Solving Varnish Problems in Gas Turbine Lubricants - TLT Article - Jan08

Diunggah oleh

Azhar1109Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Solving Varnish Problems in Gas Turbine Lubricants - TLT Article - Jan08

Diunggah oleh

Azhar1109Hak Cipta:

Format Tersedia

32-38 tlt feature 1-08 12/18/07 10:13 AM Page 32

By Linda Day

Contributing Editor

32 JANUARY 2008 T R I B O LO G Y & LU B R I C AT I O N T E C H N O LO G Y

32-38 tlt feature 1-08 12/18/07 10:14 AM Page 33

If youve been plagued by the sludge and varnish

issues raised by new base oils, take heart.

Editors Note: This subject of this months feature article was conceived by

STLEs Power Generation Industry Council.

O

xidation and varnish have been recognized as problems since the Civil War,

but only in the last few years has the problem reached epidemic propor- Article highlights:

tions in power generation and other gas-turbine applications. Investigating the

The new turbines that have come on-line in the last five years are designed

to put out more energy from smaller equipment, says Dave Wooton of Wooton

causes of varnish.

Consulting, and that means more stress on the unit and the lubricant. But A closer analysis

increasing stress is not the only contributor to the problem. In the same time

into oxidation and

frame, turbine users have switched their turbines from base-load to peaking

and from Group I base oils to Groups II and III. formulation issues.

A lot of people blame the new base oils for the problems, says Wooton, Probing the effects

but Im not one of them. I do believe the new formulations were put

together improperly when these oils first came out, because lubricant

of lightning.

manufacturers werent accounting for the different chemistry of the base-

stocks. But there are many other problems as well.

Regardless of source, Wooton notes that a little varnish can cause a

big headache: If a valve sticks just a little, the computer controlling the

unit shuts it down, and the trip-out cost can be $30,000-$100,000 or

more. (see Figure 1)

Causes of varnish

The problematic nature of Group II oils is aptly expressed by the Chi-

nese Curse: May you live in interesting times. These oils can be more resist-

ant to varnish or more prone. Group I oils typically have much higher

concentration of aromatics (typically in excess of 10%), which tend to

oxidize quickly. Because of their purity, Group II oils are inherently much

more stable, but without aromatics they are also much poorer solvents.

And that means that oxidation byproducts that do form tend to drop out

of solution and form varnish more easily. The situation is further compli-

cated by the fact that most power generation gas turbines nowadays are

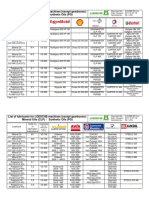

Figure 1. A valve stuck with

peaking units that allow plenty of time for varnish to form in cool oil when

lubricant varnish.

the unit isnt running.

Chevron introduced the technology to make modern Group II oils, and

STLE member Dr. Mark Okazaki, the Chevron senior staff scientist who for-

mulated the companys turbine oils, is well aware of the problems: We had a

chance to use Group II oils before everyone else, and so we found out what

some of the issues are, Okazaki says. First off, certain Group I additives dont

work well with Group II base oils because of the lower solvency. You have to take

a new approach.

And even the best additive systems available today cant always prevent the

problem. Okazaki and others point to oxidation and static discharge as the two

main causes of sludge and varnish, along with several other potential root causes:

Micro-dieseling. Its possible for small entrained air bubbles in the oil to get com-

pressed and heated enough to explode and burn the oil. CONTINUED ON PAGE 34

T R I B O LO G Y & LU B R I C AT I O N T E C H N O LO G Y JANUARY 2008 33

32-38 tlt feature 1-08 12/18/07 10:14 AM Page 34

CONTINUED FROM PAGE 33

Incompatible oils and additives. In some

(Courtesy of Lubricants Magazine, September 2005, available at www.lubricantsuniversity.com)

cases, changing to a Group II oil without

testing the compatibility with the previ-

ously used Group I oil can cause decom-

posed and/or fresh additives left over

from Group I to drop out or react in unex-

pected ways with the Group II additives.

Contamination with chemicals. The pre-

servative fluids used to protect new equip-

ment from corrosion may not be compati-

ble with the turbine oilturbine oils are

typically ashless (no metals), and the met-

als in some preservative and flushing flu-

ids (typically calcium) can react with the

acidic components of the turbine oils to

form an insoluble soap.

Figure 3. Oxidation stabilities of different additive pack-

Contamination with cleaning fluids. ages in one Group II oil. In order to have RPVOT and TOST

This is a special problem in the paper results on the same scale, the TOST result must be multi-

industry, where machinery may be plied by 10.For example,the real result (TOST) for additive

sprayed with lye to clean it. package A is about 5,000 hours, not 500. Note that RPVOT

and TOST may yield dramatically different results.

