3 Gate 1

Diunggah oleh

Enoch Twumasi0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

11 tayangan4 halamanWuzhou Gate Valve Installation and Direction

Judul Asli

3_GATE~1

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniWuzhou Gate Valve Installation and Direction

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

11 tayangan4 halaman3 Gate 1

Diunggah oleh

Enoch TwumasiWuzhou Gate Valve Installation and Direction

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

Anda di halaman 1dari 4

~wy ®

Gate Valve

Installation and use direction

ZHEJIANG WUZHOU VALVE CO.,LTD

‘Valve type

Hand operated rising stem wedge disc gate valve

‘Usage and feature

Usage

Series flange ends, thread ends and weld end cast steel wedge style gate valve are generally used

in oilfield, chemical-industrial, power-station for cutting and connecting the various pipes.

Features

Strength | High-pressure | Low-pressure

‘Nominal testing Sealing Sealing air ‘Temperature Applicable

‘Pressure ‘pressure testing: testing: ‘Range ‘medium

(Mpa) (Mpa) Pressure ‘Pressure,

(Mpa) (Mpa)

16 24 176

25 3.75 2.75

40 6.0 4a

64 96 7.04

100 150 10

160 24.0 176 ol

25.0 375 275 0.6MPa_ =425°C GAS

150 3.0 22 And WATER

300 78 5.7

600 15.0 11.0

900. 20.1 a7

1500 37.5 275

2500 63.0 46,2

‘Working theory and configuration direction

1. Series gate valve are designed and made under standard API 600,JB/17746, tested under

standard API598, JB/T9092,

2. Hand whee! moving clockwise will close the gate and cut the pipe. As ant-clock will open the

gate.

3. The valve with sealing fitting, as the gate is opened, the stem is on the highest position, The

back sealing of the vaive will keep the packing and the material apart, that will extend the

using time of the packing,

4, The sealing fixing adopts the welding F6 stainless steel or Stellile which is good

abrade-resistance, Corrode-resistance, ant-bruise for extending the use,

5. Use the Flexible wedge for reliable seal,

6. The valves have reasonable configuration, beautiful design, excellent feature, reliable sealing

function.

‘The request of installation

1. To install any valves must be sure the security and easy to operate, repair, uninstall and

installment,

2. ‘The stem must be vertical installed in the aclinic pipes.

2

‘Keep the same directions of material flowing and valve body marked direction. without mark,

please install by valve principle, Do not install on the wrong way.

Before the installation. checking the style requested, The inside and outside of the valves are

clear or not. the valve is in the good condition or not.

‘When install the flanged ends valve, must keep the consistent and reasonable clearance of the

valve's flange and the pipe’s flange. Do not appear the wrong link, crossing link or opened.

‘Put the washer in the middle of flange. The screw keep tie and balance. After fix the screw.

checking the clearance of the parts, which kept the same.

‘When install the threaded end valves .put the moving ends into the both side of the valves,

According as the fact the sealing material can use the PTFE and Sealing glue. Do not dirty

the inside room of the valve.

‘As the fact, adopting the measure to resist the corrode and keep the temperature.

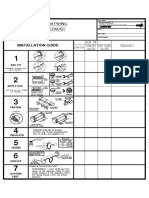

Valve configuration simple picture and main parts, material list

A) Flanged ends explicit rod wafer gate valve

No [Parts name | Material

1 [Body WCB ( pa

2 | Seat A10S+HF

3__ | Wedge WBF wee | Be

4 | Sem 1Cr13 wee di

3 __|[ Sua B7 |

6 _| Hex head nut_| 21

7__| Gasket Graphite and stainless steel it

8 [Backseat | 1Cri3 ao

9 | Bonnet wee x

10__| Stuffing cover | 1Cr13 +

11 _| Packing ‘Graphite ——

12_| Gand ‘WCB e

13 [Yoke mut | Copperalloy n a

14__|Handwheel__ | KTH330 :

n x

‘Main outline dimension and ends size 4

(Attached products catalog)

Maintain

1

au

ut the valve in the draught place with filling of two side. For the long time store, smearing

the mst-proof oil inthe regulated time,

Mast close the gate when the valve stored, that is for protecting the sealing face.

