Clipsal Ceiling Fan Installation Instructions

Diunggah oleh

testnationHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Clipsal Ceiling Fan Installation Instructions

Diunggah oleh

testnationHak Cipta:

Format Tersedia

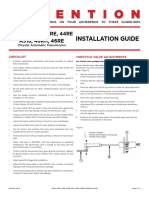

Fan Installation Checklist

The following guidelines should be followed to ensure quiet operation.

1. Ensure all bolts and screws are properly tightened when assembling fan.

2. Check fit of support hook to rubber support insulator. If loose, fit rubber

sheathing provided to ensure neat fit.

3. Place rubber washers supplied, between support insulator and support

insulator brackets for tight fit.

4. Prevent loose split pins from rattling by covering with small piece of

insulation tape or other suitable method.

5. Ensure top and bottom cowls are securely fixed and slightly clear of ceiling

and fan motor. t

A few minutes spent checking the above will in most cases ensure silent

operation of the fan.

Remove excessive slack

Capacitor

3 speed controller

on cable to prevent rattling

Place rubber sheathing

inside downrod.

provided over the support

hook if required.

for Airflow

Prevent split pins from rattling

Place rubber washers

provided between support

insulator and support insulator

brackets to effect a tight fit.

ceiling sweep fans

Top and bottom cowls must be firmly

attached to downrod and should clear

ceiling and fan motor by approximately Check for tight connection

10mm all round. between support insulator

brackets and downrod. A bolt

and nut should be used. If a

split pin is used to retain the

Wiring and installation instructions

nut, prevent it from rattling

2. Installation should be tested over by using insulation tape.

Check that there are no loose

Check for tight connection

parts within the capacitor housing.

between the downrod and

Bend brackets holding capacitor

capacitor housing. Prevent

and/or terminal block to tighten

split pin from rattling.

if necessary

F996 9922 Check list included

The Clipsal 2031VF3C and 31VF3C series ceiling sweep Wiring Connection

fan controllers have overcome the problems associated with 2031VF3C and 31VF3C series fan speed controls are

choke or other electronic controllers. They are a very connected as illustrated in the diagram below.

compact, cool running device offering 3 speed control of the NOTE: All permanent electrical installations are required to

specified fans. be made by a licensed electrician.

The controller employs the use of capacitors to achieve

linear speed control of the fans. This method of control

A ACTIVE , COMMON

.

overcomes the annoying motor growl emitted from fans

controlled by other electronic (Phase control) speed setters SWITCHED

and ensures quiet operation of the fan motor. ACTIVE

Models Available

Two fan control models are available in 2000 series or standard

pattern plate style.

Cat No. 2031VF3CA and 31VF3CA designed to suit:

COMMON

Airflow fans Motor No

ACES 36 KA36

ACES 48AL KA48L

NEUTRAL SWITCHED

Cat No. 2031VF3CB and 31VF3CB designed to suit:

ACTIVE

Airflow fans Motor No

ACES 48 KA48 Installation

ACES 56 KA56 The arrangement of the controller is vertical as a standard

ACES 56AL KA56L for easy change-over. (Capacitor below mech.) To mount

AFLR 48 KW48M the controller in a horizontal position.

Simply

1. Lever the knob from the shaft

2. Prise mech out of aperture and rotate 90

3. Clip mech into new position and replace knob.

Anda mungkin juga menyukai

- Practical Guide to International Standardization for Electrical Engineers: Impact on Smart Grid and e-Mobility MarketsDari EverandPractical Guide to International Standardization for Electrical Engineers: Impact on Smart Grid and e-Mobility MarketsBelum ada peringkat

- Carrier Wrac BrochureDokumen36 halamanCarrier Wrac BrochureJyrus Jyles CadienteBelum ada peringkat

- Overview of Fire Alarm & Detection Systems-R1Dokumen60 halamanOverview of Fire Alarm & Detection Systems-R1Kenn Wahh100% (1)

- Application Guide Loop Testing Techniques PDFDokumen2 halamanApplication Guide Loop Testing Techniques PDFkaliBelum ada peringkat

- Chilled Water Fan Coil Unit (FWW-EC)Dokumen16 halamanChilled Water Fan Coil Unit (FWW-EC)Elliot MayerBelum ada peringkat

- NFPA 92,3, 101 Defines DesignDokumen19 halamanNFPA 92,3, 101 Defines Designabpau01559Belum ada peringkat