A closer look at oxidation The two main types of antioxidant addi-

and formulation tives are phenols, good for temperatures up

Varnish is the hot issue in gas to about 130 C, and amines for tempera-

turbines, says STLE member tures above that. If phenols get too hot, they

Greg Livingstone, director of polymerize and turn into sludge themselves.

fluid technology for EPT, Inc., Amines also have a tendency to polymerize

(Environmental Power Techno- and turn into varnish when they themselves

logies) in Calgary, Alberta, Ca- oxidize.

nada, a company that markets The excellent high-temperature perform-

filtration equipment to remove ance of amines can sometimes be mislead-

varnish-forming components. ing: Many accelerated tests for oxidation sta-

Its easy to predict oxidation in bility are run at high temperatures where

Group I formulations because it amines perform well, but this may not reflect

proceeds in a predictable, grad- actual performance in the real world. Phenyl

ual and linear fashion, and you alpha naphthyl amine, or PANA, is a good

have proven tests to monitor it. example. A significant amount of PANA gives

But Group II formulations go the oil an extremely high RPVOT value (ASTM

along fine with no signs of D2272, a measurement of the oils resistance

breakdown until suddenly to oxidation), Livingstone says, but when it

youre in total failure depletes, it can form tons of varnish and

mode. (see Figure 2) sludgeit actually catalyzes the reaction. The

OEMs dont restrict the heavy use of this

additive, and many of the oil companies use

it because even though it increases varnish

potential, it gives great oxidation stability

(see Figure 3). Its tough for the end-user to

find out about PANA, because the oil com-

panies may not want to reveal their formula-

Figure 2. An RPVOT chart of oxi-

tions. According to Mark Okazaki, PANA is

dation in a Group II oil shows how

suddenly degradation occurs. In this not necessarily a problem when used in

test, the RPVOT residual ratio limit by small concentrations and in combination

ASTM D-4378 is 25%. with other antioxidants such as phenolics.

(Courtesy of ASTM D-2272) As it turns out, one of the best ways to

34 JANUARY 2008 T R I B O LO G Y & LU B R I C AT I O N T E C H N O LO G Y

32-38 tlt feature 1-08 12/18/07 10:14 AM Page 35

keep amine additives working is to make sure

that phenolic additives are also present.

Phenols will rejuvenate and regenerate the

amines and keep them from depleting, says

Livingstone. As soon as the phenols are

gone, thats when problems appear to start.

Livingstone strongly recommends moni-

toring oil condition using the RULER,

invented by STLE member Dr. Robert Kauff-

man with the University of Dayton (Ohio)

Research Institute and Fluitec, the company

that manufactures and markets the tool.

(Courtesy of Fluitec)

The RULER analyzes the types and

amounts of antioxidants present, not the

quality of the antioxidant says Kauffman.

But once you can see depletion patterns,

you can correlate that with the oxidation Figure 4.The RULER provides a chart showing the amount of amine and phenolic antioxidants.

patterns of the oil and the varnish tenden- Comparing a standard with a sample of the current oil provides a measure of the oils proper-

ties. When phenols drop, amine antioxidants can become part of the problem instead of part

cies. When you understand the depletion

of the solution.

mechanism, you can better understand how

to stop the secondary reactions that cause The trouble with lightning

(Courtesy of www.Kleentek.com/video.asp)

the problems. The tool is useful because its You can watch lightning in the sky during a

small and portable, and its predictive rather thunderstormand in some cases you can

than reactive. (see Figure 4) also watch it in the oil reservoir of a gas tur-

Kauffman differentiates between sludge bine. (see Figure 5 or you can check out an amaz-

and varnish, which he says form via different ing video at www.kleentek.com/video.asp).

mechanisms. Some of the amines will poly- Figure 5. A look inside the oil

It used to be that clicking noises emanat-

merize and make sludge, especially if they reservoir of this turbine re-

ing from the housing was thought to indicate veals a lightning storm of

arent sterically hindered, he says, but air hammering. But when people began static discharge that causes

sludge isnt as bad as varnish because it pulling out burnt filter elements, it became severe oxidative damage to

isnt as stickyit can plug filters and tight apparent that something else was going on. the lube oil.

clearances, but it doesnt tend to stick to STLE fellow Dr. Akira Sasaki of Kleentek in

bearings. Japan, widely regarded as the guru of this

Kauffman believes that varnish is related subject, first clarified the damaging nature of

to the depletion of particular antioxidants. static discharge in gas turbine lube oils. His

