Alco Controls: Pressure Controls PS1 / PS2 Series

Diunggah oleh

kuraimundJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Alco Controls: Pressure Controls PS1 / PS2 Series

Diunggah oleh

kuraimundHak Cipta:

Format Tersedia

Alco Controls

Pressure Controls PS1 / PS2 Series

Technical Bulletin

Adjustable Single and Dual Pressure Controls for high and low pressure

applications.

Features

Adjustable pressure range

Narrow adjustable differential depending on model

Range and differential pointer in units bar and psig

Range and differential individually lockable by wire seal

High rated SPDT contacts for all versions

Shatter resistant contacts

Heavy duty, finger-proof terminal blocks

Captive terminal and cover screws

Dual pressostats with two independent SPDT switches

Manual toggle for system checkout and override

Standard pressure connection 7/16-20 UNF for

1/4 SAE male flare connection

Low pressure and high pressure versions available with Single Pressostat PS1

TV approval according to EN 12263 to meet requirements of

DIN 8901 and EN 378

Automatic and manual reset versions

Some versions with convertible auto/manual reset

Locking plate and mounting screws included

Options (minimum lot size 100 pieces)

Alternative pressure connectors including 6 mm ODF solder connection

Factory set to customer specification

Dual Pressostat PS2

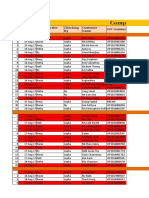

Selection Table Single Pressure Controls PS1

Adjustment Range

Upper Differential Lowest Factory Leakage Test Pressure

Type PCN

Setpoint Setpoint Setpoint Setting Pressure Connection

bar bar bar bar bar

Low Pressure Controls

PS1-A3A 4 370 700 7/16-20 UNF

PS1-A3K 4 370 600 capillary/nut

PS1-A3L 4 714 945 -0.5 7 0.5 5 -0.9 3.5 / 4.5 24 cap./solder tube

PS1-A3U 4 712 201 solder 6 mm

PS1-A3X 4 713 430 solder tube

PS1-R3A 4 350 100 External reset 7/16-20 UNF

-0.5 7 approx. 1bar -0.9 3.5 24

PS1-R3K 4 713 431 Capillary/nut

above setpoint

High Pressure Controls

PS1-A5A 4 350 500 7/16-20 UNF

PS1-A5K 4 370 400 capillary/nut

PS1-A5L 4 715 136 6 31 2 15 3 16 / 20 35 cap./solder tube

PS1-A5U 4 713 325 solder 6 mm

PS1-A5X 4 713 434 solder tube

PS1-R5A 4 350 700 External reset 7/16-20 UNF

PS1-R5K 4 370 300 6 31 approx. 3bar - 20 35 capillary/nut

below setpoint

26.02.2014 - Pressure Controls PS1 / PS2 Series

Pressure Controls PS1 / PS2 Series

Selection Table Single Pressure Controls PS1 TV (EN 12263)

Adjustment Range

Upper Differential Lowest Factory Leakage Test Pressure

Type PCN

Setpoint Setpoint Setpoint Setting Pressure Connection

bar bar bar bar bar

Pressure Limiter for low pressure protection EN 12263 PSL (automatic reset)

PS1-W3A 4 368 300 7/16-20 UNF

-0.5 7 0.5 5 -0.9 3.5 / 4.5 24

PS1-W3U 4 713 437 solder 6 mm

Pressure Cut Out for low pressure protection EN 12263 PZL (external reset)

PS1-B3A 4 470 400 External reset 7/16-20 UNF

-0.5 7 approx. 1bar -0.9 3.5 24

PS1-B3U 4 715 141 solder 6 mm

above setpoint

Pressure Limiter for high pressure protection EN 12263 PSH (automatic reset)

PS1-W5A 4 353 200 7/16-20 UNF

PS1-W5K 4 359 100 6 31 2 15 3 16 / 20 35 capillary/nut

PS1-W5U 4 713 439 solder 6 mm

Pressure Cut Out for high pressure protection EN 12263 PZH (external manual reset)

PS1-B5A 4 353 300 External reset 7/16-20 UNF

PS1-B5J 4 715 758 6 31 approx. 3bar - 20 35 cap./solder 6mm

PS1-B5U 4 712 332 below setpoint solder 6 mm

Safety Pressure Cut Out for high pressure protection EN 12263 PZHH (internal manual reset)

