Osver - WQR - 2 4G

Diunggah oleh

Erik Jhonattan Jara YpanaqueJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Osver - WQR - 2 4G

Diunggah oleh

Erik Jhonattan Jara YpanaqueHak Cipta:

Format Tersedia

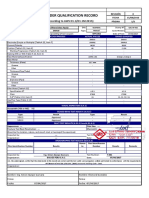

REVISIN 0

WELDER QUALIFICATION RECORD

FECHA 15/08/2016

(According to AWS D1.1/D1.1M:2015) PGINA 1/1

Welders name : Marcos Ohara Salas Aquije DNI: 45294591 Stamp N: GAL-W-002

Welding Process used : SMAW Type: Manual Code Welder: -

Identification of WPS followed by welders during welding of test coupon: WPS-002 Date of Test: 07/04/2017

MANUAL OR SEMIAUTOMATIC VARIABLES FOR EACH PROCESS ACTUAL VALUES RANGE QUALIFIED

Process/Type [Table 4.12, Item 1] SMAW SMAW

Electrode (Simple or Multiple) [Table 4.12, Item 7] SIMPLE SIMPLE

Current/Polarity DCEP DCEP

Position [Table 4.12, Item 4] 4G F, OH

Welding Progression [Table 4.12, Item 5] - -

Backing (YES or NO) [Table 4.12, Item 6] - -

Base Material/Specification ASTM A36 Group 1, Group 2

Base Metal

Thickness: (Plate) 12.7 mm 3 mm - 25.4 mm

Groove - Unlimited

Fillet

Thickness:(Pipe/Tube) - -

Groove - -

Fillet

Diameter:(Pipe) - -

Groove - -

Fillet - -

Filler Metal [Table 4.12]

Specification N A 5.1 A 5.1

Class E7018 E7018

F-N [Table 4.12, Item 2] F4 F1, F2, F3 Y F4

Gas/Flux Type [Table 4.12] - -

Others - -

VISUAL INSPECTION (4.9.1)

Acceptable (YES or NO): YES

GUIDED BEND TEST RESULTS (4.31.5)

Type Result Type Result

SIDE 1 Approved - -

SIDE 2 Approved - -

FILLET TEST RESULTS (4.31.2.3 and 4.31.4.1)

Appearance: --- Fillet Size: ---

Fracture Test Root Penetration: --- Macroetch: ---

(Describe the location, nature, and size of crack or tearing of the specimen)

Inspected by: --- Test Number: --

Organization: --- Date: --

RADIOGRAPHIC TEST RESULTS (4.31.3.2)

Remar Film Identification

Film Identification Number Results ks Number Results Remarks

- -

- -

Inspected by: Ing. Simon Quispe Guevara Test Number: T-001

Organization: GALVEC PERU S.A.C. Date: 07/04/2017

We, the undersigned, certify that the statements in this record are correct and the test welds were prepared, welded and tested in conformance with the requirements

of Clause 4 of AWS D1.1/D1.1M, (2010) Structural Welding Code - Steel.

Organization:

Nombre: Ing. Simon Quispe Guevara Nombre: ElioCoral Gonzles

Firma: Firma:

Fecha: 07/04/2017 Fecha: 007/04/2017

MANUAL DE CALIDAD REVISIN 0

REGISTRO DE ENSAYO DE DOBLEZ GUIADO FECHA 15/08/2016

N PGINA 1/1

OPERARIO PROCESO

Nombre : Marcos Ohara Salas Aquije Procedimiento : SMAW

DNI : 45294591 Posicin : 4G

Cdigo : - Proceso de Soldeo : WPS-002

MATERIAL MATERIAL DE APORTE

Material Base : ASTM A36 Material de Aporte A 5.1

Espesor de Material 12.7 mm

ESTNDAR DE CALIFICACIN ESPECIFICACIN DE JUNTA

(According to AWS D1.1/D1.1M:2015) JUNTA DE PENETRACION COMPLETA

CONDICIONES DEL ENSAYO NORMA APLICABLE

ASTM A370-Test Methods And Definitions For Mechanical Testing Of

CONDICIONES AMBIENTALES

Steel products

INSTRUMENTO DE ENSAYO FECHA DE ENSAYO

SEGN FIG. 4.15 GUIDED BEND TEST JIG 07/04/2017

RESULTADOS DE LOS ENSAYOS

PROBETA N SOLDADOR LADO ENSAYADO RESULTADO OBSERVACIONES

1 - LADO 1 Aprobado No se observa defecto alguno

2 - LADO 2 Aprobado No se observa defecto alguno

IMGENES DE LOS ENSAYOS

SMAW SMAW

S1 SIDE 2

WPS-002 WPS-002

Nombre: Ing. Simon Quispe Guevara Nombre: ElioCoral Gonzles

FIRMA : FIRMA :