When antioxidants start to lose their capa- research using GE gas turbines (which have

bilities, typical free radical polymerization separate filters for the hot turbine section

takes place, but the polymers that used to and the cooler hydraulic section) revealed

stay in solution now drop out because of the sparking damage and burned oil on the inside

lower solvency of Group II oils. of turbine filters, and varnish collecting on

The oil in the turbine really gets beat the outside of hydraulic filters. Figure 6 (see page

up, Livingstone says. Some bearings get 36) shows microphotographs of sparking

hotter than 500 F (260 C), so the oil has all damage to the nylon filter element, and Fig-

this oxidative stress with extremely high ure 7 (see page 36) shows off microscopic nylon

flow rates. Then the same oil can go into a balls that static discharge creates. Although

different loop to activate the hydraulic cir- Sasaki has found localized temperatures up

cuits, and this is where the major contami- to 20,000 C in the heart of the spark, he

nants precipitate out. explains that the real problem is sparking,

In support of this scenario, Livingstone which cracks lube oil molecules and creates

notes that turbine systems with separate free radicals that polymerize to varnish.

sumps for the turbine section and the Once free radicals are produced, auto-oxida-

hydraulic section suffer far fewer varnish tion of the oil will not stop unless there are

problems than units with a combined sump. reasonable amounts of oxidation inhibitors

Of course, oxidation degradation is only present, he says.

one problemtheres also lightning. Most experts agree that static electricity is CONTINUED ON PAGE 36

T R I B O LO G Y & LU B R I C AT I O N T E C H N O LO G Y JANUARY 2008 35

32-38 tlt feature 1-08 12/18/07 11:09 AM Page 36

CONTINUED FROM PAGE 35

Figure 6. The effect of static discharge in the filter: On the left, a microphotograph of normal nylon filter

mesh from a gas turbine, and on the right is the same mesh after damage from static discharge.

(All photos courtesy of Dr. Akira Sasaki, Kleentek)

Figure 7. This microphotograph shows the fine balls of nylon produced by spark discharges of static electricity.

created by the high-speed flow that might conduct electricity, he says, and

of hot oil through the tiny pores low conductivity is vastly more important

of the filter element. The prob- than the base oil used.

lem has been exacerbated by In any case, the static charge that builds

more severe operating conditions up in the filter can arc there (causing the

in the newer turbines and the damage noted by Sasaki) or float down-

increasing use of synthetic filter stream in the oil.

elements that are naturally less The charge in a dielectric medium such as

conductive than natural fibers turbine lube oil tends to flow like clouds

such as cellulose. STLE member Dr. across the sky, says Duchowski. You dont

John Duchowski, director of technol- have lightning over the

ogy development for HYDAC Fil- entire sky, but from cloud

(Courtesy of Dr. John Duchowski and HYDAC)

tertechnik GmbH (now poised to to cloud and eventually to

introduce its first charge-reduction fil- ground. If you have a lot of

ter element) feels that Group II base clouds spread over the

oils also contribute to the problem in entire sky, then no one

that they do not have the relatively large cloud builds up enough

amounts of heteroatomic species that are charge to cause lightning.

present in Group I oils; these species could So our first approach to

help carry the charge away. Okazaki, however, the problem is to create a Figure 8. The light-

feels that operating temperatures are also filter element that dissi- ning that occurs on a

important: The high operating temperatures pates the charge evenly filter element is local-

of gas turbine oils drives out residual water across the entire surface ized when it occurs.

36 JANUARY 2008 T R I B O LO G Y & LU B R I C AT I O N T E C H N O LO G Y

32-38 tlt feature 1-08 12/18/07 10:15 AM Page 37

(see Figure 8). never field tested, and when the customer

But if thats all you do, he continues, used it, the RPVOT dropped 50% within the For more

the total amount of charge is still there, and first year. That should never happen. information:

an equal and opposite amount of charge According to Akira Sasaki, Japanese oil The following is a list

ends up going downstream, where it finds makers say that their gas turbine lubricants of some useful Web

the nearest ground and maybe damages have no varnish problems. For the benefit of sites and references

other system components. If the charge gas turbine users in other countries, he (see page 38) submit-

doesnt find a ground, it goes back to the wishes these oil makers would publish ted by contributors

reservoir and creates a lightning storm. The papers about why this is so. to this article:

best approach is first to eliminate the arcing 2. Monitor oil condition. According to

Web sites:

in the filter, because the damage it causes is Livingstone, regular oil monitoring is essen-

very dramatic, and second, to guide the tial. In addition to use of the RULER, he also www.cleanoil.com

(site for EPT)

charge out of the entire system right at the recommends patch tests such as Quantita-

filter housing. Matthias Schwender, whos tive Spectrophotometric Analysis, or QSA, www.fluitec.com

the manager of our filter media development developed by Analysts, Inc. QSA is designed

www.hydac.com

group, has led the effort to develop a new fil- to isolate, identify and measure the specific

ter element to do that. degradation byproducts responsible for the www.kleentek.com

formation of sludge to yield a Varnish www.lubricants

The 100% solution Potential Rating (VPR). Because the degra- university.com, a

If all of these problems sound daunting, dation of Group II formulations oils isnt lin- Chevron site also

take heart. According to Greg Livingstone, it ear, regular monitoring is essential to catch connecting to Lubri-

is possible to prevent all damage from gas degradation before it becomes suddenly cation Magazine.

turbine lubricant varnish. catastrophic.

