Acceptance Criteria

Diunggah oleh

Ramzi Dol Abdul Wahid50%(2)50% menganggap dokumen ini bermanfaat (2 suara)

681 tayangan1 halamanAcceptance Criteria for Visual

Hak Cipta

© © All Rights Reserved

Format Tersedia

DOCX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniAcceptance Criteria for Visual

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

50%(2)50% menganggap dokumen ini bermanfaat (2 suara)

681 tayangan1 halamanAcceptance Criteria

Diunggah oleh

Ramzi Dol Abdul WahidAcceptance Criteria for Visual

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 1

CIAST Shah Alam

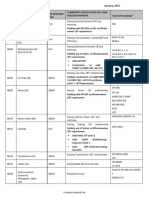

ACCEPTANCE LEVEL FOR PLATE AND PIPE

Acceptance levels plate and pipe

Table Defect

Remarks Maximum allowance

At no point shall the excess weld metal Excess weld metal will not exceed H =

Excess weld fall below the outside surface of the 2mm in any area on the parent

1

metal parent material. All weld runs shall material, showing smooth transition at

blend smoothly. weld toes.

Slag inclusions are defined as non- The length of the slag inclusion shall

Slag/silica metallic inclusions trapped in the weld not exceed 50mm continuous or

2

inclusions metal or between the weld metal and intermittent. Accumulative totals shall

the parent material. not exceed 50mm.

No sharp indications. Smooth blend

required. The length of any undercut

Undercut is defined as a grove melted

shall not exceed 50mm continuous on

into the parent metal, at the toes of

3 Undercut intermittent. Accumulative totals shall

the weld excess metal, root or

not exceed 50mm. Max D=1mm for

adjacent weld metal.

the cap weld metal. Root undercut not

permitted.

Individual pores 1.5 max. Cluster

Trapped gas, in weld metal, elongated,

Porosity or porosity maximum 50mm total area.

4 individual pores, cluster porosity,

Gas Cavities Elongated, piping or wormholes 15mm

piping or wormhole porosity.

max. L continuous or intermittent.

Cracks or Transverse, longitudinal, star or crater

5 Not permitted

Laminations cracks.

Surface breaking lack of side wall

Incomplete fusion between the weld fusion, lack of inter-run fusion

Lack of fusion

metal and base material, incomplete continuous or intermittent not to

6 Laps

fusion between weld metal. (lack of exceed 15mm. Accumulative totals not

Cold lap

inter-run fusion) to exceed 15mm over a 300mm length

of weld.

Damage to the parent material or weld

metal, from an unintentional touch

7 Arc strikes Not permitted

down of the electrode or arcing from

poor connections in the welding circuit.

No stray tack welds permitted. Parent

Damage to the parent material or weld

Mechanical material must be smoothly blended.

8 metal, internal or external resulting

damage General corrosion permitted. Max.

from any activities.

D=1.5mm. Only 1 location allowed.

Mismatch between the welded or

9 Misalignment Max H = 1.5mm

unwelded joint.

Excess weld metal, above the base

10 Penetration Max H 3mm

material in the root of the joint.

Lack of root The absence of weld metal in the root

11 Not permitted

penetration area, two root faces showing.

Lack of root fusion, not to exceed

Lack of root Inadequate cross penetration of (one)

12 50mm total continuous or

fusion root face.

accumulative.

Excessive penetration, collapse of the

13 Burn through Not permitted

weld root

Angular

14 Distortion due to weld contraction 5mm max. Plate only

distortion

Root Weld metal below the surface of both 50mm maximum length

15

concavity parent metals 3mm maximum depth

Acceptance Criteria Visual Inspection

Anda mungkin juga menyukai

- Dangerous Google - Searching For Secrets PDFDokumen12 halamanDangerous Google - Searching For Secrets PDFtamasradu89% (19)

- AK Interactive - AK Learning Series 09 - Buildings in Dioramas The Ultimate Guide To MakeDokumen92 halamanAK Interactive - AK Learning Series 09 - Buildings in Dioramas The Ultimate Guide To MakeAgustin Maldonado Octavio100% (12)

- 202 1sp 0 Saw Cs CsDokumen8 halaman202 1sp 0 Saw Cs CskrishimaBelum ada peringkat

- Duplex Stainless Steel - Part 1 - TWIDokumen6 halamanDuplex Stainless Steel - Part 1 - TWItuanBelum ada peringkat

- Acceptance Level TWI SampleDokumen1 halamanAcceptance Level TWI SampleFadhlan D Luffy100% (1)

