Bone Ash Project 1-3 On Progress Qa

Diunggah oleh

Oshogbunu Onoriode ErnestJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Bone Ash Project 1-3 On Progress Qa

Diunggah oleh

Oshogbunu Onoriode ErnestHak Cipta:

Format Tersedia

Table of Content

1 INTRODUCTION ..................................................................................................................................... 2

1.1 Aim ............................................................................................................................................... 4

1.2 Objectives ..................................................................................................................................... 4

1.3 Content of this Thesis ................................................................................................................... 4

2 Literature Review .................................................................................................................................. 5

2.1 Alternative materials for substituting Portland Cement Mixture ................................................. 5

2.1.1 Pozzolanic Materials ............................................................................................................. 5

2.2 Factors that influences the strength and durability of Cement Mix proportion ........................ 14

2.3 Laboratory tests on to determine the relative compressive strength of cube mortar. ............. 14

2.3.1 NON destructive test UPV ................................................................................................... 14

3 Medothology....................................................................................................................................... 15

3.1 Description of Laboratory Tests .................................................................................................. 15

3.1.1 Mixtures .............................................................................................................................. 15

3.1.2 Flow test .............................................................................................................................. 16

3.1.3 Molding and Curing test...................................................................................................... 18

3.1.4 Laboratory Test to determine the homogeneity of the Cube Mortar Using UPV .............. 20

3.1.5 Laboratory Test on the Crushing Strength .......................................................................... 23

4 Presentation and Discussion of Result ................................................................................................ 24

References .................................................................................................................................................. 25

[Type text] Page 1

1 INTRODUCTION

In regards to the fast growing and massive construction in the industry, the cost of cement

production is of high demand due to its main constituent. Additionally, the high demand of

conventional aggregates for cement or concrete mixture has adversely caused an ecological

imbalance to the earth. This prompts the necessity for research for alternative material which

could be substitute for cement. Moreover several researchers have contributed to this area of

research by proposing substitute materials which meets the suitable strength and durability of

cement paste or concrete mixtures (Adaba et al, 2012). Most of these researchers focused their

research on maximum economy of the substitute material in terms of volume stability, cost and

reduction of energy dissipation during cement or concrete raw mix production (Jackson et al,

1996).

Cement is considers as a bonding agents when mixed with water and other additive liquid to

produce a paste termed cement paste or mortar. In every production of 1 ton of cement, a certain

quantity of CO2 is dissipated into the atmosphere which is indirectly causes pollution in the

sense that, the ozone layers are depleted and the oxygen is reduced in the environment. Still

much adverse effect observed from cement production to the ecosystem is seen considering

about 1.6 ton of natural resources are consumed. This requires a large amount of energy for the

production.

The application of substitute materials such as bone ash, rice husk, recycled concrete, Palm oil,

wood ash are seen to be adequate substitute for cement mixture. Though as much benefit is

obtain in production terms integrity of the cement mixture is diminish. This fact is valid

considering law of diminishing return. Most of these suitable binders substitute are pozzolanic

materials. Pozzolans material are cementing material with siliceous, aluminous of both has its

main constituent. These main proves better integrity of cement mixture in considering

segregation, reducing bleeding in all adequate workability of the mixtures (Uwe, 2015). . Palm

oil fuel ash, rice husk ash and wood ash contains pozzolanic material thus; they can be used as

cement replacement material since; their chemical composition meets the standard of ASTM.

Adding pozzolans as cement replacement material to concrete would reduce the slump and

increase the water demand due to the high neness of these replacement materials According to

[Type text] Page 2

the ASTM standard, the bone ash does not meet the requirement of been classify as pozzolan due

to the high content of calcium oxide (Adaba et al, 2012).

However, this thesis work was on bone ash which is rich in calcium carbonate which is an

important content for Ordinary Portland cement. Bone ash is commonly used in industries for

ceramic production a common product is the China porcelain. This is in concern to the strength

and reduction in weight of its product compared to full Portland cement mixtures. Some

researchers have proven from results obtained from the strength and cost analysis of the various

types of cement replacement materials showed that the bone powder ash had the highest

compressive strength due to its large amount of C3S while, rice husks ash had the highest value

of C2S (Adaba et al, 2012).

As it is expected that the primary function of the substituting material is the strength of the

concrete, the most influential factor to determine the full strength if the cement is curing despite

the cement mixture invariable affects the strength. The strength of the cement mixture increase

as the days of curing increases. The variable factor is the extent of hydration of the cement

mixture while place inside a deep clean water having a normal temperature. Thus, hydration of

the bone ash mixture in the concrete is relevant in this thesis which indirectly affects the cement

mixture.

On other hand, the mixture of the bone ash- cement paste homogeneity would varies which

affects the elastic modulus, density, void and that account for the strength of the its mixture. The

Ultrasound Pulse velocity apparatus is a commonly used to examine the density and voids. Its

other application measures structural engineering parameters which are detecting defects and

assess deterioration. Ultrasonic wave propagation characteristics that can be used for these

purposes are: velocity attenuation, frequency, and energy (Udegbunam et al. 1999). These test

evaluates were presented in relative to the curing days of the cement paste in this thesis.

Obviously, the strength of the BA cement mixtures is expected to vary to amount of the BA

percentage substitutes for the cement. Hence, this concern to the relative increase in strength of

the BA cement mixture to UPV measured properties and curing days.

[Type text] Page 3

1.1 Aim

This research aimed at using bone ash as a substitute for cement mixture (Portland cement

mixture) to analysis the effect of the percentage substitute the curing days.

1.2 Objectives

Prepare three cube mould of the Portland cement mixture with percentage substitute of

0%, 20%, 30% and 40% of bone ash

Determination of the workability of the different mixtures focusing more on the

consistency of the mixture through flow test.

Carryout curing test which is necessary in determine the difference in the cube mortars

strength

Determination and homogeneity (elastic modulus, void) of the cube mortar a non-

destructive test (UPV)

Establish a relative equation between the UPV and crushing compressive strength of the

cube mortar to determine the actual compressive strength relative to curing days.

1.3 Content of this Thesis

Chapter 1 of this thesis presents an introduction on the high demand of cement

production with the necessity of preferable substitute for the beneficial of light weight

construction and sustainability of the ecosystem.