Our philosophy at EPT is holistic, he www.wooton-

3. Minimize sparking. A lot of the OEMs consulting.com

says. Its like links in a chainas soon as have duplex filters so that you can change

you have a weak link, the chain will break and on the fly, but no one ever changes on the

youll have varnish. If you do just one or two fly, says Livingstone. Instead, he recom-

things, that wont work. You have to do it all. mends that oil be run through both banks of

Livingstones program involves the fol- filters, cutting the flow rate in half and

lowing: greatly reducing static charge. Better yet,

1. Choose a good oil. According to Liv- invest in charge-reduction filter elements.

ingstone, OEMs have only general specs for 4. Maintain the oil. Since

turbine oils, and all the lube oils on the the worst varnish problems

market meet the specs. Its ironic, he says, happen in the hydraulic system

varnish is the No. 1 failure mode of turbine when the oil cools, the ideal

oil, one of the highest-profile issues that solution is a turbine with sepa-

turbine oils have ever had, yet the OEMs rate oil systems. Failing that,

have no good language in their specs for every effort should be made to

resistance to sludge and varnish. Todays keep the oil warm when it gets

standardized ASTM tests dont really to the hydraulic system, either

address the problem. by adjusting control software

Theres hope for standardized tests in the to stroke the valves regularly,

(Courtesy of Dr. Akira Sasaki, Kleentek)

future: Chevrons Mark Okazaki is heading or by heat-tracing the lines.

an ASTM group to develop a new varnish Up to a certain point, var-

test based on the Mitsubishi Heavy Indus- nish can be rejuvenated.

tries Dry TOST test (a 500-hour test of Sasaki has tested oils by clean-

resistance to varnish formation), and ing them, leaving them at room

Andrea Wardlow of ExxonMobil is spear- temperature for 14 days, filter-

heading the effort to develop a cycling test ing and noting the color of the Figure 9. This filter test run by Dr.Akira Sasaki shows

that would measure varnish tendencies in a filter pad. Fresh oil with suffi- results for oil used for 16,200 hours over 7.5 years.

hot/cold cycling environment. cient oxidation inhibitors will The TAN was 0.14 for the new oil and 0.31 for this

Meanwhile, its best to choose an oil leave the filter white after 14

used oil. The oil was cleaned, then allowed to sit at

based on field experience. Just because an room temperature.The three columns represent the

days, but if the inhibitors have

oil performs well in a lab doesnt mean that amount of oxidation after 1, 7 and 14 days.The four

been depleted, the filter will be rows represent the unadulterated used oil, and the

it will perform in the actual application, yellow to brown. Partially used used oil with 10%, 20% and 30% virgin oil added.

says Okazaki. I know of one oil that was CONTINUED ON PAGE 38

T R I B O LO G Y & LU B R I C AT I O N T E C H N O LO G Y JANUARY 2008 37

32-38 tlt feature 1-08 12/18/07 10:15 AM Page 38

CONTINUED FROM PAGE 37

oil that would normally leave the filter they are sub-micron-sized particles, he con-

brown can be rejuvenated by the addition of tinues. The way to remove those is through

10% to 30% of the same brand of virgin oil an electrostatic oil cleaner. Both EPT and

(see Figure 9 on page 37). At a point where the Kleentek have these. This is the last line of

base oil is no longer healthy, rejuvenation defense to remove contaminants before they

doesnt work and the oil must be replaced. settle out and form varnish.

5. Remove contaminants. We advocate Success. Simply put: If you go through

using technology that will remove both sol- all five major steps, you will eradicate your

uble and insoluble contaminants, says Liv- varnish problem, says Livingstone. It will

ingstone. Its tricky because when you strip go away.

away soluble contaminants, you have to be And youll be able to return to less inter-

extremely careful not to take additives with esting times. TLT

them. EPT uses ion-charged bonding, ICB,

to remove soluble contaminants in a narrow

band of chemistry. Linda Day is a free-lance feature writer based in

Insoluble contaminants cant be re- Houston. You can reach her at linda@day

moved through normal filtration because creative.com.

References

1. Yano, A., Watanabe, S., Miyazaki, Y., Tsuchiya, M. and Yamamoto, Y. (2004), Sludge

Formation During the Oxidation Process of Turbine Oils, Tribology Transactions, 47 (1),

pp. 111-122.