Fecha: 07/04/2017 Fecha: 07/04/2017

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Astm D429 - 03 PDFDokumen22 halamanAstm D429 - 03 PDFJavier Enrique Toro Yentzen100% (1)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Guide to basic welding techniquesDokumen7 halamanGuide to basic welding techniquesJaveed A. KhanBelum ada peringkat

- MBG 531 2017 GratingDokumen34 halamanMBG 531 2017 GratingErik Jhonattan Jara YpanaqueBelum ada peringkat

- Liquid Penetrant Testing Questions Levl 1&2Dokumen36 halamanLiquid Penetrant Testing Questions Levl 1&2Joshnewfound100% (3)

- TWI - Presentation Welding DefectsDokumen22 halamanTWI - Presentation Welding Defectssajux100% (2)

- LIQUID PENETRANT EXAM REPORTDokumen24 halamanLIQUID PENETRANT EXAM REPORTzat572000Belum ada peringkat

- Esr 2236Dokumen6 halamanEsr 2236MD MDDBelum ada peringkat

- Astm 633-15 PDFDokumen6 halamanAstm 633-15 PDFMuthuswamyBelum ada peringkat

- AWS A4.2M 2006 Standard Procedures For Calibrating Magnetic Instruments To Measure The Delta Ferrite Content of Austenitic and Duplex Ferritic-Austenitic Stainless Steel Weld Metal PDFDokumen58 halamanAWS A4.2M 2006 Standard Procedures For Calibrating Magnetic Instruments To Measure The Delta Ferrite Content of Austenitic and Duplex Ferritic-Austenitic Stainless Steel Weld Metal PDFErik Jhonattan Jara YpanaqueBelum ada peringkat

- Stainless Steel Grade AISI 304 PDFDokumen2 halamanStainless Steel Grade AISI 304 PDFSarita ForgingBelum ada peringkat

- Sample Internship ReportDokumen34 halamanSample Internship ReportIsaac Okorie zaku89% (9)

- Astm A283 PDFDokumen2 halamanAstm A283 PDFrodriguez.gaytan88% (8)

- Waffle Slab Joint DetailsDokumen6 halamanWaffle Slab Joint DetailsReymond Longtable100% (1)

- CBT Questions for Piping Code ASME B31.3Dokumen41 halamanCBT Questions for Piping Code ASME B31.3arulselvamBelum ada peringkat

- MAG General Business Certificate of Quality AnalysisDokumen1 halamanMAG General Business Certificate of Quality AnalysisErik Jhonattan Jara YpanaqueBelum ada peringkat

- ASTM A36 steel certification documentDokumen1 halamanASTM A36 steel certification documentErik Jhonattan Jara YpanaqueBelum ada peringkat

- Certificado de Calidad DEVELOPERDokumen1 halamanCertificado de Calidad DEVELOPERErik Jhonattan Jara YpanaqueBelum ada peringkat

- AISC Properties ViewerDokumen3 halamanAISC Properties Viewerchriscivil12Belum ada peringkat

- DWG-M02 - Rev 0Dokumen1 halamanDWG-M02 - Rev 0Erik Jhonattan Jara YpanaqueBelum ada peringkat

- G92 X0.y0. G21 G91 G00x723.371y15.296 G41 M07 G01x-.361y3.983 G02x-720.i-360.j3974.73 G01y10. G01x360.y40. G01x360.y-40. G01y-10. G01y-4. M08 G40 M02Dokumen1 halamanG92 X0.y0. G21 G91 G00x723.371y15.296 G41 M07 G01x-.361y3.983 G02x-720.i-360.j3974.73 G01y10. G01x360.y40. G01x360.y-40. G01y-10. G01y-4. M08 G40 M02Erik Jhonattan Jara YpanaqueBelum ada peringkat

- Astm17 0901Dokumen5 halamanAstm17 0901Erik Jhonattan Jara YpanaqueBelum ada peringkat

- A524-96 (2012) Standard Specification For Seamless Carbon Steel Pipe For Atmospheric and Lower TemperaturesDokumen9 halamanA524-96 (2012) Standard Specification For Seamless Carbon Steel Pipe For Atmospheric and Lower TemperaturesChuthaBelum ada peringkat