- Kobelco FillerDokumen24 halamanKobelco FillerRamzi Dol Abdul WahidBelum ada peringkat

- ASME IX Interpretation-Part7Dokumen37 halamanASME IX Interpretation-Part7kevin herryBelum ada peringkat

- Cswip Exams 1 PDFDokumen65 halamanCswip Exams 1 PDFFethi BELOUISBelum ada peringkat

- AWS D17.1 WPQR Guides PDFDokumen2 halamanAWS D17.1 WPQR Guides PDFTAGUI100% (3)

- Cswip 3 1 Macro PDFDokumen36 halamanCswip 3 1 Macro PDFtheBelum ada peringkat

- Brazing BPS 107-1 PDokumen5 halamanBrazing BPS 107-1 Pmbe josephBelum ada peringkat

- Self-Study On API RP 571 - Damage MechanismDokumen84 halamanSelf-Study On API RP 571 - Damage Mechanismrosli2503100% (2)

- Weld AbilityDokumen34 halamanWeld AbilityGauthamSarangBelum ada peringkat

- Weld Fit Up Inspection Employee TrainingDokumen10 halamanWeld Fit Up Inspection Employee TrainingBadiuzzama Azmi100% (1)

- WIS5 - Appendix 2Dokumen86 halamanWIS5 - Appendix 2Reza Fakhrizal100% (1)

- Electrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedureDokumen2 halamanElectrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedurePrashant Puri100% (1)

- 09 Sec 09 - ASME IX Summary-07revisedCCDokumen38 halaman09 Sec 09 - ASME IX Summary-07revisedCCamalhaj2013Belum ada peringkat

- Pressure Vessel Dimension InspectionDokumen2 halamanPressure Vessel Dimension InspectionNorman MoralesBelum ada peringkat

- Welding Consumables Control RegisterDokumen5 halamanWelding Consumables Control RegisterAli Mhaskar100% (2)

- 19 - Weld Fit Up Inspection Employee TrainingDokumen10 halaman19 - Weld Fit Up Inspection Employee TrainingManoj KumarBelum ada peringkat

- API 510 Petrosync Course PDFDokumen301 halamanAPI 510 Petrosync Course PDFAkramKassis100% (1)

- Welding Practice For Duplex-1 PDFDokumen18 halamanWelding Practice For Duplex-1 PDFBipin Rohit100% (1)

- Cover Letter Mechanical EngineerDokumen1 halamanCover Letter Mechanical Engineeraju shamsudeenBelum ada peringkat

- Quarter4 M 1 SMAW 10 FinalDokumen25 halamanQuarter4 M 1 SMAW 10 FinalTitser Ramca100% (1)

- QW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) ExaminationDokumen8 halamanQW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) Examinationডঃ শুভম চ্যাটার্জীBelum ada peringkat

- 01 Samss 051 PDFDokumen13 halaman01 Samss 051 PDFnadeem shaikh100% (1)

- Shell Petroleum Development Company: (Implemented/Issued For Review/Complete)Dokumen17 halamanShell Petroleum Development Company: (Implemented/Issued For Review/Complete)Siva RamBelum ada peringkat

- Agitator SizingDokumen4 halamanAgitator SizingArbee AquinoBelum ada peringkat

- 6GR RequirementsDokumen1 halaman6GR Requirementswalitedison100% (1)

- SAIC-W-2006 Rev 8Dokumen4 halamanSAIC-W-2006 Rev 8saravananmenmathiBelum ada peringkat

- ARAMCO QM Number ListDokumen3 halamanARAMCO QM Number ListMohamed Yousuf Syed MohamedBelum ada peringkat

- ASME Section IX Welding Procedure Qualification: Antonius P. BramonoDokumen50 halamanASME Section IX Welding Procedure Qualification: Antonius P. BramonoHAKANBelum ada peringkat

- WIS5 - HandoutDokumen319 halamanWIS5 - HandoutReza FakhrizalBelum ada peringkat

- Consumable by AWS D5.1Dokumen8 halamanConsumable by AWS D5.1Fuaz Sukarya Abu Fatih100% (1)

- TIG-welding Gases PDFDokumen2 halamanTIG-welding Gases PDFwenigmaBelum ada peringkat

- Guide For Make WPSDokumen84 halamanGuide For Make WPSvohuu1102100% (1)

- Submerged Arc Welding (Saw)Dokumen5 halamanSubmerged Arc Welding (Saw)Nnaji Chukwuma SlamBelum ada peringkat

- Technical Specification PDFDokumen101 halamanTechnical Specification PDFAsma KhanBelum ada peringkat