Chapter 2 present the literature of subjects reviewed in order to acquire better

understanding to construct a methodology of fulfilling the aim of this research.

Chapter 3 provides detailed methodology of the thesis with examples showing the

evaluation of the workability and relation between the homogeneity content and the

crushing strength of the cube mortar.

Chapter 4 presents and discussed results obtained from laboratory test and parametric

analysis on curing days

Chapter 5 presents the conclusion and future recommendation of thesis.

[Type text] Page 4

2 Literature Review

The following subjects where review In order to acquire a good understanding of this research

topic and establish a logic methodology in attaining the aim and objectives, the following

subjects were reviewed;

Alternative materials for substituting Portland Cement Mixture; Pozzolans and Bone ash

properties and performance with Portland Cement mixture.

Factors that influences the strength and durability of Cement Mix proportion

Laboratory tests on to determine the relative compressive strength of cube mortar.

2.1 Alternative materials for substituting Portland Cement Mixture

2.1.1 Pozzolanic Materials

Pozzolans are powder like materials that reacts with lime powder, commonly ordinary Portland

cement which releases CO2 by hydration of the cement, to form compound to strengthen or bind

other properties of the concrete or mortar mixtures (B, King, 2000). Pozzolans are siliceous or

[Type text] Page 5

siliceous and aluminous materials which in themselves do not possess any cementitious value but

in finely divided form and in the presence of moisture will chemically react with calcium

hydroxide (CH) to form a compound with cementitious value according to this general equation:

Pozzolans + CH = C-S-H

Calcium silicate hydrates (C-S-H) is the strength-forming products of cement hydration (Yilmaz,

K.2010).

They are different approach for the usage of pozzolans mortar that is well recommended for lime

mortars. In application, the necessary elements of adequate practice includes, appropriate

preparation of the pozzolans material by control the dampening down to modest suction, use of

small volumes of mortar, regulate the rate of curing and protection from the harsh weather

condition are very vital.

The hardened process of an ordinary Portland cement (OPC) is by drying and carbonation. This

transition is achieved by the conversion of the calcium hydroxide (slaked lime) to calcium

carbonate by reacting with the atmospheric carbon dioxide. Other other hand, an hydraulic

mortar becomes hardened by chemical reactions between calcium hydroxide and reactive

silicates aluminates in the presence of water. In natural hydraulic lime, the reacting minerals,

that is, silicates and aluminates are supplied by the clay minerals. Where hydraulic setting of

pozzolan mixture are required, the minerals for not in sufficient quantities to reach the setting

requirement.

Where pozzolan are used as additive for any lime mortar, regardless of hydraulic and non-

hydraulic modifies the characteristics. Their reaction assist to form stable reaction compound in

[Type text] Page 6

the mixture that reduces early leaching or frost damage, thus increases durability. The

compressive strength hand density of the mortar varies with the types of pozzolan material, also

increases as the porosity reduces. Moreover, the softer the pozzolanic material, less

impermeable and flexible the mortar mixture. Likewise, the harder the pozzolanic material which

are usually hard-burned materials, such as fly ash would react to produce a harder mortar closer

to the hardness of ordinary Portland cement. An example of a softer pozzolan is a brick dust

obtained from clay bricks heated at temperature less than 950C.

Past research have argued that early setting and increased in durability of lime mortar can be

achieved by addition of small ratio of cement to the pozzolan material. However, research have

proven that the pozzolan gauge for lime mortar are not durable unless in a relative ratio of

pozzolan cement are around 1:1. The ratio produces a very hard and brittle mortar that may not

be conservative enough for usage. Similar situation could also occur in some modern high fired

hydraulic Portland cements.

2.1.1.1 Types of pozzolans

Fly ash

Fly ash are the most come types of pozzolan material adopted for Portland cement or concrete.

[Type text] Page 7

For the over 50 years now, the application of fly ash have grown much significantly with about

15 million tons used in concrete, concrete production and grout in the U.S in 2005 (ACAA20

06). The average percentage usage of fly ash in concrete ranges from 15% to 25% by mass of the

cementitious material contents. Percentage usage may be influenced by geographical location or

climate. Higher percentage are of ranges of 30% to 50% applicable for massive structures such

as foundation and dams to modest temperature rise. Recent research have demonstrated high

percentage proportion of 40% to 60% can be adopted for structural applications with good

mechanical properties and durability (Marceau 2002). However, shortcomings are to be

expected for the use of higher percentage such as slow setting times and strength development

which causes early-age strength, thus slow down the rate of construction.

These shortcomings are observed particularly in cold weather concreting. In additional, the

durability of the concrete may be affected with regards to resistance to deicer-salt scaling and

carbonation.

Nevertheless, they is an optimum quantity of fly ash required to optimised the technical

performance of the mixture relative to the environmental and economic benefits without

affecting the rate of construction and long term performance of the finished product. The

maximum quantity of fly ash will be a subjective to the wide range of parameters and must be

quantified relative of the case by case basis.

2-1 Fly ash Dosage rating (PCA, 2015)

level of fly ash % Rating

15 low

15-30 moderate

30-50 high

[Type text] Page 8

50 very high

Effect of Fly Ash on the Properties of Fresh Concrete Workability

Fly ash of high fineness and low carbon content reduces the water to cement ratio compare to

that of a full Portland cement mixture. The other words, the workability of the cement mixture

would be reduces compared to the Portland cement mixture. But, the variant of the water content

is relative to the nature of the fly ash and other mix material. It is estimated that, there about

10% of the fly ash reduces 3% of the actual water content for Portland cement mixture.

A good ratio of fly ash to Portland cement would increase the workability of the mortar

compared to a Portland full fixture of the same slump. This indicates the flowability for fly ash

cement mixture is better than that of Portland cement mixture when vibrated. Cohesiveness and

segregation is improved with the fly ash use in the mixture. The fly ash cement mix is lubricated

the spherical particles which ease flow when pumping the mixture and wearing of the equipment.

Effect of Fly Ash on Finishing and Curing

They are significant retardation in the setting time of a mortar mixture where fly ash is used, in

other words, finishing operations are delayed. The rate of pozzolanic reaction at normal

temperatures is slower than ordinary cement hydration and fly ash concrete are necessary to for

better curing of the mixture which is a dilemma. Higher ratio of fly ash to cement are commonly

[Type text] Page 9

recommended that the minimum amount of duration should be 7 days for moist curing (Malhotra

2005). In a circumstance where proper curing cannot be provided in practice, the amount of fly

ash should be limited.

