COMPRESSOR MSWV 80 MAX TWO STAGE 175 PSIG TECHNICAL DATA

Diunggah oleh

ebebvetbJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

COMPRESSOR MSWV 80 MAX TWO STAGE 175 PSIG TECHNICAL DATA

Diunggah oleh

ebebvetbHak Cipta:

Format Tersedia

COMPRESSOR MSWV 80 MAX TWO STAGES

175 PSIG

C A S T I R O N I N D U S T R I A L C O M P R E S S O R S

TECHNICAL DATA

DISPLACEMENT MAX. PRESSURE RPM MOTOR BELT MOTOR PULLEY OIL CAP. WEIGHT DISCHARGE

MODEL

cfm psig hp 2 POLES IN IN QT IN LBS SIZE

mm inch

MSWV 80 MAX 80 175 910 20 2-B 4.5 4.72 397.3 3/4" BSP

145 5.7

62 T8 T1 49 T11 59

61 60 41 40

Position lbf.IN N.m

B

T1 49 304 34 48 47 46 45

64

T2 8 704 80 36

63

40 41 60

T9

T3 2 70 8 37 38 39

8 T2 44 43 42

T4 28 158 18 40 41 60 T9 T10

36

T5 12 1215 137

4

T6 14 334 38

T7 23 185 21 35 - 34 - 33

28 58

T8 62 141 16 29

T4

T9 HP-LP 40-41-60 19 2.2

4

32 - 31 - 30

T10 LP 40-41-60 44 5 57

27

T11 59 264 30 20

TABLE 1 - TORQUE 17 18

4

ESPECIFICATION FOR BOLTS 20

26

56 25

15 19

14 T6 16

55 B A 12 21 T7

13

24

22 23

9 57 8 ASSEMBLY OF INTERCOOLERS

9

52

T2 51

A 6

1 2 4 12 17

73

11 66 69 50 71 69

T3 66 66 53

10

54

7

70

3 5

67

65

T5

72 72 68

12

BARE PUMP PARTS

No. CODE DENOMINATION QUANTITY No. CODE DENOMINATION QUANTITY

1 709.1346-0 Flywheel 01 39 709.1347-0 HP 2.1/2" cylinder 01

2 * UNC 1/4" x 3/4" head bolt 04 40 830.0955-0 LP 4.3/4" valve plate kit 03

3 20505001 Flange cover 01 41 830.1002-0 HP 90 mm valve plate kit 01

4 830.1033-0 Crankcase gasket kit 01 42 809.1028-0 LP 4.3/4" valve plate 03

5 60082501 Oil seal 01 43 809.1027-0 HP 90mm valve plate 01

6 830.0932-0 Lock washer and nut 01 44 809.1029-0 HP 2.1/2" valve plate 01

7 60154502 33109 bearing 01 45 709.1272-0 LP 4.3/4" cylinder cover (with breather) 01

8 * NC 1/2" x 1" head bolt 26 46 709.1423-0 LP 4.3/4" cylinder cover (without breather) 02

9 60259501 Straight fitting 01 47 709.1424-0 HP 90mm cylinder cover 01

10 20504001 Flange 01 48 709.1389-0 HP 2.1/2" cylinder cover 01

11 60154501 32211 bearing 01 49 * UNC 3/8" x 1.1/2" head bolt 23

12 830.0933-0 Crankshaft 01 50 709.1457-0 Short intercooler No. 2 01

13 60267503 Key 01 51 709.1459-0 Medium intercooler No. 3 01

14 * UNF 3/8" x 3" head bolt 02 52 709.1458-0 Long intercooler No. 4 01

15 20508005 Crankshaft counter weight 01 53 21011004 3/4" nut for intercooler 10

16 830.0934-0 Connecting rod pin 04 54 21029003 Intercooler holder 03

17 30008502 Connecting rod 04 55 830.0340-5 1/4" crankcase breather tube 01

18 830.0938-0 Master connecting rod 01 56 003.0054-3 1/8" x 1/4" straight connection 01

19 60152502 Connecting rod inner bushing 02 57 830.0599-8 1/4" ring kit 01

20 60152501 Connecting rod bushing 09 58 022.0174-0 Centrifugal unloading valve 01

21 30007007 Counter weight with centrifugal mechanism 01 59 383.0111-0 HP 5/16" x 1.1/2" Allen hex bolt 06

22 830.0937-0 Counter weight kit with centrifugal mechanism 01 60 830.0957-0 HP 2.1/2" valve plate kit 01