- API 6A RadiographyDokumen4 halamanAPI 6A RadiographyminakshissawantBelum ada peringkat

- Api 650 RTDokumen3 halamanApi 650 RTAdi QCBelum ada peringkat

- Esab Storage HandlingDokumen4 halamanEsab Storage HandlingTasmanijskaNema100% (1)

- Industrial radiography A Complete Guide - 2019 EditionDari EverandIndustrial radiography A Complete Guide - 2019 EditionBelum ada peringkat

- QW-451 Procedure Qualification Thickness Limits and Test SpecimensDokumen2 halamanQW-451 Procedure Qualification Thickness Limits and Test SpecimensmiteshBelum ada peringkat

- Sa 263Dokumen8 halamanSa 263Wagner Renato AraújoBelum ada peringkat

- Air Compressor Guide AICIP and CAAA - Guidelines and Requirements For Asset Management of Pressure VesselsDokumen4 halamanAir Compressor Guide AICIP and CAAA - Guidelines and Requirements For Asset Management of Pressure VesselsTim WilsonBelum ada peringkat

- Sample Forms WPS PQRDokumen22 halamanSample Forms WPS PQRGMBelum ada peringkat

- 0301e - Guidebook For Inspectors - 2018-3Dokumen6 halaman0301e - Guidebook For Inspectors - 2018-3FranciscoBelum ada peringkat

- Enrollment Form - How To Fill UpDokumen3 halamanEnrollment Form - How To Fill UpRaja Guru100% (1)

- Repair WpsDokumen2 halamanRepair WpsyogacruiseBelum ada peringkat

- Birla Copper WPS For Tube To Tubesheet Welding MOC - CSDokumen2 halamanBirla Copper WPS For Tube To Tubesheet Welding MOC - CSJitu Padhiyar PadhiyarBelum ada peringkat

- API 652 QSTNDokumen10 halamanAPI 652 QSTNErttan Tunga100% (1)

- Oxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupsDokumen6 halamanOxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupssanketBelum ada peringkat

- CSWIP 3 1 Syllabus Exam PatternDokumen3 halamanCSWIP 3 1 Syllabus Exam PatternTaufik AliBelum ada peringkat

- Astm A335 p91 PipeDokumen1 halamanAstm A335 p91 PipeBhagwati SteelageBelum ada peringkat

- WPQ CS SmawDokumen1 halamanWPQ CS Smawniket0Belum ada peringkat

- API 570 Piping Inspector HANDALDokumen2 halamanAPI 570 Piping Inspector HANDALBidari MediBelum ada peringkat

- 02 Samss 011Dokumen36 halaman02 Samss 011OMER ELFADILBelum ada peringkat

- Api 577Dokumen1 halamanApi 577HIIOJGFBelum ada peringkat

- BGAS-CSWIP Painting Inspector - Grade 2 - Nov 30, 2015 - KolkataDokumen2 halamanBGAS-CSWIP Painting Inspector - Grade 2 - Nov 30, 2015 - KolkataIyappanDevarajanBelum ada peringkat

- Esab Inconel 625 InfoDokumen1 halamanEsab Inconel 625 InforinshadBelum ada peringkat

- ASME 9 Multi Process Welding Procedures QW200Dokumen2 halamanASME 9 Multi Process Welding Procedures QW200Teodor EzaruBelum ada peringkat

- Interpretations: ASME Boiler and Pressure Vessel Code Section IxDokumen48 halamanInterpretations: ASME Boiler and Pressure Vessel Code Section Ixjuan ninaBelum ada peringkat

- Asset Integrity Daily ReportDokumen1 halamanAsset Integrity Daily Reportعصمت ضيف اللهBelum ada peringkat

- CWI TEST Flashcards PDFDokumen30 halamanCWI TEST Flashcards PDFGary Oporto cabasBelum ada peringkat

- Sis Book Asme IxDokumen107 halamanSis Book Asme IxHamza AlamBelum ada peringkat

- API 653 Above Ground Storage Tank InspectorDokumen2 halamanAPI 653 Above Ground Storage Tank InspectorMohamed Hichem Guesmi0% (1)

- Asme Questions and Answers Part - IiDokumen6 halamanAsme Questions and Answers Part - IiAshwani Dogra100% (1)

- ASME 9 - CalculatorDokumen2 halamanASME 9 - CalculatorEmel Besir100% (1)

- Ref Bgas ExperienceDokumen1 halamanRef Bgas ExperienceFaisalBelum ada peringkat

- SAIC-LT-2007 LeaK Testing-Vacuum BoxDokumen3 halamanSAIC-LT-2007 LeaK Testing-Vacuum BoxKirubhakarPooranamBelum ada peringkat