- ZENTA Ceiling FanDokumen2 halamanZENTA Ceiling Fanorodz1Belum ada peringkat

- Halton TsaDokumen9 halamanHalton TsaNetri KrisztiánBelum ada peringkat

- Jan 2018 - Data Center Continuous (DCC) Ratings - A Comparison of DCC Ratings, IsO Definitions and Uptime RequirementsDokumen4 halamanJan 2018 - Data Center Continuous (DCC) Ratings - A Comparison of DCC Ratings, IsO Definitions and Uptime RequirementsAngan KitaBelum ada peringkat

- Intercon KK Facade Consultancy Fee ProposalDokumen50 halamanIntercon KK Facade Consultancy Fee ProposalParthiban ShanmuganathanBelum ada peringkat

- Whitepaper Preventive Fire Protection enDokumen4 halamanWhitepaper Preventive Fire Protection enlichirBelum ada peringkat

- C2000D6Dokumen4 halamanC2000D6Gestión del Talento Humano GEMRABelum ada peringkat

- Grounding Separately Derived Alternating-Current Systems and 3 4 Pole SwitchingDokumen16 halamanGrounding Separately Derived Alternating-Current Systems and 3 4 Pole SwitchingMWBABARBelum ada peringkat

- Eicr SummaryDokumen1 halamanEicr SummaryBrad WainwrightBelum ada peringkat

- Life and Property Safety SystemsDokumen32 halamanLife and Property Safety SystemsEdz EduardoBelum ada peringkat

- Fdas 2Dokumen40 halamanFdas 2Sydney PiusBelum ada peringkat

- Advances in Nitrate RemovalDokumen8 halamanAdvances in Nitrate RemovalsnahushBelum ada peringkat

- UK Building Regulations Part MDokumen4 halamanUK Building Regulations Part MzbbBelum ada peringkat

- Iec 61156-5Dokumen8 halamanIec 61156-5Andres BonuccelliBelum ada peringkat

- Prime Continuous Power vs. Standby Backup PowerDokumen5 halamanPrime Continuous Power vs. Standby Backup PowerOsama ShalabyBelum ada peringkat

- Domestic Ventilation Compliance Guide 2010Dokumen63 halamanDomestic Ventilation Compliance Guide 2010Mohamed AdelBelum ada peringkat

- Cooling LoadDokumen66 halamanCooling LoadChun Hang IpBelum ada peringkat

- BRC1H Service TrainingDokumen102 halamanBRC1H Service TrainingAnonymous 3lvZL7LQBelum ada peringkat

- Motor Wiring Diagram: 6 Lead, Single Phase, Dual VoltageDokumen1 halamanMotor Wiring Diagram: 6 Lead, Single Phase, Dual Voltagealex2628Belum ada peringkat

- Regulations and Standards for Electrical InstallationsDokumen13 halamanRegulations and Standards for Electrical InstallationsLaxman NaiduBelum ada peringkat

- Copper Wire Install StandardDokumen70 halamanCopper Wire Install Standardcharlesc5746100% (1)

- User'S Manual: Split Type Room Air ConditionerDokumen24 halamanUser'S Manual: Split Type Room Air Conditionerkhr saabBelum ada peringkat

- Cable SelectionDokumen4 halamanCable SelectionMuhammadThoriqAzmiBelum ada peringkat

- Installation, Operation and Maintenance Manual: AC-Centrifugal Roof and Wall ExhaustersDokumen8 halamanInstallation, Operation and Maintenance Manual: AC-Centrifugal Roof and Wall ExhaustersRichard Rodriguez MedinaBelum ada peringkat

- Uai B 0214Dokumen4 halamanUai B 0214Jose Puc ManzanillaBelum ada peringkat

- Install, operate and maintain QMX inline mixed flow fansDokumen12 halamanInstall, operate and maintain QMX inline mixed flow fansSebastian VaccaBelum ada peringkat

- 79U, E Spring Return and Double Acting Pneumatic Quarter-Turn Actuators Operations (2000)Dokumen12 halaman79U, E Spring Return and Double Acting Pneumatic Quarter-Turn Actuators Operations (2000)COILED TUBINGBelum ada peringkat

- Instalacion y Mantenimiento de Ventiladores NovencoDokumen8 halamanInstalacion y Mantenimiento de Ventiladores NovencoLuis Hernando ZorroBelum ada peringkat

- Install 10Dokumen2 halamanInstall 10dwight_mcgowenBelum ada peringkat

- Reverse Cycle Ducted Split Systems R32 Installation & MaintenanceDokumen8 halamanReverse Cycle Ducted Split Systems R32 Installation & MaintenanceFilipBelum ada peringkat