PS1-S5A 4 368 400 Internal reset 7/16-20 UNF

6 31 approx. 3bar - 21 35

PS1-S5U 4 711 591 solder 6 mm

below setpoint

Selection Table Dual Pressure Controls PS2

Adjustment Range Factory Setting Leakage Test

Upper Setpoint Differential Pressure Pressure

Type PCN

left right left right left right left right Connection

bar bar bar bar bar bar bar bar

Combined Low and High Pressure Controls

PS2-A7A 4 353 400 7/16-20 UNF

PS2-A7K 4 350 900 capillary/nut

1

PS2-A7L 4 713 565 -0.5 7 6 31 0.5 ... 5 ca. 4 fix 3.5 / 4.5 20 24 35 cap./solder

PS2-A7U 4 713 415 solder 6 mm

PS2-A7X 4 713 416 solder tube

PS2-L7A 4 351 100 Ext. reset 7/16-20 UNF

PS2-L7K 4 370 500 1 approx. 4bar capillary nut

-0.5 7 6 31 0.5 ... 5 3.5 / 4.5 20 24 35

below

PS2-L7U 4 713 417 solder 6 mm

setpoint

PS2-R7A 4 351 300 Ext. reset Ext. reset 7/16-20 UNF

PS2-R7K 4 713 421 approx. approx. 4bar capillary nut

-0.5 7 6 31 3.5 20 24 35

1bar above below

PS2-R7U 4 713 419 solder 6 mm

setpoint setpoint

Dual Pressure Controls PS2 TV (EN 12263)

Combined Pressure Limiter for low pressure / high pressure protection EN 12263; PSL / PSH (automatic / automatic)

PS2-W7A 4 360 100 7/16-20 UNF

1

PS2-W7L 4 450 300 -0.5 7 6 31 0.5 ... 5 ca. 4 fix 3.5 / 4.5 20 24 35 cap./solder

PS2-W7U 4 712 436 solder 6 mm

1

lowest possible setpoint: -0.9 bar

26.02.2014 - Pressure Controls PS1 / PS2 Series

Pressure Controls PS1 / PS2 Series

Selection Table Dual Pressure Controls PS2 (contd)

Adjustment Range Factory Setting Leakage Test

Upper Setpoint Differential Pressure Pressure

Type PCN

left right left right left right left right Connection

bar bar bar bar bar bar bar bar

Combined Pressure Limiter / Pressure Cut Out for low pressure / high pressure protection

EN 12263; PSL / PZH (automatic / external manual reset)

PS2-C7A 4 353 500 Ext. reset 7/16-20 UNF

1 approx. 4bar

-0.5 7 6 31 0.5 ... 5 3.5 / 4.5 20 24 35

PS2-C7L 5 715 131 below cap./solder

setpoint

Combined Low and High Pressure Controls. High side convertible from automatic to manual reset

1

PS2-M7A 4 361 300 -0.5 .. 7 6 31 0.5 ... 5 - 3.5 / 4.5 21 24 35 7/16-20 UNF

Combined Pressure Limiter Safety Pressure Cut Out for low pressure / high pressure protection

EN 12263 PSL / PZH (automatic / automatic convertible to external manual reset)

1

PS2-N7A 4 715 756 -0.5 .. 7 6 31 0.5 ... 5 - 3.5 / 4.5 21 24 35 7/16-20 UNF

Combined Pressure Limiter / Safety Pressure Cut Out for low pressure / high pressure protection

EN 12263 PSL / PZHH (automatic / internal manual reset)

PS2-T7A 4 368 500 Int. reset 7/16-20 UNF

1

PS2-T7U 4 713 424 -0.5 .. 7 6 31 0.5 ... 5 approx. 4bar 3.5 / 4.5 21 24 35 solder 6 mm

below setpoint

Combined Pressure Cut Out for low pressure / high pressure protection

EN 12263 PZL / PZH (external manual reset / external manual reset)

PS2-B7A 4 360 200 Ext. reset 7/16-20 UNF

Ext. reset

PS2-B7K 4 446 600 approx. 1bar capillary nut

-0.5 .. 7 6 31 approx. 4bar 3.5 20 24 35

PS2-B7L 4 446 700 above cap./solder

below setpoint

PS2-B7U 4 449 400 setpoint solder 6 mm

Combined Pressure Cut Out / Safety Pressure Cut Out for high pressure / high pressure protection

EN 12263 PZH / PZHH (external manual reset / internal manual reset)