- Acceptence CriteriaDokumen1 halamanAcceptence CriteriaPraviBeetlesBelum ada peringkat

- Aceptance Criteria For Visual-2Dokumen2 halamanAceptance Criteria For Visual-2ayuBelum ada peringkat

- Hardness Equivalent TableDokumen3 halamanHardness Equivalent TableRamzi Dol Abdul WahidBelum ada peringkat

- World Cup 2018Dokumen3 halamanWorld Cup 2018kurniawanBelum ada peringkat

- Lampiran 6 Hardness Conversion TableDokumen1 halamanLampiran 6 Hardness Conversion TableRamzi Dol Abdul WahidBelum ada peringkat

- Contracteg 04 v5 Feb07Dokumen31 halamanContracteg 04 v5 Feb07Ramzi Dol Abdul WahidBelum ada peringkat

- 3 Properties of SteelDokumen6 halaman3 Properties of SteelGopu PushpangadhanBelum ada peringkat

- Good Study Habits: Secrets To School Success: Darwin C. Macalanda Guidance CoordinatorDokumen39 halamanGood Study Habits: Secrets To School Success: Darwin C. Macalanda Guidance CoordinatorRamzi Dol Abdul WahidBelum ada peringkat

- Higher Algebra - Hall & KnightDokumen593 halamanHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- A Comparison of Chinese, Japanese, and Korean Shipyard Production TechnologyDokumen5 halamanA Comparison of Chinese, Japanese, and Korean Shipyard Production Technologymahmoud hosnyBelum ada peringkat

- PWHT of Dissimilar: Metal WeldsDokumen48 halamanPWHT of Dissimilar: Metal WeldswchavezbBelum ada peringkat

- Workshop Technology Question BankDokumen3 halamanWorkshop Technology Question BankKamalakanta SahooBelum ada peringkat

- JSA Meter SystemDokumen3 halamanJSA Meter SystemKorinne ShabiraBelum ada peringkat

- Plastic Welding MachineDokumen4 halamanPlastic Welding MachineFranky TreviñoBelum ada peringkat

- TDS - Nimrod C276KSDokumen1 halamanTDS - Nimrod C276KSImmalatulhusnaBelum ada peringkat

- Microstructure and Micro-Hardness Analysis of Friction Stir Welded Bi-Layered Laminated Aluminum SheetsDokumen8 halamanMicrostructure and Micro-Hardness Analysis of Friction Stir Welded Bi-Layered Laminated Aluminum SheetsMangesh LingampalleBelum ada peringkat

- Synergy CatalogueDokumen8 halamanSynergy CatalogueTino JuBelum ada peringkat

- Catalog EWM Multimatrix 2014Dokumen116 halamanCatalog EWM Multimatrix 2014Tiberiu FerenczBelum ada peringkat

- HWDP HardfacingDokumen6 halamanHWDP HardfacingHatem RagabBelum ada peringkat

- TERA Joint BrochureDokumen16 halamanTERA Joint BrochureraigoukiBelum ada peringkat

- Material Data Sheets For Piping: 1 ForewordDokumen50 halamanMaterial Data Sheets For Piping: 1 ForewordMuhammad Ramadhan Ismukada SyahrifBelum ada peringkat

- Tube Well Boring Works (Technical Specifications)Dokumen15 halamanTube Well Boring Works (Technical Specifications)Imran Aziz100% (1)

- Research On Welding Deformation For Box Girder ofDokumen12 halamanResearch On Welding Deformation For Box Girder oframiBelum ada peringkat

- KST AD Gripperspottech 23 enDokumen60 halamanKST AD Gripperspottech 23 endataroma100% (1)

- Astm A 928 Dss Pipe EfwDokumen6 halamanAstm A 928 Dss Pipe Efwarifin rizalBelum ada peringkat

- GS 96011 - 2 2020 - 08 Welding Technology Tactile Laser Welding of SteelDokumen14 halamanGS 96011 - 2 2020 - 08 Welding Technology Tactile Laser Welding of Steelpaco23Belum ada peringkat

- SWMS For Hoarding GateDokumen9 halamanSWMS For Hoarding GateSam LimBelum ada peringkat

- WeldingDokumen27 halamanWeldingsuman kumarBelum ada peringkat

- 98 2 PDFDokumen8 halaman98 2 PDFJuan TapiaBelum ada peringkat

- Resume of Garry MattsonDokumen3 halamanResume of Garry MattsonKevin KaufmanBelum ada peringkat