- FlowserverDokumen12 halamanFlowserverCesar Cedano VivarBelum ada peringkat

- Nordic 5900Dokumen4 halamanNordic 5900adalberto vegaBelum ada peringkat

- alga_enDokumen4 halamanalga_enDaniel BahamondeBelum ada peringkat

- 1341832085307-Air ConditioningDokumen28 halaman1341832085307-Air ConditioningMECHANICAL ENGINEERINGBelum ada peringkat

- Attention: Installation GuideDokumen2 halamanAttention: Installation GuideDaniel EcheverriaBelum ada peringkat

- 38EYX - Manual de InstalaciónDokumen53 halaman38EYX - Manual de InstalaciónXplo By AteoBelum ada peringkat

- ST1000 PDFDokumen32 halamanST1000 PDFFranBelum ada peringkat

- Cooling SystemDokumen5 halamanCooling SystemDmitryBelum ada peringkat

- Heater Control and AccessoryDokumen2 halamanHeater Control and Accessorydmc constructionBelum ada peringkat

- Ca GoyenDokumen23 halamanCa GoyenGunalan RavichanthiranBelum ada peringkat

- E101 3236 IR 3Z SootblowerDokumen4 halamanE101 3236 IR 3Z SootblowerKartika SuryawanBelum ada peringkat

- Diamond Power IR-3Z: Furnace Wall SootblowerDokumen4 halamanDiamond Power IR-3Z: Furnace Wall SootblowerGỗ MộcBelum ada peringkat

- Important!: Read Before Proceeding!Dokumen10 halamanImportant!: Read Before Proceeding!Digeo MachadoBelum ada peringkat

- Installer's Guide: Condensing UnitsDokumen8 halamanInstaller's Guide: Condensing UnitsOmar PiñaBelum ada peringkat

- Points Eliminator: Conversion Part No. 2030Dokumen2 halamanPoints Eliminator: Conversion Part No. 2030masakpBelum ada peringkat

- 2ttb3Dokumen8 halaman2ttb3mikecom21Belum ada peringkat

- (OM) Operation ManualDokumen5 halaman(OM) Operation ManualDennys GuizarBelum ada peringkat

- Instruction Manual-Smc 33KVDokumen9 halamanInstruction Manual-Smc 33KVRAKESH CHANDRA PATRABelum ada peringkat

- BR33 Rotary Valve ManualDokumen20 halamanBR33 Rotary Valve ManualHimozaesBelum ada peringkat

- Eclipse Information Guide: 1.0 ApplicationsDokumen4 halamanEclipse Information Guide: 1.0 ApplicationsJuan David Muriel CastilloBelum ada peringkat

- CBF IomDokumen2 halamanCBF Iomjul.bastienBelum ada peringkat

- Installation and Start-Up Instructions: 38YCC-50 HZ Split System Heat PumpDokumen8 halamanInstallation and Start-Up Instructions: 38YCC-50 HZ Split System Heat PumpAflredo FloresBelum ada peringkat

- Cooker Hood Hotte Dunstabzugshaube Dampkap Cappa Campana ExaustorDokumen5 halamanCooker Hood Hotte Dunstabzugshaube Dampkap Cappa Campana ExaustorAleksander RzeczyckiBelum ada peringkat

- !!!WARNING!!!: 2R-Series 2R2500 & 2R3500 Double Acting & Spring Return Scotch Yoke ActuatorsDokumen7 halaman!!!WARNING!!!: 2R-Series 2R2500 & 2R3500 Double Acting & Spring Return Scotch Yoke ActuatorsAmaury FreireBelum ada peringkat

- Condensing Units: Installer's GuideDokumen8 halamanCondensing Units: Installer's GuideHoàngViệtAnhBelum ada peringkat

- Nokia - Web Based Provision Configuration Guide For Symbian ClientsDokumen9 halamanNokia - Web Based Provision Configuration Guide For Symbian ClientstestnationBelum ada peringkat

- Due Diligence QuestionnaireDokumen5 halamanDue Diligence QuestionnairetestnationBelum ada peringkat

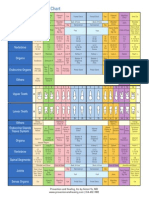

- Tooth-Organ Meridian Chart: Sense Organs Joints Spinal Segments Vertebrae OrgansDokumen1 halamanTooth-Organ Meridian Chart: Sense Organs Joints Spinal Segments Vertebrae Organsmoumona100% (1)