PS2-G8A 4 368 600 Ext. reset Int. reset 7/16-20 UNF

PS2-G8U 4 713 427 6 31 6 31 approx. 4bar approx. 4bar 20 21 35 35 solder 6 mm

PS2-G8X 4 713 428 below setpoint below setpoint solder tube

1

lowest possible setpoint: -0.9 bar

Technical data

Environmental conditions Materials and compatibility

Ambient temperatures Housing materials cover: Polycarbonate (PC)

storage and transportation: -50 C to +70 C frame: Steel, with ROHS compatible

operation: -50 C to +70 C anti corrosion protection

Medium temperature range TS Materials with medium contact

at pressure connector: -50 C to +70 C pressure conn. (A) / bellows: brass /bronze

Dust and water protection IP44 Control mounted pressure conn. (K,L,U,X) / copper / bronze

EN 60529 / IEC 529: flush against wall bellows:

Vibration resistance: 4g @ 10 1000 Hz Medium compatibility HFC, HCFC

Electrical contacts Approvals

Type of contacts - PS1: 1 x SPDT contact EN 12263 (TV) specific models, see selection

- PS2: 2 x SPDT contacts Low Voltage Directive

Contact material - standard: CuAg3 73/23/EWG 93/68/EWG; all models

Heating load (AC1): 24A / 230V AC EN 60947-1, EN 60947-5-1:

Inductive load (AC15): 10A / 230V AC UL / CSA: File Nr. E85974

Startup / Locked Rotor UL: 144A / 120 / 240V AC German Lloyd standard models when used

Inductive load (DC 13): 0.1A / 230V DC; 3A / 24V DC with marine cable glands

6A / 12V DC (accessory)

Motor rating UL (FLA): 24A / 120 / 240V AC

26.02.2014 - Pressure Controls PS1 / PS2 Series

Pressure Controls PS1 / PS2 Series

Name Scheme Adjustable Single Pressostats

PS 1 - A 7 A

Product Name

PS1 = standard version Pressure Connector

PSA = customer specific version A = 7/16-20 UNF male

C = R male, stainless steel with steel bellows

J = 1 m capillary with 6mm-ODM solder tube

K = 1 m capillary with 7/16-20 UNF flare nut and schrader valve

Function

opener

A= Pressure control, automatic reset L = 1 m capillary with -ODM solder tube

B= Pressure cut out, external manual reset EN 12263 U = 6 mm ODF solder, 80 mm length

R= Pressure control, external manual reset X = -ODF solder, 80 mm length

S= Safety pressure cut out, internal manual reset

EN 12263 Pressure Range

U= Convertible from R to A 1= -0,75 3 bar

W= Pressure limiter, automatic, DIN / EN 12263 2= -0,8 1.5 bar

X= Pressure control, automatic with extended adjustment 3= -0,5 7 bar

spindles 4= 1 20 bar

5= 6 31 bar

Name Scheme Adjustable Dual Pressostats

PS 2 - A 7 A

Product Name

PS2 = standard version Pressure Connector

PSB = customer specific version A= 7/16-20 UNF male

C= R male, stainless steel with steel bellows

K= 1 m cap tube and schrader valve opener,

Function

7/16-20 UNF flare nut

A= both sides: automatic pressure controls L= -ODM solder with 1 m cap tube

B= both sides: cut out, external manual reset, EN 12263 U= 6 mm ODF solder, 80 mm length

C= left side: pressure limiter, automatic, EN 12263 X= -ODF solder, 80 mm length

right side: cut out, external manual reset, EN 12263

G= left side: cut out, external manual reset, EN 12263

right side: safety cut out, internal manual reset, EN 12263

L= left side: automatic pressure control, Pressure Range

right side: external manual reset left side right side

M= left side: automatic pressure control, 7 = -0,5 7 bar 6 31 bar

right side: convertible from R to A.

N= left side: automatic pressure control, EN 12263 8 = 6 31 bar 6 31 bar

right side: convertible from R to A EN 12263.

R= both sides: external manual reset 9 = -0,75 3 bar 6 31 bar

S= both sides: safety cut out, internal manual reset, EN 12263

T= left side: pressure limiter, automatic, EN 12263

right side: safety cut out, internal manual reset, EN 12263

U= both sides: convertible from R to A

W= both sides: pressure limiter, automatic reset, DIN / EN 12263

X= both sides automatic pressure controls;

extended adjustment spindles

Y= left side: automatic reset, right side: convertible from R to A;

extended adjustment spindles

Z= both sides convertible from R to A;

extended adjustment spindles

26.02.2014 - Pressure Controls PS1 / PS2 Series

Pressure Controls PS1 / PS2 Series

General Hints

High pressure limiters and pressure cut outs with type approval

Manual reset low pressure

according to EN 12263 feature a double bellows design.