2. Wooton, D.L., The Lubricants NemesisOxidation Part I, Practicing Oil Analysis

Magazine, March-April 2007, p. 26.

3. Wooton, D.L. The Lubricants NemesisOxidation Part II, Practicing Oil Analy-

sis Magazine, May-June 2007, p. 34.

4. Livingstone, G.J., Prescott, J. and Wooton, D., Detecting and Solving Lube Oil

Varnish Problems, Power Magazine, August 2007.

5. Sasaki, A., Uchiyama, S. and Yamamoto, T. (1999), Generation of Static Elec-

tricity During Filtration, Lubrication Engineering, 55 (9), p. 14-21.

6. Sasaki, A., Uchiyama, S. and Yamamoto, T. (1999), Free Radicals and Oil Auto-

Oxidation Due to Spark Discharges of Static Electricity, Lubrication Engineering, 55

(9), p. 24-27.

7. Practical Approaches to Controlling Sludge and Varnish in Turbine Oils,

William Moehle and Vincent Gatto, Albemarle Corp; Dave Wooton, Wooton Con-

sulting and Greg Livingstone, EPT Inc., NORIA LE2007, Louisville, Ky., May 2007.

8. Residue Analysis on RPVOT Test Samples for Single and Multiple Antioxidants

Chemistry for Turbine Lubricants, Andy Sitton, Focus Laboratories; Jo Ameye, Fluitec

and Robert Kauffman, UDRI, ASTM JAI, December 2005, ASTM Turbine Oil Symposium,

Norfolk, Va.

9. Physical, Performance and Chemical Changes in Turbine Oils from Oxidation, Greg J.

Livingstone, Brian T. Thompson, and Mark E. Okazaki, Journal of ASTM International, Decem-

ber 2005, Joint Oxidation and Turbine Oil Symposium, Norfolk Va.

10. ASTM D-6971Standard Test Method for Monitoring of Amine and Phenolic Antioxidants

in Non-Zinc Containing Turbine Oils by Linear Sweep Voltammetry (RULER).

38 JANUARY 2008 T R I B O LO G Y & LU B R I C AT I O N T E C H N O LO G Y

Anda mungkin juga menyukai

- 1.2. BTR - Lubrication NotesDokumen17 halaman1.2. BTR - Lubrication Notesvishnu vishnu G.T.Belum ada peringkat

- Basic of Oil AnalisisDokumen21 halamanBasic of Oil AnalisisPatricia MenaBelum ada peringkat

- Lubricant Condition Monitoring: Why The Lubricants MonitoringDokumen14 halamanLubricant Condition Monitoring: Why The Lubricants Monitoringrbdubey2020Belum ada peringkat

- PT Tiara WebinarDokumen155 halamanPT Tiara Webinardhavit wijayantoBelum ada peringkat

- ISO 6743-12 - 1989 - Part. 12 - Family Q - Heat Transfer FluidsDokumen4 halamanISO 6743-12 - 1989 - Part. 12 - Family Q - Heat Transfer FluidsMassimiliano VolaBelum ada peringkat

- Section 5 - Fuel, Lubricating Oil, and CoolantDokumen11 halamanSection 5 - Fuel, Lubricating Oil, and CoolantRamon100% (1)

- Calcium Sulfonate Grease vs. Lithium ComplexDokumen5 halamanCalcium Sulfonate Grease vs. Lithium ComplexTawfiq ZidanBelum ada peringkat

- Natural Gas Engines LubricationDokumen9 halamanNatural Gas Engines Lubricationjameel babooramBelum ada peringkat

- LZ 360 - Fluid Technology - IGO N OGL - Z124Dokumen45 halamanLZ 360 - Fluid Technology - IGO N OGL - Z124tiến thử huỳnhBelum ada peringkat

- Synthetic Gear Oil SelectionDokumen9 halamanSynthetic Gear Oil Selectionsmallik3Belum ada peringkat

- KITTIWAKE MA-K27468-KW Oil Test Solutions Iss 10 Single Pages SmallDokumen6 halamanKITTIWAKE MA-K27468-KW Oil Test Solutions Iss 10 Single Pages SmallCorina StanculescuBelum ada peringkat

- Oil and Your EngineDokumen39 halamanOil and Your EngineMillet westBelum ada peringkat

- Design Engineer's Guide - Selecting A Lubricant For Ball ScrewsDokumen10 halamanDesign Engineer's Guide - Selecting A Lubricant For Ball ScrewsDat RomanBelum ada peringkat

- Material Science: BY:-Prerna AgrawalDokumen13 halamanMaterial Science: BY:-Prerna AgrawalPrerna AgrawalBelum ada peringkat