23 * UNF 5/16" x 1.1/4" head bolt 02 61 830.1032-0 Washer kit 01

24 20501001 Crankcase 01 62 013.0752-0 M6 x 1 x 55 Allen hex bolt 08

25 003.0029-2 3/8" plug 01 63 007.0116-0 Air filter 03

26 830.0775-0 3/4" oil level sight 01 64 007.0118-0 Filter element 03

27 709.1316-0 Crankcase cover 01 65 20517005 Intercooler adaptor 02

28 * UNC 5/16" x 3/4" head bolt 06 66 022.0177-0 LP 1/8" ASME safety valve 03

29 003.0031-4 3/4" plug 01 67 21011001 3/4" x 1/2" straight connection 04

30 60273501 LP 4.3/4" piston 03 68 003.0036-5 3/4" niple 01

31 830.1000-0 HP 90mm piston 01 69 809.1043-0 Intercooler kit 01

32 830.0939-0 HP 2.1/2" piston 01 70 709.1369-0 Discharge tube No. 1 01

33 000.0077-0 LP 4.3/4" ring kit 03 71 709.1456-0 Discharge tube No. 5 01

34 000.0080-0 HP 90mm ring kit 01 72 022.0189-0 HP 1/8" ASME safety valve 02

35 000.0075-0 HP 2.1/2" ring kit 01 73 21011002 3/4" x 3/4 straight connection 06

36 830.1031-0 Upper gasket kit 01 - 709.1359-0 Pulley (not shown) 01

37 709.1306-0 LP 4.3/4" cylinder 03

38 709.1308-0 HP 90mm cylinder 01 * Part available in the market - not sold by Schulz

Note: HP = high pressure LP = low pressure

CT 190 APRIL/003 025.0352-0

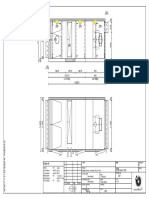

DIMENSIONS MAINTENANCE

WARNING

MSWV 80 MAX

Turn off power before servicing and be sure the air tank is unloaded. These

H instructions are based on normal operating conditions. If the compressor is

located in an exceedingly dusty area, increase the frequency of all

inspections.

DAILY

- Inspect the compressor visually.

G

D

- Check oil level and add some if necessary, before turning the

compressor on.

- Drain moisture from the piping system.

C B F - Be sure there is no excessive or unusual vibration or noise.

A E WEEKLY

- Remove and clean intake air filters; do not wash the filter element.

A B C D E F G H - Check V-belts for tightness. Belt tension should be adjusted to allow

approximately 3/8" to 1/2" (9 to 13 mm) deflection with normal thumb

mm 650 120 244 540 344 14 780 960

pressure.

inch 25.6 4.7 9.6 21.2 13.5 0.55 30.7 37.8 - Clean cylinders externally, cylinder head, motor, fan blade, tubing, and tank.

- ASME safety valve should be tested manually to see if it is working properly.

INSTALLATION AND OPERATION INSTRUCTIONS MONTHLY

- Check entire system for air leakage around fittings, etc by using water and

INSTALLATION AND LOCATION soap lather.

1. Installation: Install the compressor in a covered, well - Check the pressure switch operation.

ventilated area, free of dust, toxic gases, humidity or any

- Check for oil contamination and change it if necessary.

other kind of pollution. The compressor should be located no

closer than 32" (800mm) from a wall or any other obstacle QUARTERLY

that could interfere with the air flow through the fan. This - Change the air filter element every 300 working hours or quarterly.

distance will also make maintenance easier. Place the (Whichever occurs first).

compressor on a leveled surface. Rotation of the flywheel - Fasten bolts and nuts as required. (See Table 1)

must be in the direction of the arrow cast into the flywheel.

- Change oil more frequently if compressor is located in a very dirty

The maximum ambient temperature recommended while

environment.

working is 104F or 40C. If necessary, install an exhaust fan

to guarantee fresh air and to dissipate heat. - WHILE RUNNING IN A PERIOD OF ABOUT 100 WORKING HOURS THE OIL

Before making the electrical connections, check oil level and LEVEL SHOULD BE CAREFULLY CHECKED.

top-up lubricating oil. For type of oil, see table at the end of ANNUALLY

these instructions. - Test and calibrate the pressure switch, pressure gauge, pilot valve,

2. Electrical connection: The country's valid electrical discharge valve and safety valve according to their own technical standards.

standards must be followed regarding Low Voltage Electrical These parts must be removed from the tank and pump to be tested.