The provision for fly ash to be added to a cement of about 50% should be satisfactory but

precaution should be considered for the required early strength for the project and adequate moist

curing. However, the necessary fly ash provision may be determine by the finishing

requirement. Where proper curing cannot be provided for the mortar or concrete mixtures, the

amount of fly ash should be limited to about less than 25% ratio of the Portland cement.

Slag material

Ground granulated blast-furnace slag GGBS are also commonly known as slag cement. It was

first developed in Germany in 1853 (Malhotra 1996). It began to be use as a cementitious

material in the early 1900s (Abram 1925). They are by-products form discharge in large amount

by the production process of iron and steel. The necessity of recycling slag in order to promote

sustainability in the ecosystem as per reducing environmental pollution. This pozzolan material

requires certain properties that as quite difficult to obtain form natural material. Though the

relevance of attaining a friendly ecosystem in this 21st century has prompt the necessity of saving

energy and reduction of carbon dioxide. In North America region, the commonly concrete or

mortar mixture constitute a partial replacement between 30% and 70% (PCA, 2000).

Lime (CaO) and silica (SiO2) are the primary minerals which constitute a slag and similar

minerals are contains in an ordinary Portland cement. This means that a slag is soluble in pure

water and exhibits alkalinity. When heated to a high temperature of 1,200C or greater, the

[Type text] Page 10

presence of any organic material are removed from its content and forms a glassy sandlike

granulated material. The GGBS is a by-product of pig iron and formed by rapid cooling of the

molten slag quench by water and instantaneously tapped. The granulated material are ground to

be less than 25 microns, having a surface area fineness of 400 to 600m2/kg Blaine. It relative

density ranges from 2.85 to 2.95 and a bulk density from 1050 to 1375kg/m3.

The rapid quenching facilitate the formation of the granulated slag and when properly done,

expected hydraulic property. Hence, this hydraulic property makes it effective for slag to be used

as pozzolan material preferred for cement replacement. In the case, when the hydraulic material

is slowly cool, then the hydraulic inert cannot provide the required effectiveness to be used as

pozzolanic material. Although, the application of GGBS in form of Portland slag cement is not

common in some places (India) and experiences of adopting it as a partial replacement of cement

or mortar mixture.

Performance of Slag as partial replacement for Portland cement

As similar to the case of fly ash, the water to cement ratio content is reduced as the percentage of

GGBS is increased. The affects the workability of the cement mixture, likewise the delay in

construction and finish. However, the hydration during curing is controlled which might be

preferable for required early strength of the concrete or cement mixture. The limitation is that the

retardation of the hydration heat slows the setting time of the mixture.

In considering the maximum compressive strength of concrete increased by 55% at 40%

replacement of fine aggregate by copper slag, and up to 75% replacement, concrete gain more

strength than control mix concrete strength which was full Portland cement mixture. It is

observed that for all percentage replacement of fine aggregate by Copper slag the flexural

strength of concrete is more than control mix (Chavan, et al, 2013).

BONE ASH

Bone ash is a produce of animal bone commonly used for china ceramics, up to 50% of the

ceramic weight. Its process of production is done by removing any meat articulated to the bone.

The bones is then treated to remove organic material by heating the bones to about 1000C or

more. During the process of heating, the bones are sterilised as well. Afterward they are grind

[Type text] Page 11

into fine particles to become powder like and suitable to be used as cementitious material. The

figure? Shows the sterilised bone and powder form. (Ceramic dictionary, 2015).

A research conducted at Universit Paul Sabatier in Castres, France in to determine the physical

and chemical properties if an incinerated bone or pulverised bones. The result showed that

pulverised bones are rich in calcium were calcium (30.7%) and phosphate (56.3%), that a rich

compounds, mainly a mixture of Ca10(PO4)6(OH)2 and Ca3(PO4)2. A significant amount of

sodium (2.7%), potassium (2.5%) and magnesium (0.8%) were also observed. The prompt of this

research was the bovine spongiform encephalopathy (BSE) crisis in the European beef industry

as an effect of importing of waste products have been banned by the European community. Thus

the need for alternative disposal or recycling of the meat or bone meal waste product was

established (Deydier E., et al. 2005).

Moreover, the use of bone ash would be very applicable in developing country where livestock is

staple food production and relative to the fact for limitation of cement materials. The use of one

incinerated or pulverised bone can be considered as artificial pozzolanic material. Bone ash are

force to constitute the hydraulic property by calculating them are higher temperatures (Yilmaz,

K.2010).

The composition of a pulverised bone ash was compared to that of a Portland cement

composition. Table 2 presents the differences in percentage. The similarity between these

materials is of minimal differences for most of the minerals yet, pulverised bine bone cannot be a

cementitious material without the present of cement (BS 12, 1996). The reason for this

ambiguity is that unlike during cement production, the pulverise bones, do not go through much

[Type text] Page 12

high temperature. In the cause of this, remainders of the organic materials in the pulverised bone

retards the cementitious properties.

Table 2-2 Comparison of chemical composition of Portland cement and pulverised bone (aggregate form of

bone ash) (Falade, 2012)

The loss of ignition is limited is measured by considering the extent of carbonation and hydration

of free lime and free magnesium due to atmospheric exposure of the pulverised bone (1.14%).

The alkaline property cause by the combination of K2O and Na2O for pulverised bone is 2.18%

which is low. This is beneficial considering the possible reduction of the destructive alkali

aggregate reaction (Neville, A. M. 2003). Also, the limits pulverise bone alkalinity is free from

cyanide which is an agent of corrosion of reinforcement. In addition, the specific gravity is

lower than that of Portland cement which indicate the applicability of pulverised bone ash

mixture to be a light weight cement or concrete mixture.

Performance of Pulverised Bone ash as partial replacement of Portland cement

A research study was done (Falade et al, 2012), that the partial replacement of pulverised bone

ash to cement paste and mortar. It was concluded that the replacement of 20% cement with

pulverised bone have no significant effect for a 28 days compressive strength of a full Portland

cement mixture (control specimen without pulverised bone).