- Maf WPS 113Dokumen1 halamanMaf WPS 113Erik Jhonattan Jara YpanaqueBelum ada peringkat

- Páginas DesdeASME B16.5-2013Dokumen2 halamanPáginas DesdeASME B16.5-2013Erik Jhonattan Jara YpanaqueBelum ada peringkat

- 3G SmawDokumen1 halaman3G SmawErik Jhonattan Jara YpanaqueBelum ada peringkat

- FIANSA P13 PR015 BM CR1 M01 - Rev.3Dokumen1 halamanFIANSA P13 PR015 BM CR1 M01 - Rev.3Erik Jhonattan Jara YpanaqueBelum ada peringkat

- Osver - WQR - 2 4GDokumen2 halamanOsver - WQR - 2 4GErik Jhonattan Jara YpanaqueBelum ada peringkat

- 3G FcawDokumen1 halaman3G FcawErik Jhonattan Jara YpanaqueBelum ada peringkat

- CANTEX Fitting Brochure 200809Dokumen48 halamanCANTEX Fitting Brochure 200809Kim Ill JeongBelum ada peringkat

- TOOLS AND EQUIPMENT USE IN CONCRETE WORKS - BadioDokumen4 halamanTOOLS AND EQUIPMENT USE IN CONCRETE WORKS - BadioAshiya SampacoBelum ada peringkat

- ASME BPVC Section II-2013 - Mates Electrodes and Filler Metals 428Dokumen1 halamanASME BPVC Section II-2013 - Mates Electrodes and Filler Metals 428joshBelum ada peringkat

- Gypsum BoardDokumen2 halamanGypsum BoardCindy AmyzaBelum ada peringkat

- All About CanningDokumen12 halamanAll About CanningGayathri Fernando100% (1)

- Building Construction (9019) PDFDokumen7 halamanBuilding Construction (9019) PDFMani Deep50% (2)

- Professional Belt Grinding in Manual Trades and Industry.: MetalDokumen40 halamanProfessional Belt Grinding in Manual Trades and Industry.: MetalthuanBelum ada peringkat

- 07 Rawlbolts Plugs AnchorsDokumen1 halaman07 Rawlbolts Plugs AnchorsLincolnBelum ada peringkat

- Tubing Data-Engineered Combinations MS-06-117Dokumen7 halamanTubing Data-Engineered Combinations MS-06-117kirlaniano@gmail.comBelum ada peringkat

- InstrumentsDokumen10 halamanInstrumentsRomyna Mae GalangBelum ada peringkat

- C200-Roadworks Notes and Details-C210Dokumen1 halamanC200-Roadworks Notes and Details-C210Don WangBelum ada peringkat

- Chapter2 Materials Used in Vacuum SystemsDokumen36 halamanChapter2 Materials Used in Vacuum SystemsDeepak PatwardhanBelum ada peringkat

- Polyflor Global Approved AdhesivesDokumen24 halamanPolyflor Global Approved AdhesivesRatna Ayu K 201102Belum ada peringkat

- Planning, Analyzing and Designing of Staff Quaters Building by Using STAAD ProDokumen12 halamanPlanning, Analyzing and Designing of Staff Quaters Building by Using STAAD ProInternational Journal of Application or Innovation in Engineering & ManagementBelum ada peringkat

- Copper Tube HandbookDokumen96 halamanCopper Tube HandbookAnonymous S9qBDVkyBelum ada peringkat

- Splicing Bar Resources: Additional Information On Lap Splices Can Be Found HereDokumen5 halamanSplicing Bar Resources: Additional Information On Lap Splices Can Be Found HereLiyakhat aliBelum ada peringkat

- Transparent (Light Transmitting) ConcreteDokumen3 halamanTransparent (Light Transmitting) Concretevenkateswara rao PothinaBelum ada peringkat

- Is 2269.2006-Hex Soc Hd. Cap ScrewDokumen20 halamanIs 2269.2006-Hex Soc Hd. Cap ScrewdombipinBelum ada peringkat

- Engineering Utilities 2Dokumen8 halamanEngineering Utilities 2Vanissa MontillaBelum ada peringkat

- 3'' TANKFLY Flanged Butterfly ValveDokumen2 halaman3'' TANKFLY Flanged Butterfly Valvezahid nawazBelum ada peringkat

- Knjiga 3 - CUPOV Divulje - Hyperbolic Mixers PartDokumen2 halamanKnjiga 3 - CUPOV Divulje - Hyperbolic Mixers PartDicle KarabiberBelum ada peringkat

- Brick TableDokumen1 halamanBrick TablewilliamBelum ada peringkat