On decreasing pressure below the lower setpoint, contacts 1-4

open, contacts 1-2 close and latch. On pressure rise above fixed

differential per Selection Table and after pressing the manual

reset button, contacts 1-2 will open and contacts 1-4 will close

again.

Should the inner bellows leak, then the larger surface area of the

outer bellows creates a larger force and causes the pressostat to

a pre-empted cut out. This represents a fail-safe function.

Electrical contacts

PS1 / PS2 pressure controls are equipped with high rated double

snap action contacts for shatter-free and reliable operation. All

contacts are designed as Single Pole Double Throw (SPDT)

contacts. Dual Pressostats PS2 come with two independently Manual reset high pressure

actuated SPDT contacts. On increasing pressure above the upper setpoint, contacts 1-2

open, contacts 1-4 close and latch. On falling pressure below

Switch Points fixed differential per Selection Table and after pressing the

The set points are adjustable with internal adjustment spindles. manual reset button, contacts 1-4 will open and contacts 1-2 will

The range spindle allows presetting the upper switch point close again.

together with the lower switch point. The differential spindle is

used to preset the lower switch point. The dependency between

upper and lower set point is as follows:

lower set point = upper set point differential

Parts with manual reset feature a fixed differential. Manual reset

is possible as soon as pressure falls below / rises above this fixed

differential (see selection table). For operational safety, all PS1 / PS2 with manual reset are

Contact function designed as trip-free controls, i.e. pressing the manual reset

Contacts on Single Pressostats PS1 are labeled 1-2-4, contacts button while the pressure has not reached its reset threshold will

on Dual Pressostats are labeled 11-12-14 on the left side and 21- not operate the electrical contacts.

22-24 on the right side. Installation and maintenance

1, 11, 21 refer to the common pole. A front access manual toggle

2, 12, 22 refer to the lower setpoint and is provided for checking out

4, 14, 24 refer to the upper setpoint. This is true for all control operation. On low

functions: low pressure controls, high pressure controls, manual pressure controls this toggle

or automatic reset types. may be used to override the

Automatic reset low pressure signal during

On pressure rise above the upper setpoint, contacts 1-2 (11-12; system evacuation, avoiding

21-22) open and contacts 1-4 (11-14, 21-24) close. On the need to undo the electrical

decreasing pressure below lower setpoint contacts 1-4 (11-14; wiring for this purpose.

21-24) open and contacts 1-2 (11-12; 21-22) close.

The standard mounting holes for mounting brackets are equipped

with a universal thread to fit both, M4 and UNC 8-32 screws.

The standard wholesale

package includes two

mounting screws and a

locking plate. Several hole

patterns for surface mounting

are provided, see physical

dimensions.

26.02.2014 - Pressure Controls PS1 / PS2 Series

Pressure Controls PS1 / PS2 Series

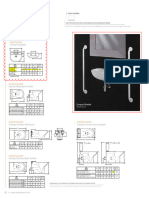

Physical Dimensions (mm)

PS1 PS2

Pressure Connections:

A J L K U X

7/16 -20 UNF Capillary Tube with Capillary Tube with Capillary Tube with Flare 6 mm ODF 1/4 ODF

male (1/4SAE) 6 mm ODM Solder Tube 1/4 ODM Solder Tube Nut + Schrader depressor Solder Tube Solder Tube

Accessories

25 25

12,5

12,5

4,5

25 4,5 25 Locking Plate (20 pieces)

803 783

30

40 65

18 40 50,5

Mounting bracket angle Mounting plate for units with hood 25,2 41

0 714 144 0 714 145

(incl. screws) (incl. screws)

12,6 25,2 12,6

25,2

25 101.5

12,5 8 5.3 12.7 12.7

82

25,2

120

4,5

47.5

25.4

25

5.6

12,6

M4

5

4

4.2

25 70

Extension bracket Horizontal mounting bracket Univ. mounting bracket

0 714 146 0 716 063 0 714 147

(incl. screws) (incl. screws) (incl. screws)

26.02.2014 - Pressure Controls PS1 / PS2 Series

Emerson Climate Technologies

ologies GmbH shall not be liable for errors in the stated capacities, dimensions, etc., as well as typographic errors. Products,

Products, specifications,

speci designs and technical data contained

in this document are subject to modification by us without prior notice. Illustrations are not binding.

bin

The Emerson Climate Technologies logo is a trademark and service mark of Emerson Electric Co. Emerson Climate Climate Technologies Inc. is a subsidiary of Emerson Electric Co.