[Type text] Page 13

2.2 Factors that influences the strength and durability of Cement Mix

proportion

Get from text book

2.3 Laboratory tests on to determine the relative compressive

strength of cube mortar.

2.3.1 NON destructive test UPV

Destructive test CRUSHING STRENGTH

[Type text] Page 14

3 Medothology

This chapter described the following features of this thesis;

Description of Laboratory tests on :

o Evaluating the solid mortar relative variance in its homogeneity (properties density,

porosity and actual compressive strength) in respect to days of curing using Ultra

Pulse Velocity apparatus.

o Flow test to examine the workability of the mortar in respective to the mixtures and

curing days

o Destructive test to evaluate the axial compressive strength of the mortar mixtures

using a UTEST compression machine.

Analytical procedure to determine the UPV and the mortar NDT compressive strength

equation for better degree of accuracy in evaluating the mortar compressive strength.

3.1 Description of Laboratory Tests

3.1.1 Mixtures

A parametric study was carried out on different mortar mixtures for better accuracy of result to be

evaluated on a specific mix. The mortar mixtures as earlier stated were substitution of bone ash (BA) for

Portland cement in proportions of 10% to 40%. Each of the mortar mixtures, three (3) batches were

mixed to fill three moulds. A control mix of full Portland cement was also made for relative comparison

to the BA mixtures. The

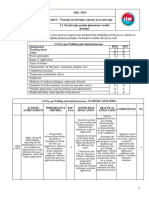

Table 3-1 Samples of adopted for Parametric Study

% Mixtures Bone Ash Portland Sand (g) Water (g) W/C

(BA) (g) Cement

(PC)(g)

BA 0% 0 1 3000 600 0.55

BA 20% 200 800 3000 600 0.55

BA 30% 300 700 3000 600 0.55

BA 40% 400 600 3000 600 0.55

[Type text] Page 15

Figure 3-1 Mortar mixture for 30% BA substitution for Portland cement

Afterward, the workability of the mortar mixtures was examined before placing them into the moulds.

3.1.2 Flow test

It is alluring to predict the actual variables that influence the mortar mixture to attain required

wetness and cohesion. However, a flow test was adopted to examine the workability of the BA

mixtures in order to give account of the most adequate proportion of the BA mixtures. The water

content plays an important role in the mixtures in terms of the mix consistency that is the

wetness of the concrete mix suitable for workmen on site. But water-cement ratio was kept sand

throughout the test in order to differences in the wetness and binding of the BA mixtures.

The following procedure of the flow test is itemized as below:

The necessary full Portland or BA mixtures was mixed as described in section (Mixture)

Then the mortar mixture was poured into the truncated cone and then flush

Next, the mortar mixture is tap 20 -25 times with a tamp rod to prevent air entrapment

and void

The filled truncated cone is vibrated as well

Top of the truncated cone filled with the mortar mixture is flushed with a trowel

[Type text] Page 16

Figure 2 Flow test on the Bone ash cement mixture workability

Afterward, the truncated cone filled with mortar mixture is lifted and instantly dropping

the truncated cone 20 times in a circular manner at the ends of the poured mortar mixture

less than 15 second.

Allow the mortar mixture to flow freely and settle

Lastly the average diameter of the spread is estimated as the difference between the

diameter (25cm) initial base of the truncated cone and the maximum diameter of the

spread for both perpendicular directions was sum up and then divided by diameter of

initial cone base. The result is represented

Example 3.1

For 0% BA mixtures consistency is evaluated as below:

[Type text] Page 17

Table 3-2 Results from flow test

BA %Mixtures 0 20 30 40

Diameters (cm) 17.7 17.5 1 2

Flow % 70.8 70 4 8

The result 70.8% from the full Portland cement mixture indicates the relative high degree

of wetness compared to others as the BA% mixture is increased to 40%. This explains the

reduction in consistency of the mortar mixture as more volume of bone ash are

substituted for the Portland cement. In practical terms, the mortar mixture, the lesser the

workability rate the mortar which thus gives difficulty of to site men. The setting time

and hardening time of the concrete is quicker. Therefore, if a higher percentage of bone

ash is to be used, then the mixtures is to be made of use immediately on site. The

conventional acceptable flow percent value for a good workability mortar in terms of

consistency is estimated to be 100 5% (Masonry construction world, 2015). In making

comparison of the flow test result to 100 5%, implies the water to cement ratio of the

mortar is quite minimal to improve the consistency ignoring the high cohesion, that poor

resistance to segregation observed as the BA proportion to Portland cement is increased.

3.1.3 Molding and Curing test

The main variable which influences the aim of this research is the curing period of the

cube mortar mixtures. This influences the water absorption, homogeneity properties

(density, elastic modulus, capillarity a) of the cube material and likewise the compressive

strength of the cube mortar. A sequence of moulding and curing the cube mortar

Please i need the photo for curing of the cube here

The moulds were well assembled and oiled with lubricant to allow ease in

releasing the mortar after hardening

After evaluating the workability of each of the BA mixtures, they were poured

into cubic moulds to form the cube BA mix mortars

[Type text] Page 18

The moulds were left covered for 24 hours with a cloth to retained moisture after

hardening in regards to reduce hydration of the mortar.

After 24 hours, the mould were removed and washed after used for the next batch

of BA mortar mixtures to be poured.

Figure 3 Label cube mortar BA 20%

At this time the mortars had hardened which was then labelled accordingly to the

batch mixtures.

3.1.3.1 Curing stage

Next is curing, a clean water with a room temperature about 20 to 32 was

filled up in a tank. Proper precautions were taken to ensure the water is free from

acidic material by checking the acidic level of the water to indicate 7.

Demarcation was created to differentiate between the full Portland mixtures and

the BA mixtures. The BA mixtures were also separated in respect to the

percentage mixtures for easier identification.

Then, next the cube mortars are weighed to account for the initial mass before

curing. This is required to evaluating the amount of water absorbed by the mortar

and porosity.

[Type text] Page 19

Lastly they are placed deep inside the water filled tank, ensuring that whole

surface area of are sink in water.

These cube mortar are left with the designated days for curing and then taken out to determine

their homogeneity properties by using an Ultrasound Pulse velocity sensor.

