovations.co.zaBelum ada peringkat

- Forging and Extrusion: M Jamil Ms/IeDokumen51 halamanForging and Extrusion: M Jamil Ms/IeM. RazaBelum ada peringkat

- OCTOBER 2020 Surplus Record Machinery & Equipment DirectoryDokumen714 halamanOCTOBER 2020 Surplus Record Machinery & Equipment DirectorySurplus RecordBelum ada peringkat

- FT - F0233-300 - v. Compuerta NRS PDFDokumen1 halamanFT - F0233-300 - v. Compuerta NRS PDFDaniel AlvarezBelum ada peringkat

- B766!86!2015 Electrodeposited Coatings of CadmiumDokumen9 halamanB766!86!2015 Electrodeposited Coatings of CadmiumJONADHBelum ada peringkat

- European Steel and Alloy GradesDokumen2 halamanEuropean Steel and Alloy Gradesfarshid KarpasandBelum ada peringkat

- ERA Apc06 DreherDokumen35 halamanERA Apc06 Dreherrafael_faria_4Belum ada peringkat

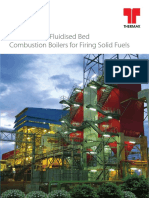

- Atmospheric Fluidised Bed Combustion Boilers For Firing Solid FuelsDokumen12 halamanAtmospheric Fluidised Bed Combustion Boilers For Firing Solid FuelsRaj KumarBelum ada peringkat

- Welding Procedure Specification (WPS) : Joint DetailsDokumen4 halamanWelding Procedure Specification (WPS) : Joint DetailschandraBelum ada peringkat

- My PPT 2Dokumen11 halamanMy PPT 2NahomBelum ada peringkat

- Practical Assessment Hegman Grind GaugeDokumen2 halamanPractical Assessment Hegman Grind GaugeZak ZakuBelum ada peringkat

- Ydr DMSF SDokumen2 halamanYdr DMSF SFelipeBelum ada peringkat

- Durability of Coating Repair Systems For Offshore Services - Eurocorr 2014Dokumen17 halamanDurability of Coating Repair Systems For Offshore Services - Eurocorr 2014ANIBALLOPEZVEGA100% (1)

- Material Science Chapter 7.2 PDFDokumen15 halamanMaterial Science Chapter 7.2 PDFamraqstnaBelum ada peringkat

- Mesh To Micron Conversion Chart Ecologix SystemsDokumen3 halamanMesh To Micron Conversion Chart Ecologix SystemsPitipong SunkhongBelum ada peringkat

- Trelleborg Applied Technologies Syntac 450Dokumen2 halamanTrelleborg Applied Technologies Syntac 450mhrdd222Belum ada peringkat

- Packaging Materials For Fish ProductsDokumen22 halamanPackaging Materials For Fish ProductsJustin Robert GalvezBelum ada peringkat

- Re CessnaSingle 1996on Structural Repair MM SESR04Dokumen167 halamanRe CessnaSingle 1996on Structural Repair MM SESR04chipocludo7av2100% (4)

- User Manual DP323C: Issue 2Dokumen30 halamanUser Manual DP323C: Issue 2Ajmaster.ltBelum ada peringkat