- Book 4 Music AlphabeticalDokumen1 halamanBook 4 Music AlphabeticaltestnationBelum ada peringkat

- Book 2 Music AlphabeticalDokumen1 halamanBook 2 Music AlphabeticaltestnationBelum ada peringkat

- How To Flip The Magnet On Spooky Remote v1.1Dokumen4 halamanHow To Flip The Magnet On Spooky Remote v1.1testnationBelum ada peringkat

- Book Music Master List Alphabetical v2Dokumen1 halamanBook Music Master List Alphabetical v2testnationBelum ada peringkat

- 40+ Songs for Relaxation and ReflectionDokumen1 halaman40+ Songs for Relaxation and ReflectiontestnationBelum ada peringkat

- Book 7 Music Alphabetical PianoDokumen1 halamanBook 7 Music Alphabetical PianotestnationBelum ada peringkat

- Book 6: Faithfully (Journey) For The First Time v3 Right Here Waiting That's What Friends Are ForDokumen2 halamanBook 6: Faithfully (Journey) For The First Time v3 Right Here Waiting That's What Friends Are FortestnationBelum ada peringkat

- 40+ Songs for Relaxation and ReflectionDokumen1 halaman40+ Songs for Relaxation and ReflectiontestnationBelum ada peringkat

- Book 5 Music AlphabeticalDokumen1 halamanBook 5 Music AlphabeticaltestnationBelum ada peringkat

- Book 8 Collection of Popular SongsDokumen2 halamanBook 8 Collection of Popular SongstestnationBelum ada peringkat

- Book 6 Music AlphabeticalDokumen2 halamanBook 6 Music AlphabeticaltestnationBelum ada peringkat

- Book 3 Music AlphabeticalDokumen1 halamanBook 3 Music AlphabeticaltestnationBelum ada peringkat

- The Energy Grid - Harmonic 695 PDFDokumen1 halamanThe Energy Grid - Harmonic 695 PDFtestnationBelum ada peringkat

- Book 3 Music Piano ListDokumen1 halamanBook 3 Music Piano ListtestnationBelum ada peringkat

- Book 7 Music PianoDokumen1 halamanBook 7 Music PianotestnationBelum ada peringkat

- NONLINEAR (NLS) DIAGNOSTIC SYSTEMS (Basic Physics and Principles of Equipment)Dokumen13 halamanNONLINEAR (NLS) DIAGNOSTIC SYSTEMS (Basic Physics and Principles of Equipment)testnation100% (1)

- FilelistingDokumen5 halamanFilelistingtestnationBelum ada peringkat

- FileDokumen5 halamanFiletestnationBelum ada peringkat

- Australian Trailer Plug Wiring InfoDokumen1 halamanAustralian Trailer Plug Wiring InfotestnationBelum ada peringkat

- Homeopathic Potencies For Remedy MakerDokumen1 halamanHomeopathic Potencies For Remedy MakertestnationBelum ada peringkat

- Move BGL Software To A New Stand-Alone PC or LaptopDokumen13 halamanMove BGL Software To A New Stand-Alone PC or LaptoptestnationBelum ada peringkat

- Funding Your Retirement Max Newnham P 266-267 PDFDokumen1 halamanFunding Your Retirement Max Newnham P 266-267 PDFtestnationBelum ada peringkat

- Funding Your Retirement Max Newnham P 266-267Dokumen1 halamanFunding Your Retirement Max Newnham P 266-267testnationBelum ada peringkat

- Using 4 Generators For Effective Cancer TreatmentDokumen9 halamanUsing 4 Generators For Effective Cancer TreatmenttestnationBelum ada peringkat

- 2011 Giant Cypress 3 SpecificationsDokumen2 halaman2011 Giant Cypress 3 SpecificationstestnationBelum ada peringkat

- Healing Codes WorkbookDokumen77 halamanHealing Codes Workbookdeepflm100% (1)

- 2011 Giant Suede SpecificationsDokumen1 halaman2011 Giant Suede SpecificationstestnationBelum ada peringkat

- Kgs1411 ServiceDokumen100 halamanKgs1411 ServiceSusan JohnsonBelum ada peringkat

- Altech UL489 Busbar SystemDokumen8 halamanAltech UL489 Busbar SystemIulius CezarBelum ada peringkat

- 2 Check List For 4.16KV VCBDokumen6 halaman2 Check List For 4.16KV VCBmatthew_70% (1)