3.1.4 Laboratory Test to determine the homogeneity of the Cube Mortar

Using UPV

The ultrasound pulse sensor was used for two main variables in this experiment which were the

actual compressive strength of the cube mortar and the density of each BA mixtures type. This

approach is on the basis of sending high frequency sound waves through the cube mortar. The

speed of the velocity is an inverse proportion of the time the sound waves travels through the

cube mortar. In this thesis, the direct method was used in achieving the aim of the test, see figure

(3.2)

Figure 3-4 Test on the cube mortar homogeneity properties

The delay in transition of the sound wave estimates the relative porosity of the cube mortar to its

density or volume. Also the elastic property of the influences the velocity of the sound waves

[Type text] Page 20

transit. There about 25 to 60 kHz was the frequency transferred through the cube mortar (Pundit,

1990). A simplified relation for the aforementioned description is given as

Furthermore, the modulus of elasticity would be regard as common parameter suitable to

describe the homogeneity properties of the cube mortar. This is established as seen below:

Where g is acceleration due to gravity and

Example 2 Evaluation the modulus of elasticity for 10% BA mixture where UPV was measured

2874 m/s after 24 hours of curing

Mortar density

Therefore,

.

It was observed as the curing days increased which influence the compressive strength of the

concrete, the modulus of elasticity increases. This effect is shown graphically in figure 3 where

the was observed that the modulus of elasticity , E of BA 0% (full Portland cement mixture)

stands to have a higher modulus of elasticity which depicts a better homogeneity properties, that

per se adequate durability for construction. Hence, it could be agreed that the substitution of

bone ashes reducing the durability of the mortar mixtures. Table 3 summarizes the UPV in

respect to their expected durability for construction in respect to the curing days .

[Type text] Page 21

20.00

Modulus of elasticity GPa

15.00

BA 0%

10.00

BA 20%

BA 30%

5.00

BA 40%

0.00

3145.00 3827.67

UPV value m/s

Figure 5 Relationship between Modulus of elasticity and UPV in respect to the adopted curing sequence days (day 1 and day

7)

Table 3-3 Summary and remark of estimated modulus of elasticity E in respect to the curing days and UPV

Theoretical

UPV Modulus of Remark on Mortar in respect to

Curing day

m/s elasticity, E UPV

GPa

Adequate, but durability

3145.00 14.19 1

condition is uncertain

BA 0%

3827.67 17.27 7 Very Adequate

28

Inadequate for construction, poor

2990.67 13.50 1

workability

BA 20% Tagged good - very good, but

3686.33 16.63 7

slight possibly of porosity

28

Inadequate for construction, poor

2930.67 13.22 1

workability

BA 30% Tagged good - very good, but

3686.33 16.63 7

slight possibly of porosity

28

Inadequate for construction, poor

2555.67 11.53 1

workability

BA 40% Adequate, but durability

3433.33 15.49 7

condition is uncertain

28

[Type text] Page 22

3.1.5 Laboratory Test on the Crushing Strength

The crushing strength of the cube mortar as itemised as follows:

After the homogeneity content of the cube are determined, the cube mortar is taken to the

uni-axial compressive machine.

The sitting platform for the concrete is cleaned thoroughly before plating the cube mortar

The cube is arrange properly with I side facing the compressive hammer. The hammer is

rest on the upward side of the cube mortar.

Next, the blind screen was used to cover the crushing machine to take caution while the

cube mortar is crushed.

The compressive mortar was set to application of load at

Figure 6 Crushing cube test of BA mortar mixture

[Type text] Page 23

4 Presentation and Discussion of Result

C3S and C2S are two important compounds responsible for strength. Together they constitute 70 to 80%

of cement (Neville and Brooks, 2003).

[Type text] Page 24

References

[Jackson, N. and Dhir, K. Civil Engineering Materials. Macmillan Press Ltd,

Houndsmills, London, 1996.].

Tornsen, H. N. 1980. "The Practical Use of Ultrasonic Pulse Velocity Measurements in

the Assessment of Concrete Quality." Magazine of Concrete Research, V 32, No. 110,

pp. 7-t5.

Swamy. R. N.. and AI-Hamed. A. H., 1982. "The Use of Pulse Velocity Measurements to

Estimate Strength of Air-Dried Cubes and Hence InSitu Strength of Concrete." In-

SiIII/NDT Testing of Concrete. SP-82, V M. Malhotra, ed., Amencan Concrete lnstitllle,

Farmington Hills. Mich.. pp.20)-227

Udegbunam, 0., Yaman. I. 0., Aklan, H.. and Hohm. T., 1999, "Developing a Rapid

Measure of Concrete Permeability for Use in QNQC Specifications," Proceedings of the

Tramponariorr Research Board, Paper No. 990565, Washington, D.

B. King, A Brief Introduction to Pozzolans. in: Alternative Construction - Contemporary Natural

Building Methods, John Wiley & Sons, London, 2000.

(2) According to Eckel, in the 1920s American publication Cements, Lime and Plaster, natural

pozzolans contain between 42 and 66 per cent silica and between 15 and 17 per cent alumina.

ACAA, 2005 Coal Combustion Product (CCP) Production and Use Survey, American Coal Ash

Association, www.acaa-usa.org, 2006.

Marceau, M.L., Gajda, J., and VanGeem, M.G., Use of Fly Ash in Concrete: Normal and High

Volume Ranges, PCA R&D Serial No. 2604, Portland Cement Association, Skokie, Illinois, 2002.

Malhotra, V.M. and Mehta, P.K., High-Performance, High-Volume Fly Ash Concrete.

Supplementary Cementing Materials for Sustainable Development Inc., Ottawa, Canada, 2005,

124 pages.

[8] Falade, F. Ikponmwosa, E and Fapohunda, C (2012) Potential of Pulverized Bone as a

Pozzolanic Material. International Journal of Scientific and Engineering Research, Vol. 3, Issue 7,

June 2012.

[20] Neville, A. M. (2003). Properties of Concrete. Pearson Education, 4th Edition.