Anda mungkin juga menyukai

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDari EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsBelum ada peringkat

- RANCO Pressure-SwitchesDokumen1 halamanRANCO Pressure-SwitchesJose Lorenzo ToralBelum ada peringkat

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Dari EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Penilaian: 4.5 dari 5 bintang4.5/5 (3)

- PN690Dokumen10 halamanPN690TÀi VÕBelum ada peringkat

- Catalogo DanfossDokumen8 halamanCatalogo DanfossJovany SegoviaBelum ada peringkat

- PS3 Pressure Switch: Technical DataDokumen10 halamanPS3 Pressure Switch: Technical DataAhmed AzadBelum ada peringkat

- PNZ SeriesDokumen2 halamanPNZ SeriesKali Dass KMBelum ada peringkat

- TF A and B Pneumatic Valve DetailsDokumen12 halamanTF A and B Pneumatic Valve DetailsHSM MECHBelum ada peringkat

- PS1 Series Single Temperature Pressure ControlsDokumen1 halamanPS1 Series Single Temperature Pressure ControlsEDUARDOMTZBelum ada peringkat

- SpeDokumen12 halamanSpeseaqu3stBelum ada peringkat

- Oetiker SC Serie IDokumen4 halamanOetiker SC Serie IHIDRAFLUIDBelum ada peringkat

- Cup Maker PartDokumen13 halamanCup Maker PartPanji HaidarBelum ada peringkat

- Valvulas de Seguridad Planta de Alcohol PDFDokumen1 halamanValvulas de Seguridad Planta de Alcohol PDFcaseroizeBelum ada peringkat

- Parveen Well Head PDFDokumen25 halamanParveen Well Head PDFRatnakar PatilBelum ada peringkat

- Desc 1569254035000 1026809Dokumen5 halamanDesc 1569254035000 1026809jose GilBelum ada peringkat

- List Spare Part Pk-OdcDokumen1 halamanList Spare Part Pk-Odctaufik hidayahBelum ada peringkat

- Shut Off PressureDokumen8 halamanShut Off PressureabbutalibbBelum ada peringkat

- Uniworld: Series Pneumatic ValvesDokumen2 halamanUniworld: Series Pneumatic ValvesSyarif Mutsaqqif100% (1)

- Panasonic R134a SF SeriesDokumen4 halamanPanasonic R134a SF SeriesChan Gel YasBelum ada peringkat

- SH MSZ-FS06 18na Obh872a PDFDokumen38 halamanSH MSZ-FS06 18na Obh872a PDFBrian SmithBelum ada peringkat

- 3CP C Section 5MDokumen1 halaman3CP C Section 5MRohan ChunaraBelum ada peringkat

- 3CP B Section 5MDokumen1 halaman3CP B Section 5MRohan ChunaraBelum ada peringkat

- Yokogawa AS-Schneider 2601 Ed1.usDokumen2 halamanYokogawa AS-Schneider 2601 Ed1.usArash SepahvandBelum ada peringkat

- 06 Control Valve BlockDokumen4 halaman06 Control Valve BlockRIAN NOFENDRIBelum ada peringkat

- Discharge Pressure Switch Poinprexx: DescriptionDokumen1 halamanDischarge Pressure Switch Poinprexx: DescriptionJERRY LIUBelum ada peringkat

- 2-Seated Type PRVDokumen3 halaman2-Seated Type PRVIslam ElhabsheBelum ada peringkat

- Proportional Pressure Control Valves Series P2 & 4VP01Dokumen12 halamanProportional Pressure Control Valves Series P2 & 4VP01abuzer1981Belum ada peringkat

- Pressure regulating valve technical manualDokumen8 halamanPressure regulating valve technical manualDavid VilchesBelum ada peringkat

- Arbus 4000 SE 190Dokumen63 halamanArbus 4000 SE 190Wellington GomesBelum ada peringkat

- Exploded View Parts List (UA32H4100AKXKE)Dokumen9 halamanExploded View Parts List (UA32H4100AKXKE)Adedeji OluwatobilobaBelum ada peringkat

- Typenschluessel EnglischDokumen2 halamanTypenschluessel EnglischcvfBelum ada peringkat

- Apeks ID BS Cross Sectn. Inner Diam. SCUBA Application SealDokumen1 halamanApeks ID BS Cross Sectn. Inner Diam. SCUBA Application SealАлексей ШишкоBelum ada peringkat

- Part Number Qty Description ConditionDokumen309 halamanPart Number Qty Description ConditionMiroslaw Gabalix GabalisBelum ada peringkat