- Lubricants For Buses and TrucksDokumen16 halamanLubricants For Buses and Trucksvijay9994Belum ada peringkat

- Technology Forum - Indoneusa - Gas Engines (Oct.2014) V2Dokumen42 halamanTechnology Forum - Indoneusa - Gas Engines (Oct.2014) V2Frana HadiBelum ada peringkat

- Lubrication TechnologyDokumen3 halamanLubrication TechnologymaheshBelum ada peringkat

- Base Stocks 基础油Dokumen18 halamanBase Stocks 基础油Yesica RozoBelum ada peringkat

- Chapter 6 LubricationDokumen24 halamanChapter 6 Lubricationchala nigussieBelum ada peringkat

- 12B OilAnalysisDokumen2 halaman12B OilAnalysisMuhamad BadarBelum ada peringkat

- STLE ORG:BOK:LS:Additives:Boundary Lubricity Additives TLT Article Sept09Dokumen8 halamanSTLE ORG:BOK:LS:Additives:Boundary Lubricity Additives TLT Article Sept09Dr. Stan Wardel BA, MA, MChem, MBA, DPhil, DSc.Belum ada peringkat

- Mil L 2105DDokumen17 halamanMil L 2105Dkamal arabBelum ada peringkat

- Whitepaper - Particle Counters For Oil Analysis - Design & Specifications PDFDokumen4 halamanWhitepaper - Particle Counters For Oil Analysis - Design & Specifications PDFAhmed El-ShafeiBelum ada peringkat

- Shell Turbo T46 PDFDokumen2 halamanShell Turbo T46 PDFdionisio emilio reyes jimenezBelum ada peringkat

- LO Analysis InterpretationDokumen36 halamanLO Analysis InterpretationPatrickBelum ada peringkat

- Limit Values For LubricantsDokumen28 halamanLimit Values For LubricantsSindley LimaferBelum ada peringkat

- Seaworthy.: A Selection of Lubricants For Marine and Offshore ApplicationsDokumen20 halamanSeaworthy.: A Selection of Lubricants For Marine and Offshore ApplicationsEduardo CastilloBelum ada peringkat

- Natural Gas Engine Lubrication and Oil Analysis - A Primer in Predictive Maintenance and Condition MonitoringDokumen7 halamanNatural Gas Engine Lubrication and Oil Analysis - A Primer in Predictive Maintenance and Condition Monitoringsatya_chaganti100% (1)

- The Effects of Soot-Contaminated Engine Oil On Wear and FrictionDokumen22 halamanThe Effects of Soot-Contaminated Engine Oil On Wear and FrictionAssimilator1Belum ada peringkat

- Using Membrane Patch Color 1708408Dokumen8 halamanUsing Membrane Patch Color 1708408Hesham MahdyBelum ada peringkat

- How To Select and Service Turbine OilsDokumen5 halamanHow To Select and Service Turbine OilsmvanzijpBelum ada peringkat

- Lubricants FinalDokumen18 halamanLubricants FinalRonak GandhiBelum ada peringkat

- Lubrication SystemsDokumen9 halamanLubrication SystemsCeno EdwinBelum ada peringkat

- Splash Lubrication PDFDokumen32 halamanSplash Lubrication PDFRajender KumarBelum ada peringkat

- tr0199990210510 - en Oil GDokumen26 halamantr0199990210510 - en Oil GSojib hossainBelum ada peringkat

- EIC N 1001 0 Hydraulic FluidsDokumen13 halamanEIC N 1001 0 Hydraulic FluidsCharitha LiyanagamaBelum ada peringkat

- ANALEX PQL Datasheet PDFDokumen2 halamanANALEX PQL Datasheet PDFmaye palominoBelum ada peringkat

- Diesel Engine LubricationDokumen28 halamanDiesel Engine LubricationBrian ASBelum ada peringkat

- Lubrication of Power Plant Equipment PDFDokumen34 halamanLubrication of Power Plant Equipment PDFRavinder SharmaBelum ada peringkat

- Overview of Rotating Disc Electrode (RDE) Optical Emission Spectroscopy For In-Service Oil AnalysisDokumen6 halamanOverview of Rotating Disc Electrode (RDE) Optical Emission Spectroscopy For In-Service Oil AnalysisenioleaoBelum ada peringkat

- Viscosity and Viscosity ModifiersDokumen37 halamanViscosity and Viscosity ModifiersmaiatostiBelum ada peringkat

- Shell Turbo T PDFDokumen3 halamanShell Turbo T PDFrehmanBelum ada peringkat

- Bio-Based Hydraulic FluidsDokumen50 halamanBio-Based Hydraulic FluidsAnibal Rios100% (1)