Chavan, et al, International Journal of Advanced Engineering Research and Studies E-ISSN2249

8974 Int. J. Adv. Engg. Res. Studies /II/IV/July-Sept., 2013/95-98 Research Paper PERFORMANCE

OF COPPER SLAG ON STRENGTH PROPERTIES AS PARTIAL REPLACE OF FINE AGGREGATE IN

[Type text] Page 25

CONCRETE MIX DESIGN R R Chavan*1 & D B Kulkarni2 Address for Correspondence 1 Student,

M.Tech. (Civil Structures), *Associate Professor, Department of Civil Engineering, Rajarambapu

Institute of Technology, Rajaramnagar

http://ceramicdictionary.com/en/b/4031/bone-ash-manufacture

Deydier E., G. R. (2005). Physical and chemical characterisation of crude meat and

bone meal combustion residue: "waste or raw material?". Journal of Hazardous

Materials , 141-148.

BS 12 (1996). Specifications for Portland Cement British Standard Institution, London, 15th

Edition.

International Journal of Scientific & Engineering Research Volume 3, Issue 7, June-2012 1 ISSN

2229-5518 IJSER 2012 http://www.ijser.org Potential of Pulverized Bone as a Pozzolanic

material F. Falade, E. Ikponmwosa, C. Fapohunda

Pak. J. Engg. & Appl. Sci. Vol. 13, July, 2013 (p. 82-93) 82 A Study on the Compressive and Tensile

Strength of Foamed Concrete Containing Pulverized Bone as a Partial Replacement of Cement

Funso Falade1 , Efe Ikponmwosa2* & Christopher Fapohunda3

[Type text] Page 26

Anda mungkin juga menyukai

- 17 Samss 007Dokumen12 halaman17 Samss 007Cherukunnon Jubu0% (1)

- For The Various Engine Oils Approved by Pratt and Whitney, Refer To The Pratt and Whitney Service Bulletin No. 13001Dokumen36 halamanFor The Various Engine Oils Approved by Pratt and Whitney, Refer To The Pratt and Whitney Service Bulletin No. 13001arunBelum ada peringkat

- Chapter 5 - Lubrication ManagementDokumen41 halamanChapter 5 - Lubrication ManagementAdinz DinBelum ada peringkat

- Fundamentals of Thermodynamics Solutions ch05Dokumen190 halamanFundamentals of Thermodynamics Solutions ch05Cierré No'Middlename Jones100% (10)

- Dr Sreevalsa Kolathayar MIGS, MISET: Expert in Seismic Hazard and Geotechnical Earthquake EngineeringDokumen14 halamanDr Sreevalsa Kolathayar MIGS, MISET: Expert in Seismic Hazard and Geotechnical Earthquake EngineeringsreevalsakolathayarBelum ada peringkat

- Economic and Financial Analysis For Polymer Modified BitumenDokumen11 halamanEconomic and Financial Analysis For Polymer Modified Bitumennicholas100% (1)

- Study of Strength Properties of Polyester Fibre Reinforced ConcreteDokumen5 halamanStudy of Strength Properties of Polyester Fibre Reinforced ConcreteJournal 4 ResearchBelum ada peringkat

- Development of High Strength Concrete From Recycled Aggregate Concrete.Dokumen94 halamanDevelopment of High Strength Concrete From Recycled Aggregate Concrete.Micah GentleBelum ada peringkat

- CIDECT Design Guide 8Dokumen122 halamanCIDECT Design Guide 8paris06275% (4)

- Partial Replacement of Cement With Glass Powder and Egg Shell (Powder) Ash in ConcreteDokumen51 halamanPartial Replacement of Cement With Glass Powder and Egg Shell (Powder) Ash in Concreteshivanand hippargaBelum ada peringkat

- Article Text 463742 1 10 20190116 2Dokumen7 halamanArticle Text 463742 1 10 20190116 2Jiu ShitzukiBelum ada peringkat

- Plastic Mixed Reinforced ConcreteDokumen10 halamanPlastic Mixed Reinforced ConcreteUmange RanasingheBelum ada peringkat

- Dictionar Tehnic General / General Technical Dictionary: Romana/RomanianDokumen62 halamanDictionar Tehnic General / General Technical Dictionary: Romana/RomanianAma81100% (17)

- Handbook of Biopolymers Advances and Multifaceted Applications (Ahmed, Shakeel Kanchi, Suvardhan Kumar Etc.)Dokumen323 halamanHandbook of Biopolymers Advances and Multifaceted Applications (Ahmed, Shakeel Kanchi, Suvardhan Kumar Etc.)Tecuitlatl100% (3)

- Calcium Additive Into PultrusionDokumen12 halamanCalcium Additive Into PultrusionIan LeeBelum ada peringkat

- Minor Project-02: Mr. Sunil Saharan Assistant ProfessorDokumen26 halamanMinor Project-02: Mr. Sunil Saharan Assistant ProfessorSonu ChoudharyBelum ada peringkat

- Experimental Study On Partial Replacement of Fine Aggregate With Quarry Dust and Saw DustDokumen13 halamanExperimental Study On Partial Replacement of Fine Aggregate With Quarry Dust and Saw DustPerarasan MBelum ada peringkat

- Mohamed Elfatih - TechnicalDokumen11 halamanMohamed Elfatih - Technical6qwhnq9z4h100% (1)

- 8042306Dokumen99 halaman8042306Darshan KashiBelum ada peringkat

- Pumice As SandDokumen36 halamanPumice As SandArbie FerrerBelum ada peringkat

- Verification of Debye-Hückel-Onsager EquationDokumen3 halamanVerification of Debye-Hückel-Onsager EquationJOSEPH HERBERT MABEL50% (6)

- TERRAZYME Seminar With Page No ReportDokumen17 halamanTERRAZYME Seminar With Page No ReportAbhinav DhayalBelum ada peringkat

- Reference Books For IES Civil Engineering PDFDokumen1 halamanReference Books For IES Civil Engineering PDFDanish Ahmad100% (1)

- A Comparative Study On The Mechanical Properties of Concrete Using M-Sand and Ground Nut Shell Ash As A Partial Replacement of River SandDokumen17 halamanA Comparative Study On The Mechanical Properties of Concrete Using M-Sand and Ground Nut Shell Ash As A Partial Replacement of River SandIJRASETPublicationsBelum ada peringkat

- DesignDokumen28 halamanDesignA.W. SekandariBelum ada peringkat

- Use of Pervious Concrete in Pavement ConstructionDokumen3 halamanUse of Pervious Concrete in Pavement ConstructionSaul Lopez MejiaBelum ada peringkat