Installation. - Inspect and clean the suction and discharge valve(s) plate(s) every 1000 (one

OPERATION thousand) working hours (whichever occurs first), located between the

1. Initial start procedure: Before turning on the compressor, cylinder and its cover and, if necessary, replace it (them) according to the

check the crankcase oil level. It must be in the middle of the operation conditions.

OIL LEVEL SIGHT. As to the type of oil to be used and the

LUBRICATION

recommended change intervals, check at "Lubrication" and

as to its volume, check the Technical Data Table. - The first oil change should be made after 8 hours of operation.

2. Start: Turn on the electrical start key and let your - The second oil change after 40 hours of operation.

compressor run for about 10 (ten) minutes, what will keep - The third and following exchanges should be made after 200 hours of

the tank's internal pressure or compressed air around 20 operation, or 60 (sixty) days, whichever occurs first.

psig. This will optimize a homogeneous lubrication of the NOTE:

parts.

Heavy Duty and multi-viscous oils are not adequate for Schulz air

compressor's lubrication. The same applies to oils that tend to emulsify.

LIMITED WARRANTY

We recommend good industrial oil for air compressors, with rust and

oxidation inhibitors and high viscosity level (from 90 to 95), SAE or ISO, as

All component parts on your SCHULZ compressor are indicated in the table below:

warranted to be free of defects in workmanship and material

for a period of one year. Transportation charges are RECOMMENDED LUBRICANT OILS FOR SCHULZ AIR PUMPS

responsibility of the purchaser. This warranty extends to the AMBIENT TEMPERATURE 0F (0C)

original purchaser of the compressor only.

Below 32 0F 32 0F to 68 0F 68 0F to 104 0F

There are no express warranties except as contained in this Below 0 0C 0 0C to 20 0C 20 0C to 40 0C

limited warranty statement and implied warranties, SAE 10W SAE 20W SAE 30

including those of merchantability and fitness for a particular or or or

purpose, are limited to the period of warranty. ISO 32 ISO 68 ISO 100

Our liability is limited solely to replacement of

nonconforming parts as set forth herein and does not include Note: Schulz reserves the right to make changes without prior notice.

any liability for any incidental, consequential, or other

damages of any kind. This warranty gives you specific legal

rights, and you may also have other rights that vary from DISTRIBUTOR

state to state.

Schulz of America, Inc.

320 A Northpoint Parkway

Acworth, GA 30102

Phone # (770) 529-4731 / 32

Fax # (770) 529-4733

sales@schulzamerica.com

www.schulzamerica.com

Anda mungkin juga menyukai

- PSD90-1C Operation ManualDokumen41 halamanPSD90-1C Operation ManualmglemBelum ada peringkat

- Chapter 2 - EUI EngineDokumen17 halamanChapter 2 - EUI Enginenajafali100% (3)

- PCB Assembly Supplier IntroduceDokumen19 halamanPCB Assembly Supplier IntroduceJasonlonBelum ada peringkat

- Anoptimal Design For Axial-Flow Fan Blade - Theorical and Experimental StudiesDokumen10 halamanAnoptimal Design For Axial-Flow Fan Blade - Theorical and Experimental StudiesweBelum ada peringkat

- 8051 Microcontroller: An Applications Based IntroductionDari Everand8051 Microcontroller: An Applications Based IntroductionPenilaian: 5 dari 5 bintang5/5 (6)

- DWDM Network Design and ODFDokumen3 halamanDWDM Network Design and ODFhaivqvnpt1Belum ada peringkat

- Leadthrough Programming and Motion InterpolationDokumen18 halamanLeadthrough Programming and Motion Interpolationyashbhoyar60% (5)

- Sauer Danfoss 42lDokumen68 halamanSauer Danfoss 42ljuan100% (2)

- Electric Guitar - Super Mario BandDokumen1 halamanElectric Guitar - Super Mario BandHamilton OliveiraBelum ada peringkat

- Super Mario Bros. music sheetDokumen1 halamanSuper Mario Bros. music sheetJuan PerezBelum ada peringkat

- ACM User GuideDokumen21 halamanACM User Guidemlucian73Belum ada peringkat

- MSW 60 MaxDokumen2 halamanMSW 60 MaxAlex SanchesBelum ada peringkat

- Compressor MSW 60 Max Two Stages 175 PsigDokumen2 halamanCompressor MSW 60 Max Two Stages 175 PsigJoel Leandro Ibarra CoriaBelum ada peringkat