- Synthetics Lubricant Basestock Brochure - ExxonMobilDokumen13 halamanSynthetics Lubricant Basestock Brochure - ExxonMobilRafael Nakazato RecioBelum ada peringkat

- Lube Oil AnalysisDokumen8 halamanLube Oil AnalysisVuthpalachaitanya KrishnaBelum ada peringkat

- Wear Particle Analysis of OilDokumen7 halamanWear Particle Analysis of OilChandan KumarBelum ada peringkat

- Performance Evaluation of New and In-Service Turbine Oils: Turbine Oil Stability Test (TOST) ASTM D943Dokumen2 halamanPerformance Evaluation of New and In-Service Turbine Oils: Turbine Oil Stability Test (TOST) ASTM D943Gautam BandyopadhyayBelum ada peringkat

- UNIT III: Lubricants: Soami P. Satsangee CHM 181 7/10/2015Dokumen46 halamanUNIT III: Lubricants: Soami P. Satsangee CHM 181 7/10/2015anjali sharmaBelum ada peringkat

- List of Lubricants For LOESCHE-machines (Except Gearboxes) : Mineral Oils (CLP) / Synthetic Oils (PG)Dokumen8 halamanList of Lubricants For LOESCHE-machines (Except Gearboxes) : Mineral Oils (CLP) / Synthetic Oils (PG)MossaabSelaimiaBelum ada peringkat

- Cummins Oil Specifying 2017 PDFDokumen5 halamanCummins Oil Specifying 2017 PDFfneelav100% (1)

- Bab2 LubricationDokumen29 halamanBab2 LubricationFirdaus ZahariBelum ada peringkat

- MAN 270 Diesel Engine Oil: Products For The Specification Approved by NameDokumen2 halamanMAN 270 Diesel Engine Oil: Products For The Specification Approved by NameSyed JunaidBelum ada peringkat

- LubricationDokumen22 halamanLubricationEvílBoyViswaBelum ada peringkat

- What Is Oil Analysis - Bob Is The Oil GuyDokumen5 halamanWhat Is Oil Analysis - Bob Is The Oil Guyadalcayde2514Belum ada peringkat

- 100 Ways To Improve Your Lubrication ProgramDokumen29 halaman100 Ways To Improve Your Lubrication ProgramManne RajuBelum ada peringkat

- Lubricants and LubricationDokumen5 halamanLubricants and LubricationsafowanBelum ada peringkat

- D4741Dokumen8 halamanD4741rimi7alBelum ada peringkat

- Lubricant GlossaryDokumen8 halamanLubricant GlossaryAli KhanBelum ada peringkat

- Fuel DilutionDokumen18 halamanFuel DilutionMuHaZir0% (1)

- Varnis AcrDokumen9 halamanVarnis AcrAcademia de ConfiabilidadBelum ada peringkat

- Oelchecker Sommer2017 EN PDFDokumen8 halamanOelchecker Sommer2017 EN PDFAzhar1109Belum ada peringkat

- Oelchecker Winter 2016 enDokumen5 halamanOelchecker Winter 2016 enAzhar1109Belum ada peringkat

- Tech Trol Gold Synthetic LubricantDokumen2 halamanTech Trol Gold Synthetic LubricantAzhar1109Belum ada peringkat

- 2017 Gps Product CatalogDokumen60 halaman2017 Gps Product CatalogAzhar1109100% (1)

- Total - LUB - Industrial Apps - 2013 PDFDokumen20 halamanTotal - LUB - Industrial Apps - 2013 PDFAzhar1109100% (1)

- Solving Varnish ProblemDokumen7 halamanSolving Varnish ProblemAzhar1109Belum ada peringkat

- AN57 Used Lubricating Oil Analysis by FT-IRDokumen3 halamanAN57 Used Lubricating Oil Analysis by FT-IRAzhar1109Belum ada peringkat

- Turbine FundamentalsDokumen75 halamanTurbine FundamentalsingeniraBelum ada peringkat

- Test Selection and Frequency Guidelines: Fluid Properties Contamination Wear DebrisDokumen1 halamanTest Selection and Frequency Guidelines: Fluid Properties Contamination Wear DebrisAzhar1109100% (1)

- Turbine Oil Monitoring PDFDokumen23 halamanTurbine Oil Monitoring PDFAzhar1109100% (1)

- Bermuda Electric: Reliability Journey Into Unchartered WatersDokumen4 halamanBermuda Electric: Reliability Journey Into Unchartered WatersAzhar1109Belum ada peringkat

- Lab3E8 - Series and Parallel PumpDokumen8 halamanLab3E8 - Series and Parallel PumpRaied Basam0% (1)