- MR-J4-TM Instruction ManualDokumen700 halamanMR-J4-TM Instruction ManualGerard GrauBelum ada peringkat

- Rotating Trolley With Lead Screw Mechanism: International Journal On Emerging TechnologiesDokumen3 halamanRotating Trolley With Lead Screw Mechanism: International Journal On Emerging TechnologiesTeam LegendsBelum ada peringkat

- Caterpillar Machines: Spare Parts Catalogs / Repair Manuals / Operation InstructionsDokumen22 halamanCaterpillar Machines: Spare Parts Catalogs / Repair Manuals / Operation InstructionsFlo Marine100% (1)

- Selection guide for coiled tubing and casing cuttersDokumen5 halamanSelection guide for coiled tubing and casing cuttersSusin LimBelum ada peringkat

- VdsDokumen549 halamanVdsProject MarsysBelum ada peringkat

- RADAR BRIDGE MASTER E Series Radar Ship S Manual PDFDokumen161 halamanRADAR BRIDGE MASTER E Series Radar Ship S Manual PDFEdwin NyangeBelum ada peringkat

- 0304Dokumen26 halaman0304Era SyafitriBelum ada peringkat

- SH210 5Dokumen1 halamanSH210 5lionkinghd94% (36)

- Top 5 Less Lethal Guns For Concealed CarryDokumen1 halamanTop 5 Less Lethal Guns For Concealed CarryJohn HancqBelum ada peringkat

- Tool Makers MicroscopeDokumen2 halamanTool Makers Microscopesukriti dhauni100% (1)

- Service Manual: 5. Trouble ShootingDokumen2 halamanService Manual: 5. Trouble ShootingevanBelum ada peringkat

- Technical Note - Load Cell Troubleshooting - v1 - February 2016Dokumen4 halamanTechnical Note - Load Cell Troubleshooting - v1 - February 2016Mario MorenoBelum ada peringkat

- Pressure Cut-Off For Linde BPV Pumps Bulletin No. BPV 000 03.89/001/06Dokumen5 halamanPressure Cut-Off For Linde BPV Pumps Bulletin No. BPV 000 03.89/001/06Y.Ebadi100% (2)

- Model Service Manual: Green Laser PhotocoagulatorDokumen84 halamanModel Service Manual: Green Laser PhotocoagulatorfadiBelum ada peringkat

- TeSys F - LC1F150M7Dokumen3 halamanTeSys F - LC1F150M7Nuvail QahfyBelum ada peringkat

- Safeguarding Cutting and Turning MachinesDokumen84 halamanSafeguarding Cutting and Turning MachinesBianco SantanaBelum ada peringkat

- Ninebot Mini Service Manual: 1.work PlanDokumen34 halamanNinebot Mini Service Manual: 1.work PlanPaweł Gromadzki100% (1)

- Start Here: Installation, Safety, and Regulatory Information For The HPE Aruba Networking CX 6200F Switch SeriesDokumen14 halamanStart Here: Installation, Safety, and Regulatory Information For The HPE Aruba Networking CX 6200F Switch SeriesRikyBelum ada peringkat

- ! Warning: Servomotor TestDokumen1 halaman! Warning: Servomotor Testjoku jokunenBelum ada peringkat

- 77 Photography TechniquesDokumen17 halaman77 Photography TechniquesSimone Winny100% (2)

- Ubec 1at: Automatic Tank Fill Controller For Use With Unibody Electric ValvesDokumen2 halamanUbec 1at: Automatic Tank Fill Controller For Use With Unibody Electric ValvesErick Portela cruzBelum ada peringkat

- CS600 TRManual Rev JDokumen522 halamanCS600 TRManual Rev JLGBelum ada peringkat

- Grade 7 Exam TLE FirstgradingDokumen2 halamanGrade 7 Exam TLE FirstgradingGladson Bill Noay CabahitBelum ada peringkat

- Spesifikasi RIG JACKRO S175Dokumen7 halamanSpesifikasi RIG JACKRO S175Khrisna MahendraBelum ada peringkat

- 150 KVA Sub-Station Quotation 1 - FE0C73Dokumen10 halaman150 KVA Sub-Station Quotation 1 - FE0C73Forrukh100% (5)

- Service Manual: Home Sewing MachineDokumen151 halamanService Manual: Home Sewing Machinevikas bansalBelum ada peringkat

- Questions on PLC Wiring FundamentalsDokumen59 halamanQuestions on PLC Wiring Fundamentalspascal sitanggangBelum ada peringkat