- Compressor MSL 40 Max Two Stages 175 PsigDokumen2 halamanCompressor MSL 40 Max Two Stages 175 PsigJoel Leandro Ibarra CoriaBelum ada peringkat

- Bomba Jockey Aurora Mod - PVM32-6-2Dokumen6 halamanBomba Jockey Aurora Mod - PVM32-6-2EdinsonUribeTorresBelum ada peringkat

- Bowex CouplingDokumen1 halamanBowex Couplingrakhikishore143Belum ada peringkat

- (MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PC: HMG / Ministry of Local DevelopmentDokumen1 halaman(MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PC: HMG / Ministry of Local DevelopmentRanjit Kumar ShahBelum ada peringkat

- 1 1/2" Elima-Matic Clamped Metallic: Performance SpecificationsDokumen1 halaman1 1/2" Elima-Matic Clamped Metallic: Performance SpecificationsAldy DankersBelum ada peringkat

- Cast Iron Industrial Compressors: Direct Drive Compressor MSV 6 OilfreeDokumen2 halamanCast Iron Industrial Compressors: Direct Drive Compressor MSV 6 Oilfreedanny caceresBelum ada peringkat

- DAZRUAMB6E0 Rev E Schematic Acer Chromebook Cb3-532 C47C Quanta ZRUADokumen43 halamanDAZRUAMB6E0 Rev E Schematic Acer Chromebook Cb3-532 C47C Quanta ZRUACarlosBelum ada peringkat

- R410A Split System Technical Specification 18K-24K-36K-48K-60KDokumen1 halamanR410A Split System Technical Specification 18K-24K-36K-48K-60Kmustafa ahmedBelum ada peringkat

- Moog SpringDokumen18 halamanMoog SpringRicardo Rangel PosadasBelum ada peringkat

- Pile Setting Date: 8m 13 Pcs 8m 19 PcsDokumen1 halamanPile Setting Date: 8m 13 Pcs 8m 19 Pcsk.o.m channel (kmeng)Belum ada peringkat

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Dokumen1 halamanPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisBelum ada peringkat

- 2660 2680 Ce Cghi 2Dokumen2 halaman2660 2680 Ce Cghi 2kocur79Belum ada peringkat

- Acqua Tedela Pump Series - 1Dokumen22 halamanAcqua Tedela Pump Series - 1Janzzen CrudaBelum ada peringkat

- Ahu - Tower 2Dokumen182 halamanAhu - Tower 2Biruntha SelvarajBelum ada peringkat

- IC For Samsung UE32D4003BW, LED Driver Control ICDokumen2 halamanIC For Samsung UE32D4003BW, LED Driver Control ICFrancisco ChaoBelum ada peringkat

- FTB129 - Detail of BeamDokumen1 halamanFTB129 - Detail of BeamRAMENDRA NATH MONDALBelum ada peringkat

- CHELSEA DJ2 CP UMA Schematics Document ArrandaleDokumen95 halamanCHELSEA DJ2 CP UMA Schematics Document ArrandaleGerges YacoupBelum ada peringkat

- Floor Plan Base Plate Details: Ladd Construction & DesignsDokumen1 halamanFloor Plan Base Plate Details: Ladd Construction & DesignsGadBelum ada peringkat

- Sistemas de Lubrificação de Linha SimplesDokumen204 halamanSistemas de Lubrificação de Linha SimplesSalatiel MarquesBelum ada peringkat

- ENGINE OIL AND VACUUM PIPING PARTSDokumen4 halamanENGINE OIL AND VACUUM PIPING PARTSBurik8Belum ada peringkat

- Panaflo Fba08a12u1a DatasheetDokumen2 halamanPanaflo Fba08a12u1a DatasheetAbdullah AliBelum ada peringkat

- Bravo: Technical Catalogue Compressor - CSL 40BR/250L 2 STAGES - 175 PsigDokumen4 halamanBravo: Technical Catalogue Compressor - CSL 40BR/250L 2 STAGES - 175 PsigALINE CARDOSOBelum ada peringkat

- Summary of steel bill of materials for assembly MK'D B8Dokumen1 halamanSummary of steel bill of materials for assembly MK'D B8Titus PraveenBelum ada peringkat