- Recycled Plastic Used in Concrete Paver Block PDFDokumen3 halamanRecycled Plastic Used in Concrete Paver Block PDFRusel ZahrawBelum ada peringkat

- Stabilization of Expansive SoilDokumen4 halamanStabilization of Expansive SoilSamara LujanBelum ada peringkat

- SRD Project Doc FinalDokumen65 halamanSRD Project Doc FinalRavi JoshiBelum ada peringkat

- Coconut Husk FiberDokumen12 halamanCoconut Husk FiberArnie Romero CrispinoBelum ada peringkat

- Technical Review On Biomass Conversion Processes Into Required Energy FormDokumen6 halamanTechnical Review On Biomass Conversion Processes Into Required Energy FormRicardo ValenciaBelum ada peringkat

- Utilization of Fly Ash in Rural Road Construction in India and Its Cost EffectivenessDokumen6 halamanUtilization of Fly Ash in Rural Road Construction in India and Its Cost Effectivenessceanil100% (1)

- EN8592 UNIT 2 Grey Water HarvestingDokumen14 halamanEN8592 UNIT 2 Grey Water Harvesting2CIVIL3045 SONIYA ABelum ada peringkat

- Compound Stress and Strain GuideDokumen8 halamanCompound Stress and Strain Guideshweta_7705870% (1)

- Proceedings PDFDokumen139 halamanProceedings PDFR RathiBelum ada peringkat

- COconut Shell PaperDokumen10 halamanCOconut Shell PaperPeer MohamedBelum ada peringkat

- Experimental Study On Stabilization of Clay Soil Using Coir FiberDokumen18 halamanExperimental Study On Stabilization of Clay Soil Using Coir Fiber153-B RAKSHITHABelum ada peringkat

- Visvesvaraya Technological University Jnana Sangama, BelagaviDokumen27 halamanVisvesvaraya Technological University Jnana Sangama, BelagaviVBelum ada peringkat

- Excel Sheet For Sieve Analysis of Aggregate and To Calculate Fineness ModulusDokumen6 halamanExcel Sheet For Sieve Analysis of Aggregate and To Calculate Fineness ModulusAnonymous 3hPIuGABBelum ada peringkat

- 1.1 Concrete: "Partial Replacement of Coarse Aggregate With Ceramic Tile in Concrete"Dokumen11 halaman1.1 Concrete: "Partial Replacement of Coarse Aggregate With Ceramic Tile in Concrete"Naveen SBelum ada peringkat

- Performance Evaluation of Flexible Pavements With Modified Bitumen BindersDokumen8 halamanPerformance Evaluation of Flexible Pavements With Modified Bitumen BindersIJRASETPublicationsBelum ada peringkat

- Review On Defluoridation Techniques of Water: Piddennavar Renuka, Krishnappa PushpanjaliDokumen9 halamanReview On Defluoridation Techniques of Water: Piddennavar Renuka, Krishnappa PushpanjaliSangram PhadtareBelum ada peringkat

- Carbon Fiber Reinforced Concrete (Carbocrete) : Seminar PresentationDokumen17 halamanCarbon Fiber Reinforced Concrete (Carbocrete) : Seminar PresentationharikaBelum ada peringkat

- Fly Ash Based Geopolymer MortarDokumen9 halamanFly Ash Based Geopolymer MortarRama Arul SakthiBelum ada peringkat

- Domenico MS Delicato Peat CharasteristicsDokumen289 halamanDomenico MS Delicato Peat CharasteristicsJulián Cabezas PeñaBelum ada peringkat

- Experimental Study On Concrete (M30) by Partial Replacement of Fine Aggregate With Copper SlagDokumen8 halamanExperimental Study On Concrete (M30) by Partial Replacement of Fine Aggregate With Copper SlagIAEME PublicationBelum ada peringkat

- Prospects of Low Cost Housing in IndiaDokumen6 halamanProspects of Low Cost Housing in IndiaRam Prabesh YadavBelum ada peringkat

- SELF CURING ADMIXTURE PERFORMANCE REPORTDokumen60 halamanSELF CURING ADMIXTURE PERFORMANCE REPORTnhulugallaBelum ada peringkat

- Use of Traditional Material in Low Cost: HousingDokumen70 halamanUse of Traditional Material in Low Cost: HousingSarang WarjurkarBelum ada peringkat

- An Experimental Study On Concrete With Partial Replacement of Cement by Rice Husk Ash & Coconut Shell AshDokumen11 halamanAn Experimental Study On Concrete With Partial Replacement of Cement by Rice Husk Ash & Coconut Shell AshInternational Journal of Application or Innovation in Engineering & ManagementBelum ada peringkat

- Fly Ash Fly Ash: Utility Bonanza From DustDokumen8 halamanFly Ash Fly Ash: Utility Bonanza From DustRajanmyth Mala100% (1)

- Characterization of Leachate From Municipal Solid Wastes Landfill Site of Itanagar, Arunachal PradeshDokumen4 halamanCharacterization of Leachate From Municipal Solid Wastes Landfill Site of Itanagar, Arunachal PradeshIJAMTESBelum ada peringkat

- Final Year Research Project ProposalDokumen7 halamanFinal Year Research Project ProposalLee-Ann LimBelum ada peringkat

- Civil Highway Network System ReportDokumen30 halamanCivil Highway Network System Reportsayali patilBelum ada peringkat

- Mechanical Properties Soil Stabilized With Nano Calcium Carbonate and Reinforced With Carpet Waste FibersDokumen11 halamanMechanical Properties Soil Stabilized With Nano Calcium Carbonate and Reinforced With Carpet Waste FibersCristianAMejiaBelum ada peringkat

- Stabilization of Black Cotton Soil With Marble DustDokumen4 halamanStabilization of Black Cotton Soil With Marble DustIJRASETPublications100% (1)

- 22m High Wall at Durga Temple With PECDokumen5 halaman22m High Wall at Durga Temple With PECGerald TanBelum ada peringkat

- Material Design: Construction PracticesDokumen19 halamanMaterial Design: Construction PracticesP Guru RajuBelum ada peringkat

- Application of Waste Materials As Fillers in Bituminous MixesDokumen9 halamanApplication of Waste Materials As Fillers in Bituminous MixesDipendra AwasthiBelum ada peringkat

- Revised Project Proposal: Dr. Pabitra RajbongshiDokumen27 halamanRevised Project Proposal: Dr. Pabitra RajbongshiZAKIR MIRBelum ada peringkat