- PRT-0081 Rev 02 CertificatesDokumen10 halamanPRT-0081 Rev 02 CertificateszakriashafiqmBelum ada peringkat

- 9040 Printer Spare PartsDokumen53 halaman9040 Printer Spare PartsPruthvi ModiBelum ada peringkat

- PBC Section IIIDokumen21 halamanPBC Section IIICarlos CáceresBelum ada peringkat

- Eska Valve ERG-S Series Double Stage Pressure RegulatorDokumen4 halamanEska Valve ERG-S Series Double Stage Pressure RegulatorRONAL QUISPE MAMANIBelum ada peringkat

- 240117-Commercial Proposal Comments_LK(1)Dokumen6 halaman240117-Commercial Proposal Comments_LK(1)Михаил ПолковниковBelum ada peringkat

- Advanced Motion Controls PS16L72Dokumen5 halamanAdvanced Motion Controls PS16L72Servo2GoBelum ada peringkat

- Sistema de Lubricacion Pump HorizontalesDokumen16 halamanSistema de Lubricacion Pump HorizontalesRodríguez EdwardBelum ada peringkat

- Air Preparation ProductsDokumen6 halamanAir Preparation ProductssenamotoBelum ada peringkat

- Softstarter range catalogue guideDokumen16 halamanSoftstarter range catalogue guideEdwin Santiago Villegas AuquesBelum ada peringkat

- Pressure Regulating Valves: - AGECT-PRV-2015Dokumen10 halamanPressure Regulating Valves: - AGECT-PRV-2015Irwansyah CahyaBelum ada peringkat

- Air Filter SilencerDokumen2 halamanAir Filter SilencerDavid OteroBelum ada peringkat

- PotterDokumen4 halamanPotterCamilo AyalaBelum ada peringkat

- Temporary Bline List For Tank (Sheet-1 & Sheet-2)Dokumen2 halamanTemporary Bline List For Tank (Sheet-1 & Sheet-2)thmaraishriBelum ada peringkat

- Pi Page Gauge High Pressure Connection Ash Pi 61aDokumen4 halamanPi Page Gauge High Pressure Connection Ash Pi 61aSurya VamsiBelum ada peringkat

- Pre-amplified Pressure Gauge Sensor Data SheetDokumen3 halamanPre-amplified Pressure Gauge Sensor Data Sheetzahir.parkerBelum ada peringkat

- BWB Controls R-Pilot Pressure SensorDokumen2 halamanBWB Controls R-Pilot Pressure Sensoralvipin0010% (1)

- Krohne Optiflux 1000 Electromagnetic Flow SensDokumen12 halamanKrohne Optiflux 1000 Electromagnetic Flow SensAlejandro DallosBelum ada peringkat

- Candy Cdp6650x 12Dokumen26 halamanCandy Cdp6650x 12melany77Belum ada peringkat

- Attachment #1 - 수정Tag 제작요청 - 수처리 - No OPDokumen8 halamanAttachment #1 - 수정Tag 제작요청 - 수처리 - No OPKasthuri CoimbatoreBelum ada peringkat

- SVSW-007002-G04-0001 Rev C Bill of Material - Code 1Dokumen7 halamanSVSW-007002-G04-0001 Rev C Bill of Material - Code 1chuminhBelum ada peringkat

- Model: P660 Series: Differential Pressure Gauge With Diaphragm ElementDokumen6 halamanModel: P660 Series: Differential Pressure Gauge With Diaphragm ElementTÀi VÕBelum ada peringkat

- Technical Manual Technical ManualDokumen45 halamanTechnical Manual Technical Manualhüseyin vururBelum ada peringkat

- Lap.harian Sparepart 消耗品庫存 .Dokumen46 halamanLap.harian Sparepart 消耗品庫存 .Al GhifaryBelum ada peringkat

- Piston Pump PVDokumen16 halamanPiston Pump PVtreinamentoBelum ada peringkat

- FE1148 4inch FPS 4400 Sales - Tech Brochure 03 - 15 FRANKLIN ELECTRIC PUMPDokumen28 halamanFE1148 4inch FPS 4400 Sales - Tech Brochure 03 - 15 FRANKLIN ELECTRIC PUMPZaen SalimBelum ada peringkat

- Brocure Pump FPS 4400 4 Inch Franklin ElectricDokumen28 halamanBrocure Pump FPS 4400 4 Inch Franklin ElectricErich ThomasBelum ada peringkat