- Page 1272Dokumen1 halamanPage 1272EmilyTheDwarfBelum ada peringkat

- Process Capability Report For Cycle TimeDokumen4 halamanProcess Capability Report For Cycle TimeNea MilosevicBelum ada peringkat

- Compressor MSV 20 SD Two Stages 175 PsigDokumen2 halamanCompressor MSV 20 SD Two Stages 175 PsigJoel Leandro Ibarra CoriaBelum ada peringkat

- 2-4 Estructura Sistema DesplazamientoDokumen9 halaman2-4 Estructura Sistema Desplazamientolevinton jose tobias genesBelum ada peringkat

- Series Pump OperationDokumen3 halamanSeries Pump OperationTaha Elhasseen AbdelrahmanBelum ada peringkat

- CombiChem 40A-315 CL-SS - 2Dokumen2 halamanCombiChem 40A-315 CL-SS - 2Renalyn TorioBelum ada peringkat

- Shank Adapter PDFDokumen18 halamanShank Adapter PDFfelipe100% (1)

- PBL62 1 30M3Dokumen1 halamanPBL62 1 30M3Hai Tran HongBelum ada peringkat

- MotionGoo Stepper Motor-34HT38S8300 Torque CurveDokumen1 halamanMotionGoo Stepper Motor-34HT38S8300 Torque CurveMake RownBelum ada peringkat

- KDI Marine Propulsion 40.8 - 50 HPDokumen4 halamanKDI Marine Propulsion 40.8 - 50 HPHaythem JameiBelum ada peringkat

- CurvasDokumen4 halamanCurvasGabriel MuniveBelum ada peringkat

- Performance CurvesDokumen2 halamanPerformance CurvesYohan ManaligodBelum ada peringkat

- Oils Per Machine FEBDokumen4 halamanOils Per Machine FEBKudakwashe ZvayiBelum ada peringkat

- Features Description: CMOS 16-Bit MicroprocessorDokumen35 halamanFeatures Description: CMOS 16-Bit MicroprocessorEhab AlhouraniBelum ada peringkat

- Eep000094 01021480065 3 ST Det 2728 R0 - SH - 4 - of - 30Dokumen1 halamanEep000094 01021480065 3 ST Det 2728 R0 - SH - 4 - of - 30Vikram DalalBelum ada peringkat

- MTS DB 40MM SSSDokumen1 halamanMTS DB 40MM SSSDesign Selaras Lawang SewuBelum ada peringkat

- RNP W RWY 33 (AR) Approach Chart for Campinas / Viracopos Int'l Airport (SBKPDokumen1 halamanRNP W RWY 33 (AR) Approach Chart for Campinas / Viracopos Int'l Airport (SBKPLuciano PedroBelum ada peringkat

- Ser!Es: C.B.I. PuiipsDokumen3 halamanSer!Es: C.B.I. PuiipsBradley PortBelum ada peringkat

- MotionGoo Stepper Motor-34HT46D4500 Torque CurveDokumen1 halamanMotionGoo Stepper Motor-34HT46D4500 Torque CurveMake RownBelum ada peringkat

- MotionGoo Stepper Motor-34HT46D4500C1 Torque CurveDokumen1 halamanMotionGoo Stepper Motor-34HT46D4500C1 Torque CurveMake RownBelum ada peringkat

- Caprari HMU1 Centrifugal Pump PDFDokumen1 halamanCaprari HMU1 Centrifugal Pump PDFGiorgiana RosuBelum ada peringkat

- Caprari HMU1 Centrifugal PumpDokumen1 halamanCaprari HMU1 Centrifugal PumpGiorgiana RosuBelum ada peringkat

- Regolatore Aspirazione Rh38EDokumen2 halamanRegolatore Aspirazione Rh38EДжон ДиллинджерBelum ada peringkat

- Design Manual Is-800 Chapter 3Dokumen38 halamanDesign Manual Is-800 Chapter 3Vivek Kumar GopeBelum ada peringkat

- Bull1524r0 L8543219Dokumen76 halamanBull1524r0 L8543219Benjamin HewittBelum ada peringkat

- SM30 - Media Key - Rev SaDokumen1 halamanSM30 - Media Key - Rev SajjoaquimmartinsBelum ada peringkat

- Hydra Brake PartsDokumen1 halamanHydra Brake PartsVishnuBelum ada peringkat

- British Commercial Computer Digest: Pergamon Computer Data SeriesDari EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesBelum ada peringkat

- Vibration Signatures of Reciprocating CompressorsDokumen7 halamanVibration Signatures of Reciprocating CompressorsebebvetbBelum ada peringkat