- Usage of Recycled Aggregate in ConstructionDokumen23 halamanUsage of Recycled Aggregate in Constructionchetan maitriBelum ada peringkat

- Geopolymeric Building Materials by Synergetic Utilisation of Industrial WastesDokumen2 halamanGeopolymeric Building Materials by Synergetic Utilisation of Industrial WastesNithin Devarajan67% (3)

- Cement Concrete and SuperplasticizersDokumen13 halamanCement Concrete and SuperplasticizersSaroj BhattaraiBelum ada peringkat

- Experimental Investigation of The Performance of Rubberized Concrete Mixtures Without AdditivesDokumen15 halamanExperimental Investigation of The Performance of Rubberized Concrete Mixtures Without AdditivesIAEME PublicationBelum ada peringkat

- Structural Steel Reuse in ConstructionDokumen12 halamanStructural Steel Reuse in ConstructionMuhammad MurtazaBelum ada peringkat

- Sanitary Engineer II: Passbooks Study GuideDari EverandSanitary Engineer II: Passbooks Study GuideBelum ada peringkat

- Fractional Operators with Constant and Variable Order with Application to Geo-hydrologyDari EverandFractional Operators with Constant and Variable Order with Application to Geo-hydrologyBelum ada peringkat

- Basher Second Paper Journalof Constructional Steel ResearchDokumen12 halamanBasher Second Paper Journalof Constructional Steel ResearchOshogbunu Onoriode ErnestBelum ada peringkat

- Notes On Suspension Pipe Bridges (3/1998) : Gilles CorcosDokumen20 halamanNotes On Suspension Pipe Bridges (3/1998) : Gilles CorcosOshogbunu Onoriode ErnestBelum ada peringkat

- KK Bracelocation Illustration2Dokumen1 halamanKK Bracelocation Illustration2Oshogbunu Onoriode ErnestBelum ada peringkat

- Wave Analysis Report 3Dokumen312 halamanWave Analysis Report 3Oshogbunu Onoriode ErnestBelum ada peringkat

- Research Topic: Optimisation of Offshore Wind Turbine Supporting StructuresDokumen12 halamanResearch Topic: Optimisation of Offshore Wind Turbine Supporting StructuresOshogbunu Onoriode ErnestBelum ada peringkat

- Sample of Structural Analysis Proposal With StrusoftDokumen28 halamanSample of Structural Analysis Proposal With StrusoftOshogbunu Onoriode Ernest100% (1)

- Research Topic: Analysis and Design Optimisation of Offshore Wind Turbine Supporting StructuresDokumen17 halamanResearch Topic: Analysis and Design Optimisation of Offshore Wind Turbine Supporting StructuresOshogbunu Onoriode ErnestBelum ada peringkat

- Masterseal 380 TDSDokumen2 halamanMasterseal 380 TDSArasu DonBelum ada peringkat

- M&MSDokumen2 halamanM&MSASIST MechBelum ada peringkat

- 2019 - 1.2. Zavarivanje Gasnim Plamenom I Srodni PostupciDokumen25 halaman2019 - 1.2. Zavarivanje Gasnim Plamenom I Srodni PostupciticmaBelum ada peringkat

- Aff Ref Question Bank FullDokumen31 halamanAff Ref Question Bank Fullyash agrawalBelum ada peringkat

- Your Refrigerant For Sustainable Chilling and FreezingDokumen8 halamanYour Refrigerant For Sustainable Chilling and FreezingJavier AffifBelum ada peringkat

- California Bearing RatioDokumen5 halamanCalifornia Bearing RatioAbhishek Sharma67% (6)

- Visco Elastic DamperDokumen4 halamanVisco Elastic DampergauravBelum ada peringkat

- Rollinson & Pease 2021 - Geochemical BookDokumen285 halamanRollinson & Pease 2021 - Geochemical BookLuciano SilvaBelum ada peringkat

- Astm F-568M - 98Dokumen8 halamanAstm F-568M - 98awesome_600Belum ada peringkat

- Li-Ion pd2019 Mot SolutionsDokumen2 halamanLi-Ion pd2019 Mot SolutionsManuel BermudezBelum ada peringkat

- 02 WholeDokumen121 halaman02 WholeBarohBelum ada peringkat

- Hydac Filter ElementsDokumen30 halamanHydac Filter Elementsatorresh090675Belum ada peringkat

- Act-70ga (Xla-60) TDSDokumen1 halamanAct-70ga (Xla-60) TDSFairmont Ind Quality DivisionBelum ada peringkat

- ASTM D6373 15 Especificacion PGDokumen7 halamanASTM D6373 15 Especificacion PGPedro AlvelaisBelum ada peringkat

- 12.3 PPTDokumen22 halaman12.3 PPTKingProBelum ada peringkat

- Che1015 Petrochemical-Technology TH 1.0 37 Che1015 55 AcpDokumen2 halamanChe1015 Petrochemical-Technology TH 1.0 37 Che1015 55 AcpAGSI FAFBelum ada peringkat

- Emcompress Newsl 051027Dokumen4 halamanEmcompress Newsl 051027Cesar Rodolfo Angulo DelgadoBelum ada peringkat

- ProjectDokumen27 halamanProjectAbhishek YadavBelum ada peringkat

- Silicone Sealants: High Performance SealantDokumen4 halamanSilicone Sealants: High Performance SealantParamdeep SinghBelum ada peringkat

- Sop Magnesium Anode Installation - ThiessDokumen10 halamanSop Magnesium Anode Installation - ThiessbonnicoBelum ada peringkat

- SSC Resistance of QT-900 and QT-1000 Coiled TubingDokumen11 halamanSSC Resistance of QT-900 and QT-1000 Coiled TubingSeçkin ÖztelBelum ada peringkat

- Atomic Absorption Analysis Cookbook Section 10 Analysis of Medicines and Biological SubstancesDokumen42 halamanAtomic Absorption Analysis Cookbook Section 10 Analysis of Medicines and Biological SubstancesLe HuyBelum ada peringkat

- Renu Yarn List: Type Quality Brightness Country of Origin MOQDokumen4 halamanRenu Yarn List: Type Quality Brightness Country of Origin MOQSharif0721Belum ada peringkat