- Installation Instructions Spool Type Elastomer Expansion JointsDokumen2 halamanInstallation Instructions Spool Type Elastomer Expansion JointsAmina TaissaBelum ada peringkat

- Standard Sewer DetailsDokumen59 halamanStandard Sewer DetailsPhanhai KakaBelum ada peringkat

- DIN Metric Flange Dimensions GuideDokumen5 halamanDIN Metric Flange Dimensions GuideSara MahmoudBelum ada peringkat

- Installation ManualDokumen5 halamanInstallation ManualUhudhu AhmedBelum ada peringkat

- HARRIS UK CatalogueDokumen56 halamanHARRIS UK CataloguekuraimundBelum ada peringkat

- RAKTherm Reinforced Piping SystemsDokumen13 halamanRAKTherm Reinforced Piping SystemskuraimundBelum ada peringkat

- Building Evacuation PlanDokumen19 halamanBuilding Evacuation Plankuraimund100% (1)

- RAK Compact Disable Wash BasinDokumen1 halamanRAK Compact Disable Wash BasinkuraimundBelum ada peringkat

- Ball Float ValveDokumen2 halamanBall Float ValvekuraimundBelum ada peringkat

- Gas Safety and Measurement Amendment Regulations 2011 PDFDokumen33 halamanGas Safety and Measurement Amendment Regulations 2011 PDFkuraimundBelum ada peringkat

- VSR Series: Vane-Type Waterflow SwitchDokumen1 halamanVSR Series: Vane-Type Waterflow SwitchkuraimundBelum ada peringkat

- Medical Gas Pipeline SystemsDokumen218 halamanMedical Gas Pipeline Systemsmedo2005100% (10)

- ROCA - Tilting Wall Bracket (816323000)Dokumen2 halamanROCA - Tilting Wall Bracket (816323000)kuraimundBelum ada peringkat

- ACPE Qualifications FeesDokumen1 halamanACPE Qualifications FeeskuraimundBelum ada peringkat

- Crane FS Balancing Valve IOMDokumen2 halamanCrane FS Balancing Valve IOMkuraimundBelum ada peringkat

- Compressed Air HSEDokumen50 halamanCompressed Air HSEOdalis ToscanoBelum ada peringkat

- Basic Dimensions For NPT American National Taper Pipe ThreadsDokumen2 halamanBasic Dimensions For NPT American National Taper Pipe ThreadsAndi DumayBelum ada peringkat

- Atex GuidelinesDokumen76 halamanAtex GuidelinesAN.ADAMMSBelum ada peringkat

- Dyke Wall PDFDokumen1 halamanDyke Wall PDFkuraimundBelum ada peringkat

- Omron LY2 Data SheetDokumen16 halamanOmron LY2 Data SheetkuraimundBelum ada peringkat

- Oxygen, DissolvedDokumen6 halamanOxygen, DissolvedkuraimundBelum ada peringkat

- E01 0Dokumen9 halamanE01 0Zaher El HajjBelum ada peringkat

- Review of The WaterMark Certification SchemeDokumen107 halamanReview of The WaterMark Certification SchemekuraimundBelum ada peringkat

- AWWA M23-2002 PVC Pipe Design and Installation, 176p PDFDokumen176 halamanAWWA M23-2002 PVC Pipe Design and Installation, 176p PDFEagle3232100% (11)

- Flowsheet Symbols and PenI Diagrams PDFDokumen30 halamanFlowsheet Symbols and PenI Diagrams PDFRajeshBelum ada peringkat

- Inst Symbols P ID FunctionDokumen37 halamanInst Symbols P ID FunctionkuraimundBelum ada peringkat

- 45-59-025 Avkcms enDokumen2 halaman45-59-025 Avkcms enkuraimundBelum ada peringkat

- RMC Thermal Balancing ValvesDokumen2 halamanRMC Thermal Balancing ValveskuraimundBelum ada peringkat

- The Comprehensive Guide To Swimming Pool OwnershipDokumen42 halamanThe Comprehensive Guide To Swimming Pool OwnershipAhmedBelum ada peringkat

- Pop Cad Bmi StndrdsDokumen106 halamanPop Cad Bmi StndrdskuraimundBelum ada peringkat

- Product Overview - LeuschDokumen32 halamanProduct Overview - Leuschprihartono_diasBelum ada peringkat

- Arun Thogiti - ResumeDokumen3 halamanArun Thogiti - ResumeSundarapandi JeyasuriyanBelum ada peringkat

- Facade Cladding: Cladding London The Way It Should Be.....Dokumen7 halamanFacade Cladding: Cladding London The Way It Should Be.....samuelBelum ada peringkat