Clear the valve before installation,

(Check the pressure, diameter before installation that will avoid wrong install

‘The valve can be installed in any place except itis appointed. Which is easy to work and fix.

the driver must keep cleaning. use lubricant inthe regulated time.

Fault, reason and fix

Fault Reason Fix measure

Leakage of the | 1. ‘The gland is not tie 1. Tie the nut

packing 2. Notenough filling loop 2, Add the loop

3. Packing beyond the time or

wrong store

3

Replace the packing

Leakage of the

sealing room

4. Attached dirt or the sealing

loop damaged

4,

Clear the dirt or replace

sealing parts

Leakage of the

gasket or self

sealing ends

5. Screw or stuffing box are not

tie with sealing foop

5. Tie the screw that enable the

‘bonnet tie and raised

Hand wheel is not

flexible or wedge

isc can be not

opened

6. Packing is too tie

7. The gland fixing is incline

8. Yoke thread is damaged or

attached dirt

9. The yoke nut is damaged or

broken

10, The stem bent

=

9,

Loosen the nut on the gland

Correct the gland

Open and repair the screw

thread or clear the dirt

Replace the yoke aut

10, Conrect the stem

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Piping Training CourseDokumen411 halamanPiping Training Coursemsaad2100% (15)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Project Sheet: Features BoskalisDokumen2 halamanProject Sheet: Features BoskalisEnoch TwumasiBelum ada peringkat

- Cbod Petroelum Market Update Crude: Price Component PMS AGO LPGDokumen2 halamanCbod Petroelum Market Update Crude: Price Component PMS AGO LPGEnoch TwumasiBelum ada peringkat

- 00813-0300-4485 Rosemount DP Flow Meters June 13Dokumen50 halaman00813-0300-4485 Rosemount DP Flow Meters June 13Enoch TwumasiBelum ada peringkat

- (22560394 - Economics and Business) Model of The Factors Influencing Competitiveness of The Latvian Fisheries Sector ClusterDokumen7 halaman(22560394 - Economics and Business) Model of The Factors Influencing Competitiveness of The Latvian Fisheries Sector ClusterEnoch TwumasiBelum ada peringkat

- Application of Lean To Hotel's Operations: Raising Housekeeping ProductivityDokumen14 halamanApplication of Lean To Hotel's Operations: Raising Housekeeping ProductivityEnoch TwumasiBelum ada peringkat

- Heating Coil Pipe Stress AnalysisDokumen6 halamanHeating Coil Pipe Stress AnalysisEnoch TwumasiBelum ada peringkat

- Universal Expansion Joints 10 14inDokumen1 halamanUniversal Expansion Joints 10 14inEnoch TwumasiBelum ada peringkat

- Cam-Set Data Sheet PDFDokumen2 halamanCam-Set Data Sheet PDFEnoch TwumasiBelum ada peringkat

- The Effect of Lean Operations in ManufacDokumen7 halamanThe Effect of Lean Operations in ManufacEnoch TwumasiBelum ada peringkat

- The Effect of Inventory Management On Firm Performance: Controlling For Key Confounding VariablesDokumen10 halamanThe Effect of Inventory Management On Firm Performance: Controlling For Key Confounding VariablesEnoch TwumasiBelum ada peringkat

- Thermo S PDFDokumen20 halamanThermo S PDFEnoch TwumasiBelum ada peringkat

- MSDS NEMO 2041 EN NewDokumen16 halamanMSDS NEMO 2041 EN NewEnoch TwumasiBelum ada peringkat

- MSDS Nemo 6153 - English - Mar14Dokumen18 halamanMSDS Nemo 6153 - English - Mar14Enoch TwumasiBelum ada peringkat

- ControTrace Installation Checklist PipeDokumen1 halamanControTrace Installation Checklist PipeEnoch TwumasiBelum ada peringkat

- 11 Flame Arrester 4 RampiniDokumen5 halaman11 Flame Arrester 4 RampiniEnoch TwumasiBelum ada peringkat