- Solution Manual - Mechanical Vibrations 4th Edition, Rao PDFDokumen864 halamanSolution Manual - Mechanical Vibrations 4th Edition, Rao PDFRafael Lemanski Dos Santos100% (3)

- Compressor CSW 40 Max Two Stages 175 PsigDokumen2 halamanCompressor CSW 40 Max Two Stages 175 PsigJoel Leandro Ibarra CoriaBelum ada peringkat

- Computer Networking: A Top Down Approach ,: 5 Edition. Jim Kurose, Keith Ross Addison-Wesley, April 2009Dokumen80 halamanComputer Networking: A Top Down Approach ,: 5 Edition. Jim Kurose, Keith Ross Addison-Wesley, April 2009Hoang NguyenBelum ada peringkat

- Trunks & GSMDokumen107 halamanTrunks & GSMdumera2002Belum ada peringkat

- Lenovo, HP, Dell laptop installment plans comparisonDokumen4 halamanLenovo, HP, Dell laptop installment plans comparisonBilal AjmalBelum ada peringkat

- ZCL LACS Documentation 2018Dokumen27 halamanZCL LACS Documentation 2018Alid Franco AñonuevoBelum ada peringkat

- Computerized Grading System for Samar State UniversityDokumen2 halamanComputerized Grading System for Samar State UniversityFlorlyn Mae Sudio RemegioBelum ada peringkat

- AM33C93A SCSI-Bus Interface Controller Timing 3Dokumen2 halamanAM33C93A SCSI-Bus Interface Controller Timing 3SD_DucksoupBelum ada peringkat

- LVTN01 ESWK1 PGroup 4Dokumen2 halamanLVTN01 ESWK1 PGroup 4Clifford LeagueBelum ada peringkat

- 8 RELAYS Users GuideDokumen13 halaman8 RELAYS Users GuideJacob BertrandBelum ada peringkat

- Soliphant M With Electronic Insert FEM58: Functional Safety ManualDokumen12 halamanSoliphant M With Electronic Insert FEM58: Functional Safety ManualTreeBelum ada peringkat

- SDG1000 Programming ManualDokumen40 halamanSDG1000 Programming ManualjuanBelum ada peringkat

- VNX5100 PGDokumen22 halamanVNX5100 PGSujit FrancisBelum ada peringkat

- Riverbed Xirrus Wi-Fi Designer: Product Release NotesDokumen3 halamanRiverbed Xirrus Wi-Fi Designer: Product Release NotesLuchoNandoBelum ada peringkat

- AOP Panel EngDokumen36 halamanAOP Panel EngWanderley Terci EstevesBelum ada peringkat

- Unlocks - v1.01 Mod or bf2142 Mod Files or FoldersDokumen3 halamanUnlocks - v1.01 Mod or bf2142 Mod Files or FoldersLarry RockBelum ada peringkat

- Information Sheet-CHS NCIIDokumen9 halamanInformation Sheet-CHS NCIIRenel CuaresmaBelum ada peringkat

- GearTeq GearTraxFeaturesDokumen1 halamanGearTeq GearTraxFeaturesErhan GencBelum ada peringkat

- DSAM Help Manual PDFDokumen254 halamanDSAM Help Manual PDFVíctor MayaBelum ada peringkat

- Pegatron H24Z (Asus F82)Dokumen58 halamanPegatron H24Z (Asus F82)franlc1Belum ada peringkat

- Red Hat Virtualization-4.4-Installing Red Hat Virtualization As A Standalone Manager With Local Databases-En-UsDokumen89 halamanRed Hat Virtualization-4.4-Installing Red Hat Virtualization As A Standalone Manager With Local Databases-En-UsNguyen Ho LongBelum ada peringkat

- Slot Dipping Device by LecoreDokumen4 halamanSlot Dipping Device by Lecoretarun1976Belum ada peringkat

- ODA X4-2 TechDokumen23 halamanODA X4-2 TechjaccehBelum ada peringkat

- Fast Extraction of Viewing Frustum PlanesDokumen11 halamanFast Extraction of Viewing Frustum PlanesdanielsturzaBelum ada peringkat

- Sharp Lc32bd6x LCD TV SMDokumen212 halamanSharp Lc32bd6x LCD TV SMkothuraBelum ada peringkat

- Eprom: FeaturesDokumen12 halamanEprom: FeaturesmanzellaBelum ada peringkat