- Ashrae 90.1-2010Dokumen92 halamanAshrae 90.1-2010asarlakBelum ada peringkat

- Dryers: DRYERS - Are Equipment Used For Producing A Dry Solid Product From A Wet Feed General Types of DryersDokumen5 halamanDryers: DRYERS - Are Equipment Used For Producing A Dry Solid Product From A Wet Feed General Types of DryersTristan Paul Guerra OrodioBelum ada peringkat

- Electrodynamics Class NotesDokumen237 halamanElectrodynamics Class NotesSwashy Yadav80% (5)

- W22 Homework #8 AnwsersDokumen4 halamanW22 Homework #8 Anwsersiamayesha725Belum ada peringkat

- Approximation Methods: Physics 130B, UCSD Fall 2009Dokumen90 halamanApproximation Methods: Physics 130B, UCSD Fall 2009Luz PeñaBelum ada peringkat

- Biblioteca Ingenieria Petrolera 2015Dokumen54 halamanBiblioteca Ingenieria Petrolera 2015margaritaBelum ada peringkat

- Catalogo Bticino de InterruptoresDokumen1 halamanCatalogo Bticino de InterruptoresEdgar David Becerra GomezBelum ada peringkat

- Differential Gear MechanismDokumen32 halamanDifferential Gear MechanismMohammad Amir100% (2)

- FILE 51 Use of Grinder or Angle GrinderDokumen1 halamanFILE 51 Use of Grinder or Angle GrinderJonathan BobadillaBelum ada peringkat

- EPSRC Thermal Management Sheffield Drying Tech Feb 2010 PDFDokumen50 halamanEPSRC Thermal Management Sheffield Drying Tech Feb 2010 PDFVampireSuicideBelum ada peringkat

- The Bearing Capacity Evaluations of A Spread Footing On Single Thick Stratum or Two-Layered Cohesive SoilsDokumen19 halamanThe Bearing Capacity Evaluations of A Spread Footing On Single Thick Stratum or Two-Layered Cohesive SoilsJohnclaude ChamandiBelum ada peringkat

- NSGAFÖU 1,8/3 KV: Product InformationDokumen3 halamanNSGAFÖU 1,8/3 KV: Product InformationAttila HorvathBelum ada peringkat

- Air Circuit Breakers For The 21st Century: Catalogue No.'00-P55EDokumen4 halamanAir Circuit Breakers For The 21st Century: Catalogue No.'00-P55EAsif ShahBelum ada peringkat

- DX Service and MaintDokumen20 halamanDX Service and MaintCarlos MenaBelum ada peringkat

- CAT 323 DL 2013 LeafletDokumen20 halamanCAT 323 DL 2013 LeafletLuka BornaBelum ada peringkat

- Electromagnetic RadiationDokumen22 halamanElectromagnetic RadiationSelva Kumar0% (1)

- PWM Control IC: BM1P107FJDokumen30 halamanPWM Control IC: BM1P107FJArokiaraj RajBelum ada peringkat

- Instrumentation AssignmentDokumen5 halamanInstrumentation AssignmentShreyee PalBelum ada peringkat

- Drive-Technology: SDA - Spindle Direct Drive ActuatorDokumen19 halamanDrive-Technology: SDA - Spindle Direct Drive ActuatorYAKOVBelum ada peringkat

- CATERPILAR3516 1550-2200 BHPDokumen6 halamanCATERPILAR3516 1550-2200 BHPNadia AnandaBelum ada peringkat

- SolarPro2 4Dokumen100 halamanSolarPro2 4lgv2Belum ada peringkat

- Catalog Solar-PV String Inverters Hopewind V4.3.1Dokumen14 halamanCatalog Solar-PV String Inverters Hopewind V4.3.1Atiq SaberBelum ada peringkat

- Sungrow Hybrid SH5K-30 5kW Inverter ManualDokumen154 halamanSungrow Hybrid SH5K-30 5kW Inverter Manualraymknd gerard macarineBelum ada peringkat

- Decarbonization MagazineDokumen86 halamanDecarbonization MagazineSynergy IndustriesBelum ada peringkat

- DNV Maritime Forecast 2050 2021-WebDokumen82 halamanDNV Maritime Forecast 2050 2021-WebДмитрий Ганжа100% (1)

- Design and Simulation of A Sine Wave Inverter With PID Control For Nonlinear Load ApplicationsDokumen12 halamanDesign and Simulation of A Sine Wave Inverter With PID Control For Nonlinear Load ApplicationsReno ReoBelum ada peringkat

- ICE 160 230 0296 HammerDokumen119 halamanICE 160 230 0296 HammerRıfat BingülBelum ada peringkat

- 28 Psychrometric ProcessesDokumen19 halaman28 Psychrometric ProcessesPRASAD326100% (7)

- GT ManualDokumen10 halamanGT Manualsoldatbr4183Belum ada peringkat