- Construction Claims DelaysDokumen23 halamanConstruction Claims Delaysgerx11xregBelum ada peringkat

- NCAR AIP 2010 AerodromeDokumen170 halamanNCAR AIP 2010 AerodromeAbhishek Man ShresthaBelum ada peringkat

- Arnco FTTX Fiber SolutionsDokumen3 halamanArnco FTTX Fiber SolutionsPeterLOW0218Belum ada peringkat

- MM Singapore - Press Release (Critical Design Errors Caused Collapse at Nicoll Highway) PDFDokumen20 halamanMM Singapore - Press Release (Critical Design Errors Caused Collapse at Nicoll Highway) PDFJames Jatmiko OetomoBelum ada peringkat

- CA7 CommandsDokumen9 halamanCA7 CommandsArvindUpadhyayBelum ada peringkat

- Previews NSF 51 12 PreDokumen11 halamanPreviews NSF 51 12 PreEl_Proesor0% (1)

- Roopa Rani - Final PDFDokumen52 halamanRoopa Rani - Final PDFSrinivas SeenuBelum ada peringkat

- Planning of Rural Roads in IndiaDokumen14 halamanPlanning of Rural Roads in IndiaSubin GeevargheseBelum ada peringkat

- Account Statement As of 26-08-2022 18:16:42 GMT +0530Dokumen4 halamanAccount Statement As of 26-08-2022 18:16:42 GMT +0530jagapriya sivaraman6897100% (1)

- Man Co4 Lo1 AssessmentDokumen3 halamanMan Co4 Lo1 AssessmentHarshwardhan KhardeBelum ada peringkat

- Common SAP Testing Terminology Ensures Project UnderstandingDokumen8 halamanCommon SAP Testing Terminology Ensures Project UnderstandingZelimir KovacevicBelum ada peringkat

- Thapar Institute of Engineering & Technology, PatialaDokumen3 halamanThapar Institute of Engineering & Technology, PatialaMr SamBelum ada peringkat

- 11 Momentum TransferDokumen10 halaman11 Momentum TransferJohn Bryan AldovinoBelum ada peringkat

- Hazard RegisterDokumen18 halamanHazard RegisterImenuel AlexBelum ada peringkat

- Microsoft Dynamics GP 2013 - System Admin Guide PDFDokumen110 halamanMicrosoft Dynamics GP 2013 - System Admin Guide PDFsivextienBelum ada peringkat

- Cost and Pricing MGT For Competitive AdvantageDokumen45 halamanCost and Pricing MGT For Competitive Advantageilona gabrielBelum ada peringkat

- Complaint Service Report (Striker Note)Dokumen16 halamanComplaint Service Report (Striker Note)Kheme VitoumetaBelum ada peringkat

- Satyam Company ProfileDokumen7 halamanSatyam Company ProfileArghya GuhaBelum ada peringkat

- Maine Industrial Tire v. T.Y Cushion TireDokumen28 halamanMaine Industrial Tire v. T.Y Cushion TirePriorSmartBelum ada peringkat

- McGraw-Hill’s Handbook of Transportation Engineering Chapter 12: Traffic Congestion SolutionsDokumen30 halamanMcGraw-Hill’s Handbook of Transportation Engineering Chapter 12: Traffic Congestion Solutionsdave4359Belum ada peringkat

- Master Planning Process Diagram - Google SearchDokumen3 halamanMaster Planning Process Diagram - Google SearchKevin RotichBelum ada peringkat

- Processing Guides Isbmbottlepresentation PDF 1Dokumen25 halamanProcessing Guides Isbmbottlepresentation PDF 1Jay MehtaBelum ada peringkat

- Industrial Silos: Technical SheetDokumen31 halamanIndustrial Silos: Technical Sheetred patriotBelum ada peringkat

- Iso 9001 Document RequirementsDokumen47 halamanIso 9001 Document Requirementsksbbs100% (1)

- Vertex Payroll Tax Q Series Integration With Oracle Fusion HCMDokumen2 halamanVertex Payroll Tax Q Series Integration With Oracle Fusion HCMsam22nowBelum ada peringkat

- Resume SeetaRamDokumen2 halamanResume SeetaRamdasarinaveenBelum ada peringkat

- Certification Memorandum CS-31HB Hot Air Balloons: Classification of Design ChangesDokumen6 halamanCertification Memorandum CS-31HB Hot Air Balloons: Classification of Design ChangesakaretlerBelum ada peringkat